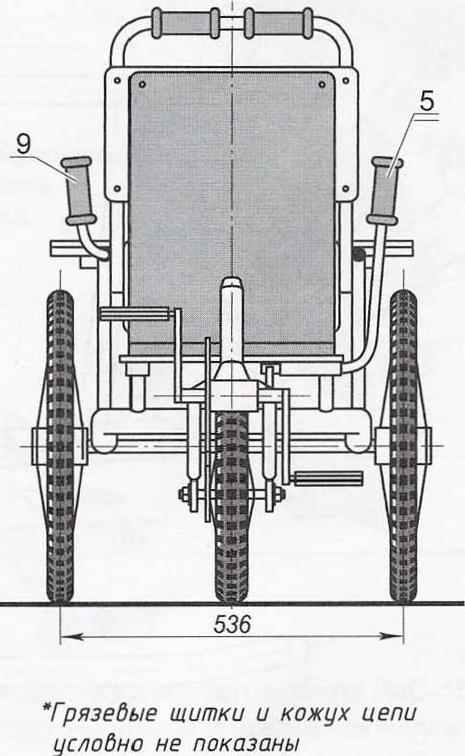

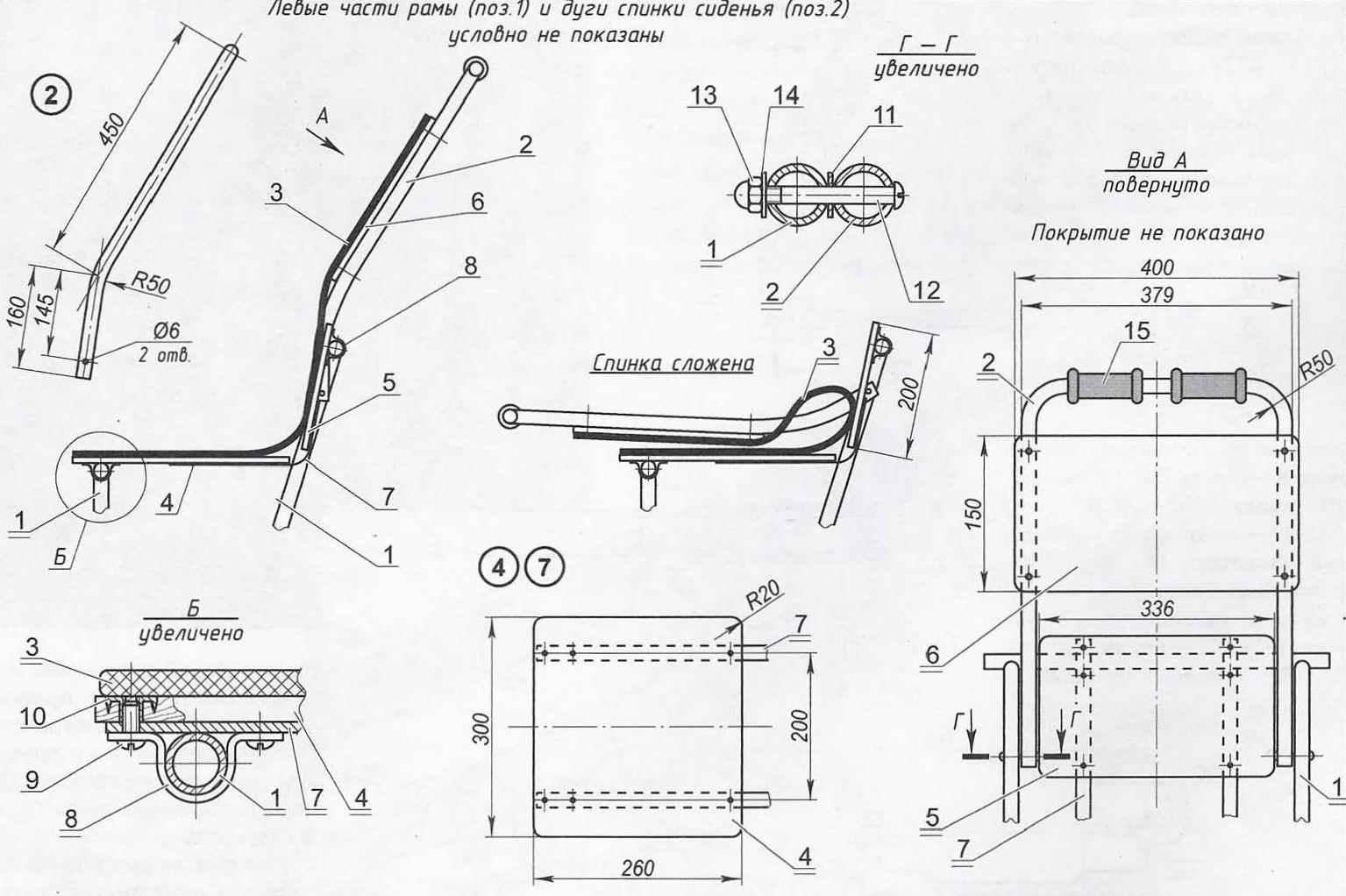

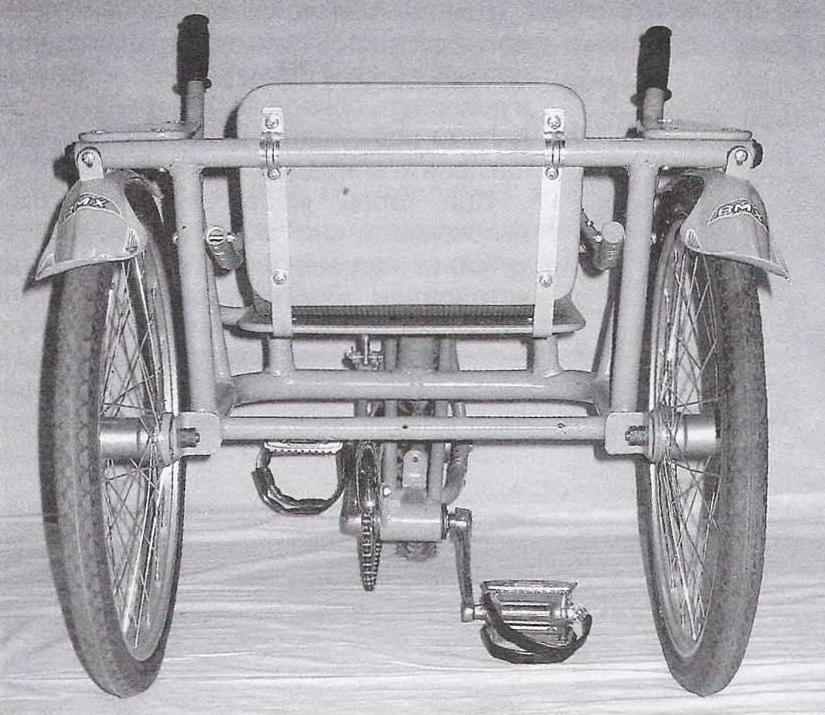

The construction — welded space frame made from thin-walled (1.5 — to 2-mm) steel tubes. The shape of the frame resembles the frame of the seat that, in General, it is. Therefore, as with any chair, he has and armrests, and backrest (though not as impressive). Support-arc backless curved pipe of 20 mm in diameter with a rather thick — 2.5 mm wall because it serves as a handle when moving the stroller.

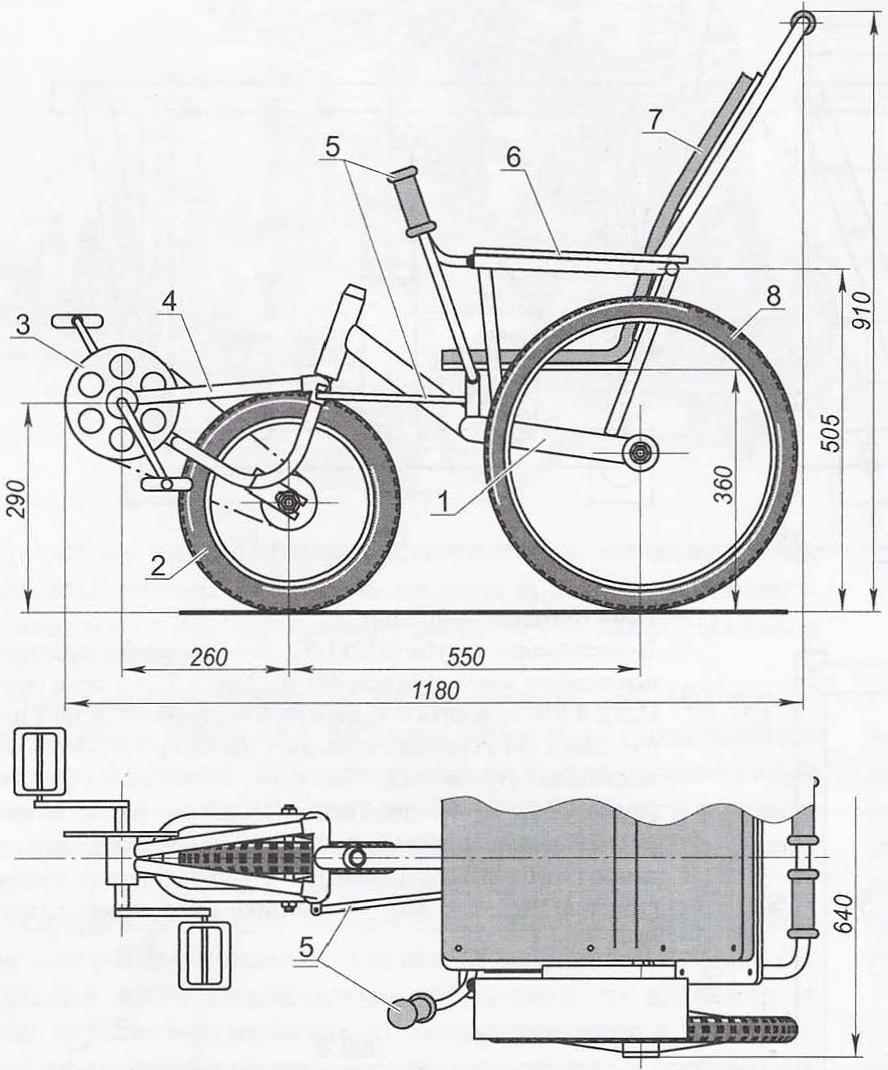

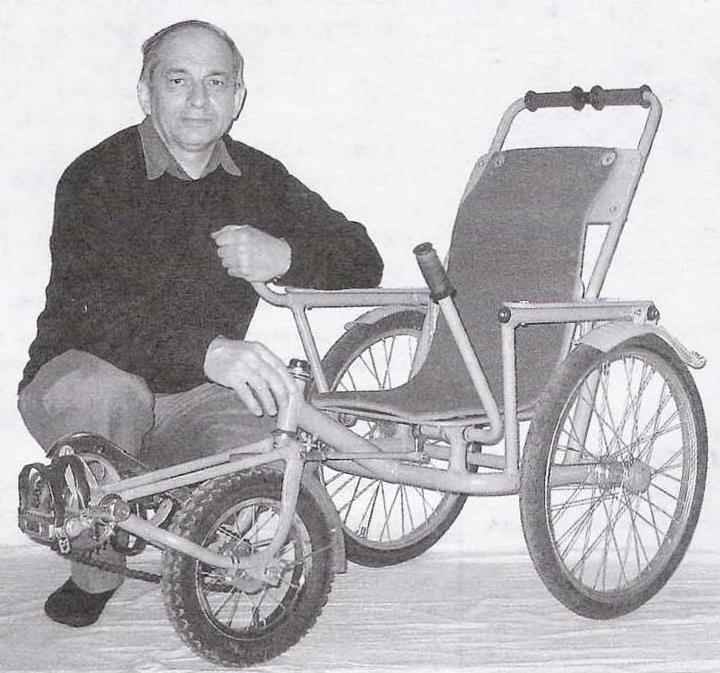

Velokolyaska “Zolga”:

1 — frame;

2 — front driven and the driving wheel (from a child’s Bicycle);

3 — pedal-power (from teenage Bicycle sprocket z = 40);

4 — plug-removal;

5 — steering;

6 — armrest (plywood s8, 2 PCs.);

7 — seat;

8 —rear support wheel (2 PCs.);

9 — handle with fixed handle.

The substrate of the upper and lower parts of the backrest and the seat base is made of bakelizirovannoj (water resistant) 8-mm plywood, and armrests. Solid polipropylenowa (PUF) cushion thickness 12 mm of the tourist rug-“skin” — attached to the dorsal substrates and the seat base with screws M6 with washers enlarged diameter.

For fixing screws M6 wafers they drilled holes with a diameter of 8 mm, into which are recessed with a hammer furniture nuts with a “mustache”. Here we note that similarly, attach the armrests, only M5 screws (three for each). Lumbar of the back substrate and the base are connected by aluminum strips of width 20 mm and thickness 2 mm which are attached to the supports of the base of the seat and to the support of the arc of the seat back with steel clamps by screws M6.

Frame (material steel):

1 — base (trumpet Ø32×1,5);

2 — bracket mounting axis of the rear wheel (area 40×40, 2);

3 — coupling (tube Ø25);

4,5 — front and rear rack (tube Ø25, 2);

6 —the support of the arc of the seat back (tube Ø25);

7 — the supports of the armrests (tube Ø25, 2);

8 — fixed arm (tube Ø25);

9 — pole (pipe Ø40);

10 — column sleeve steering fork (tube Ø32);

11 — the left (on the go) support, seat (tube Ø20×2, L = 96));

12 — right bearing seat (tube Ø20×2, L = 80);

13 — front seat supports (tube Ø20, 2 PCs.).

Rear 20-inch wheels — off road bike. “Torpedovtsy” sleeve from the inner end of the pressed on bearing 60203, and with the outer end — bearing 60101 in the glass and installed the axle flange. On the axis of the sleeve is fixed by nuts wheel M10x1, one of them — the retaining bracket. The same nuts each axis is fixed in the frame bracket.

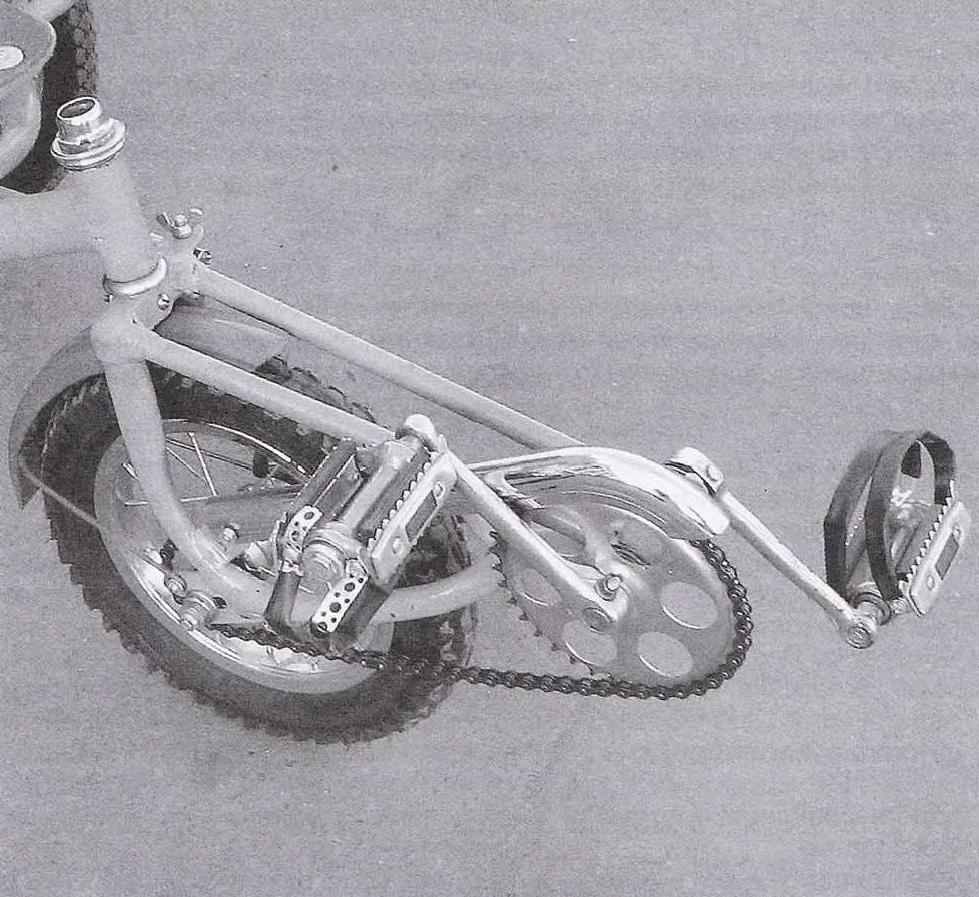

In recumbent used the scheme with a leading front (driven) wheel (diagram “Mazurchak”). The front wheel diameter of 12.5 inches collected on a standard “torpedovtsy” sleeve. Removal of the actuator combined with the fork of the front wheel is made of two shortened bike forks. In the manufacture of such a small and pretty responsible node should particularly adhere to the parallelism of the axis of the wheel and the shaft of the carriage. Therefore, the welding of this node was made in the stocks.

In recumbent used the scheme with a leading front (driven) wheel (diagram “Mazurchak”). The front wheel diameter of 12.5 inches collected on a standard “torpedovtsy” sleeve. Removal of the actuator combined with the fork of the front wheel is made of two shortened bike forks. In the manufacture of such a small and pretty responsible node should particularly adhere to the parallelism of the axis of the wheel and the shaft of the carriage. Therefore, the welding of this node was made in the stocks.

Stuffing Dobby unit borrowed from a child’s Bicycle. The length of each connecting rod is 140 mm, it is perfectly acceptable for a confident and effortless pedaling.

The rear wheels are mounted rigidly to the frame, using angle brackets (or rather attached their axes, and the wheel then put on axle). The wheel hubs has been modified for standard bearings (before there were two of the cone, and between them lay the balls without separators).

Plug-removal drive pedal (material: steel):

1 — body of the carriage (pipe Ø45×2,5);

2 — strut fork (of a Bicycle, “PAL”);

3 — the steering fork (of a Bicycle “Butterfly”);

4 — eyelet axis of the front wheel (strip 40×4, 2);

5 — coupling (pipe 014×1,5, 2);

6,7 — mounting brackets flap chain (strip 20×2,5);

8 — pivot arm-pylon (band 20×4);

9 —pole frame.

The wheels are equipped with mud flaps. And above the rear wheels they are secured with thick rubber washers to the drive, if need be, it would be possible to correct their position manually. In the free ends of the tubes of the frame scored on glue wooden plugs, to which by means of screws attached to the rubber cushion — stops.

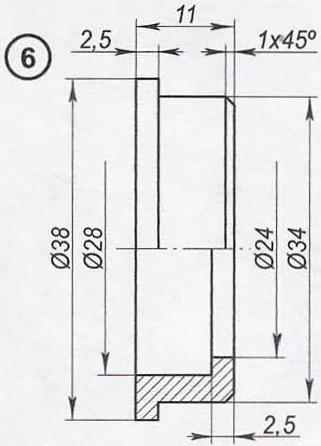

The attachment point of the rear wheel (left) to the frame:

1 — axis (45 steel);

2 — bracket frame;

3 — the bearing 60203 (40x17x12);

4 — bearing 60101 (28x12x8);

5 — Bush of a wheel;

6 —Cup bearing 60101 RS;

7 —nut and locknut M10;

8,9 — washers;

10 — cap locknut.

Steering:

1 — lever steering (tube Ø22×4);

2 — arm shaft (round 14);

3 — shaft sleeve — left (during) the bearing seat;

4 — front support of the seat;

5 — plain bearing (brass, round Ø20, 2);

6 — wedge;

7 — fry(short bike connecting rod);

8 — pin Ø6; 9 — pin;

10 — fork rod;

11 — craving (circle Ø8);

12 — locknut;

13 —ball terminals;

14 — the case of the ball end;

15 —pivot arm-hog;

16 —wing nut;

17 — spring washer;

18 — cap;

19 — pin plugs.

Management of the recumbent is made by one hand using the l-shaped lever, leaning forward and backward (respectively, left-right). At the end of a long (vertical) shoulder fixed handle. Short (horizontal) lever arm bearings (propylene) is mounted in a guide tube — left (in the direction) of the elongated support seat, and at its end a wedge fixed bipod made from cropped of the left pedal connecting rod. Thrust (rod diameter: 8 mm) through the ball tip connects the lever-hog (welded to the fork drive) with bipod shaft steering lever. In the pictures the tip is connected to the pylon on the lower side. But it does not matter. The steering linkage is limited to one side of the pillow-emphasis.

Rear wheel with modified hub and its mount to the frame

The steering gear is variable: control can be exercised not only by the left hand (as in the execution), and right (with appropriate symmetrical installation of the l-shaped lever and the other elements) or from both hands (when you install two l-shaped levers with a set of elements).

For fixing the feet on the pedals, with the help of standard screws M5 fixed strips of perforated mounting strip, wearing a plastic bag.

Frame and other metal components covered with soil (“rust”) and two coats of alkyd enamel. The wooden parts before painting pre-impregnated with protective solutions.

The design of the seat and its folding:

1 —frame;

2 — the arc of the seat back (pipe Ø20×2,5);

3 — coating (Mat “foam”) ;

4 — seat base (plywood s8);

5 — substrate lumbar seat (plywood s8);

6 — seat back (plywood s8);

7 —communication (dural strip 20×2,2);

8 — the clamp (steel strip 20×2,4 PCs.);

9 — mount clamp (screw M6, 4 pieces);

10 — anchor nut M6 (with sharp “whiskers”, is recessed into the plywood, 4 PCs.);

11 —washer-gasket (s1, 2);

12 — bolt MB (2 PCs.);

13 — a cap nut M6 (2 PCs.);

14 — washer; 15 — the handle of the arc of the back (rubber, 2 PCs.).

For partial folding veloceleste storage is necessary to disconnect the rod tip (unscrewing the nut) and turn the drive 180 degrees (pedals under the seat) and the seat back is tilted forward on the base.

For partial folding veloceleste storage is necessary to disconnect the rod tip (unscrewing the nut) and turn the drive 180 degrees (pedals under the seat) and the seat back is tilted forward on the base.

With such a small wheelbase of veloceleste she could roll over during the maneuver. But “Sole” installed “smart” steering wheel: the driver deflects the lever, and thus he is forced to bend in the direction of rotation, thereby preventing the overturning of the recumbent. Braking is performed on the bike, move the pedals back.

Of course, the top speed “Solgi” small: 15 — 20 km/h, but the stroller is not designed for racing. Turning radius outside rear wheel when turning left — 1500 mm, turning to the right — 1650 mm, that is, for turns enough of a platform with a diameter of just over three meters. Weight of the stroller is about 19.5 kg. After a few workouts you can learn to manage a recumbent with the legs (without hands). To do this, loosen the wing nut and detach the tie-rod steering: in this case, “Sole” you can turn around almost on the spot. After several months of operation of the recumbent O. Zotov wrote: “Yesterday I spent two hours riding on “Sole”. Well, what can I say… Super! Pedaling is much easier than my old stroller. The first ten or fifteen minutes could not cope with the management: want to turn right it turned left, like the left — turned right, but then everything went like clockwork. … With me “Sole” and I’m not going to change anything. I now “Soligo” do not give up for any millions. You know, I once stole a wheelchair so I’m afraid that “Tolgoi” can happen the same. I can’t take it”.

V. UL

Recommend to read

RODSTER FOX

RODSTER FOX

The FOX roadster project was born in 2004 from a youthful idea to build an open sports car with an original appearance to satisfy personal design ambitions.

Back in my school years, I... CANDLESTICK… ON THE WALL

CANDLESTICK… ON THE WALL

There is a great variety of candlesticks, but usually — in the desktop version. Meanwhile, very nice to look at here this wall option, it is available for self-production: after all,...

There are many enthusiasts for whom the recumbent was the only passion and hobby. And there are people for whom the velomobile is literally life. More precisely, the ability to move that, in General, interrelated.

There are many enthusiasts for whom the recumbent was the only passion and hobby. And there are people for whom the velomobile is literally life. More precisely, the ability to move that, in General, interrelated. But that’s not us. And imported velomobiles are not always fully meet the expectations of the future owner. Because you want to be in the design were taken into account it is your characteristics, your capabilities, your wishes. In short, we need an individual project! But will take anyone over him?

But that’s not us. And imported velomobiles are not always fully meet the expectations of the future owner. Because you want to be in the design were taken into account it is your characteristics, your capabilities, your wishes. In short, we need an individual project! But will take anyone over him? Recumbent, or rather velokolyaska designed to suit the height of owner: 155 cm Its dimensions (width, height, length) 640x910x1180 mm in the folded state, respectively: 640x650x920 mm.

Recumbent, or rather velokolyaska designed to suit the height of owner: 155 cm Its dimensions (width, height, length) 640x910x1180 mm in the folded state, respectively: 640x650x920 mm.