Tourists, anglers-hunters, and simply lovers of water recreation dream of having a convenient, lightweight, transportable boat. For this purpose, in my opinion, a rubber inflatable boat is most suitable.

The boat I purchased, “Last-5”, weighs about 18 kg and carries three people. In calm weather and light wind, it glides easily on the water. But its drawback is high wind resistance. As soon as the wind increases to just 2—3 on the Beaufort scale, rowing it becomes almost impossible. To avoid being at the mercy of bad weather, a light outboard motor can be installed on the boat.

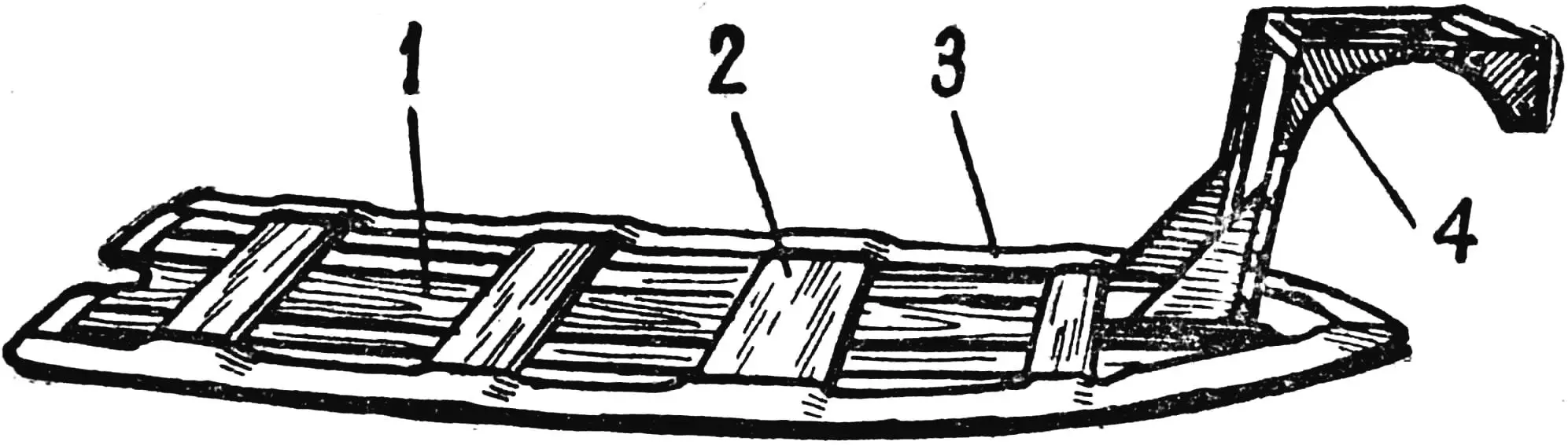

Figure 1 shows the “Last-5” boat with a “Salut” outboard motor. Its speed at medium engine rpm is about 8—12 km/h.

Figures 2—4 show the device for mounting the motor to the boat. It consists of a folding transom board, covered with canvas (tarpaulin), two brackets made of duralumin angles, a transom board, a rubber pad with tarpaulin, and a spreader.

CONSTRUCTION

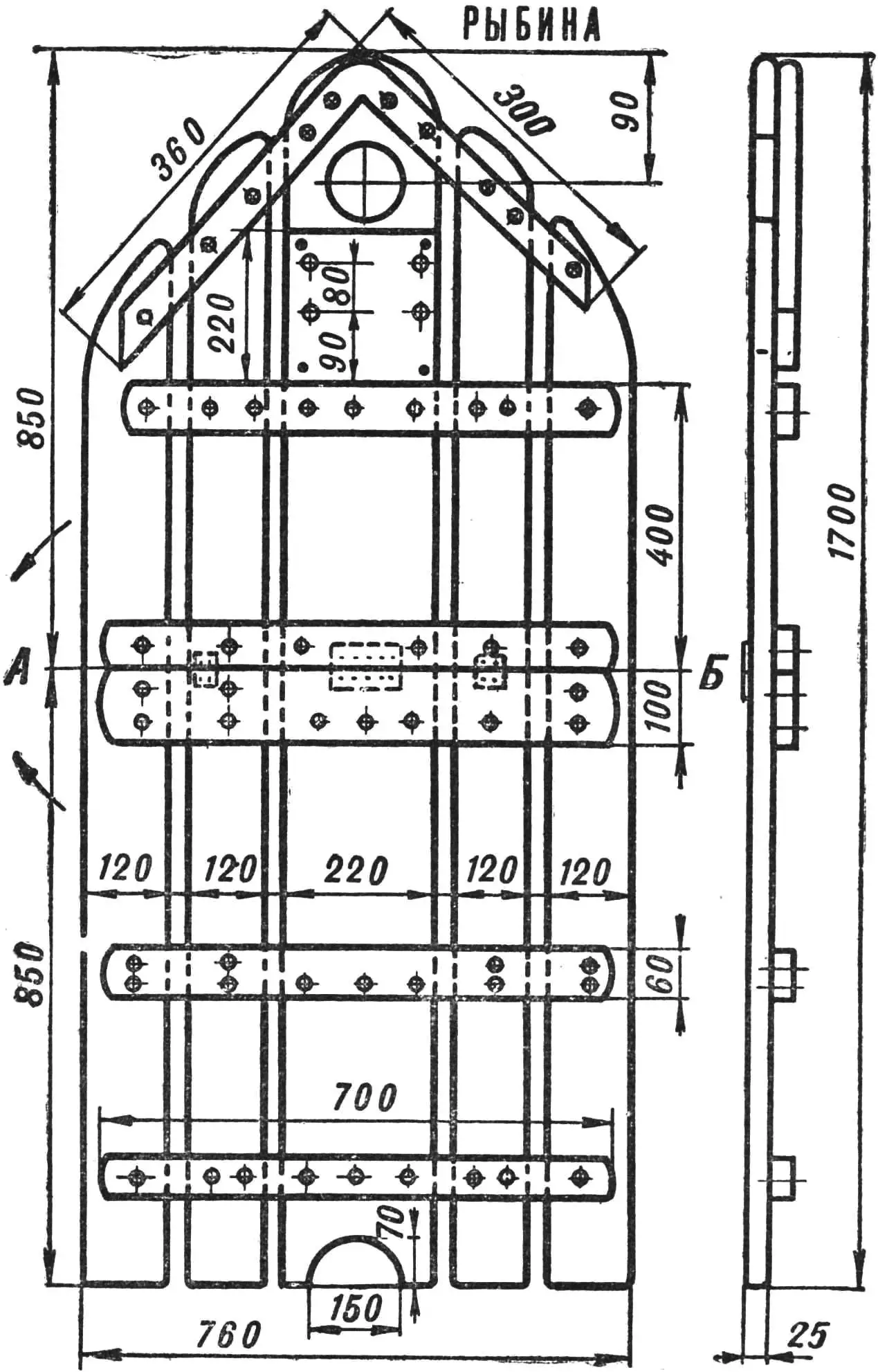

FOLDING TRANSOM BOARD (Fig. 2) is made from spruce boards 15 mm thick. The outer edges have an oval shape. The longitudinal and transverse boards are fastened with countersunk screws. The transom board folds inward along line A—B (as shown by arrows). The hinges are three metal loops.

The bracket mounting plate is made from a spruce board 220 X 220 X 20 mm, which is fastened at the corners and in the middle with screws. A duralumin plate 220 X 220 X 1 mm is placed on the bottom side. Four holes Ø 6 mm are drilled in the plate, the middle board of the transom, and the duralumin plate, through which bolts pass to fasten the brackets. After manufacturing, the transom board is painted with oil paint, and after the paint dries, it is covered with tarpaulin (on the bottom side) to protect the hull from damage.

1—2 — transom board parts, 3 — tarpaulin, 4 — bracket.

The transom board is inserted into the boat, and after inflation, the boat gains greater rigidity, allowing even standing to cast a spinning rod.

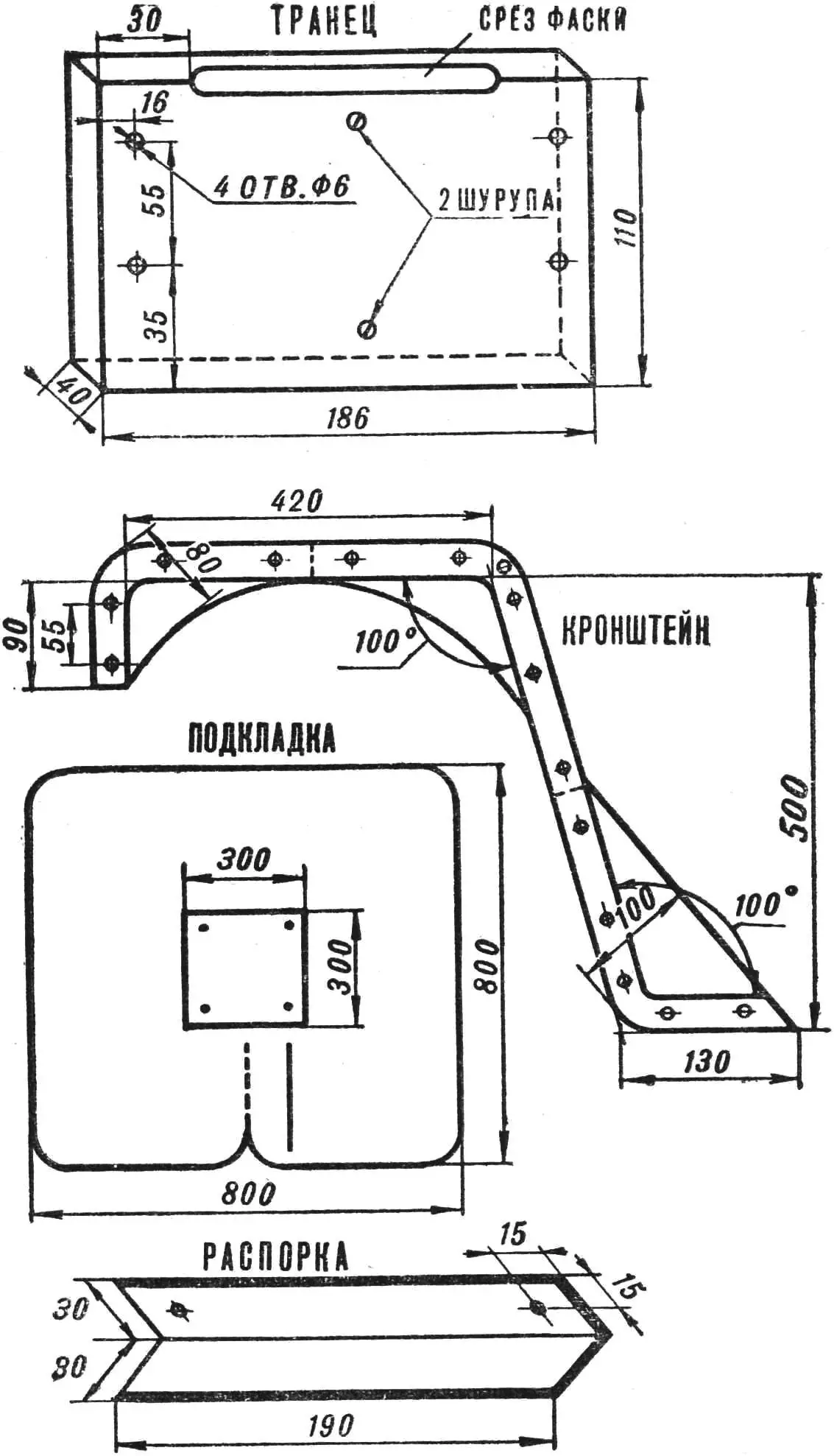

BRACKET (Fig. 4) is made from duralumin angles 30 X 30 X 3 mm. Since they bend poorly and are difficult to weld, when manufacturing, it is necessary to make the angles not very sharp and fasten them with duralumin gussets 2.5—3 mm thick. They are fastened to the angles with semi-countersunk rivets.

The brackets are fastened to the transom board with four bolts 45 mm long. After assembly, the brackets are primed and painted with waterproof enamel.

TRANSOM is made from dry spruce, 40 mm thick.

A steel backing plate of the same dimensions, 1 mm thick, painted with oil paint, is screwed to the outer part with two screws. The transom is fastened to the brackets with four bolts 50 X 6 mm.

The rubber pad with tarpaulin is shown in Figure 4. It is made from microporous rubber 300 X 300 X 20 mm and sewn at the corners to the tarpaulin. It needs to be placed under the brackets on the boat’s tube. It will prevent the boat from being rubbed by the angles during heavy waves and protect the rubber hull from gasoline spillage or if the motor tips over.

SPREADER is made from a duralumin angle 30 X 30 X 3 mm, 190 mm long. It is fastened to the bracket in its horizontal part with two bolts 15 X 5 mm.

The entire device is simple to manufacture, easily installed on the boat, and provides reliable mounting of the outboard motor.

In conclusion, I would like to say that after installing the outboard motor, the inflatable boat becomes a full-fledged vehicle and its usage possibilities expand.

K. ANISIMOV