The advantages of a velomobile compared to a bike known to all. First things first- it is resistance, and thanks to her and comfort (although relative) is also much higher. I want to share with readers design another simple and compact recumbent. In the feature I want to include the word “universal” because it allows the drive to connect to the work in addition to legs and arms.

The advantages of a velomobile compared to a bike known to all. First things first- it is resistance, and thanks to her and comfort (although relative) is also much higher. I want to share with readers design another simple and compact recumbent. In the feature I want to include the word “universal” because it allows the drive to connect to the work in addition to legs and arms.

The advantage of the design of this recumbent is that it’s based on an old standard (even without the Dobby unit) frame from a normal road bike type “salute”. It is possible to adapt the frame and any other, cut the top of the pipe and strengthening it segment (by welding) the connection between the seatpost and the front inclined tube under the seat of the velomobile. Almost all of the other nodes is also standard — from bicycles to mass production.

Getting to the manufacturing of the velomobile, the old frame carefully bent feathers the rear of the plug so that the distance between its ends was 550 mm. Tips on the feathers after this you need again to put in parallel. They have the slots for the axles that need to counterbore a round file to a width of 17 mm with the appropriate rounding.

Then in half-inch pipe from two sides hammered by the hammer bars-“axis” with a diameter of 16 mm to a depth of 50 mm and at the ends of the cut thread M16. Entering the pipe with the axes in the machined grooves of the ends of the plugs, “strung” on each end sequentially: a washer, a bearing 203, the rear wheel without mechanical “stuffing”, another of the same bearing. Cementing all nut M16 — get a rear axle of the recumbent.

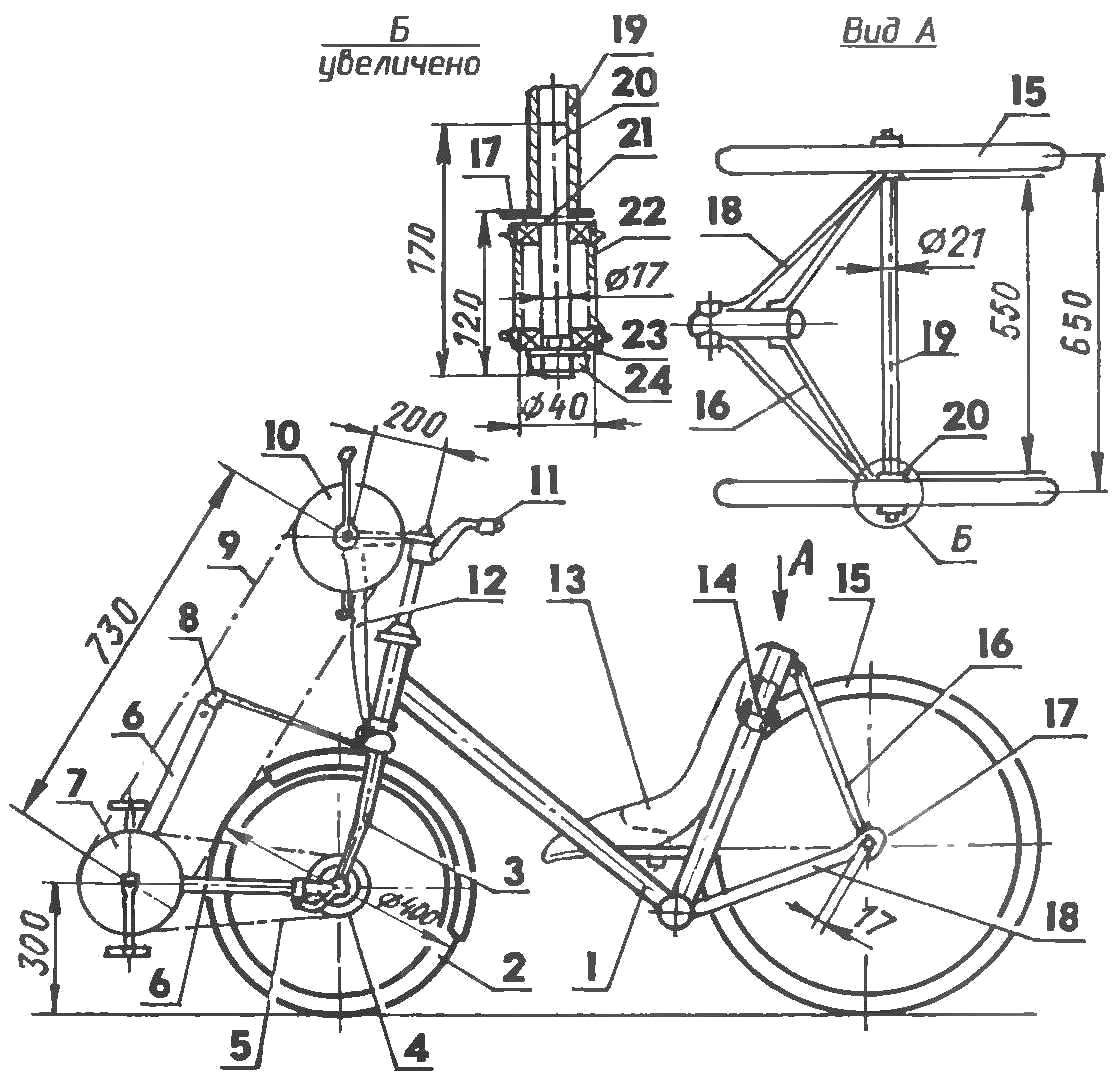

Recumbent with double drive:

1 — frame (from bike type “salute”); 2 — driving wheel (off the bike type “Kama”); 3 front fork (bike type “Kama”); 4 — driven by a small sprocket z = 15 (from bike type “Kama”), 5 — chain primary drive, 6 — sub-frame main drive (part of the frame of the old bike with BB, node); 7 — sprocket primary drive (road bike); 8 — pull mounting of the subframe to the frame (steel, Ø16 rod); 9 — additional chain drive, 10 — hand auxiliary drive (road bike); 11 — the wheel (off the bike of the Salyut type); 12 — subframe manual drive (road bike); 13 — seat (plastic, covered with foam rubber); 14 — bolt M6 seat mounting (2); 15 — rear wheel (road bike, 2 pieces); 16 — brace the rear of the plug (2 PCs.); 17 — the tip of the rear plug (2 pieces); 18 — rear plug; 19 — rear axle (pipe 1/2″); 20 — drive axle (shaft Ø17, 2 PCs); 21 — washer (4 PCs); 22 — bushing (machined, 2 PCs.); 23 – the bearing 203 (4 PCs); 24 – nut M16 (2 PCs.)

To the front fork freely was part of the axis M10 of the drive wheel, its feathers lightly stretch, and the grooves at the ends of the counterbore file And the plug and drive sprocket for easy pedaling and management it is best to use from bike type “Kama” (wheel diameter 400 mm). Small driven sprockets would be good to pick up with a number of teeth equal to 15.

From another old frame (any model) with a hacksaw, cut out bottom bracket shell with the rear fork and the seat tube. This part is used for the manufacture of the main shapers of the recumbent. Moreover, if the plug is too long, it is trimmed, the ends tapered and cut along the slot width 11 mm—for installation on the axis of the front wheel turning forks. And seat tube with a hard thrust attached to the base of the front fork.

In fact, the recumbent is ready. This scheme allows to install an additional manual drive of the Dobby unit with rods and bushings-arms instead of the pedals, attaching it on the steering wheel. When this treadle dobrodey still a large drive sprocket.

On the bridge between the seatpost and the front (inclined) pipe fixed seat, plastic chair, glued soft foam gasket. The wheel should be positioned so that neither feet nor hands while pedaling did not concern him.

Now sit in a chair — and went. Legs rotate driving wheel via the main drive, and the hands (relaxed and straight sections of the route and on the climbs) — optional; they simultaneously control the movement. In difficult conditions and on tight turns the hands shift on the wheel In a good way!