CAR — FOR WHAT? You need a car? What? This question confronts everyone who intends to buy a car manufactured in the factory. But as you know, choosing the right type of machine is limited. Even more urgent this question, if the car decided to build their runes.

CAR — FOR WHAT? You need a car? What? This question confronts everyone who intends to buy a car manufactured in the factory. But as you know, choosing the right type of machine is limited. Even more urgent this question, if the car decided to build their runes.

For example, I really need the car for everyday driving in any season, whatever the weather and road conditions. If this, say, “Moskvich”? Not quite. The layout of the body of type “sedan” has a lot of drawbacks — it is not once mentioned in print. The production of cars with a body “wagon” we started relatively recently.

Next: start the engine with liquid cooling in the bitter cold is very troublesome, especially for the individual wearer. In addition, winter operation quickly brings the car in disrepair — due to corrosion from the salty snow slush and mud. Not by chance my fellow owners of “Moskvich”, “Volga” and “the Cossacks” for most of the year keeping their equipment on the joke. In cold and bad weather, when the car most needed, they become pedestrians. I use And built my machine at any time of the year.

To make a long journey to reside in the body “sedan” for the night, you need all the Luggage to pull or to drag, which takes a lot of time and effort. On the same overnight the four of us I don’t think. And for me, this option does not present any difficulties as well as, for example, transportation of the refrigerator, TV or washing machine.

For all these features I deliberately went to the rejection of many indisputable advantages of the “Muscovite”: comfort, quietness of the engine, soft suspension, high speeds and good acceleration, security, service and parts. I needed another car.

To come to that decision was helped by the owner Yuri Dolmatovsky, which, incidentally, was called “I need a car.”

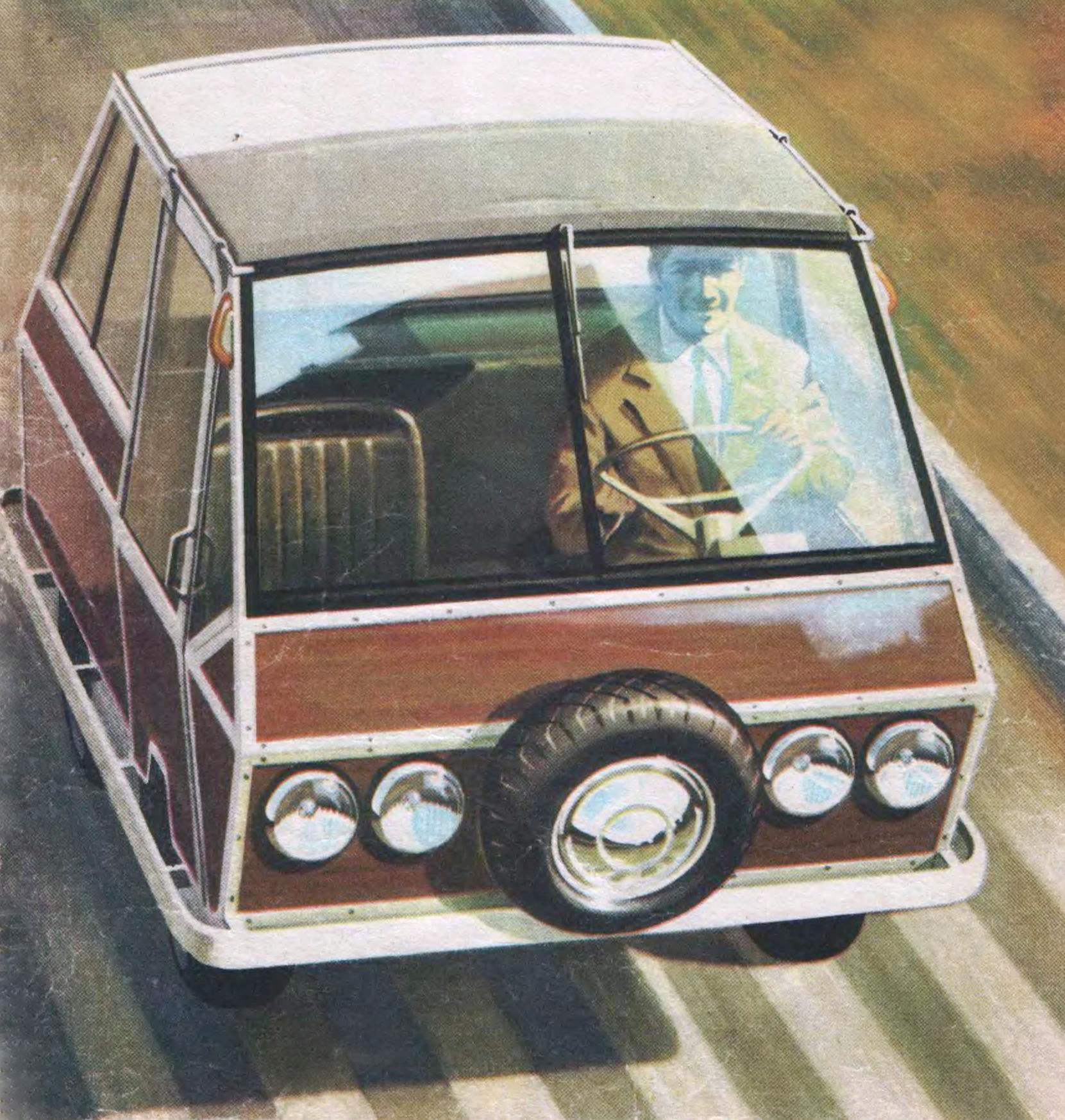

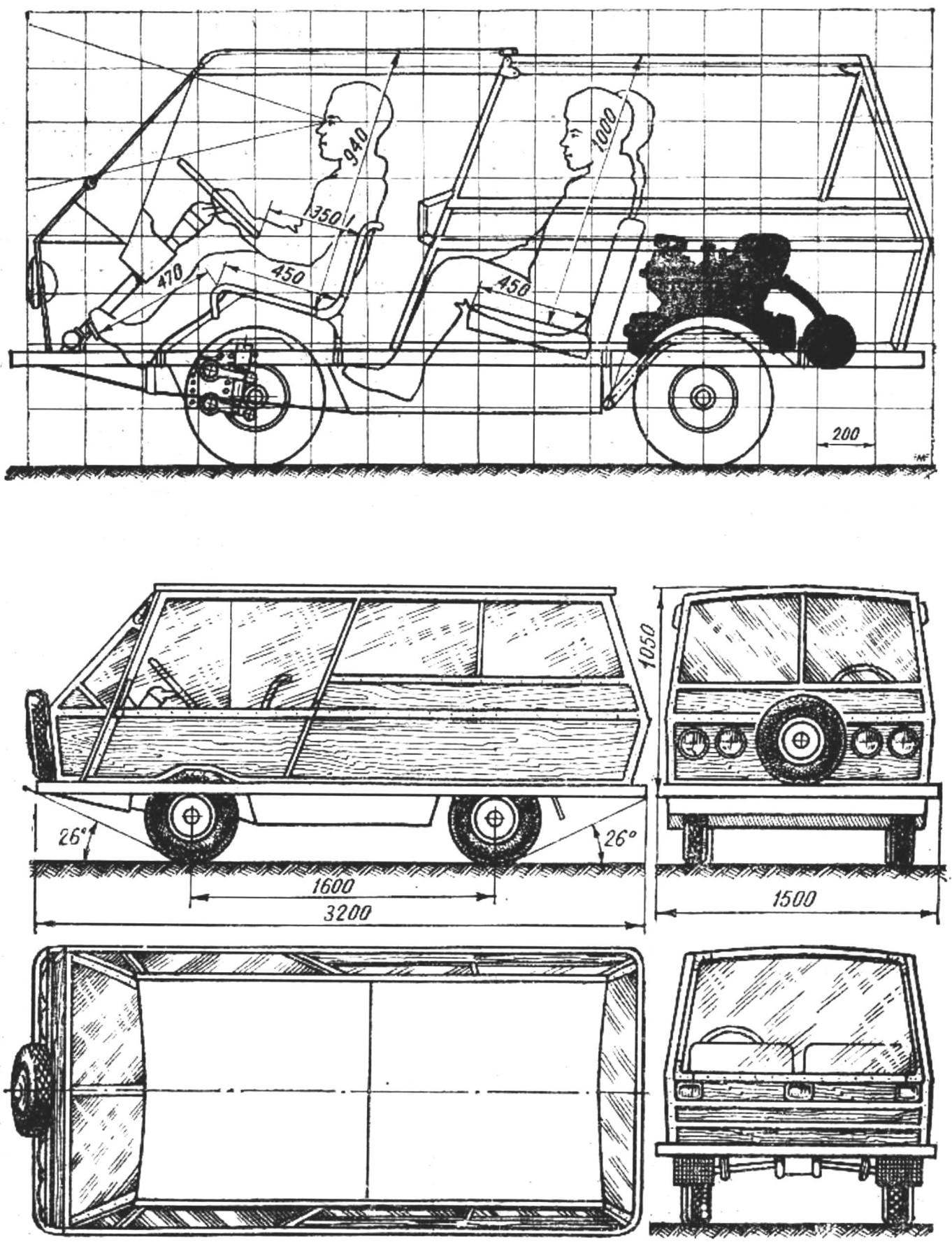

Fig. 1. The layout of the micro-car, only “minimax” and suspension parts:

And rocking the steering gear: 1 — stock gear racks С3А, 2 — intermediate, 3 — threaded bushing rocking chairs, 4 rocking chair 5 — ball end, 6 — rods; B — the exposure of the body: 1 — dvigaysya back door, 2 — frame, 3 — front panel 4 — spare tire, 5 — steering gear 6 — helm and instrument panel, 7 — windshield, 8 — openable roof part (avizent), 9 — a hard part of the roof 10 — window rear, 11 — trim body (aluminum square), 12 — side panel 13 — С3А engine and main gear, 14 — longitudinal girder frame 15, and the bottom of the cabin, 16 — sliding doors, 17 — door lock — front suspension: 1 — paw of a trapezoid, 2 — solitaire mounting front axle С3А, 3 — heavy duty bracket fixing the lower ear of the shock absorber, 4 — Cup, 5 — spring, 6 — the bottom Cup 7, the lower ear of the shock-absorber, 8 — shaped bolt 9 — amplifying tube.

Amateur microautomation now decided, in my opinion, the three main areas. The first is to make little micro-car “as real,” that is, similar to any industrial design. The second, more promising direction — new design solutions, search in the field of design. The best examples of the latter are widely known series CD, created with the participation of the artist-designer E. Molchanov, as well as the car Scherbinin brothers.

From this group in recent years emerged as an independent branch of another area, which conditionally could be called “functional”. It is the creation of machines with non-standard configurations, designed for use under certain conditions: on off — road terrain; water hazards — amphibious ATVs; for urban distress — agile tricycles and so on. Incidentally, the current “Technical specifications” for the construction of improvised vehicles do not provide for design of such machines, limiting the search on a number of indicators (the dimensions or shape of the body, the engine capacity etc.), however not disturbing to have interesting (obviously for the national economy).

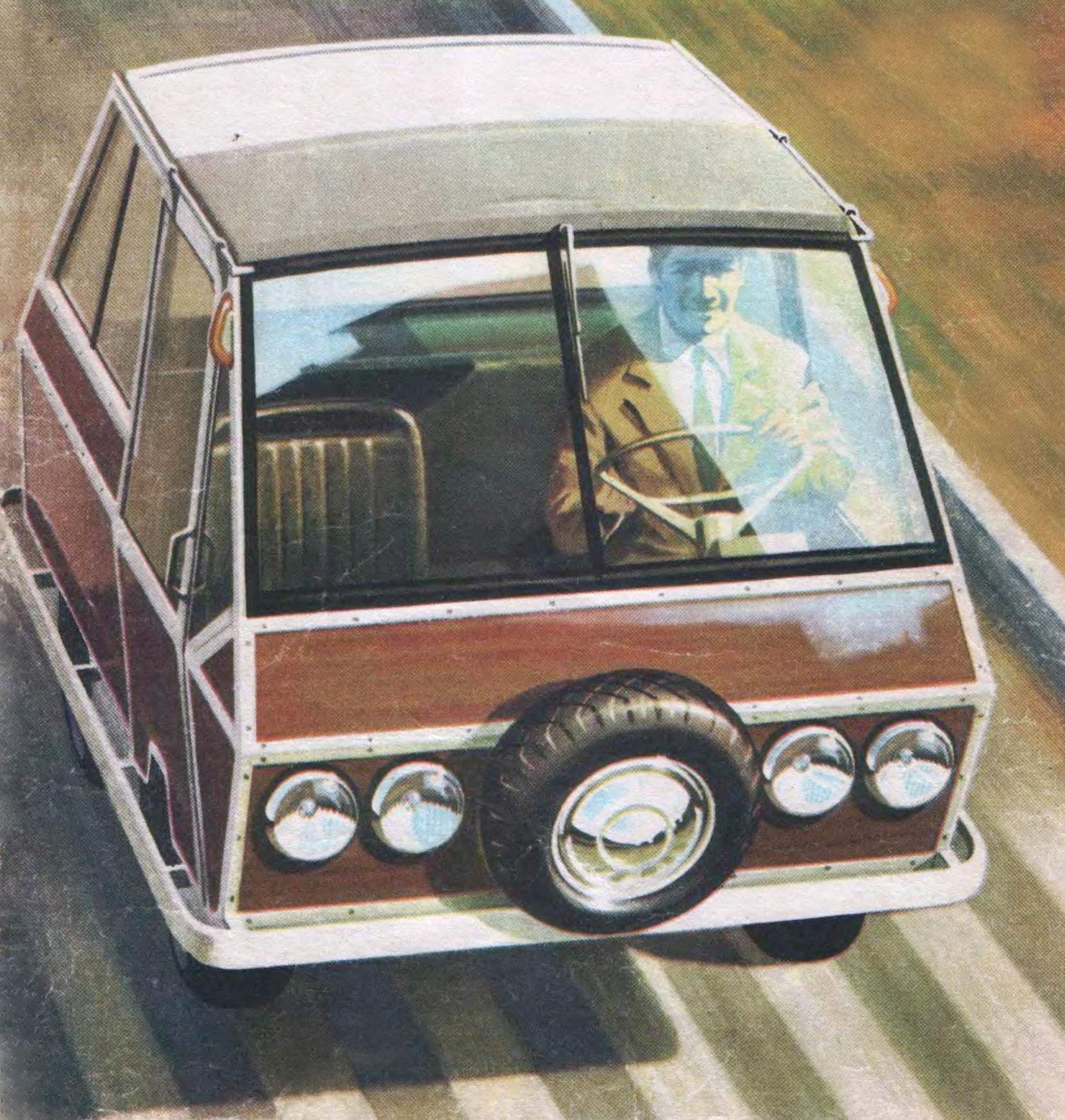

Well-defined goals did you set yourself and I, conceiving this design. As can be seen from the “beginning of the list of requirements I needed the car-wagon, which, with low technical costs would have the maximum benefit and with minimum external dimensions maximum internal volume. Therefore, the name “minimax”. There are a lot of possibilities for self-expression, for the full realization of their ideas. This gives great moral satisfaction. And the work of their hands, in my opinion, is the best rest from operations.

MINIMAKS — WAGON LAYOUT

To build mikroavtomobili wagon fans started recently. This was, undoubtedly, a sign of technical maturity of the authors of the new designs. The development of this scheme is presented in the following order: “Squirrel” (the so-called agricultural option, USSR), Pininfarina (Italy), “Ant” (USSR).

When you create a “Minimax” (Fig. 1) I decided the following tasks: move to the fully closed body; the expansion of the internal dimensions without much increase in external facilitation and simplification of the power scheme; expansion of doorways; modernization of the steering mechanism.

Of course, along with the great advantages of the wagon layout has its drawbacks (otherwise, machines of this type would have been a primary distribution). First of all, it should be noted that the driver is not in the “comfort zone”, near the center of gravity of the machine. So it “shakes” a lot more than cars classic design. If make softer the suspension, this will lead to an increase in “guapiruvu” — longitudinal rocking of machine, generally peculiar to the wagon layout, with a small base and spaced mass. This is particularly noticeable when driving over rough terrain, therefore I had to slightly increase the stiffness of the front suspension.

The front location of the driver in the car wagon and is more dangerous in case of hitting an obstacle. Therefore, “Minimax” taken the location of the spare wheel on the front of the body — it is to a certain extent may work as a shock absorber. Nodal solution with the aim of improving security was the choice of the frame: outside dimensions of the body around the perimeter of a closed power frame, located at a height of 400 mm from the roadway.

design FEATURES

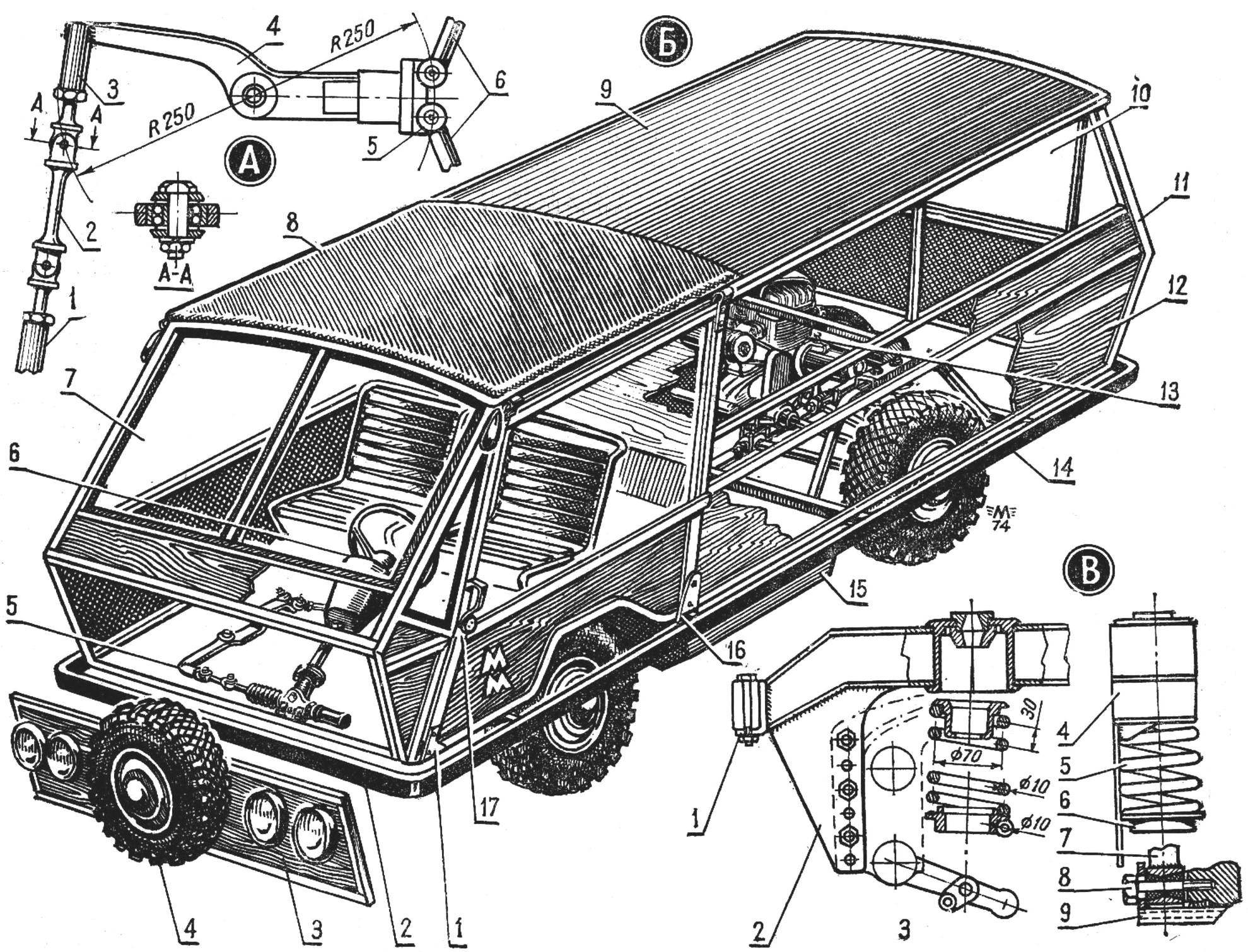

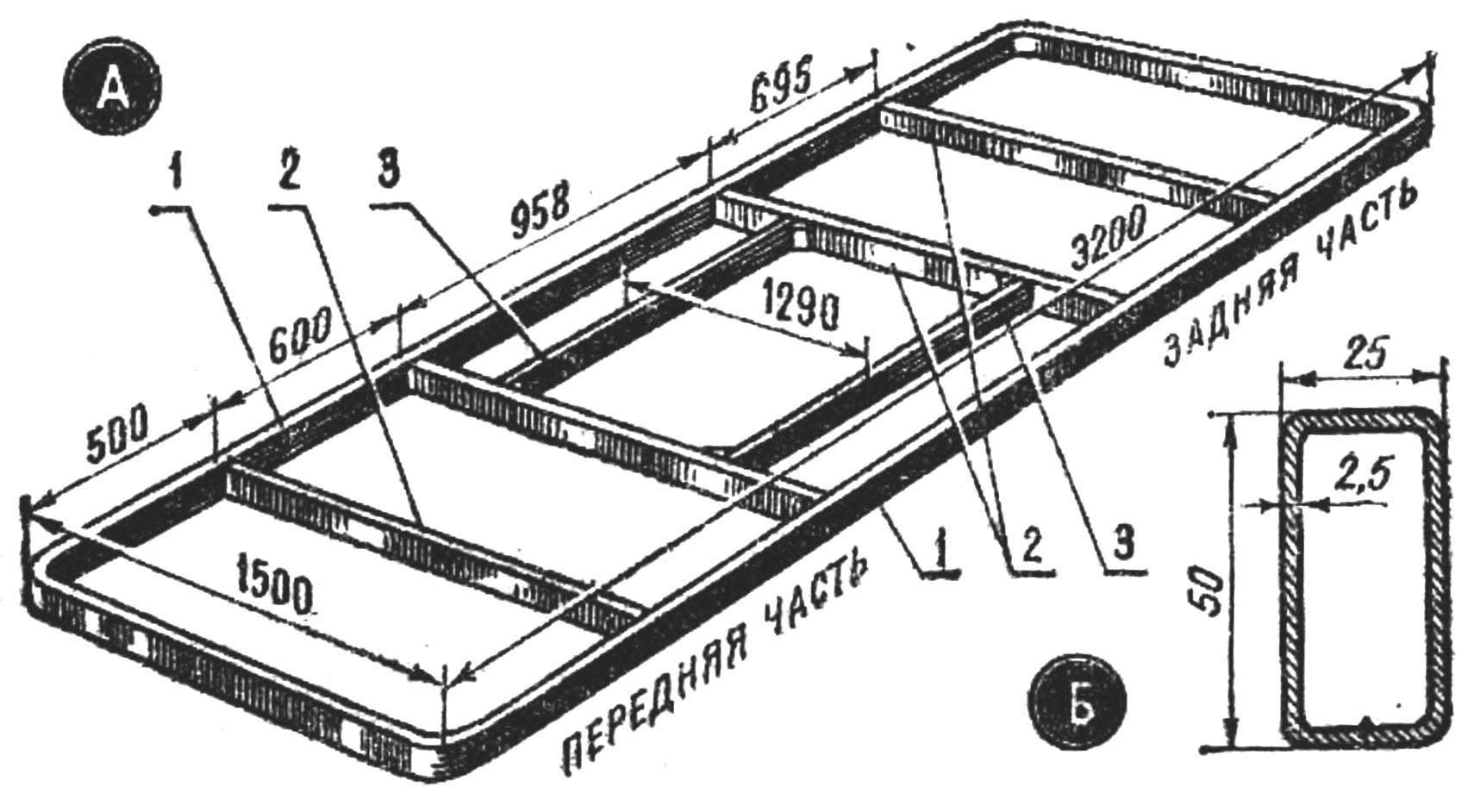

Flat frame (Fig. 2) made of steel welded pipes of rectangular cross section 50X25 mm, with 2.5 mm wall thickness, forming a rectangle 3200X1500 mm with four transverse ridges, and two longitudinal elements. The frame essentially is the main Assembly slipway: all the other nodes in the chassis and body are attached thereto with bolts.

In the “Minimax” sliding doors. When the wagon body is easier to implement. In addition, this design allows you to make them much wider, without any increase in winery Parking dimensions, which is inevitable when opening the door. With wide doors For small-car wagon means additional convenience for the driver and front passenger. In this sense, the “Minimax” some advantages compared to, for example, with the micro-car, only car type “Fiat Multipla”. Through a wide door fall into the “minimax” and the passengers in the back seat; in the cabin fits a refrigerator or other bulky Luggage. The dimensions of the rear Flip-up doors also contribute to this.

Fig. 2. Frame construction made of rectangular pipes:

A — General view: 1 — longitudinal rails, 2 — crossbars, 3 — spar bridge mount; B — cross section of the pipe.

Wagon layout imposes a restriction on the size of the wheel: because the driver is placed above the front axle. Furthermore, the increase of the machine’s center of gravity affects its stability. Besides it is necessary to meet the existing technical requirements that limit the height of not more than 1450 mm.

Completely satisfy all of the conditions of the tyres of 5.00—10 motorized С3А, although they limit the total weight of the vehicle permissible load: 250 kg per wheel.

The use of these tires has pushed For the use of bridges motorized for the front suspension taken С3А mounted on two longitudinal cross-welded box section mounted on the first two transverse crosspieces of the frame. The necessary stiffness is achieved by additional spiral springs mounted on the shock absorbers. At the same time reinforced the attachment point of the lower ear of the shock absorber. A preliminary preload of the springs is adjustable just as it is recommended for “Cossacks” (magazine “Behind the wheel”, 1970, № 2).

The layout of matousek provides the ability to install the power unit of “Zaporozhets” ZAZ-965. However, the first version of the “Minimax” power unit installed С3А, with a slightly increased compression ratio (to 7.8); this is used of the rear part of the frame С3А with the engine, main transmission and balance wheels rear wheel suspension.

I consider it my duty to warn followers that the use of suspension С3А (or С3Д), even with proper load distribution between the wheels, the chassis limits the weight of the machine limiting value of 1000 kg. in dry weight of “Minimax”, which is 640 kg payload, thus, does not exceed 300 kg. So in the long tourist trip taking into account traffic in the car things can go 2-3 persons only. The task to meet the 640 kg is difficult, if a machine is not maintained strict control over the weight of the parts. It is often built handmade have a dry weight of 800 kg (or even more), leading to exceptionally fast tire wear and suspension components. For this reason, a lot of homemade machines later almost have to redo.

Steering and addition to the nodes, borrowed from С3А has a longitudinal rocking chair, front end of which is connected by a rod with the steering rack mechanism. At the rear end of rocking fixed the ball joints the steering linkage.

Brake drum installed on all four wheels. The hand brake operates on the rear wheels only.

The body is assembled from several individual nodes. The frontal portion consists of two lower longitudinal rectangle tube 50X25 mm, which are welded to the uprights, and fastened to them by bolts to the transverse steel sections, lined the bottom (floor of the front compartment) with Micarta thickness of 7 mm, at the front of the PCB 4 mm, rear and sides — sheet steel 1 mm.

Frame front glazing is made of bent parts thickness of 1.5 mm and tube 15X1,5 mm (upper contour and the middle strut). The windshield is composed of two halves, carved from laminated glass.

The Board assembled at the M5 bolts made of aluminum profiles and sheets of Micarta 3.5 mm. They are connected with the middle bulkhead (between the passenger and metoodika) and rear Board. The sides and middle bulkhead attached to the frame, and the front edges of the sides supported by pillars made of the same rectangle tube 50X25 mm. At the top of the edges of sides front and back are connected by arcs, welded pipe 25×2,5 mm.

The longitudinal contours of the roof formed aluminum profiles with a rectangular section 40×20 mm and the protruding shelf, which serves as a drainage and guide rail for moving the door. Profiles frame mounted on front and glass on both arcs.

The roof consists of two parts: the back, between the arches, — from a sheet of Micarta; front — soft, tubular frame, removable.

The side glazing is assembled within the aluminum profiles. Door rhombic shape, moving in the upper two rollers; each has a bottom rail. Closed doors are firmly fitted into the front groove of the front portion and adjacent the rear edge of the body overlapping. Free sliding door is provided with a special mechanism (see Fig. 1B): during initial movement the rear lower corner of the door slides in the oblique guide rail, the outlet bottom of the door from the body. Additional rear door matousek is suspended on two upper loops.

The passenger compartment floor made from a sheet of Micarta 6 mm thick and fixed on the walls of a steel sheet 1 mm thick between the cross members and inner longitudinal members of the frame.

The frames of the front seats checked of steel tubes 20X1 mm, which are stretched rubber bands. “Zaporozhets” and is wearing a leatherette cases. The rear seat and its backrest can be lifted (with shipping) or moved from the plane of the cover matousek, resulting in a total bed size 1900X1250 mm. While the front seats are not removable, and in the lower part of the cabin there is enough space for Luggage.

Fig. 3. Scheme inputs to directly affect the “minimax” in four projections, and the principal dimensions of the seats.

The dashboard on the steering column. The management of The transmission near the driver’s seat. Traction and control cables are held in the center tunnel below the level of the frame, I in the front and passenger compartments they guarded.

The body inside and outside lined with plastic imitating wood.

Forms of machines have determined the proportional composition of flat surfaces, especially wooden panels. At the same time such planes the most technologically advanced in relation to domestic production conditions. The lack of aerodynamics the accepted form almost no role, because in urban conditions, the average (or even maximum) the rate is small, From the point of view of technical aesthetics it should be noted that modern design also makes extensive use of plane throughout substitute streamlined shape. This circumstance in this case was so specific that attempts to write on the body “Minimax” panoramic windshield “Moskvich” on several models (scale 1 : 10) is clearly shown; and flat glass, the machine looks much better. With the selected shape of the body is also in good agreement constructive solution of the upper rails and rhombic contour of the doors. In the end, when the length of the machine less, than “Zaporozhets”, the internal volume it has turned out more than the “Volga”.

Experience has shown car use in Moscow and on the roads near Moscow (mileage over 30 thousand km), the basic design of the machine acapellas successful. Winter operation has convincingly demonstrated large advantages of the two-stroke engine with air cooling.

Due to the high culture weight even with 350 cm3 motor car With two passengers has sufficient acceleration for the movement in Moscow “green wave”, and the maximum speed reaches 70 km/h. Small power of the engine is felt only on long climbs and when overtaking or if in a car sit two passengers: pick-up drops significantly. Therefore, if the assumed distant tourist trip with the necessary Luggage, it is advisable to install a more powerful engine.

P. ZACK, the engineer-designer, winner of the NTTM