Brake system the car has a drive on the front wheel (same as the moped, the drive lever the front brake is on the right hand steering) and the rear wheels. ECHR circumstances allow, the brakes of the rear wheels it is best to withdraw on foot. However, it is also possible variant with a lever actuator on a separate arm.

The wheel of mokiki almost the same as on a “Mini-mokiki” Riga manufacture. So is the controls of the tricycle: on the left handlebar grip — clutch lever and switch gear of the engine, on the right — grip throttle and front brake lever.

The starter engine converted to manual transmission. For this purpose, the lever kickstarter rearranged so that, sitting in the driver’s seat, it was easy to grab his hand and pull sharply upwards. Of course, you need to modify the lever of the starting device is to replace the folding pedal comfortable grip.

The driver’s seat is of simplified construction. It is based on the details of the old folding duralumin and fabric chairs. The covering of a seat — of nylon twine, foam and faux leather.

Floor machine — plywood, consists of two parts, cut from 6 mm plywood. To the frame they are attached a 5 mm bolts and nuts. Plywood on top of stacked rubber mats.

As already mentioned, three-wheeled mokik has a body of the closed type with the door on the right side of it. For such a light and easy machine is designed and simplified technology for producing panels of double curvature, without requiring the use of complex matrices or boob. This method consists in the following. Of slats and plywood linings-kerchiefs vyklevyvajutsja two frame sides. So they get strictly the same, you can line their path on the floor or sheet of plywood, and then outline to score before the half is quite thick (about 4 mm) nails. When Vileika these nails will be the reference pins of a makeshift slipway to build RAM-side. Please note: each of the frames has broken. To make it, it is necessary after the curing of the epoxy glue to saw received frame > to re-glue it with plywood linings and battens-liners.

Covering the side panels is a composite material of fiberglass and epoxy resin. Forming such a plating is as follows. To start on the outside of the frame tightly stretched plastic film. Stick it to the frame you can glue “Moment” or tape. Further, the sidewall must be installed on the trestle so that the inner surface of the panel facing up. Thereafter, a polyethylene film laid fiberglass (two or three layers), the layers of carefully privorovyvat to each other and to the frame. In conclusion, the impregnated cloth is served (cut around the perimeter of the window pane) pieces of polyethylene film, which also adapt to Vileika. Poured over a shallow, dry, well-sifted sand. The latter not only compresses layers of fiberglass, but slightly pushes polyethylene film, giving Vileika bulge, creating the so-called surface double curvature. The bulge is determined by the amount of sand. Note that the convexity on the right and left panels should be the same.

After curing the epoxy resin, the sand is poured, plastic film removed and you will be beautiful, lightweight, polished sidewall of the body. The left only needs podsalivanii and vyskazyvanii (if necessary), and the right will have to modify: cut through the door.

Similarly collected and vyklevyvajutsja the rest of the panel — two front and rear. Between the panels are joined with epoxy glue and screws.

Glazing machine is made in a very original way, taken over from the modelers and designers of velomobiles for which the problem of reducing structural weight is no less acute than our three-wheeled mokik. “Windows” all Windows is taut Mylar film. First of wooden slats for each window frame is going. Next to each of them with glue BF-2 attached Mylar film. For this purpose the outer side of each frame smeared with glue, after drying lubricated again. Then the frame is superimposed on the tape, cut along its outline with a small allowance, the edges of the film are bent on spread with adhesive edges, after which the film finally “welded” to the frame of electric iron controller which is set to “silk”. Next, each of the frames is installed in a corresponding window opening and attaches to it with screws. Now we have tight-natugo pulling the film. Done “with the help of the same electric iron: its control is set to the highest temperature, after which the film neatly proslejivaetsya. The result of this operation make a perfect “glass”. They are quite durable and will last a long time. Well, at least spoiled a short time and replace: pull the new film in just a half an hour.

The car body is glued from the inside, any cheap cloth, such as a yarn or velvet. Before you mount it to the frame, with slinky seat should be installed fuel tank of suitable capacity polyethylene cans. In principle, five litres of fuel will be enough for a few days not too intense ride. To all, we need a few to upgrade the engine is to organize the forced cooling. To make it not too difficult. To do this, remove the right cover of the boat and install on the flywheel (rotor) of the generator of the impeller. The casing duct is bent at the place of duralumin, or corrugated iron. On the right side of the machine body is cut a hole for intake of cooling air engine and closes a light lattice-blinds. Another hole is needed in the back of the case — near the filler neck of the fuel tank.

The door body has a double-sided trim — it gives it greater rigidity. The inner lining is best to do a thin (not more than 3 mm) plywood or laminate followed by pasting the same cloth, which covered the inner surface of the cabin. The door is hung on two homemade curly loops and supplied emphasis, warning her damage in the event of excessive opening. The optimum angle of the open door is approximately 70 ° to the longitudinal axis of the machine.

Front mudguard wikiepedia of fiberglass and epoxy binder on a simple blockhead, carved from foam and putty plasticine or window putty. Similarly wikiepedia case lights.

For mokik is recommended to install, in addition to the headlights, Parking lights and “turn signals” produced by the industry for bikes. In addition, it is also desirable to install a pair of rear view mirrors.

Riding a three-wheeled car requires a certain skill — for example, when cornering in advance of need to reduce speed. Besides, the car is very sensitive to inconsistent work brakes the rear wheels — no equalizer brake-force requires quite frequent adjustment of the brakes.

I. GALKIN, engineer

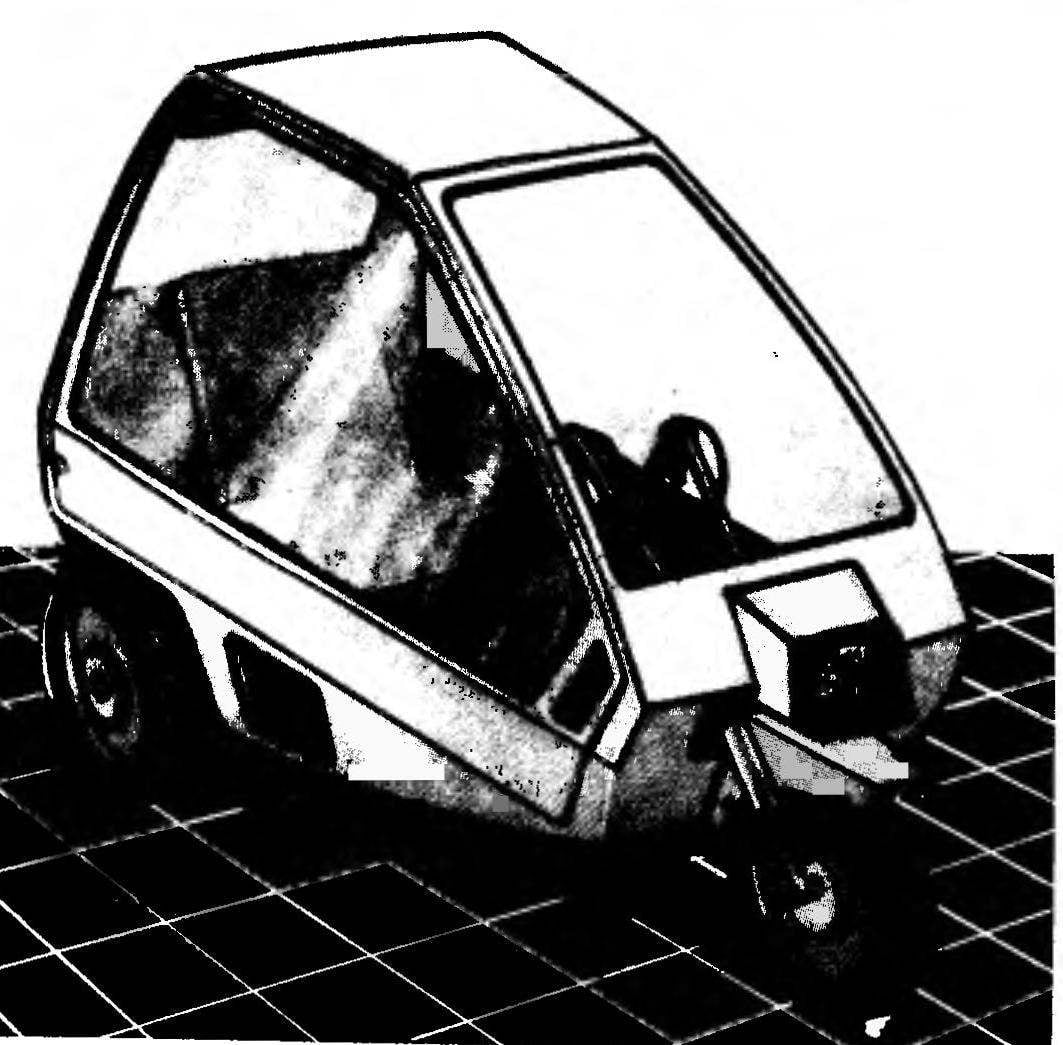

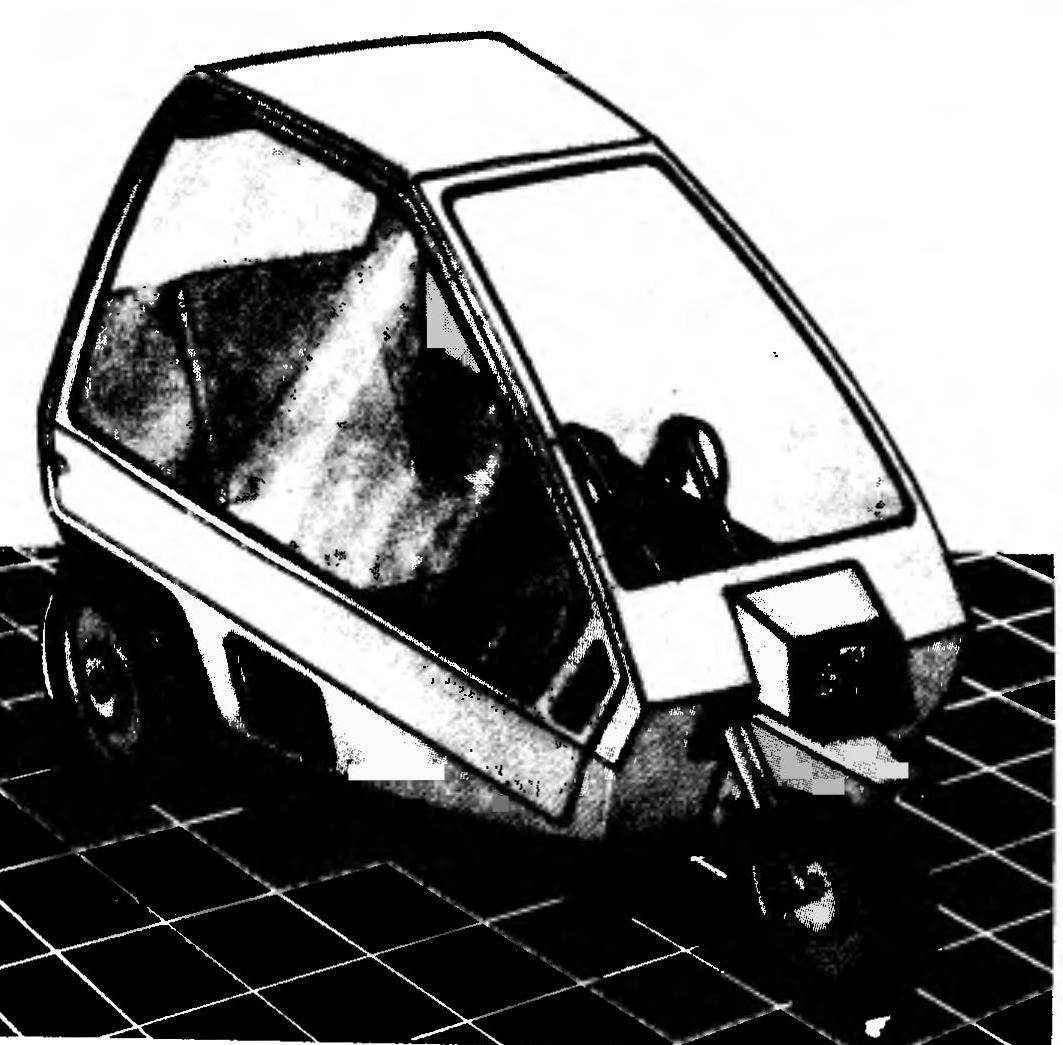

Easy tricycle Lama, apparently, ‘ will be the perfect means of transport for many — including for people who have lost mobility, deprived of the ability to walk normally. It is stable, develops a moderate speed — up to 30 km/h, and its one door body, made with simplified technology, well protects the driver from the vagaries of the weather. But most importantly — mokik with the engine up to 50 cm 3 and such a low speed in accordance with the rules of the road vehicle is not, and therefore can be made without a license and without registration in GAI.,

Easy tricycle Lama, apparently, ‘ will be the perfect means of transport for many — including for people who have lost mobility, deprived of the ability to walk normally. It is stable, develops a moderate speed — up to 30 km/h, and its one door body, made with simplified technology, well protects the driver from the vagaries of the weather. But most importantly — mokik with the engine up to 50 cm 3 and such a low speed in accordance with the rules of the road vehicle is not, and therefore can be made without a license and without registration in GAI.,