If you remember that sports cross-country skis designed for movement, mainly for the track, and a wide hunting transcend any snow, it will be very clear what the proposed design is a home-made sled is significantly different from all sorts of store: first of all, that doesn’t require groomed snow slopes. Even quite popular now trehmernye cat “Chuk and GEK” saved on the hill with deep snow, and these can easily rush down, leaving behind only a white cloud and a wide trail. He will emphasize the basic design feature that gives it such “off”.

If you remember that sports cross-country skis designed for movement, mainly for the track, and a wide hunting transcend any snow, it will be very clear what the proposed design is a home-made sled is significantly different from all sorts of store: first of all, that doesn’t require groomed snow slopes. Even quite popular now trehmernye cat “Chuk and GEK” saved on the hill with deep snow, and these can easily rush down, leaving behind only a white cloud and a wide trail. He will emphasize the basic design feature that gives it such “off”.

The main difference

Indeed, if an ordinary sledge reserve two lines of the traces of its narrow runners, and “Chuk and GEK” – three wide, then offer will remain only one wide band, because they have a skid is the case in the form of a flat ski. And just as the real skiing to preserve the direction of motion has a longitudinal groove on the slip plane, and the considered variant of the sled from the bottom of the casing, two longitudinal (in the form of strips) of Senegalese that adds to the wide trail in the middle of two narrow grooves that make this winter the projectile keeps it steady even on a compacted slope or solid Naste.

From what and how

For the manufacture of sledge-“all-terrain” does not require any special materials or techniques: regular Board, plywood and traditional a minimum of simple tools to work with: saw, hacksaw, plane, gimlet or awl and a screwdriver with screws.

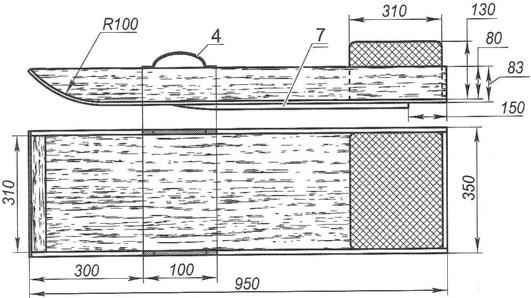

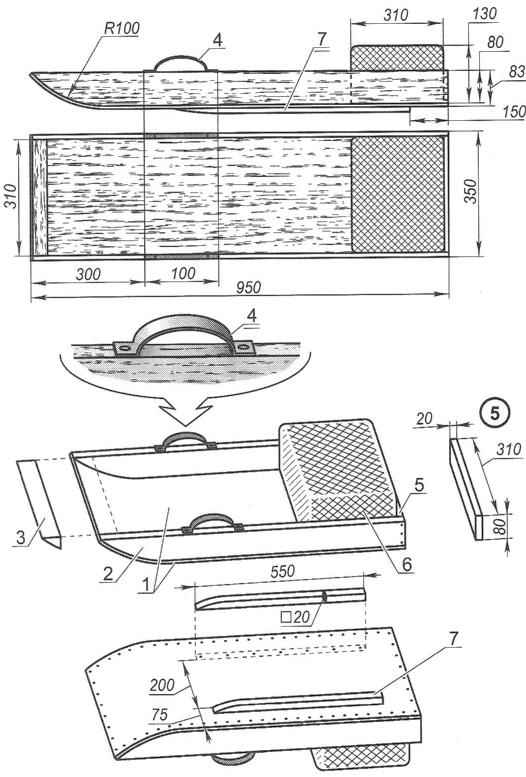

The figure shows that the sleds consist essentially of two main elements: it is a box-frame and bottom-snake. Let us consider how they structures are manufactured and assembled.

For frame will fit a narrow Board with a thickness of 20 mm. Main frame parts is its sidewall, because they give the necessary “ligaabrama” form the sled. The front part of the sidewalls with the saw and plane is slightly curved up in a small arbitrary angle: so that with him nailed to a plywood bottom sled doesn’t hit the snow and went at him go.

Rear sidewalls are connected by a rectangular cut of the same Board, like themselves, but from the front they bonded over a narrow bar, closing the contour of the frame. On top of the sidewalls attached padded handle of a suitable plastic or of a lap belt.

From the bottom to the frame is mounted on a rectangular sheet of plywood, forming in fact a second essential element of the sledge: the bottom of the Shoe. Repeating folded the front in the form of sidewalls, the bottom forming a rising sock snake, thus completing the making of the collected design the required form of the actual sled. There remains only the final part: set on a sliding surface of the bottom of the runner guide rail-cutters. They are in front of the required bevel; are fixed rails with inner side of the bottom.

Child’s sled made from a single slideway:

1 – the bottom-rail;

2 – side panel frame (s20, 2 PCs.);

3 – the front strap of the frame (in place);

4 – pen (2 PCs.);

5 – the back strap of the frame;

6 – seat-cushion;

7 – sahores (2 PCs.)

All connections are made with screws with countersunk heads, and to enhance can be used glue (carpenter, PVA, “Time”),

At the rear of the sled for more comfort and convenience attached upholstered seat cushion on the basis of foam rubber or latex: it should be sewn in nylon or canvas cloth, not lag snow. To maintain the shape under the top layer of the pillow you can attach the plywood. The thickness of the cushion must be larger than the height of the frame of the sled.

Finish

Since the sled – wood, and the tree frosty friends, and special trim design is in principle not required. However, if you consider that there are in the spring thaw, the snow is getting wet, and also that three of his children – some of the recommendations still should give. The easiest and most effective option is to paint the sleigh a bright oil paints: a frame with one color, the bottom-snake inside others -get practical and beautiful.

It is clear that (even regardless of this), all parts should be thoroughly cleaned to leave no burrs and burrs, then Polish with sandpaper. Most convenient to do this before Assembly.

For the sliding surface of the sled possible a special kind of treatment, slightly more complicated, but effective. Meaning the coating is paraffin, which not only protects the plywood from moisture of melted snow, but also reduce the friction coefficient of the sled. To do this, a few candles carefully melted in a jar on low heat and brush with several layers applied to the bottom, trying as it is necessary to impregnate it each time carefully rubbing the cooled layer tube, as do the skiers using the ointment.

Thus treated, the sled will be bright “rocket” to rush down the snowy slope.