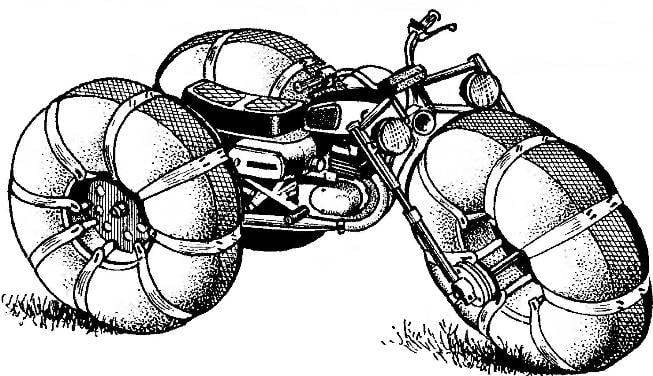

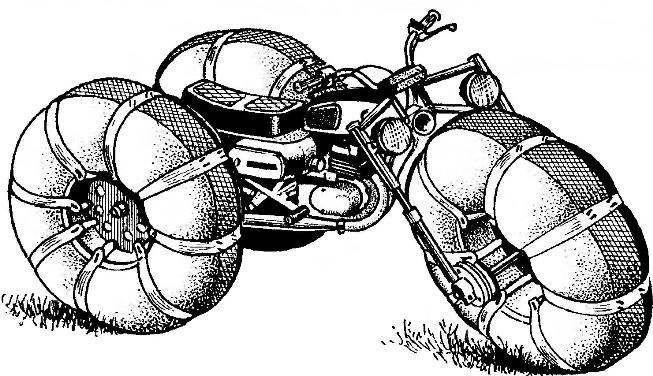

All three wheel pneumatic structurally the same. The only difference is that the front is screwed to the hub flange by eight M8 bolts, and the rear attached to their hubs by steel rivets with diameter of 8 mm and reinforced spokes — four on each wheel.

Rims and wheel cradle made of pipe diameter 18×2 mm disks of sheet steel 3 mm thick To reduce the mass in the discs drilled holes with a diameter of 40 mm. per wheel welded on hooks 16 of rod with a diameter of 8 mm.

To them are attached the cross-bandages — cuts of rubber-fabric belts with a width of 60 and a thickness of 10 mm that hold the Pneumatics on the lodgment.

The longitudinal bands are made of canvas fire hose. At the intersection of the cross they “stitched” steel brackets from wire with a diameter of 3 mm. However, the possible exploitation of the air suspension and no tires on the front wheel. If necessary, Pneumatics can be enhanced to put on them doubles of the same cameras cut to a smaller diameter.

Intermediate gearbox and rear axle are mounted on a special U-shaped frame of the rear suspension, welded pipes with diameter 32×3 mm. This frame consists mainly of two side members and cross beams, reinforced top plate. To the frame of the motorcycle it

connected in the same way as regular swingarm rear suspension.

The sliding spars, as they have a device for tensioning the chain of an intermediate transmission. The rear ends of the spars, rolled up gorack way and provided with screw bushes for the rear axle and tension suspension chain. Approximately in the middle in both longitudinal welded landing sleeve to the axis of the intermediate shaft. In addition, the left are brackets for installation of the cable and levers of the brake mechanism of the rear wheels.

The device chain tension intermediate transfer represent the two sided bolt with left and right thread M18 x 1 5 and lock nuts. The tension of the crawler chain is governed by two bolts M18 x 1 5, welded to the main bearing cups of the rear axle.

The hub of the intermediate gear is integral with the small sprocket (z = 18, t= 19,05). To the hub flange with six M8 bolts with countersunk heads attached brake disc 300 mm in diameter and the large sprocket (z = 40, t = 12,7). Pressed into the hub, two bearings 204, which revolve on an axis with a diameter of 12 mm and are lubricated through the grease fitting mounted on the hub between a small sprocket and brake disc. The penetration of dirt outside the insulated bearings felt seals.

The rear-axle design is simple: a long shaft rotates in four bearings 207. The shaft has three keyways under the prismatic dowel hub pairs of wheels and the driving sprocket, and two grooves for snap rings.

To glasses Central bearings in the front welded bolts, while serving a suspension chain tensioners and mounting hardware to the frame of the rear suspension, and rear eyelets to attach boot. Between the hub of the driving sprocket and the inner bearings on the shaft wearing shaped spacers with flanges that hold the glasses felt seals.

The external bearing cups welded eyelets for attaching the lower ends of the tubular struts. The upper ends of the struts are screwed to podselenie through the holes intended for installation of the rear lights and indicators.

The bearings are lubricated “Lito-crowbar-24” once in three years after a partial disassembly of the nodes. Undercarriage sprocket (z = 72, t = 19,05) —from agricultural unit, light weight. To the hub it is attached by rivets 8 mm diameter, pre-heated in the forge.

A brake mechanism of the rear wheels — disc, tick-borne type. Brake levers are installed in the bracket, the shelves of which is welded to the right side rail. To the cheeks of the levers “epoxy” glued the lining of asbalteco cardboard with a high coefficient friction on steel. The cable from the brake pedal passes through a short sheath is placed between the adjusting clutch and front brake lever. Adjusting the clutch is in the housing, screwed to the bracket under the right side rail.

Represented a brake mechanism is quite complicated to manufacture. If possible, it is easier to use a hydraulic actuated disk brake from a motorcycle “IZH-Planeta-5” or “IZH-Jupiter-5-01”. Accordingly, fit the mounting bracket and pedal for drive the brake master cylinder.

The trunk made half a lattice in order to not accumulate snow. The main materials of its construction — a steel rod with a diameter of 7 mm and steel sheet with thickness of 1.8 mm and an Inclined front wall and the bottom are welded together with a box-like casing, which protects the chain from accidental hits her with foreign objects. The trunk is quite durable and tough and allows you to carry not only a decent load. Behind a eye, employee turnbuckles.

The pneumatic trunk attached with bolts M10 in four points: top — podselenie bottom to the eyelet of the Central bearing cups of the rear axle.

All newly manufactured nodes after Stripping edges were painted bright red nitroemali paint to forced movement on roads of General purpose pneumatic visually stood out in the traffic. Then the nodes were installed on the frame of the bike “Voskhod-ZM”, which previously removed all that was not required for the operation of the suspension: fenders, front fork, swingarm rear suspension with dampers, etc. Equipment alteration were not exposed.

And a little bit about safety. Air suspension called the “Losharik” is not accidental: due to spring quilted it with temper. Therefore, I recommended his friend while riding on it to avoid sharp turns and abrupt braking (the first is fraught with rollover, second cliff bands), and the snowy edge and other similar obstacles to overcome with the move, and right angle. The recommendation went in store after my friend “traveled”, “Losharik”, that became for him a truly unique vehicle.

V. PETROV, Krasnoyarsk Krai

Once television was a popular program “you can”, where the craftsmen talked about their designs. Perhaps it first appeared the information about the pneumatic-tired machines. A publication in the journal “modelist-Konstruktor” has prompted many enthusiasts, including our own, Angarskaya (mostly fishermen) to manufacture such machines with their own hands. Pneumatic bribed his external simplicity, which promises a good performance.

Once television was a popular program “you can”, where the craftsmen talked about their designs. Perhaps it first appeared the information about the pneumatic-tired machines. A publication in the journal “modelist-Konstruktor” has prompted many enthusiasts, including our own, Angarskaya (mostly fishermen) to manufacture such machines with their own hands. Pneumatic bribed his external simplicity, which promises a good performance.