Imagine: around the entrance waiting for us miniature car a nice modern shape. Let’s do a small trip. The door swings open, as usual, and gently rolled back, releasing a wide opening for planting. Installed on hinges of the seat POPs out, we get them directly from the pavement, and they can easily occupy the same position.

Imagine: around the entrance waiting for us miniature car a nice modern shape. Let’s do a small trip. The door swings open, as usual, and gently rolled back, releasing a wide opening for planting. Installed on hinges of the seat POPs out, we get them directly from the pavement, and they can easily occupy the same position.

It is possible to go. But look: in the cockpit not usual for all controls and devices — they are replaced by a single lever and a few buttons. The driver slightly deflects the lever and the car smoothly and quietly moves off.

Bursting out into a broad Avenue, our crew is not inferior in speed to its neighbors — an ordinary car. Although we have not heard the usual rumble of the engine, not smell of gasoline and exhaust… You guessed it — a miniature electric vehicle that for many is still only a fantasy.

Interestingly, in fact, the electric car almost the same age as diesel. At birth, at the end of the last century, it developed even more rapidly than other types of vehicles. Suffice it to say that the electric vehicle in 1899 for the first time broke the 100-kilometer line speed, reaching unprecedented for those times the numbers: 106 km/h But too high were the main disadvantages of this machine: large mass, small power reserve even at a low average speed. There was another, serious and powerful rival a car with a gasoline engine. About the electric car long forgotten.

Remembered about it only in 60-ies, when there was, especially in the capitalist countries, the so-called “problem of transport in big cities”: poisoning the streets of the poisonous exhaust gases of automobiles, is not illegal dump on the road — so many of them.

Needed a new, silent and compact vehicle specifically for cities that were not allocated in the atmosphere of settlements harmful gases. This tool aims to become electric car.

In our country, many designers in recent years are working to create various kinds of electric vehicles for the city. Amateur automakers are able to provide in this important work is invaluable in the power that their electric cars can embody the original decision, to become a testing laboratory for scientists.

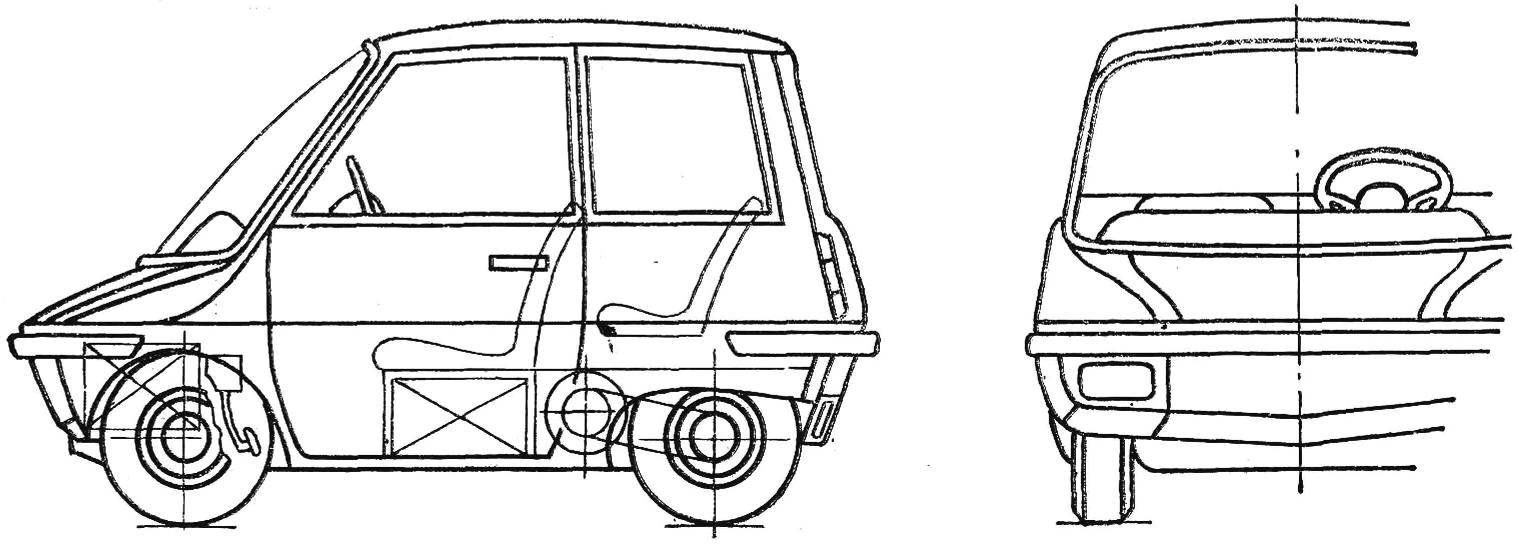

Fig. 1. Diagram of urban electric vehicle (side view front).

The electric car provides great opportunities for technical creativity, and its development and construction are not associated with great difficulties and costs. The machine can be made on the basis of standard electrical equipment and components from conventional cars. It is distinguished by extreme simplicity in manufacture and in operation. The size of the electric car may be small: in fact the battery is easily placed under the seats, and a smaller gasoline motor.

Here is one of possible options is quite simple and miniature electric vehicles. It is suitable for trips around the city for hours without intermediate recharging of the batteries and is designed for the average family consisting of two adults and one or two children, that is, the number of seats corresponds to the formula “2 + 2”.

In the electric vehicle, no complex units, even the drive from the motor to the drive wheels can be simplified. Front and rear axle, suspension, brakes, wheels, steering column from a regular used car or microcar. To control used two pedals; one connected with the rheostat and changes the movement speed, the second brake pedal.

Batteries you can use standard lead acid, voltage 6 or 12 V. These batteries are inexpensive, reliable and simple to use, but have two very significant drawback — a large mass and low energy intensity (i.e. the energy produced per unit weight, the average 18-25 W•h/kg). A very promising Nickel-iron batteries, which are compared to the lead much longer service life and less weight, their energy intensity is 23 to 30 W•h/kg. Other types of special batteries with high energy capacity at low weight, has not yet emerged From the experimental stage. Almost all the electric vehicles manufactured even at the factory, now supplied with lead batteries.

Batteries — the heart of the electric vehicle and at the same time the weakest of his place. After all, the characteristics of the electric — power reserve, dynamics, speed, weight — depend primarily on them. Due to the low intensity of each battery is necessary to increase their number, which in turn leads to an increase in machine weight and reduce the reserve of speed and dynamics.

It is therefore necessary to reach the minimum weight of all components and the body of the electric vehicle. Existing models the total mass of the battery is 50-70% of the total mass of the electric vehicle.

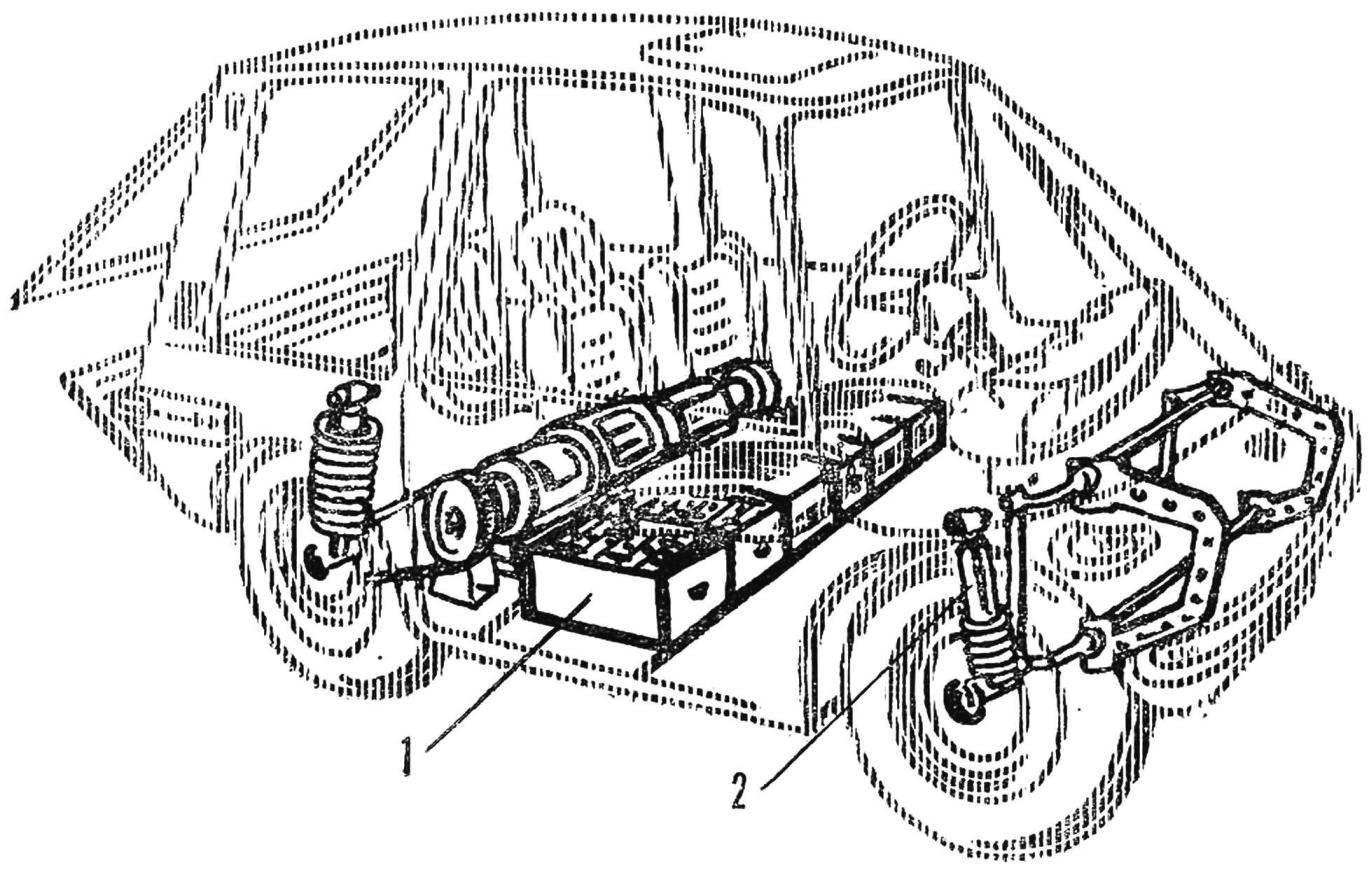

Fig. 2. The overall layout of the nodes of the electric car:

1 — battery, 2 — front suspension.

Of course, raising the reserve can be achieved and the intermediate charges of the batteries, for short stops joining conventional networks, however, this approach is not very convenient. And the designers found the ability to recharge the battery not even at bus stops, and in the right way. Because in urban traffic the machine is often slow, coasting or going downhill. In this case, the motor can be a generator, generating current to recharge the batteries. This principle is called energy recycling, and in time to perform automatic switching for discharge or recharging batteries, are special electronic thyristor control systems, which also contribute to a more rational consumption of electricity.

On our electric car under the front seats is installed in one or two rows 6 or 12 batteries: their number depends on the type, characteristics, weight and dimensions. Possible to install 4 extra batteries in the space between the rear wheels, but with correspondingly reduced capacity of the Luggage compartment. The average weight of one battery of about 30 kg of their total weight will be about 360 kg. All batteries must be installed on extendable trays for 3-4 pieces each to be able to perform regular inspection and maintenance. Full charging is conducted at night for 8-9 hours from the mains using the charging device.

As a motor it is proposed to use two traction sereznyh DC motor with a capacity of 3-5 kW. Both electric motors are mounted on the subframe directly behind the battery, transversely, on the same axis. Each of them through a belt or chain drive rotates the wheel. Depending on the power motor, the design speed of the electric vehicle and the diameter of its wheels is changed accordingly the gear ratio.

Independent rear suspension, original design, using standard springs and hydraulic shock absorbers from “zaporozhtsa”. The wheels are mounted on trailing arm box-section swinging on an axis common with the axis of the motors. Chain drives enclosed in housings levers. For this purpose, can also be used a wishbone rear suspension of the “Zaporozhets” or another car, but with a corresponding change in their structure.

Front suspension and steering can be applied from ZAZ-965 without any changes, but this way the front suspension with two transverse torsion bars will create an obstacle to the legs of the driver and install the pedals. However, you can carry forward the whole suspension system, but it will increase the length of the electric vehicle. It is therefore proposed that the spacing of the torsion bars suspension: upper torsion bar is located above and connected with the lower by using frame-shaped. This frame from the inner side around the front body panel and also serves as a safety cage or a special buffer to protect the driver and passengers in the accident. The ends of the arms from the torsion bars is connected to the rotary racks; they are thrust steering linkage that also moved to the top. It is expedient to provide for the safe design of the steering column, for example, telescopic type.

As the control system of the electric vehicle can apply a simple rheostat drum type: engine it communicates with the foot control. Braking may be performed by reversing the traction motor, however, in order to enhance the security of electric vehicle it is necessary to provide conventional braking system. Rheostatic control system the simplest and cheapest, but its use has a significant energy loss, especially during acceleration of the electric vehicle. Therefore, advanced systems are esreality, semiconductor controlled valves (thyristors) with a pulse method of regulation traction electric motor. Such systems reduce energy loss, improve the characteristics of the motor, and ensure the recuperation of electricity. Thanks to the creation of high-power semiconductor valve rectifiers have an opportunity to convert the DC from batteries into alternating current required frequency. This allows you to use the more reliable AC motors different from DC motors significantly reduced weight and size, and this is very important for electric vehicles. To learn more about these new systems, according to the book O stavrovo “Electric vehicles” (Moscow, “Transport”, 1968).

The body may be laminated of fiberglass and have a high and wide side Windows, front windshield, increased size, especially in the lower part. This gives the driver a great review, which is important in cramped conditions of urban flow. On the panel are mounted the necessary instruments and tables, and with its outer side in the longitudinal transparent overlay, you can install 2 or 4 lights. Oblong sidelights and direction indicators front-mounted on the side fillets of the body so as to be visible at both the front and side. Also attached the rear turn indicators and brake light.

The side door of the electric car can make a normal, opening on hinges, but it’s pretty tempting can be a new design of sliding doors as the coupe cars. This will significantly reduce electric vehicle occupied a Parking space, it will be free to leave, even if the distance between adjacent machines does not exceed 25-30 cm Seat are simplistic: after all urban trips are short, and people will not feel tired as during long distance travel. But when designing the base front seats need to consider the security requirements for them: at all loads during a possible accident seat should not move from his seat. It is necessary to provide the use of seat belts.

Rear children’s seats are integral or separate, they are slightly smaller and are located on a hill, under the floor of which is the electrical part of the machine.

The rear seats can be foldable or detachable, which allows this part of machines used for transportation of Luggage. With the same purpose, the rear wall of the electric car rises like passenger cars. In addition, the rear or one side glass can be made to open inwards: this will allow you to put shopping in the electric car directly from the street, not opening doors.

With electric you can set the wheels of small diameter from sidecars, size 5,20—10. But due to the large mass of the electric vehicle and the use of standard suspensions it is better to use wheels from “Zaporozhets” or “Zhiguli”.

So, our electric vehicle designed. Here are the main options until only an estimate. Depending on types of used electrical equipment electric car at an average speed of 32-40 km/h should have a reserve of 60-70 km and a maximum speed of 65-70 km/h. the length of the electric car of 2.5—2.7 m, width 1.5—1.6 m, height 1.5 m. the Own weight of the batteries and depending on their number from 600 to 800 kg, the load of 350 kg. Theoretical acceleration of the electric vehicle from standstill to a speed of 60 km/h 10-12 s, which is considered quite acceptable for a modern and urban movement.

We have offered you a General outline of the device passenger electric car for the city; variations of the same design and can be unlimited. Initially, you experienced to do the easiest version of the electric, and then gradually complementing and modernizing it, come to the most optimal variant. So, ahead unknown road searches where Amateur designers can find interesting solutions. And the prospects are enormous: the creation of a special light and energy-batteries, light and powerful electric motors the minimum sizes which could be placed directly in the wheels, the creation of new electronic control systems for electric vehicles, the use of AC and convenient charging of devices using only one lever to control the speed and direction of movement of the machine as the electric car of the future, described at the beginning, the creation of durable and lightweight chassis, comfortable exterior modern forms.

Good luck, electric car!

E. KOCHNEV, engineer

THE COMMENT OF THE EXPERT

Problems of electric vehicles was addressed in the “Modeller-designer” in a time when (“large automobile” and was not involved in them. Then, electric cars were interesting cars-toys. In recent years the situation has changed. Electric cars are becoming more and more necessary. Therefore, the number of institutions and factories explores, builds and tests electric vehicles, launching the release of their experimental batches.

Does this mean that Amateur designers now have nothing to do in the field of electric vehicles? It seems to us, on the contrary, it is now possible to study, use and develop the accumulated experience of experts. Whiter — try to solve is not solved their problems.

And there are a lot of problems. Here and relief design of mechanisms and the body of the electric vehicle to reduce its mass, despite the presence of ka it heavy batteries and other electrical devices. Protection of people from shock — in fact the voltage can (depending on the type and number of batteries, their connections) to achieve 200-300 V. the heating Device body, the design legasey battery containers and many more.

Article E. Kochneva gives Amateur designers the essential ideas of the construction of the electric vehicle. In the future we will try to acquaint readers with the modern domestic and foreign electric vehicles: experimental, serial, and… Amateur. And such already is!

Y. DOLMATOVSKY, candidate of technical Sciences, head. the laboratory of the State scientific-research Institute of automobile transport