George S. khokhlachov — military retiree, he was 77 years old. My entire adult life, he enthusiastically engaged in technical creativity: innovative work, radio, photos and much more. In their tireless search for homebrew regularly refers to the publications in scientific and popular journals, including the journal “modelist-Konstruktor”. One of his last works G. S. khokhlachov decided to present the readers of our magazine: “the Last two years, I was fascinated by the design of the recumbent. From the book A. S. Popolove “let’s invent a recumbent” as a prototype of the selected “Springmail” N. Kudrin and V. Schipacheva. The frame design and General arrangement have not undergone significant changes, but the drive turned out, from my point of view, original and, I think, may interest the readers of the magazine and fans of velomobiles”.

George S. khokhlachov — military retiree, he was 77 years old. My entire adult life, he enthusiastically engaged in technical creativity: innovative work, radio, photos and much more. In their tireless search for homebrew regularly refers to the publications in scientific and popular journals, including the journal “modelist-Konstruktor”. One of his last works G. S. khokhlachov decided to present the readers of our magazine: “the Last two years, I was fascinated by the design of the recumbent. From the book A. S. Popolove “let’s invent a recumbent” as a prototype of the selected “Springmail” N. Kudrin and V. Schipacheva. The frame design and General arrangement have not undergone significant changes, but the drive turned out, from my point of view, original and, I think, may interest the readers of the magazine and fans of velomobiles”.

Drive structure is very simple. Driving wheel — front with the upgraded standard grommet rear wheel of the Bicycle “Desna”. The sleeve has two symmetrical clutch, respectively, and two driven sprockets, which are driven by a Bicycle chain two oval leading stars. The modernization of the sleeve parts of the brake have been removed. The most difficult housing manufacturer of freewheels for the left, in the course of the velomobile, driven sprocket: need turning, milling and heat treatment.

Clutch housing — an exact copy of the staffing with the exception of the working part (the location of the rollers), to be executed with the purity of processing is not below 8-th class and in mirror image in relation to the standard clutch. Material — steel 20X or 40X. After fabrication, the part must be cement to a depth of 1 — 1.2 mm and tempering to a hardness HDTV 32-40HRC. To ensure the smooth running of the couplings, the diameter of the rollers should be the same. I picked up the rollers with a micrometer. Lubrication of the node should be liquid.

Device host velomobile shown in the photographs and in figure 1.

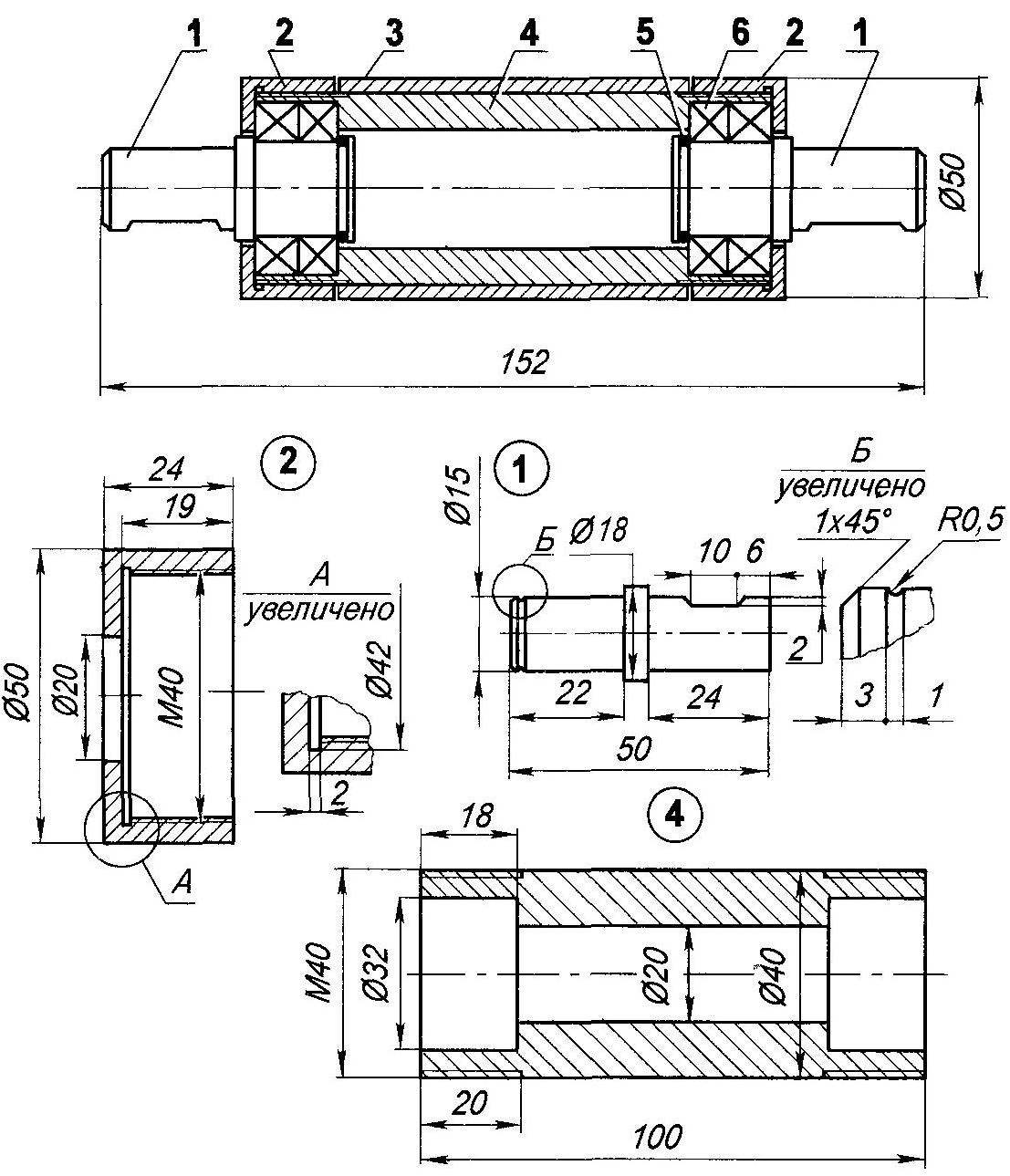

Drive front drive wheel

Pedal bushing frame:

1 — axle pedals (2 PCs); 2 — cover (steel, round 50, 2); 3 — body pedal bushing (steel, circle 50); 4 — bearing housing (steel, lap 45); 5 — lock ring (2pcs); 6 — bearing 6003RS (4 PCs)

Leading asterisks coaxial, but independent. Each of them with its own pedal (bike Tourist) and is mounted on its axis. Stroke occurs when the pedal is pressed. Thus the sprocket via sprung loaded chain makes a part turn and then on the return stroke of the pedal under the influence of the spring returns to its original position.

The independence of the leading sprockets and pedals provides the opportunity to work in different modes: both feet first (as in rowing), alternately left and right, or even only one leg.

The levers of the pedals can be extended and then included in the work of the hands while performing the control. The implementation of this option in my plans to further improve the presented design of the recumbent.

When you use a recumbent on dirt roads it is advisable to install an elliptical leading asterisks, factory or homemade. On roads with asphalt, you can use leading asterisks from the bike “Tourist”.

As seen from the above illustrations and description, the drive design is pretty simple, so I think experienced homebrew if you wish to reproduce it.

G. KHOKHLACHOV, Krasnodar