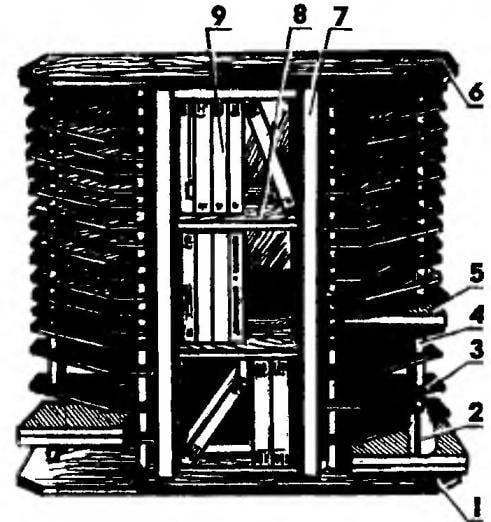

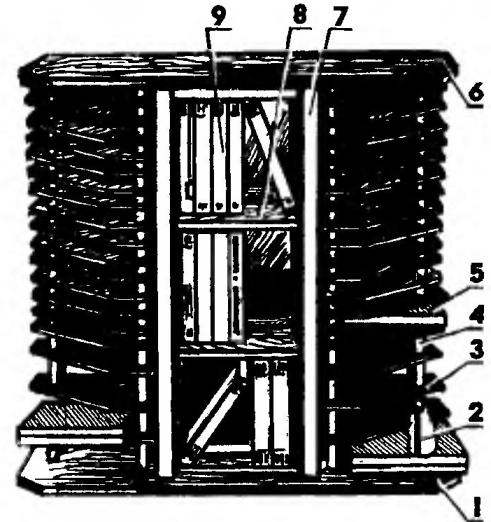

Many things quietly accumulate, and modern video cassettes, diskettes and CD-ROMs is not an exception. Gradually they grow mountain which would need to somehow arrange to not collapse and take up less space. One of the options of rational storage and offers the Hungarian magazine”, Earmaster-hobby”. This kind of “skyscraper”, each floor is a separate “apartment” for floppy disks or CDs, and the Central “tower” — a video cassette.

Structurally, the vault consists of three separate blocks on a common “Foundation”-the bottom under a single roof. Two blocks intended for floppy disks, the same, only the mirror is made; and the middle part — the tower — self-insert, are designed for videos. She’s going of the plank blanks 10 mm thick and has the appearance of a mini-shelves: two racks with shelves between them.Side blocks — the basis of design. They consist of metal rods (threaded studs) connecting the bottom and the roof of boards thickness 10 mm; for threaded rods, plywood or plastic plate with dividing spacers. The whole package is pulled together by nuts screwed onto the shanks of the studs embedded in the floor and the roof.