There was a time when artistic design pursued purely decorative goals. Artists worked only on the form of machines. This explains the presence of a large number of decorative elements in the designs of automobiles of the not-so-distant past. Now the tasks of artistic design have expanded significantly. A modern designer (artist-constructor), trying to make a car more beautiful, understands that purely decorative techniques are not enough. He deals with the form of the car, its proportions. And this means: something needs to be recomposed, changed, redesigned. But for this, artistic abilities alone are not enough — one must also be a constructor.

A person who possesses both artistic and engineering knowledge recomposes the car not only to make it more beautiful. The designer sets other goals for himself, the main one being to make the car convenient for humans.

A modern car should have nothing superfluous in its appearance. Wings, fins, and massive bumpers are a thing of the past. Simplicity, manufacturability of construction, maximum comfort — these are the main requirements that every artist-constructor now follows. These requirements are far from always met in the designs of homemade microcars. In the proposed project, we wanted to show how simplicity and comfort can be combined in an amateur design.

Creating machines that meet the requirements of technical aesthetics is one of the most important tasks facing amateur car construction.

Several years ago, experimental prototypes of the “Sputnik” microcar were built, intended to replace the SZA motorized wheelchair. Unlike its predecessor, the “Sputnik” is already a real car. It has a more powerful engine, allowing it to reach fairly high speeds, and a spacious body designed for two adults and two children’s seats.

“Sputnik” was not put into serial production. Nevertheless, its design is of interest, especially for amateur car builders. The technical characteristics of the car meet the requirements of the traffic police for homemade microcars.

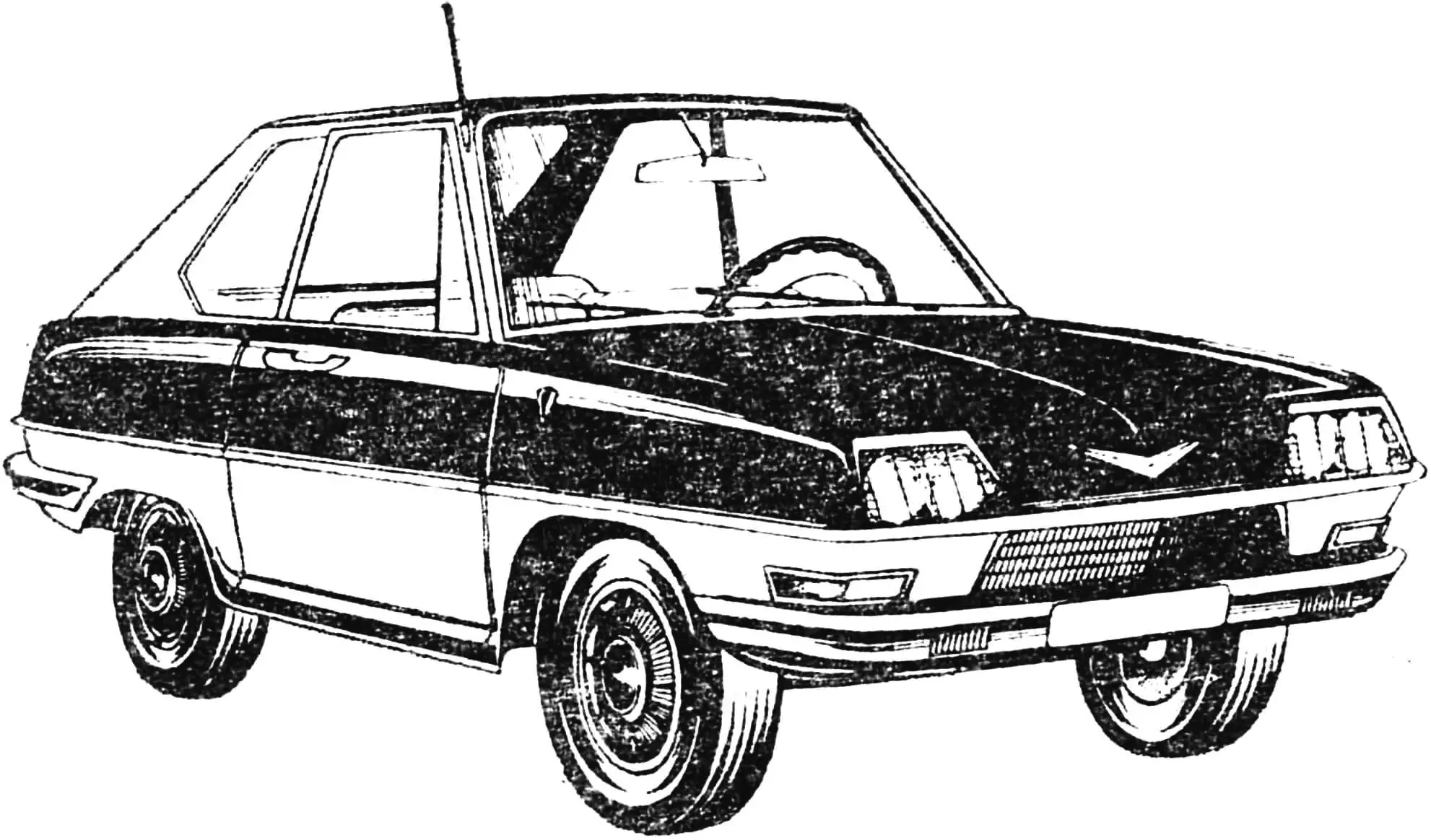

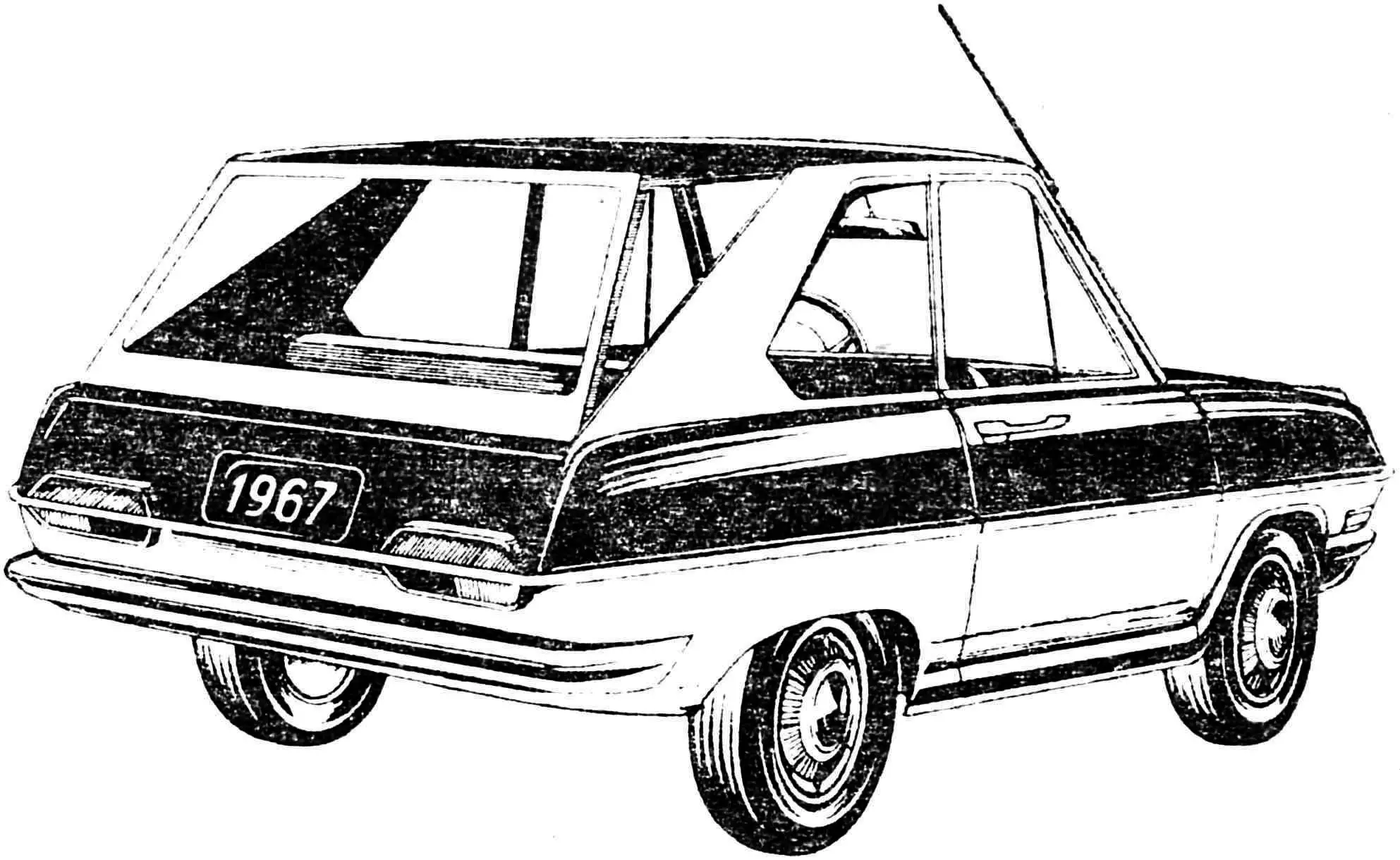

Our microcar project resembles the Serpukhov car (in layout, number of seats in the body), but differs significantly in its artistic-engineering solution.

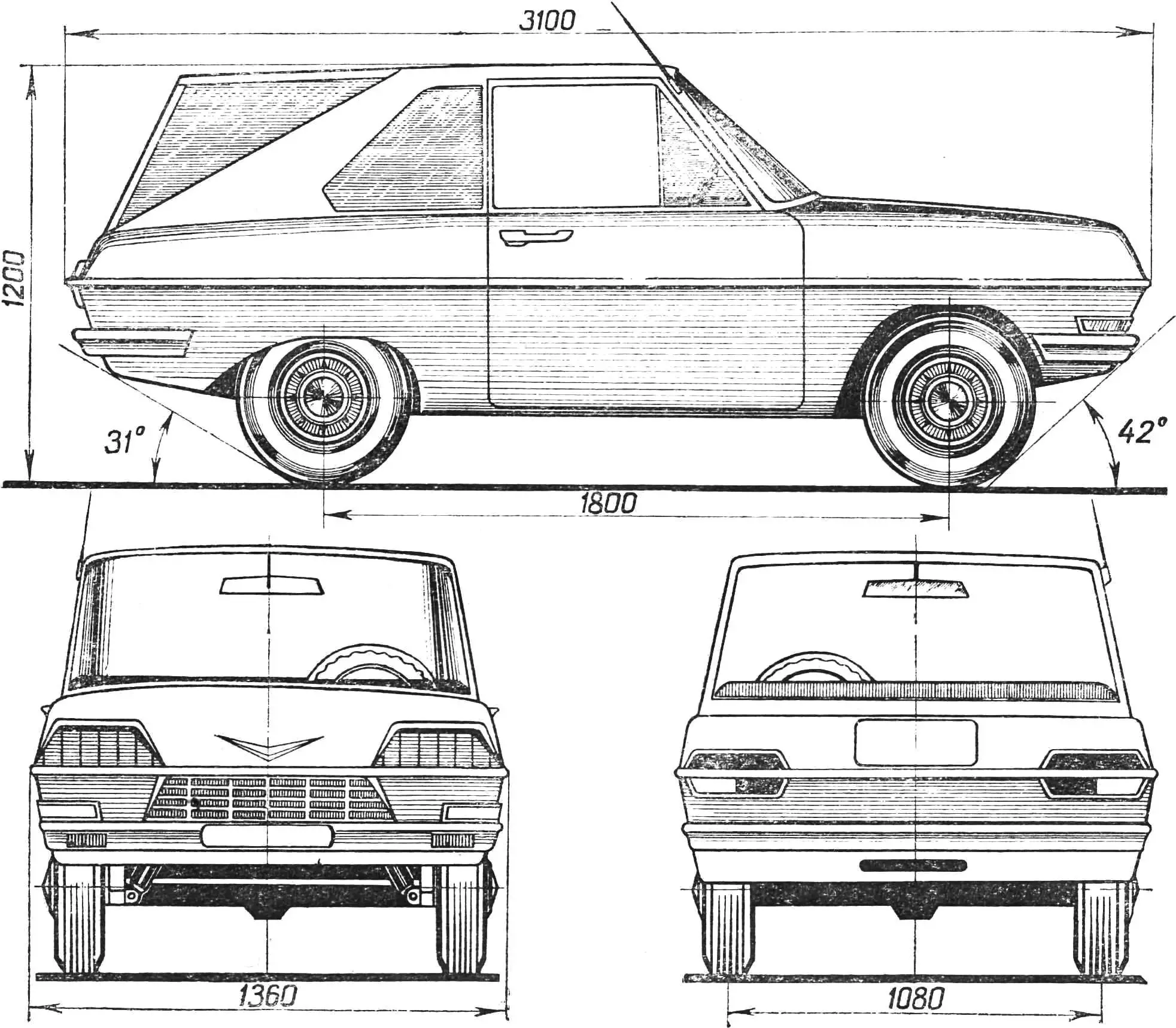

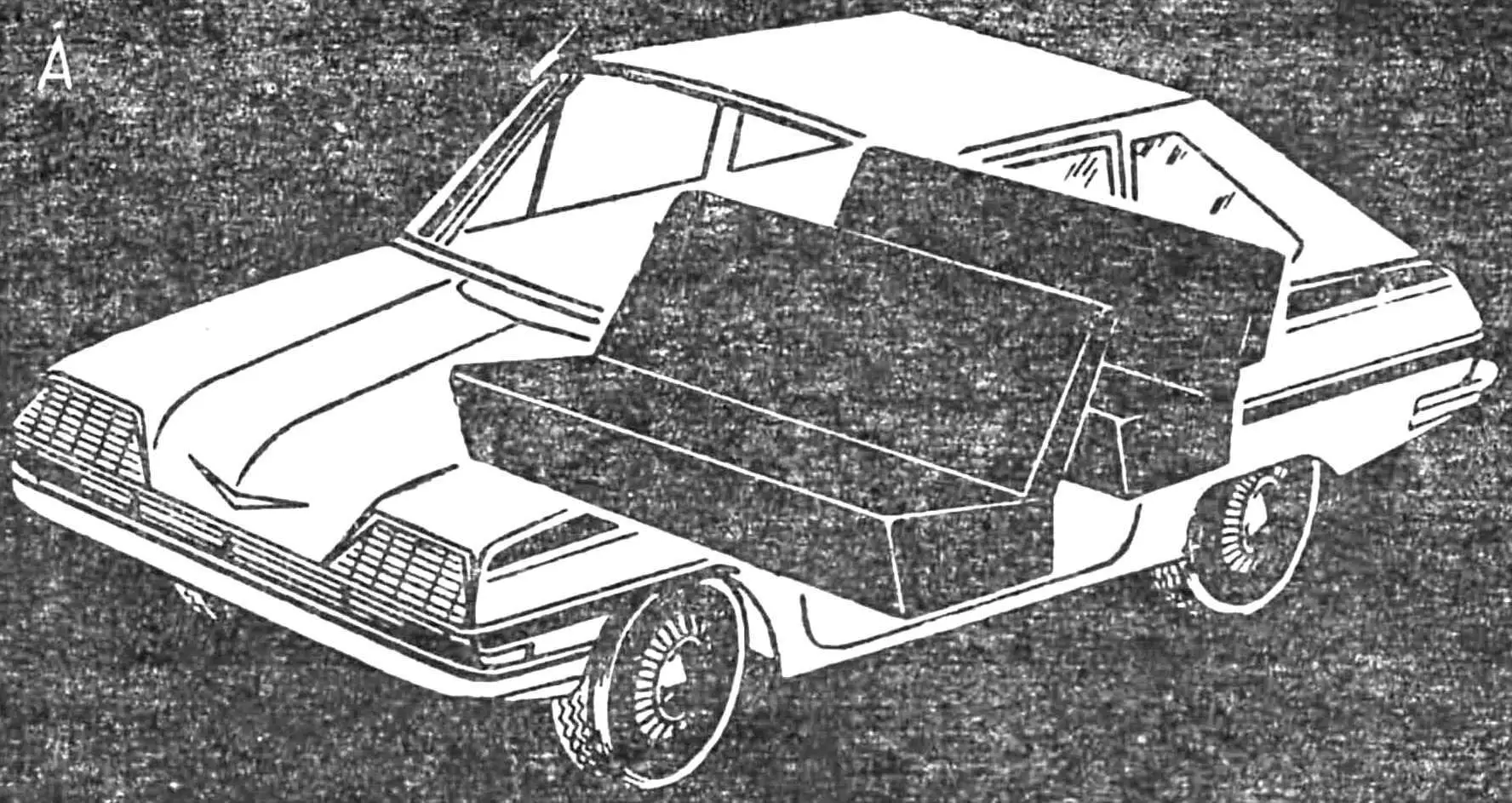

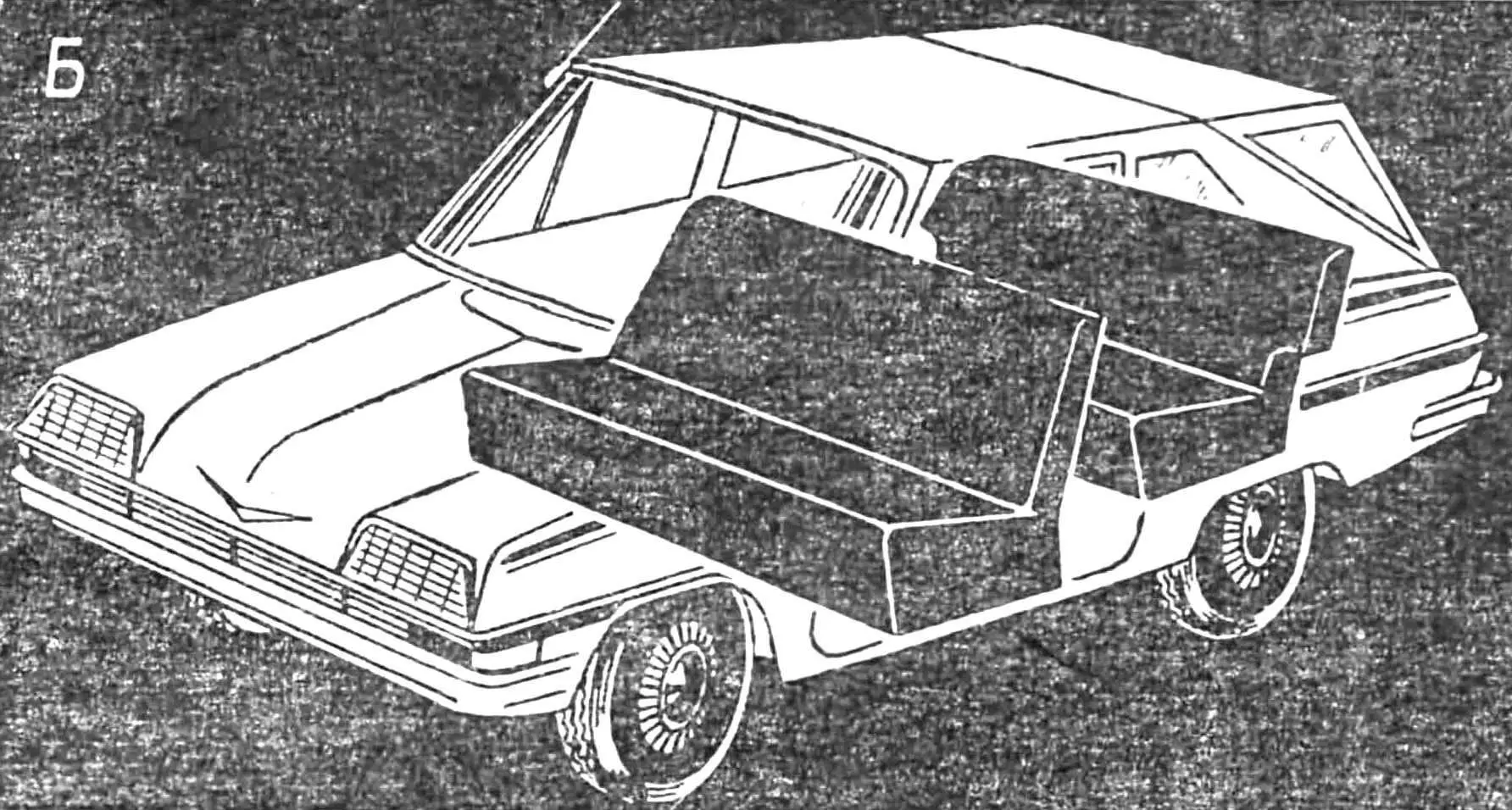

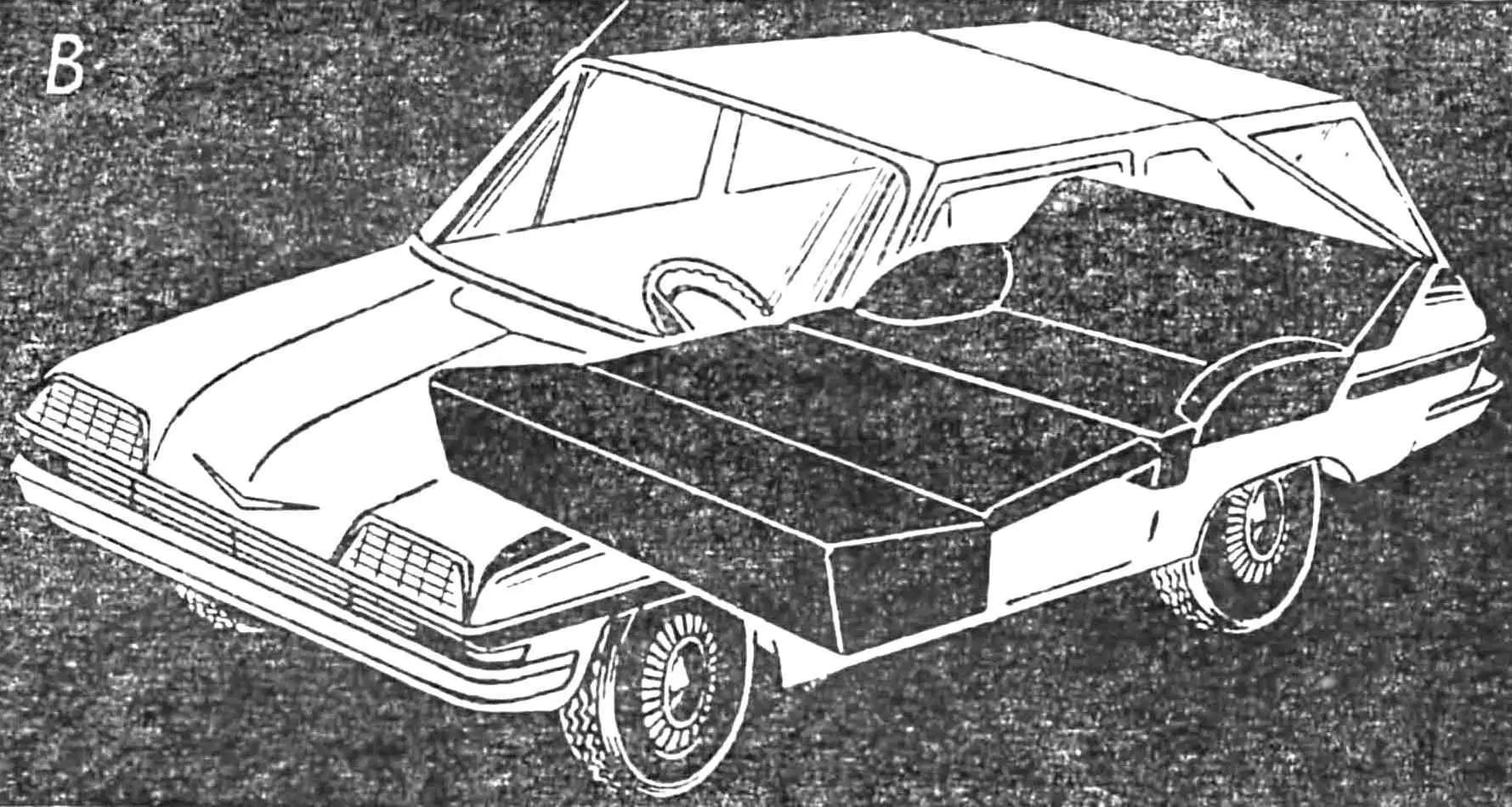

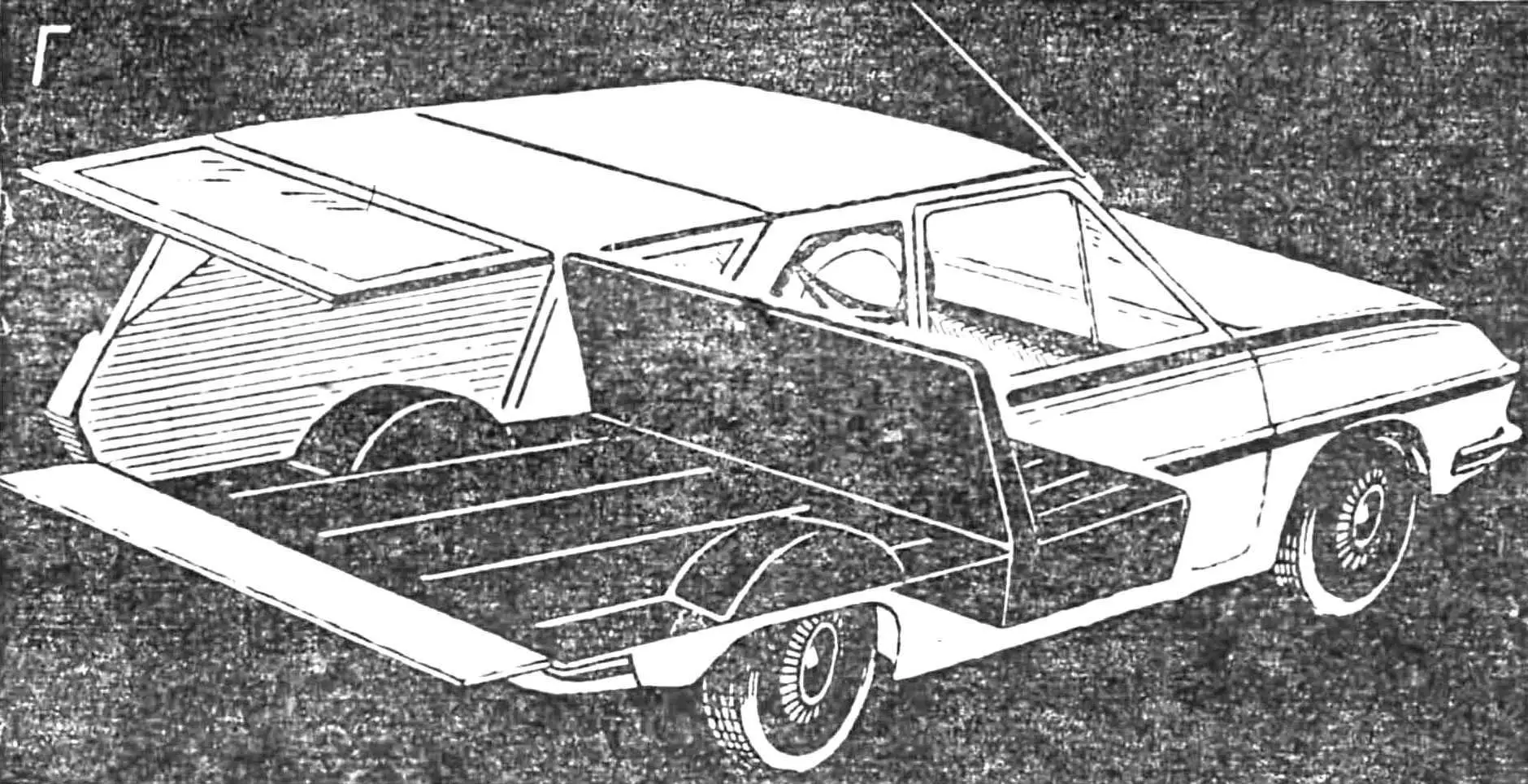

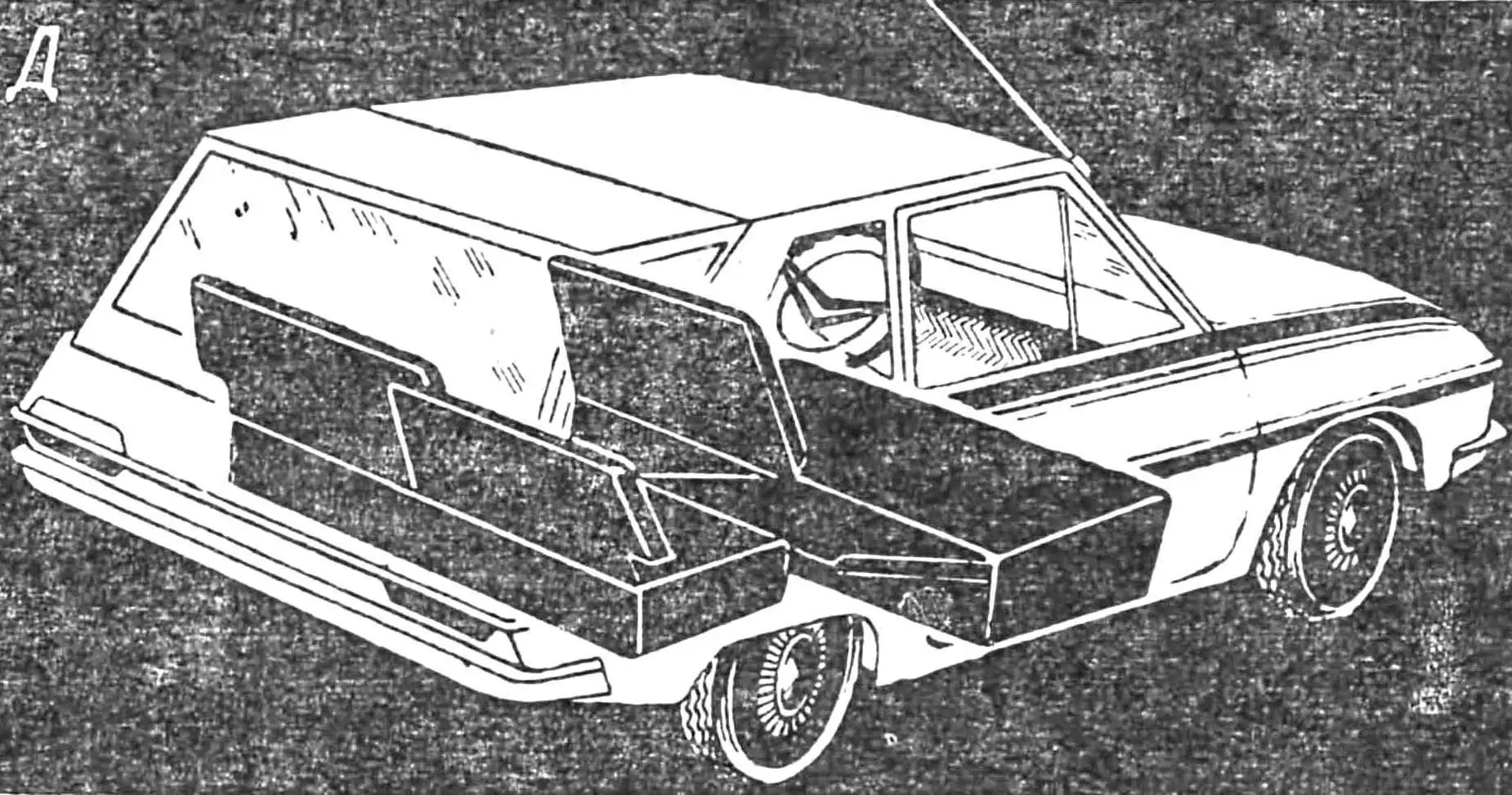

In figure 1 — a car with a conventional “coupe” body, and in figure 2 the car has a “universal” type body. And yet this is the same car (fig. 3). The specific body design allows quickly transforming a conventional “coupe” into a “universal” (“combi”) type body, and vice versa. What necessitates such a transformation?

The technical requirements of the traffic police for homemade microcars are very strict. The length of the microcar must be no more than 3.5 m, width — no more than 1.5 m, wheelbase — no less than 1.6 m. Under such conditions, it is very difficult to create a sufficiently spacious and comfortable body. Therefore, amateur car builders usually choose a two-seater car scheme. Naturally, ensuring the necessary comfort in this case is a complex and perhaps unrealistic task.

To create at least minimal comfort for four people, it is necessary to increase the useful volume of the body’s interior. This can be achieved by moving the rear seat back. But with an overall car length of 3.5 m, it will have to be installed in place of the trunk.

To summarize, we can formulate the task — to create such a body design in which, in the rear part, instead of a trunk and two children’s seats, there should be one common useful volume for transporting two adult passengers or luggage. Setting such a task is justified when creating an urban car with minimal dimensions, because such a car, as a rule, is operated not fully loaded. We must not forget that the amount of luggage can also vary. Therefore, the need arises to combine the passenger compartment and trunk into one volume. This will allow passengers to be accommodated with greater comfort or to transport more luggage.

Such a car has significant advantages over a conventional urban car due to its versatility and greater choice of options for using the useful volume of the body.

It is this combined “universal” type body that is most suitable for the design of a four-seat homemade microcar with a small overall length.

However, at exhibitions of amateur microcars, cars with “universal” type bodies are still very rare. Car designers are accustomed to traditional passenger car forms and their layout schemes. But such a tendency almost never leads to a successful artistic-engineering solution — bodies turn out to be bulky, heavy, harmonious proportions of cars are violated, comfort deteriorates, and the useful volume of the body is poorly utilized.

A — two-seater «coupe» (2+2 children’s); B — four-seater «universal»; C — sleeping places; D — with spacious trunk (van); E — scheme with one sleeping place.

Let’s examine the specific advantages of a car with a “universal” body. In the conventional version, it has two adult and two children’s seats (fig. 4, A). The “universal” body makes it already four-seater (B), allows converting seats into sleeping places (C) or creating a spacious luggage compartment (D). If the seat backs are made detachable, then the right seats (in the direction of the car’s movement) can be converted into one sleeping place (E). This is convenient during tourist trips or car rallies, when one crew member can rest while the other continues driving. And it’s not surprising if the car covers a thousand-kilometer journey not in two days, as usual, but in just one day. The length of the passenger compartment exceeds 2 m. The folding backs of the front and rear seats turn them into two sleeping places.

Transporting such cargo as a refrigerator, washing machine, or baby stroller is very troublesome even on conventional cars, and on homemade ones it is sometimes simply impossible. The “universal” body allows this to be done. It is enough just to move the rear seat forward and fold down the backrest or remove it.

Well, what if you want to give the car a more sporty appearance? This can be done in two ways. In the first — the rear part of the roof and the rear panel of the body are lowered and form a single inclined surface, and the triangular side windows are retracted inward. If you want to reduce the weight of the body, you can use the second method: make the lowering parts (roof, rear wall, and side windows) removable, and instead install a solid panel with a rear windshield. True, such a design somewhat reduces the rigidity of the body. Therefore, the joint locations of the panels should be reinforced.

What layout is most suitable for a microcar with a universal body?

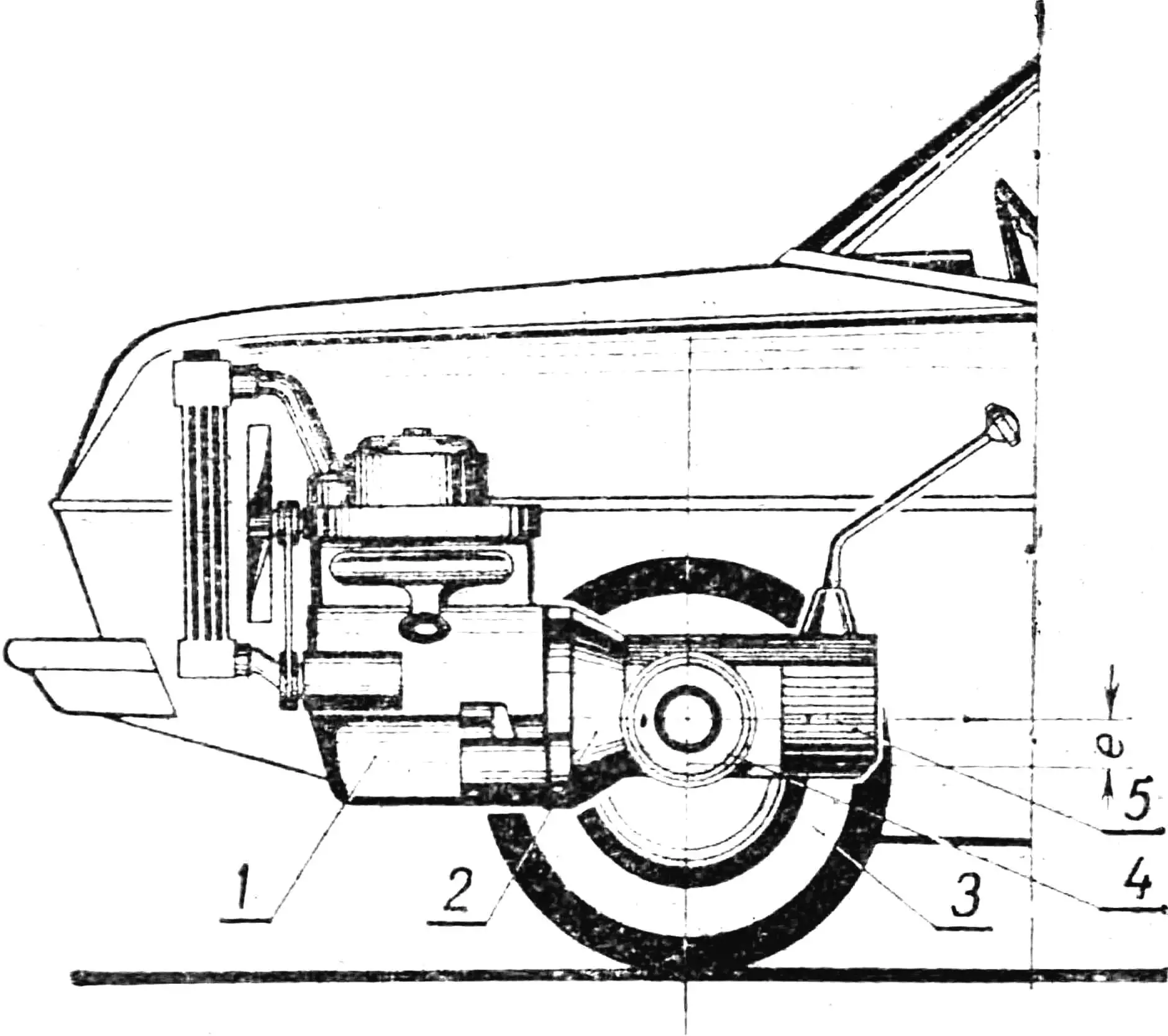

1 — engine; 2 — clutch; 3 — front drive wheel; 4 — final drive and differential; 5 — gearbox; e — wheelbase.

Designers of homemade microcars, especially young ones, as a rule, prefer to place the engine at the rear. The power transmission is simpler, there is no tunnel for the driveshaft, and there are fewer vibrations. For a car with a “universal” type body (or “coupe-universal”), such a solution is unacceptable, unless the engine is placed under the floor (as in the “Volkswagen-1500” passenger car). We will not be able to maximize the useful volume of the body — the main advantage of the “universal”. So, the engine will have to be installed at the front. The power transmission can be done in two ways: according to the conventional scheme (with a rear drive axle) or according to the front-wheel drive scheme. The second option is best suited for microcars with a “universal” body, especially homemade ones, in which, due to large size limitations, the designer has to fight for every cubic centimeter.

Owners of German “Trabants” and “Wartburgs,” English “Minis,” French “Citroëns” and “Renaults,” and American “Townuses” have already appreciated the advantages of front-wheel drive cars. Such cars lack a driveshaft to the rear axle. There is no tunnel for the driveshaft in the body, which makes the passenger compartment more spacious and allows lowering the car’s center of gravity. Front-wheel drive cars have better stability compared to conventional ones. True, the joints complicate the design. Still, the exceptional compactness of the power unit, the ability to use various types of bodies (from specialized to universal) and maximize their useful volume while lowering the center of gravity make the use of front-wheel drive very attractive precisely on homemade microcars.

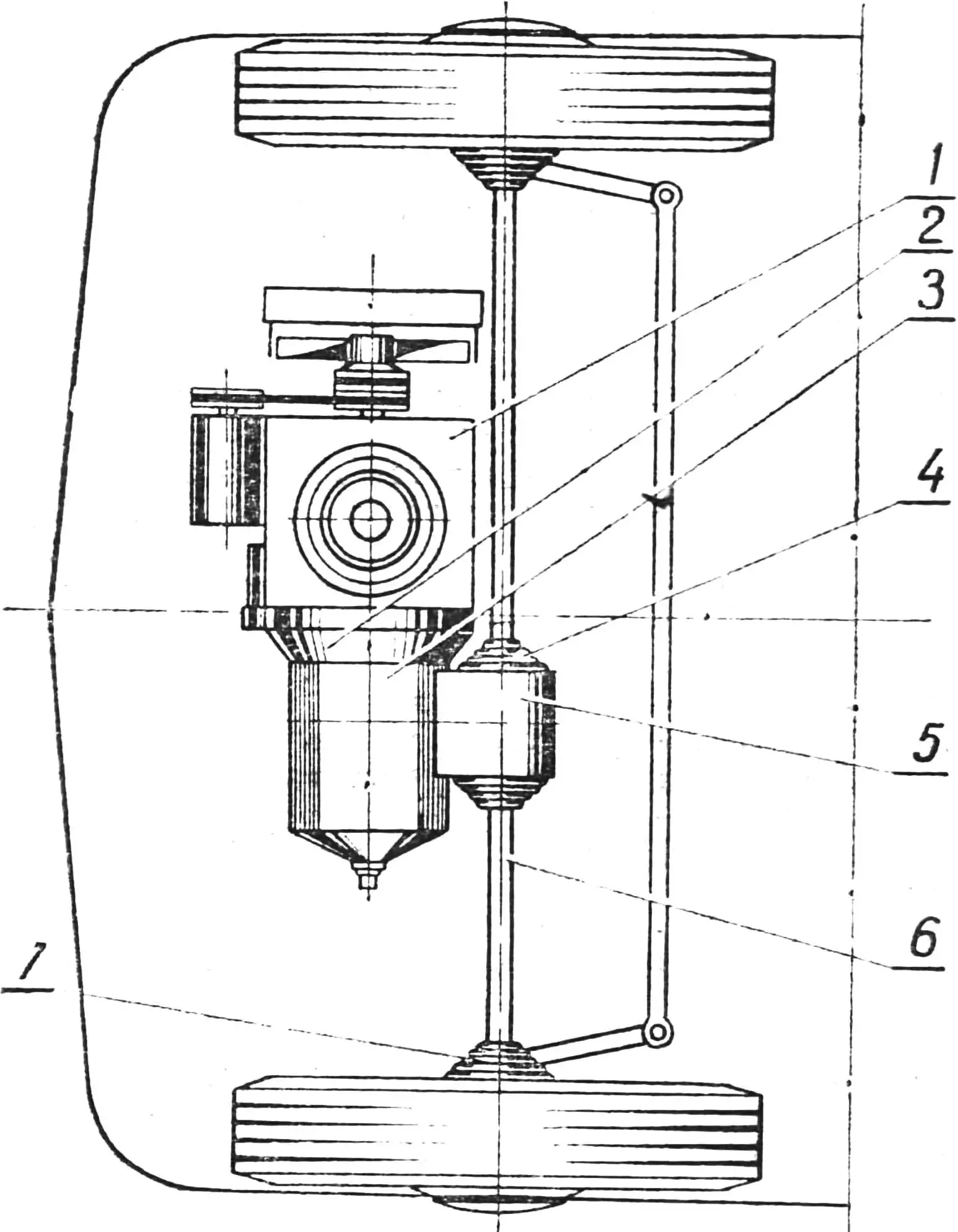

1 — engine; 2 — clutch; 3 — gearbox; 4 — universal joint; 5 — final drive and differential; 6 — half-shaft; 7 — universal joint.

There are two main types of engine arrangement for front-wheel drive cars — longitudinal (fig. 5) and transverse (fig. 6). The “Wartburg” car is built according to the first scheme. It is most suitable for V-shaped engines with small length. The engine, clutch, gearbox, and final drive with differential are made in one unit, which is installed on the frame or subframe. The front wheel suspension is independent. The torque from the final drive to the front drive wheels is transmitted through oscillating half-shafts, each having two joints.

Applying such a scheme to homemade microcars presents some difficulty: conical or spiral gear wheels of the final drive are needed, the hood is somewhat lengthened, and the car’s dimensions increase. From ready-made units, it is possible to use engines and transmission parts from M-62 or K-750 motorcycles, and drive axle units from off-road vehicles of the Ulyanovsk Automobile Plant.

Transverse engine arrangement provides even greater compactness. The engine, clutch, gearbox, and final drive with differential are also in one unit. But the final drive can be made chain, V-belt, or gear (with cylindrical gear wheels).

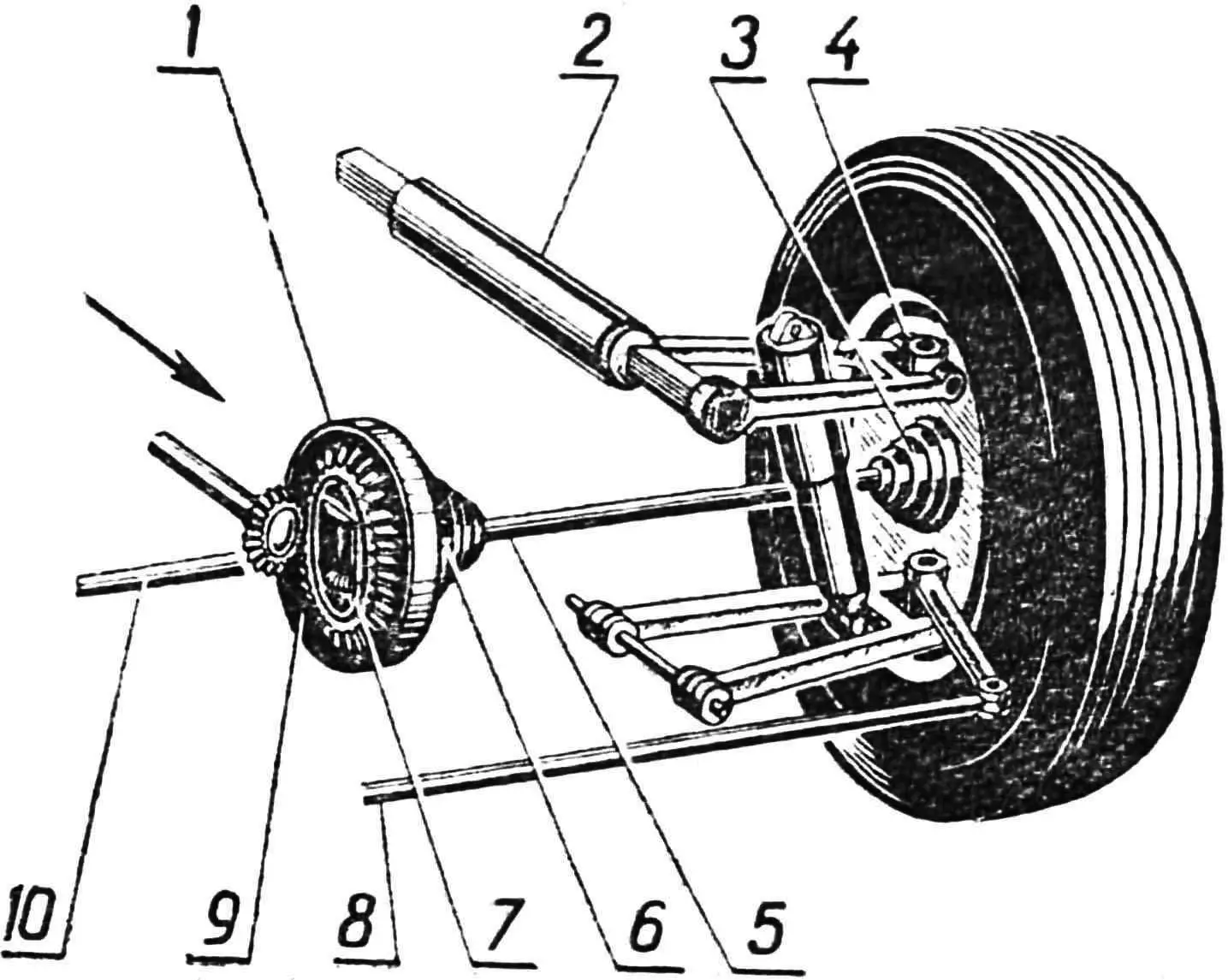

1 — final drive and differential housing; 2 — torsion suspension; 3 — universal joint; 4 — articulated connection of steering knuckle and oscillating suspension arm; 5 — half-shaft; 6 — universal joint; 7 — differential; 8 — steering linkage (located in front of the axle); 9 — final drive; 10 — half-shaft.

Note. The final drive and differential housing is installed on the frame or made in one unit with the gearbox, the oscillating suspension arms are pivotally attached to the frame, and the torsion bars are embedded at one end in the upper oscillating suspension arms, and at the other end are attached to the frame or load-bearing parts of the body, if it is of load-bearing construction. The arrow shows the direction of the car’s movement in forward motion.

Figure 7 shows one of the variants of the front drive axle (longitudinal engine arrangement). It has four universal joints (constant velocity, as in modern off-road vehicles GAZ and UAZ). The suspension is independent. It can be torsion, as shown, or spring with hydraulic shock absorbers. Parts from the S3A motorized wheelchair and cargo scooters can be used. The axis of rotation of the steering knuckle must coincide with the axis of rotation of the universal joint.

***

A number of creative tasks are set before you: selecting the engine and designing the universal joints — the most acceptable solution for the final drive. It is desirable to use as many ready-made units and parts as possible.

Young car designers, for whom building a front-wheel drive car will be difficult for now, can limit themselves to the first part — building a microcar with a combined body according to the conventional scheme (with a rear drive axle and driveshaft transmission from the engine to the final drive). It will only be necessary to install an intermediate universal joint, and the body will become a bit tighter due to the driveshaft tunnel.

To more experienced designers of homemade cars, we propose to practically implement the task of creating a fairly simple and reliable microcar with front-wheel drive. Solving this task will also make it possible to build microcars with increased cross-country ability, with all-wheel drive.

We await from our readers, from groups of car designers, reports on the results of experiments on implementing front-wheel drive on homemade microcars, microvans, as well as the use of “universal” and “coupe-universal” (combined) type bodies. We will tell about the best designs on the pages of our magazine.

V. MASIK, engineer