Original swings will be interesting not only for preschoolers but also older children, because of their design, proposed by the Polish magazine “Throb himself”, brings to use a game element. The production of this flying horse is available to each of the parents — so simple is the device in closer examination of details. Also important is the fact that do not need special tools or missing parts — only what I usually have on hand at any DIY.

Original swings will be interesting not only for preschoolers but also older children, because of their design, proposed by the Polish magazine “Throb himself”, brings to use a game element. The production of this flying horse is available to each of the parents — so simple is the device in closer examination of details. Also important is the fact that do not need special tools or missing parts — only what I usually have on hand at any DIY.

The basis of design

Unlike conventional swing here, otherwise decide not only the configuration of the seat, but his pendant. Consider these features in more detail.

Overall design reminiscent of such traditional and very popular with children large toy, outdoor rocking chair in the shape of a horse. Not only in volumetric and planar design, which also facilitates the manufacture of such swings.

There are three main parts: the body of a horse, saddle-seat and back. They are cut from a wide Board, thick plywood or particle Board. The configuration of the parts during the sawing can be simplified taking into account the capabilities and skills of the house master, as well as the methods of Assembly of prepared parts. It is only important that the final design turned out quite durable. With this purpose, for example, under the seat prompted the strengthening bars attached to the body of the horse, although there are other options to this decision (one of the alternative ways shown in the diagrams in the Assembly).

The suspension of the swing, as has been said, is also different from the usual and consistent with the peculiarities of construction, as will be discussed below.

Case

The primary circuit, resembling the profile of a horse is cut in accordance with pattern on the grid, which will need to be moved on the squares on the plane of the workpiece. At the top of the head is drilled the hole for the rod bridle (handle), which will keep hands baby.

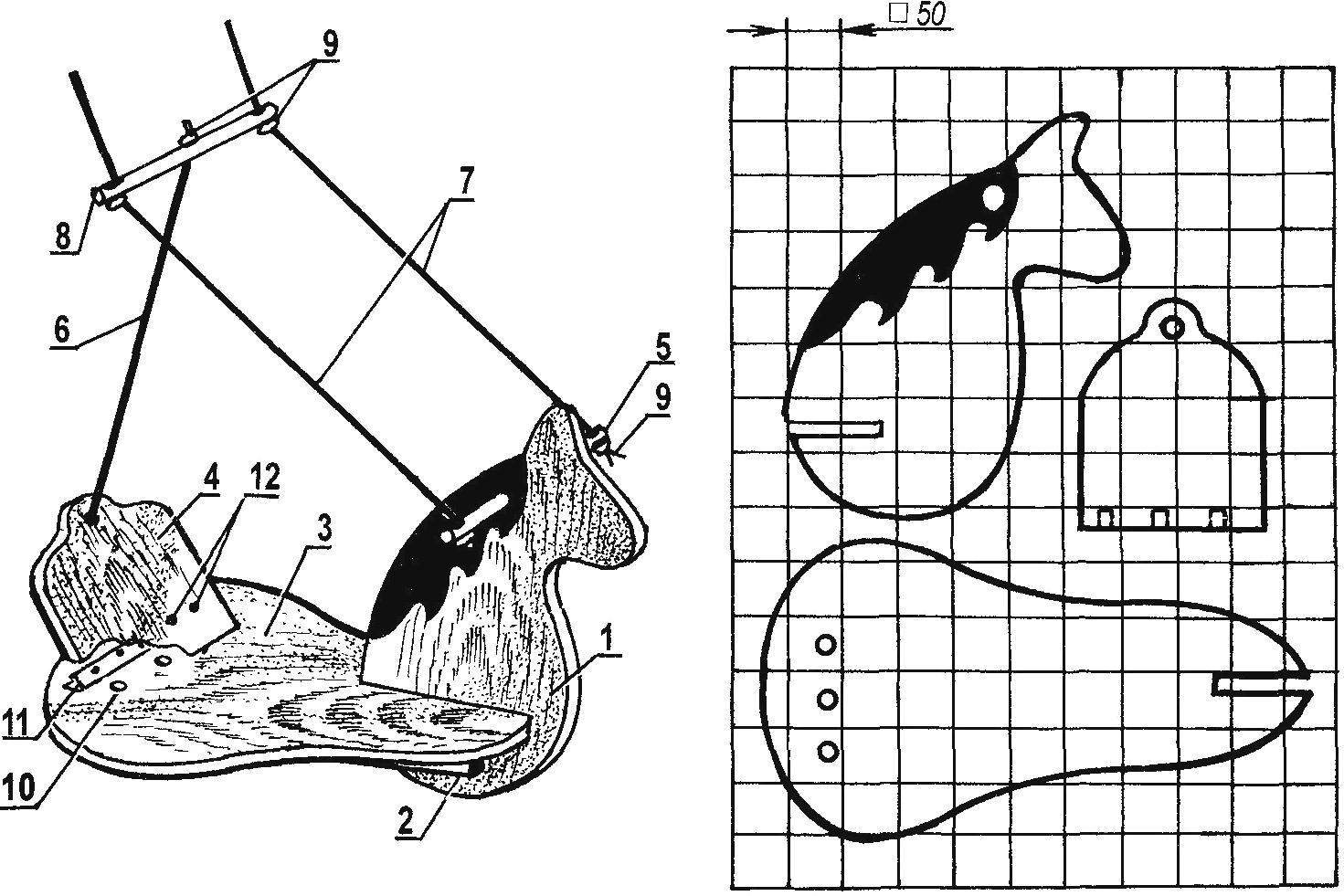

Swing-horse:

1 — the body of the horse; 2 — bars strengthen the seat; 3 — seat; 4 — back; 5 — handle; 6 — a back brace; 7 — suspension of the swing; 8 — strut suspension; 9 sites; 10 — holes for studs; 11 — metal area; 12 — bolt holes are countersunk; items 5 and 8 is a round wooden rods (size on choice)

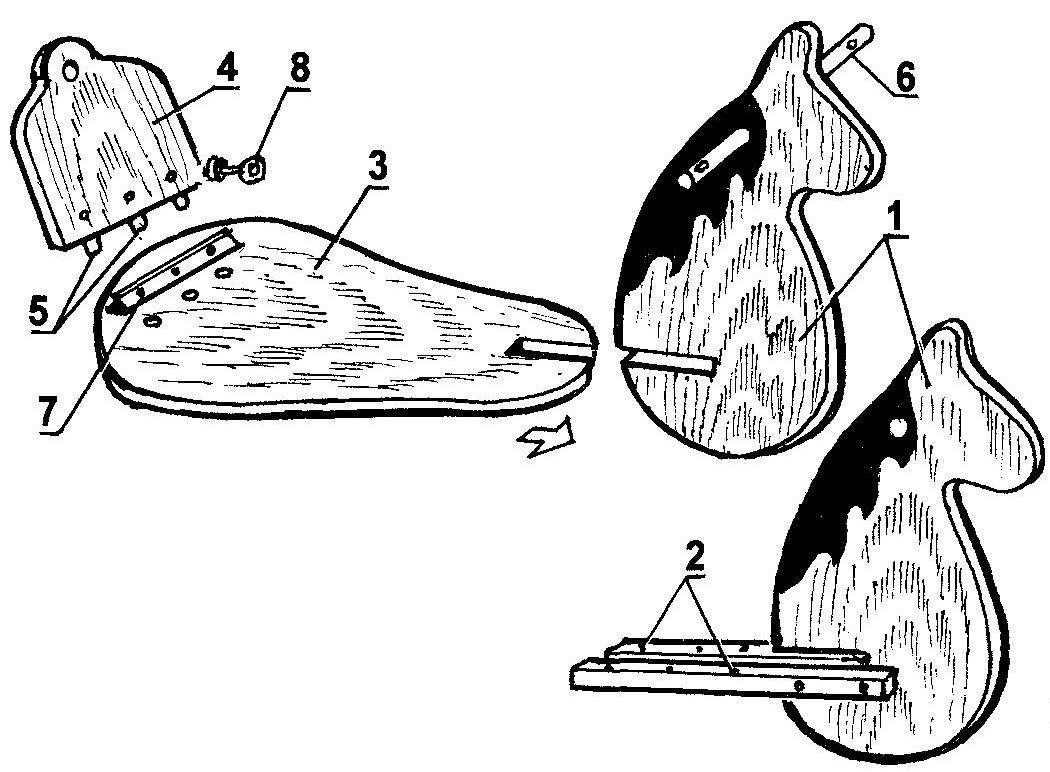

And in the lower part of the body is propyl, the corresponding thickness being joined with him in the future, the workpiece seat of the saddle. Below the cut on both sides of the body of a horse mounted on the screws with glue two pieces of wood gain additional support of the seat. In the same way they, in turn, will be attached to the bottom of the seat after connecting it with the body.

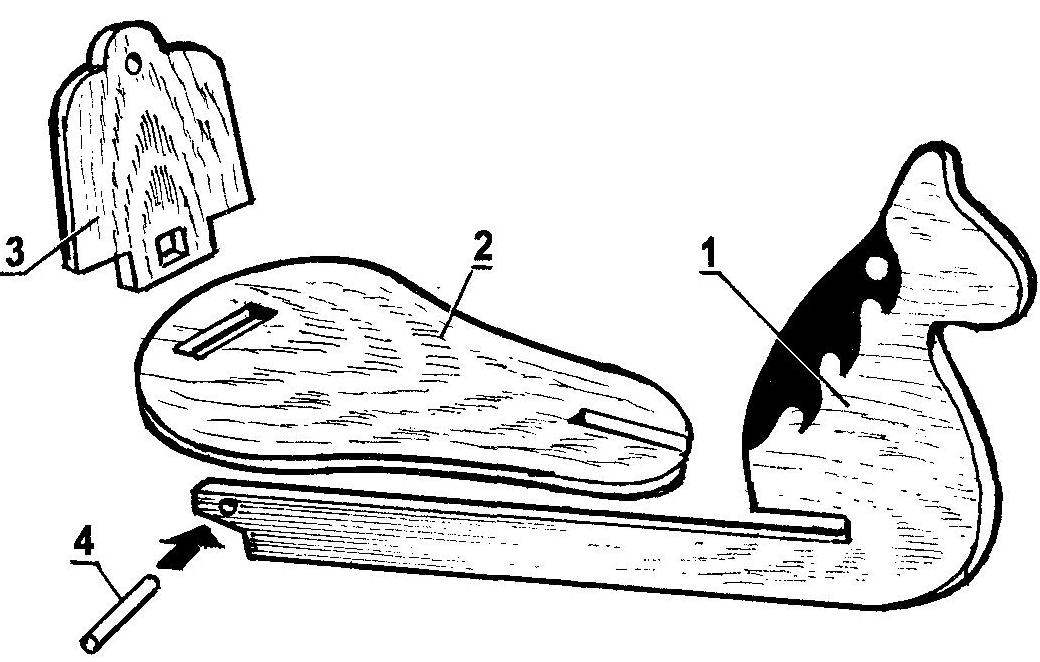

In an alternative embodiment of the strengthening bars are absent: instead, the body of the horse is going under the seat elongation, ending with a spike hole of the tooth back.

Saddle-seat

It is the same as the body of the horse is cut after the transfer of its contour with a grid on the plane of the workpiece. As already mentioned, to simplify the shape of the seat can be simply in the form of longitudinal boards. But in any case it is in front of propyl performed under the same counter-groove on the body of the horse, taking into account the thickness of the last — to counter tight connection. But in the rear seat, holes are drilled under the round spikes and bolts metal bracket for mounting the backrest. In the alternative design is one rectangular hole is for the mounting tooth of the back.

Back

In form it resembles a cutting kitchen Board, although it may be just rectangular. Sawed out boards on a grid, similar the body and the seat. Bottom in specially drilled holes inserted spikes for connection with the seat. For reliability rear backrest installed metal area, connected by bolts with the back and seat. Top back has a hole for a cord suspension.

Preparation for Assembly of the swing:

1 — body of a horse; 2 — bars strengthen the seat; 3 — seat; 4 — back; 5 — spikes; 6 — handle; 7 — metal corner; 8 — bolt with washer and nut

In an alternative embodiment, the bottom ends of the back projecting tooth with a window under the tongue lengthening the body of the horse.

Assembly

Depending on the design variable, and the sequence of Assembly. In the first case, to the body of the horse first screws are screwed bars strengthen the seat-seat; then the last fit in its groove with a notch in the housing, after which the bars are attached from below to the seat, at the back of the studs is set back. All patch elements is used in the Assembly glue (carpentry, casein or PVA). After final drying the back of backrest bolt-on installs metal corner reinforcement.

The parts and their Assembly:

1 — body of horse, with the extension under the seat and terminal pin for connection with the back; 2 seat rear window in the back; 3 — back with a tooth and the window under the tongue the body of the horse; 4 — stem-wedge for locking the backrest Assembly to the body of the horse

In an alternative embodiment of the Assembly begins with the connection of the backrest with the seat. Then it was coming for lengthening korprusa horse up to the dock with his groove, the tenon of elongation must be in the window of a tooth back and lock it by inserting the rod-wedge. Alternative manufacturing and Assembly allows one to obtain thus a collapsible design convenient for storage or transportation — for example, at departure on the nature or to the country.

Suspension

From the usual swing from the proposed design is different and the suspension system: it consists of two cords (cords), and of the three. Two traditional strands separated by a rod-strut, which ends are ongoing and are mounted on a rod handle at the head of a horse. And the third cord (brace) comes from the push-rod suspension to the seat back.

This design ensures a stable position of swing, no twisting, and at the same time does not interfere with sitting as cords spaced forwards and backwards.

From the editor

In the manufacture of swing requires special attention to the backrest, which accounts for the main load. It should be made from solid wood and not use DSP.