The author developed the design of a collapsible sail Board high resistance, which are being in a sailing sled and the ice of the Buer, will enable the novice to successfully pass all three stages of training, and experienced athletes will simply enjoy the opportunity to windsurf all year round. The weight of the equipment in any of the options does not exceed 20 kg. All items are Packed in two covers from the skis and easily transported on public transport. Assembly takes no more than 20-25 min.

The hull of the sled consists of three parallel skis. The middle ski is composed of two sections, the rear does not microparasite “stand up” at the rate of the wind (in the wind) at high speed.

The sliding surfaces side of the ski at an angle of about 25° to the horizontal plane; the roll they create sufficient force to resist leeway (side slippage) of the sled when driving sharp (the wind) courses for ice, covered with a thin layer of snow, or dense crust.

To curved tubular cross members connecting the skis, mounts stretched on light tubes, wire mesh, on which the athlete. To otkrenivat it easier, the sled is equipped with loops for the feet. The axis sails set to the longitudinal connection beam, four Ø 10 mm socket allows you to adjust the location of the portable mast.

As starting materials in the manufacture of sledges you can use two pairs of old cross-country ski run with length of 1.8 to 2 m (one of them can be with a broken toe), tube from the frame end-of-century folding metal “bed” grid with a small cell. A cot is better to take baby — she has a lighter tube.

Work on the sled start with the manufacturing of four crossbars. On thick paper in full size have to draw a cross-section of the body of the sled with the specification sections used skis. Then, using the drawing as a template, you should bend the crossmember; all they need to pre-flatten a length equal to the width of the ski. Aluminum sheet, textolite, or a solid wood cut insert thickness 4…5 mm and pressed into the flattened end of the strut. The last finally upsetting, and they drilled holes Ø 6,5 mm for fixing the side of the ski and the restrictive grid.

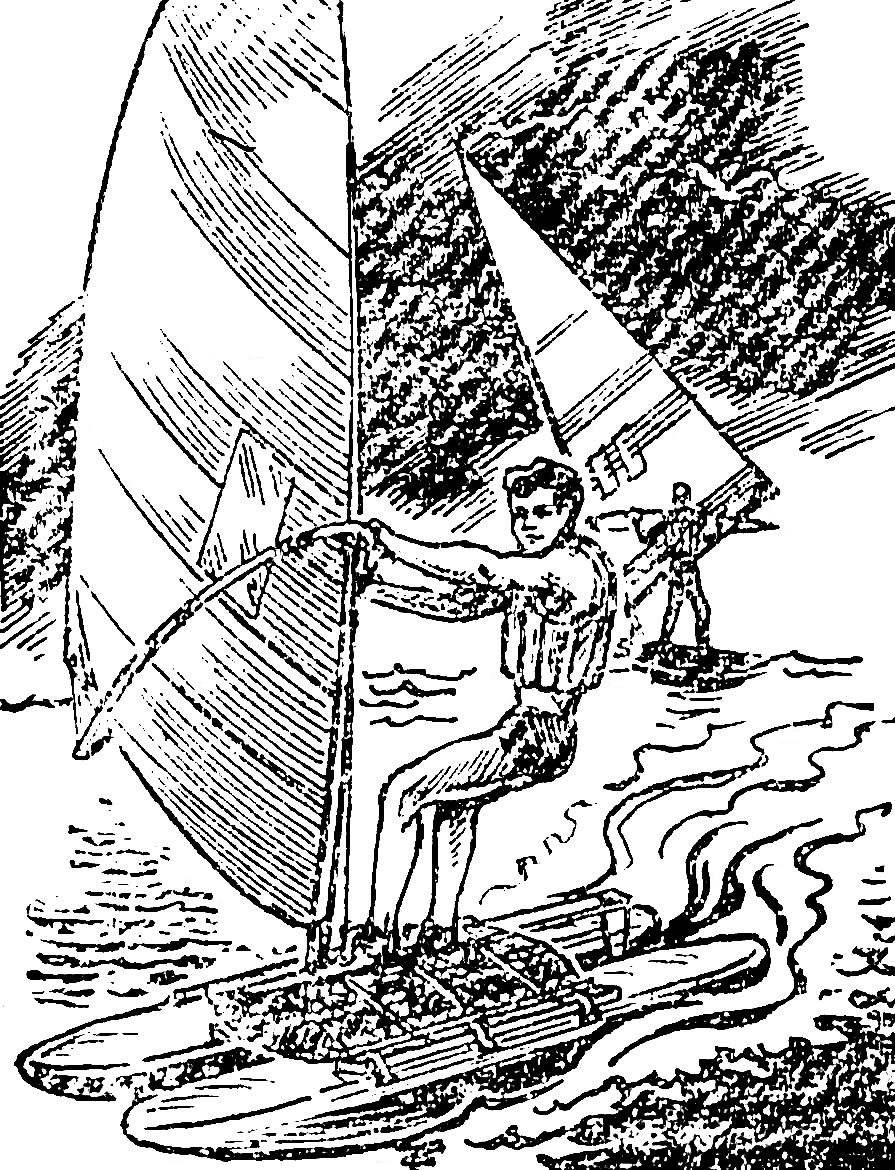

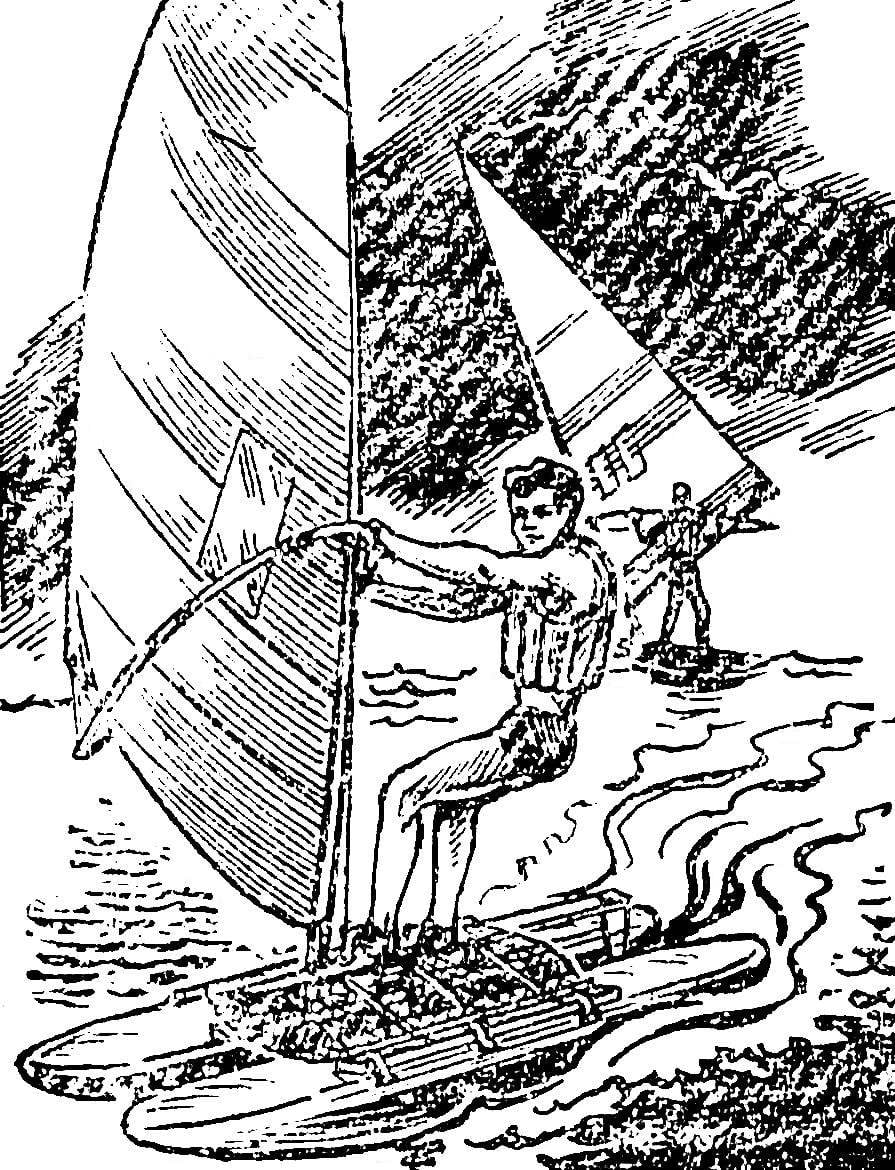

Fig. 1. General view of sailing sledges:

1 — body of the sled, 2 — mast hinge, 3 — section mast (3 piece), 4 top, 5 — sail 6 — gik.

Fig. 2. The hull of the sled Assembly

1 — skiing, 2 — cross (pipe Ø 20X1,5), 3 — limiter grid (tube Ø 16X1), 4 — metal grid 5 — a longitudinal link, 6 — loop for the foot, 7 — cut 8 — cut (bar section 40X50 mm, oak), 9 — insert, 10 — M6 screws, 11 — stud М6Х80, 12 — shaped pin M6, 13 M5 bolt.

Then, after accurate marking, it is necessary to serverlet holes in the ski. To provide greater rigidity of the body of the sledge, on the side of the slopes, in the field installation of secondary cross-members are selected grooves depth of 6…8 mm. Side of the ski with the crossbars you need to collect on the M6 bolts and nuts with countersunk heads.

The next stage — making four bosses from solid wood (oak, beech) section 40X50 mm, designed for mounting a medium (composite) skis to the crossbars of the casing. The length of each boss is determined individually; depending on the average thickness of the skis in this section (total thickness of the ski and bosses should be 100 mm). At the top of each boss you want to run the groove to a depth equal to half the diameter of the tube crossmember.

The rear part of the composite average of the skis should be installed over the front ledge, so formed a kind of redan. For fastening of skis it is best to use shaped studs, carved from a steel wire Ø 6 mm. Each pin must pass through holes drilled in the middle of the ski and the boss, and grab the crossmember and trailing link.

A longitudinal connection can be made of a tube of rectangular section 40X20 mm (wall thickness 1 mm) with a length of 1350 mm metal handle from a hockey stick or a round duralumin tubes of appropriate diameter, pre-treated before the oval section. It is set and steps the mast.

Loops for the legs the best thing to do from a metal strip, covered with tarpaulin. Their sizes are determined by Shoe size and location — height, weight and skills of the athlete.

To improve the maneuverability of the sailing sled medium ski you can install a couple of steel plates-edges, made of stainless steel 1.5 mm thick. it is Useful to provide several points of attachment along the length of the ski: this will allow adjusting the edge position of the mast.

The maximum speed of a sailing sledges develop on smooth ice, covered with small (50…100 mm) layer of snow or thick ice crust. Experts say that when the wind force 5…6 points (9…12 m/s) they can travel at speeds up to 70 km/h. of Course, in such conditions it is necessary to take care of appropriate clothing.

The change rate of the sleigh on the move requires a certain skill. Initially often have to stop and move the sled.

To improve the sliding runners of the ski the ski must be treated with ointment.

The Buer has a structure similar to a sled, only instead of skis can be used two pairs of skates of any type, set with a diamond. The position of the skates the length may vary depending on specific conditions. The location of the side of the skate is important in the development of evasive cast to the wind and uvarivanie on one skate. A more affordable method of rotation — moving the glider on the spot. Rectilinear movement is always on three skates.

Fig. 3. The body of the glider Assembly:

1 — skate, 2 — side beam (beam cross-section 60X40 mm), 3 — Central girder (precast beam cross-section 60X60 mm).

Fig. 4. Body boards, catamaran Assembly:

1 — float, 2 — centerboard, 3 — side beam (wood beam of cross section 40X60 mm), 4 — the Central beam (precast beam cross-section 40X60 mm), 5 — the lucky fin, 6 — clip to install the centerboard, 7 — ring bracket, 8 — stretching 9 — loop fastener float.

Floats windsurfer. The most suitable material for the manufacture of floats — layered rubberized percale: in this case, the body work is relatively easy and fairly reliable. You can continue to use the non rotting synthetic materials and their subsequent sealing.

The strength of the applied material (regarding the suitability of its use) is verified as follows: from fabric cut a strip width of 10 mm and tied to the load of 10 kg. If the material has stood the test, he will suit our purpose.

Cutting of float is carried out in accordance with the given pattern. When marking is not necessary just to sustain especially given the size; it is much more important to spend a smooth curve and cut the folded material to prevent any displacement of the panels relative to each other. Scraps of fabric to throw away do not: in the future they will be useful in gluing seams, making loops, etc.

Fig. 5. Float:

1 — body float, 2 — loop, 3 — sleeve, 4 — slip tape.

Longitudinal seams of the floats are glued strips of fabric with a minimum width of 30 mm. Stitched billets are turned out but the front side through the formed in the rear sleeve of Ø 140 mm. In the future, this sleeve serves to place the fitting. The latter is flared on one end of the aluminum tube to put on the ends of the segments duratough hose. Fitting is introduced in the flared part of the sleeve of the float, the fabric sleeves on both sides pre-coated with a thin layer of clay and then going to smooth folds and wrapped around the tube strong thread. The outside of the fitting is preferably carefully wrapped with insulating tape on a fabric basis.

Fig. 6. The node sealing of the fitting in the shell of the float:

1 — elbow (tube Ø 10X1), 2 — durotomy hose, 3 shell float, 4 — nylon thread, 5 — adhesive tape, 6 — tube.

Fig. 7. Diagram of float-based plastic balls:

1 — shell, 2 — internal baffle, 3 — ball.

If the shell floats taken fabric, breathable, inside you need to insert a sleeve of polyethylene film (two feet longer than the float), to seal its front end and the back to insert the fitting in the same way. Can you recommend another option: fill shell children’s rubber balls. It should be remembered that the nipples balls need to be protected from athlete’s foot.

Collapsible mast composed of three identical segments dural tube Ø 40X1,5 mm, and top — wooden boss, covered with waterproof varnish. As source material you can use athletics pole jump, sold in sporting goods stores.

Hinge design and knot fastening it to the longitudinal connection is clear from the picture. You only need to make sure the mast rotated freely around its axis.

Fig. 8. The hinge of the mast:

1 — sleeve, 2 — longitudinal connection, 3 — bolt M8, 4 — spacer, 5, 6 — M6 bolts, 7 — mast section (tube Ø 40X1,5), 8 — sidewall hinge, 9 — clip 10 — boss (32Х32Х32 mm).

Collapsible boom consists of two curved and two straight knees as well as moulded nosing NOC. The last piece is attached using two pieces of tube Ø 32X1 mm. the sections of the boom it is best to collect from dural tubes Ø 30Х1,5 mm, used as straps for the high jump.

The mast and boom can be done of wood, using only a few segments of the tubes for connecting nodes.

The centerboard and the lucky fin are made of bakelizirovannoj plywood 10 mm thick. Can be applied to ordinary plywood, but be sure to soak it with linseed oil and cover with a waterproof varnish (by the way, in the same way, should handle and wooden bars, which are installed instead of ski when you rebuild a sailing sledge in the Buer). The centerboard is secured in U-shaped brackets mounted on the hull of the Board. Staples — wire Ø 5 mm. the lucky fin is fixed to the middle bar in the aft part of the sail Board with screws.

So, we wish you a fair wind during the whole year!

N. SHERSHAKOV

Recommend to read ARCH TO ARC – READY GREENHOUSE Arched design with all other conditions being equal, will always be stronger, safer and cheaper structures of other types — especially when the arc itself consists of rods, working only... SCRAPER — EACH BRUSH When you have to prepare for painting surface with long layers previous updates, it is always difficult to remove them. The work will be simplified if it is to make a special scraper...