These circumstances suggested to me that we need to design a simple four-wheeled truck (or rather, self-propelled cart) with a motorcycle engine that was made almost of those materials, parts and assemblies, which were at hand.

This motorized engine assistant VP-150M from scooter “Vyatka” is well-proven, and with time and according to his image and likeness, with some improvements, I made another similar car with the engine from a motorcycle “Kovrovets”. Machine substitute for each other when one of them is down for maintenance or repair. But the second I use in the summer as she has only one driving the rear wheel. The first, with both rear wheels (like a race Board) — in the winter, and pet in bad weather. The differential between the drive wheels yet, but its a design I’ve already thought about and even made his sketches. It is not quite the usual side differential on the master (extended output) shaft of the truck engine. If the trials are successful, be sure to share the development with the readers of “Modeller-designer”. But suspensions will be discussed later.

Framing my “tetracycli” spatial steel trusses, welded from two frames United by five pairs of uprights and three pairs of struts. The spars and cross-beams of the upper frame — tube diameter of 27 with a wall thickness of 2 mm. Instead of the outermost cross members are welded to the frame of the traverse of the pipes with a diameter of 33.5 mm and a wall thickness of 3.2 mm, which serve as stops for the upper ends of the springs of the suspensions of the trolley. Traverse mounted on the front mounting bracket of the cylinder of the shock absorber and the steering column shaft.

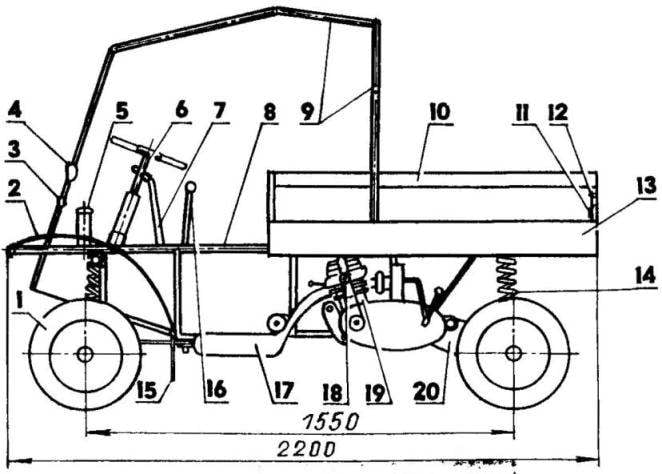

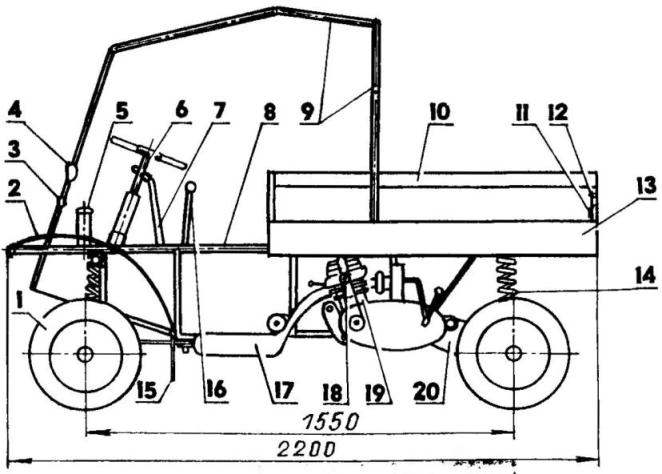

Motor truck:

1 wheel (4 pieces): 2 — front fender (tin s0,5,2); 3 — front turn signal lamp (2 PCs); 4 — a headlight (2); 5 — isolator; 6 — wheel; 7 — Parking brake lever; 8 — frame-frame; 9 — arc security; 10 — body; 11 —brake light (2 pieces); 12 — rear turn signal light (2 PCs); 13 — rear wing (sheet s0,5,2); 14 — coil springs rear and front suspension (4 PCs); 15 — splash guard (rubber, 2); 16 — gear lever; 17 — muffler; 18 — fan forced cooling of the engine; 19 — engine (from a motorcycle Kovrovets); 20— swing arm rear suspension (2 PCs); 21 — a rotary fist; 22 — beam front axle; 23 — fairing (sheet s0,5); 24 — the tie rods; 25 console suspension I-beam front axle (2 PCs.)

A supporting structure (the upper and lower frames):

1 — front bumper; 2 — the upper side rail (2 PCs); 3 — front cross member (steel pipe 33,5×3,2); 4 — bracket of shock absorber (steel pipe 40×3); 5 — bracket of the wing (2); 6 — Mirana stand (8 PCs); 7 — long upper cross member; 8 — bracket engine mount VP-150M; 9 — a support axis of the pendulum arm and the drive shaft; 10— the short upper cross member (2 PCs); 11 — osinka (2 PCs.); 12 — rear cross member (steel pipe 33,5×3,2); 13 —rear bumper; 14 — brace (steel rod d9,6 PCs); 15 — lower short cross member (4 PCs); 16 — reinforcement for side member (steel angle 25×25, 2); 17— mounting brackets of the engine of the motorcycle “Kovrovets” (“Sunrise”); 18 — an arm of fastening of the muffler (2); 19— long lower cross member (spring sheet 45×5 from the car “Victory”); 20— lower side rail frame (angle iron 25×25, 2); 21 console front suspension; 22 — bushing mounts I-beam front axle (2 PCs.); 23 — Mirana front strut (2); 24 — steering column (steel pipe 33,5×3,2);

Chassis (bottom view):

1 — wheel (sidecar С3Д, 4 pieces); 2 — knuckle (rod off the bike, 2); 3 — short and long rods; 4—beam axle (steering shaft of the truck and the hydraulic cylinders of the front fork of the motorcycle “Voskhod”); 5 — adjustment coupling rods (2 PCs); 6 — a Pitman arm; 7 — the beam clamps (screw M8-4 pieces); 8 — spring suspension (4 PCs.); 9 — console front suspension (leaf spring from car ZIL-130, 2pcs); 10 — power frame (top and bottom of the frame); 11 — brackets for attaching the engine of the motorcycle “Kovrovets” (“Sunrise”); 12 and the tube — axis pendulum with the drive shaft inside; 13 — pendulum rear suspension (2 PCs); 14 node rear wheel drive; 15 — braking system; 16 — the mechanism of a tension of the chain; 17 — mounting brackets of the engine of the scooter VP-150M; 18 — steering shaft; 19—steering column; 20—mounting bracket of the muffler (2); 21— absorber; 22 — front cross member

Spars lower frame of 25×25 mm area with additional reinforcement from below in the engine part covers from the same profile. The crossmember of the frame in the driving part is made of spring sheet section 34×5 mm from the car “Victory”: they settled in and welded the bottom of steel sheet thickness of 1 mm. in addition, to the front crossmember attached console, front suspension, made of such spring strips. The rest of the crossmember lower frame and the rack, of rectangular pipe section 25x20x2,5 mm., the Struts between frames and stands from rod with a diameter of 9 mm.

To the lower frame rails, uprights and cross members in the engine part welded mounting parts engine and transmission: brackets, supports, scarves. Supporting frames of both trucks are almost identical and differ only in the form, quantity and installation location of the brackets for mounting the power unit and transmission.

Beam front axle with a diameter of 30 mm, the first carts made from trimming the steering shaft of the truck, and the other of the two tubes of the hydraulic cylinders of the front fork of the old motorcycle “Voskhod”, stacked coaxially end-to-end in the middle and welded around the circumference. In this place on her worn and welded the cut rim of the tube.

Front wheels suspension on both trucks the same — dependent and consist of each of the three segments of the spring strip section 45×5 mm (from the car “Victory”), one of which is the crossbar of the lower frame, and two fixed consoles on it (in the shape of the letter P). The fastening is made with bolts M12. which cross bar is pressed, and in the holes of the consoles includes free. Between the parts with the rubber gaskets, reinforced cord with a diameter of 45 and a thickness of 5 mm. To the front free ends of the consoles bottom-welded sleeve, in which is inserted a beam front axle. In the field connection details the beam is wrapped with a nylon cloth impregnated with epoxy resin. The beam is fixed with M8 screws through the threaded holes in the bushing and the corresponding slot in the beam itself. For inspection, lubrication, troubleshoot the workings of the locking screws are turned out and the beam shifted slightly.

The steering knuckle of the front axle:

1 — tie rod (steel pipe 22×3); 2 — locknut M16; 3 — steering joint; 4 — pivot arm (Bicycle crank); 5 — pin (bolt M16); 6—clip (spring leaves 60×9); 7 — brake (motorized С3Д); 8 hub; 9 — the bearing 203; 10 — castellated nut М16х1,5 with cotter pin; 11 — protective cap; 12 — plate; 13 — brake drum (motorized С3Д); 14 — axis (automotive axles); 15—distance ring; 16—coupling bolt; 17 — bearing 205; 18 — castellated nut M20x1,5; 19 — castellated nut M12; 20 — bearing (bronze, 2 pieces.); 21 — pivot bushing (steel pipe 26×3); 22 — beam front axle (steering shaft truck)

The rear half bridge leading wheels (with gears):

1 — a flange of fastening of a wheel (scooter “Electron”); 2 — ball bearing 106 in the housing (2); 3 — casing half-bridge (steel pipe 48×3); 4 — platform mounting springs (St3, strip 30×2): 5 — mount plate springs (St3, sheet 10); 6 — spring d80 (steel 60G, rod d10,9 turns); 7 — bolt M10; 8 — flange of the pendulum arm (steel, sheet s2); 9 — sprocket (z = 38, scooter “Tula”); 10 — sprocket (z = 44, from a motorcycle “Voskhod”); 11 — casing the idler arm (steel, sheet 1.5); 12 — washer; 13 — a bolt M20x1,5; 14 — a bolt M5; 15 — M10 screw (x8); 16 — Planck-nut with two holes M10 (4 PCs): 17 — plate-washer with two holes d10,2; 18 — brace (steel, strip 30×2, 2); 19 — shaft-axle shaft (steel pipe 33,5×4); 20— bearing brake disc

Truck engine VP-150M

In the middle of the beam to bandage tube welded tubular cross bracket. To him with a fork attached to the lower end of the piston rod. The cylinder of the shock absorber is attached to the eyelet on the front of the upper traverse of the frame. Beam and cross member are connected by two springs. For attachment to the trailing coils introduced a circular plate through which the lower ends of the springs connected to the ends of the beam, and the upper bar with the help of ladders.

The axle (axis) of the front wheels machined automotive shafts. The bearings in the hub — 205 and 203.

Brace the steering knuckle from the spring sheet section 60×9 mm. are welded thereto swivel arms made of a Bicycle crankset. Axis to the brackets not welded, but bolted nut M20x1,5. Nut zaspirtovanny.

Rear suspension mototelecom and drives the drive wheels are significantly different from each other. The first truck front suspension, drive open-chain, single axle-shaft with both driving wheels without differential. On the last drive with gears, two axle shafts, but so far with one driving wheel. The suspension of each wheel is independent, is built on the principle of the pendulum arm. Levers-hoods are suspended on the tubular shaft, mounted in bearings of the brackets of automotive connecting rods. In the left casing placed transmission: master and slave sprocket and drive chain with a pitch of 12,7 mm sprocket Driven — combined: to the hub 38-bevel sprocket (from motor scooter “Tula”) is fixed with M5 bolts crown 42-bevel sprocket from a motorcycle “Rising”. If you want to use a smaller sprocket, the big crown can be removed, shortening the chain.

Suspension of the rear wheels, as well as the front, both mototelecom is spring loaded. All springs are of the same diameter 95 mm, formation of the 10-mm rod (9 coils with a total height of about 300 mm) spring alloy steel 60G. In the suspension with an open chain and sprocket spring located inside of the side members and rest on the rear end of the idler arm.

Brief specifications motor trucks

M. TRAIN, Khabarovsk Krai

Recommend to read NOT RAISING DUST To the broom lifted off the floor dust it can be equipped with its own humidifier. Take the flat plastic shampoo bottle, drill in the lid a few small holes, pour water and tighten on the... ROLLER+ROLLER The device shown in the illustration will be useful to all house masters, making furniture with his own hands. With its help you can easily and quickly roll while gluing forever lagging...

In a country HOMESTEAD or farm, however small, any mechanized cargo vehicle can help a lot. It helps to save money and power. Of course, when it is simple and reliable. Preferably, the machine was small in size for maneuverability and had the power (even at the expense of speed). Permeability it should also be on top. Road on not very much welcomes the emergence of these self-made vans on the highway, so their destiny is mostly unpaved country roads. As a rule, on such roads, two clear of the track (after all, they don’t even profile), so they wheeled transportation vehicles (“ants”, power tillers with trailers is the most affordable for most owners) is difficult.

In a country HOMESTEAD or farm, however small, any mechanized cargo vehicle can help a lot. It helps to save money and power. Of course, when it is simple and reliable. Preferably, the machine was small in size for maneuverability and had the power (even at the expense of speed). Permeability it should also be on top. Road on not very much welcomes the emergence of these self-made vans on the highway, so their destiny is mostly unpaved country roads. As a rule, on such roads, two clear of the track (after all, they don’t even profile), so they wheeled transportation vehicles (“ants”, power tillers with trailers is the most affordable for most owners) is difficult.