The engine was initially installed D-3 — single-cylinder, four-stroke, liquid cooled. The motor is started by the kick starter, ignition from magneto. Working on the lowest grades of gasoline, the engine remained unpretentious and reliable. His main drawback—a small capacity, only 3 HP So when I bought the engine UD-2 with 8 HP, then immediately mounted it on a mini-tractor. This motor is two-cylinder, forced air cooling. The frame was not altered, only replaced under engine brackets. However, I had to set another connecting plate for connection to the engine transmission clutch basket. These transmission units from the car “Zaporozhets”. Box with basket rotated by 180° relative to their position on the car. For this reason, the wheel reducers are designed so that they not only reduced speed but also changed the rotation transmitted from the gear box axle shafts on the reverse.

Large transmission ratio of wheel reducers allowed to do without brakes. The speed and weight of a small tractor, and he quickly stops when “squeezing” the clutch by itself.

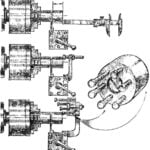

The mechanism on the PTO:

1 — gearbox; 2 — dowel; 3 — stud M10 fastening mechanism; 4 — a cover (D16); 5 —pinion (steel SOHGS); 6 — housing (D16); 7 — cover (D16, the sheet s8, 70×50); 8 — lead (steel 45); 9 — the screw of the locking position of the slider; 10 — the lever (steel 25); 11 — lever axle (45 steel, rod d8, L50); 12 — slider (45 steel, rod d12, is l105); 13 — drive shaft (сталь45, rod d25,225 1); 14 —104 ball bearing(2 PCs.); 15 — cover (D16, листв8,90×50); 16 — restrictive bushing (steel 25)

Mini-tractor “bundle” with wood-working machine

Of the wheel from the sidecar FDD came to design the mini-tractor is the best not only by mass but also by size. Everything, wheels rims these wheels — restrictor small, and he quickly stops when “squeezing” the clutch by itself.

Of the wheel from the sidecar FDD came to design the mini-tractor is the best not only by mass but also by size. Everything, wheels rims these wheels is separable, which greatly simplifies disassembly for repair camera in case of puncture.

Office mini tractor although not quite common through the broken frame, but there is a serial steering (of the car “Moskvich”) and linkage with servo horns and mounting brackets.

The PTO shaft (PTO) is driven in rotation through the makeshift gear mounted on the transmission. A handle on the housing of the gear mechanism, planted on the shaft of the mechanism and is engaged with a gear box input shaft speed, transmitting the rotation of the multistage Sustainable. Multi-layered due to the “turning point” frame design and so the PTO shaft is made of several tribes in the form of a propeller shaft with double joint (a cross joint) in the place of articulation of the front and rear semiframes.

“Life” mini-tractor was not so long, but work during several country-Stroitel-nyh seasons he had. In the end I took it apart, installing the engine on a stationary woodworking machine. The remaining components and assemblies with minor modifications used in the design of the suburban mini-van. But that’s a topic for another conversation.

E. Evsikov, Lyubertsy, Moscow region.

Recommend to read

UNIVERSAL STOPS

UNIVERSAL STOPS

Try to cut multiple identical workpieces on a lathe. How many times have to use a caliper! But if you make for his Studio, universal focus, the workpiece will turn out one in one — and... ASSAULT TANKS OF THE WEHRMACHT

ASSAULT TANKS OF THE WEHRMACHT

Classification of self-propelled artillery of the Wehrmacht were quite complex and confusing. There were several main classes of ACS: Sturmgeschütze — assault guns, Selbstfahrlafetten —...

The need to build a mini-tractor came to me simultaneously with the acquisition in the early 80-ies of the garden plots (receiving, as they said then). Those coveted six acres it was necessary to develop and sustain. I wanted to build a country house. Without mechanized assistant in this matter to do would be difficult. Industries such machines at that time almost was not allowed to get them even an acquaintance, it was almost impossible unless you’re a war veteran.

The need to build a mini-tractor came to me simultaneously with the acquisition in the early 80-ies of the garden plots (receiving, as they said then). Those coveted six acres it was necessary to develop and sustain. I wanted to build a country house. Without mechanized assistant in this matter to do would be difficult. Industries such machines at that time almost was not allowed to get them even an acquaintance, it was almost impossible unless you’re a war veteran.