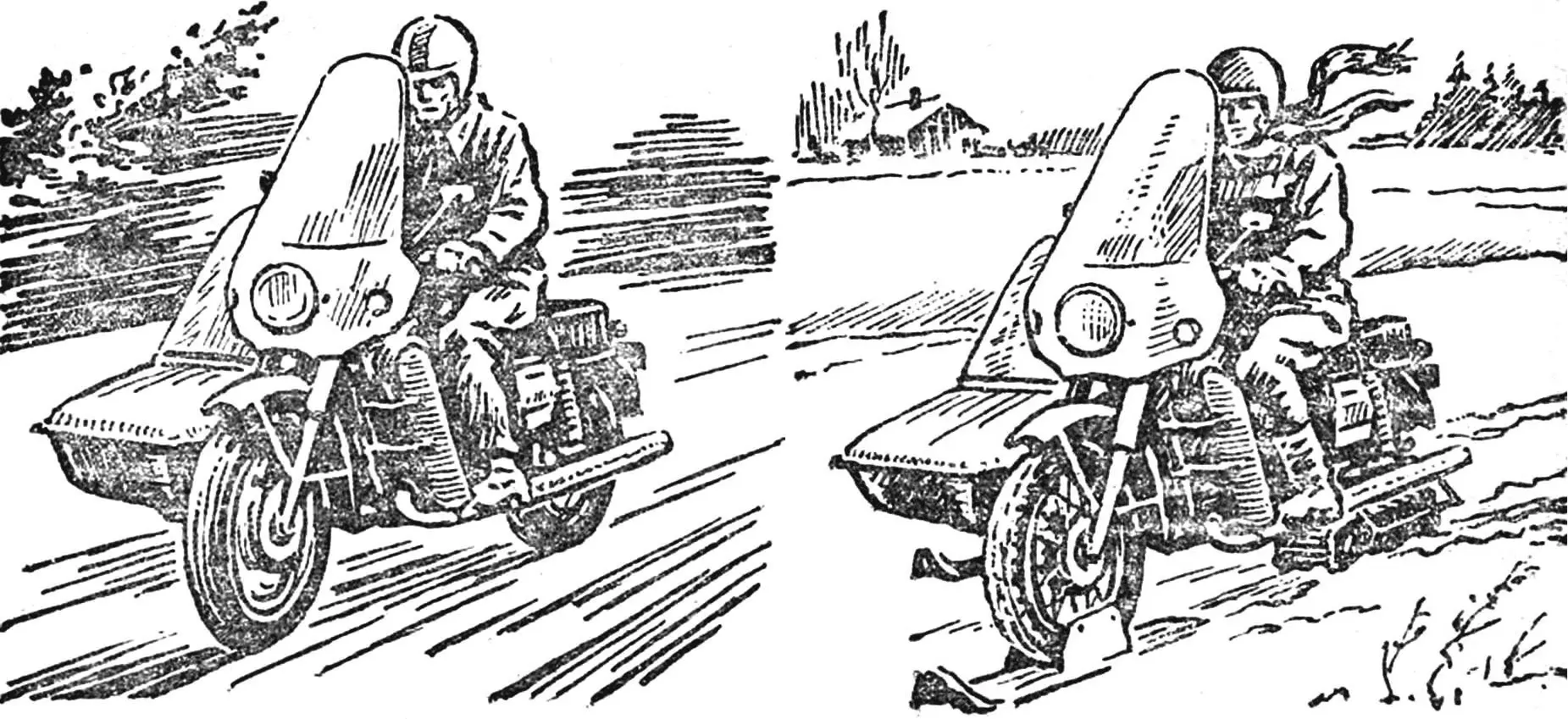

Snowmobile technology is finding increasingly wider application today. Industry and amateur craftsmen create the most diverse machine designs, specifically intended for winter operation. But then spring comes, and the powerful “Buran” goes to the garage for storage — waiting for the next season, while its owner switches to another “steed,” most often — a motorcycle. But is it advisable to have two practically identical vehicles that differ only in their running gear? Couldn’t one make a universal motorcycle-snowmobile?

This task was successfully solved by our reader from the city of Votkinsk A. Barabanshchikov.

I had long planned to get a snowmobile, but decided to refrain from buying an industrial “Buran.” And not only because this machine is expensive and, intended only for winter operation, in summer it just takes up space in the garage. Sometimes you plan to go fishing in early spring, but the road to the distant body of water has already cleared of snow, and the “Buran” won’t pass. But, unfortunately, the old friend — the motorcycle — won’t help here either: beyond the roadside the snow is still deep and loose. That’s why I settled on a design for a universal snowmobile, made on the basis of an IZH motorcycle with a sidecar.

The idea is clear from the drawing. We replace the rear wheel with a track, and put wide metal skis on the remaining wheels, and your motorcycle, without any modification, turns into an excellent snowmobile, easily overcoming climbs and drifts, and on level sections reaching speeds of up to 40 km/h. Moreover, converting it to winter configuration and back takes no more than 15 minutes, and the track-and-ski kit is compact enough to take with you.

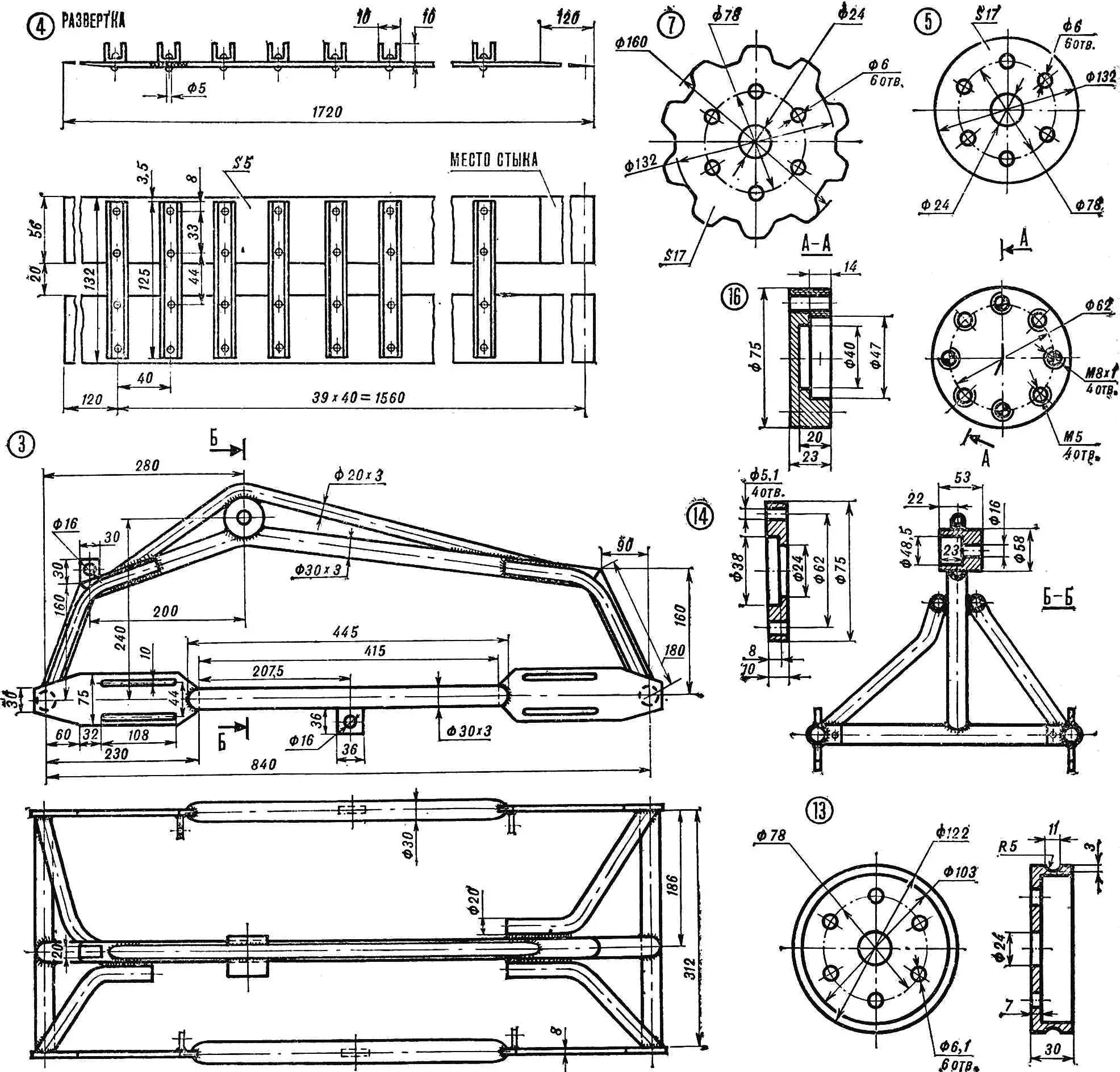

The skis for the front wheel of the motorcycle and the sidecar wheel are simple in design. Their base is a duralumin sheet with riveted longitudinal angles. They give the ski longitudinal rigidity; two steel plates are also attached to them, between which the wheel is secured with just two bolts. To reduce friction on snow, I recommend making the ski sole from stainless steel, brass, or polyethylene. And to improve handling, the front wheel ski should have a steel edge — a vertical rib on the lower plane.

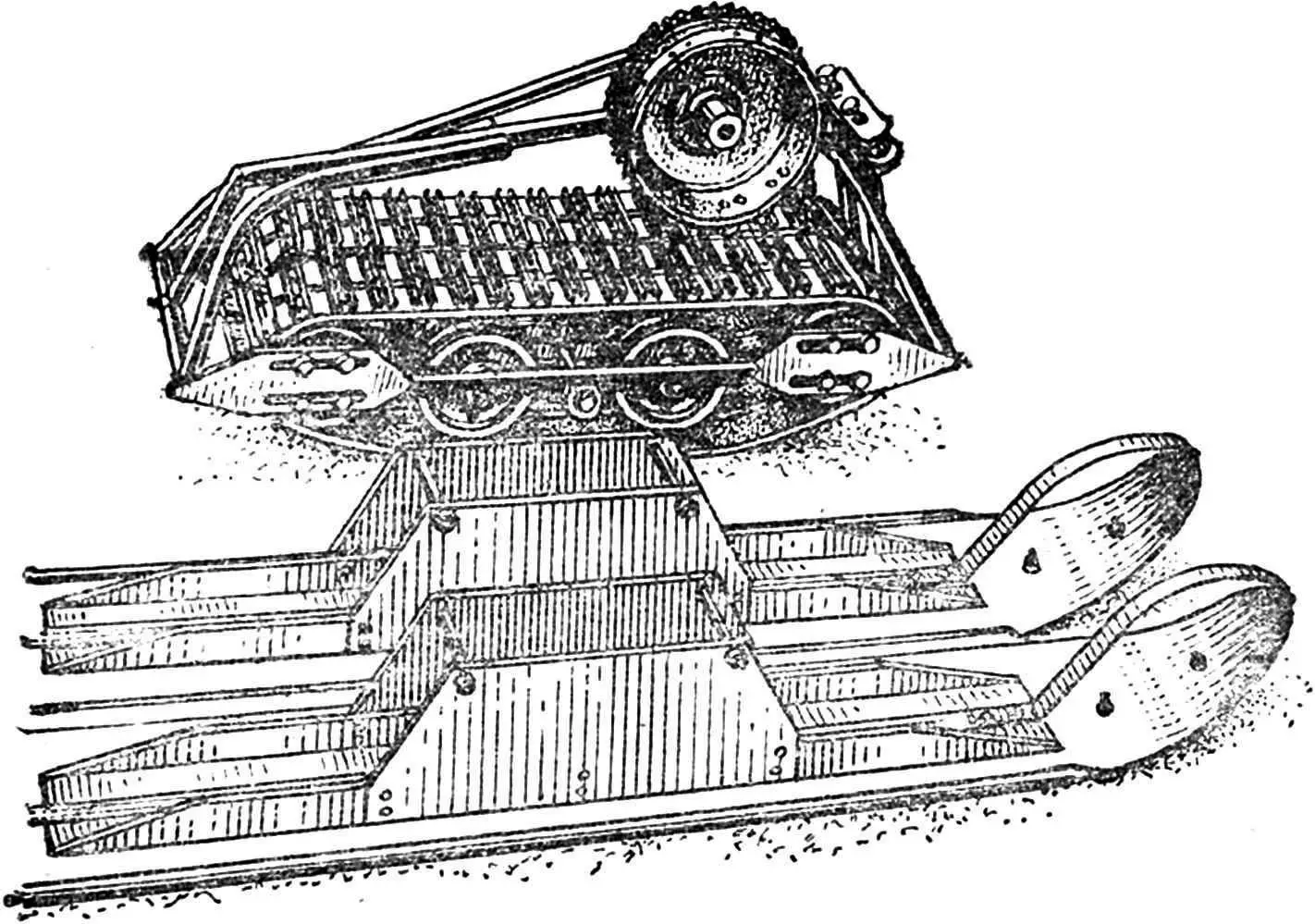

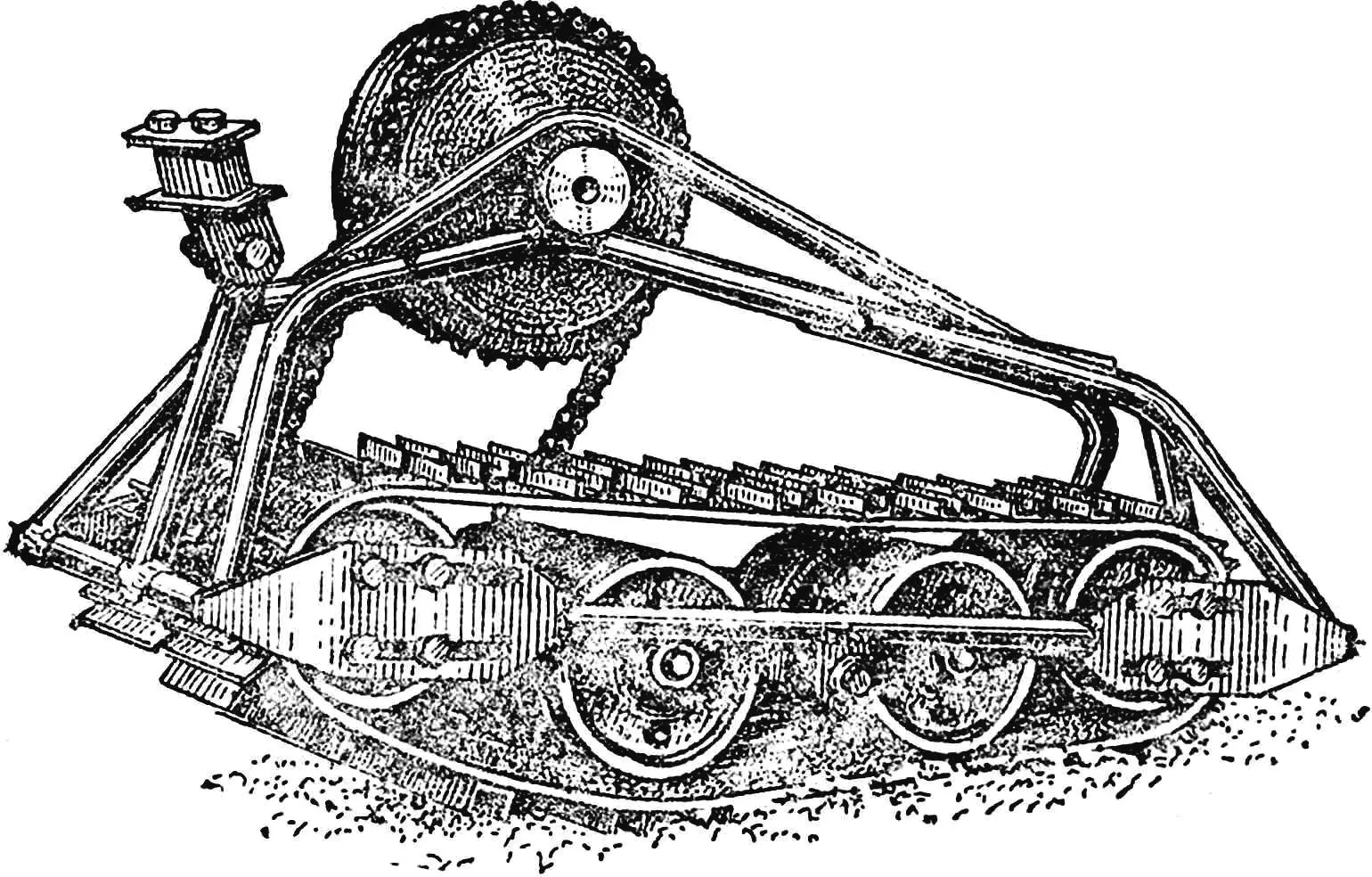

More complex in manufacture is the tracked drive unit, installed in place of the removed rear wheel of the motorcycle.

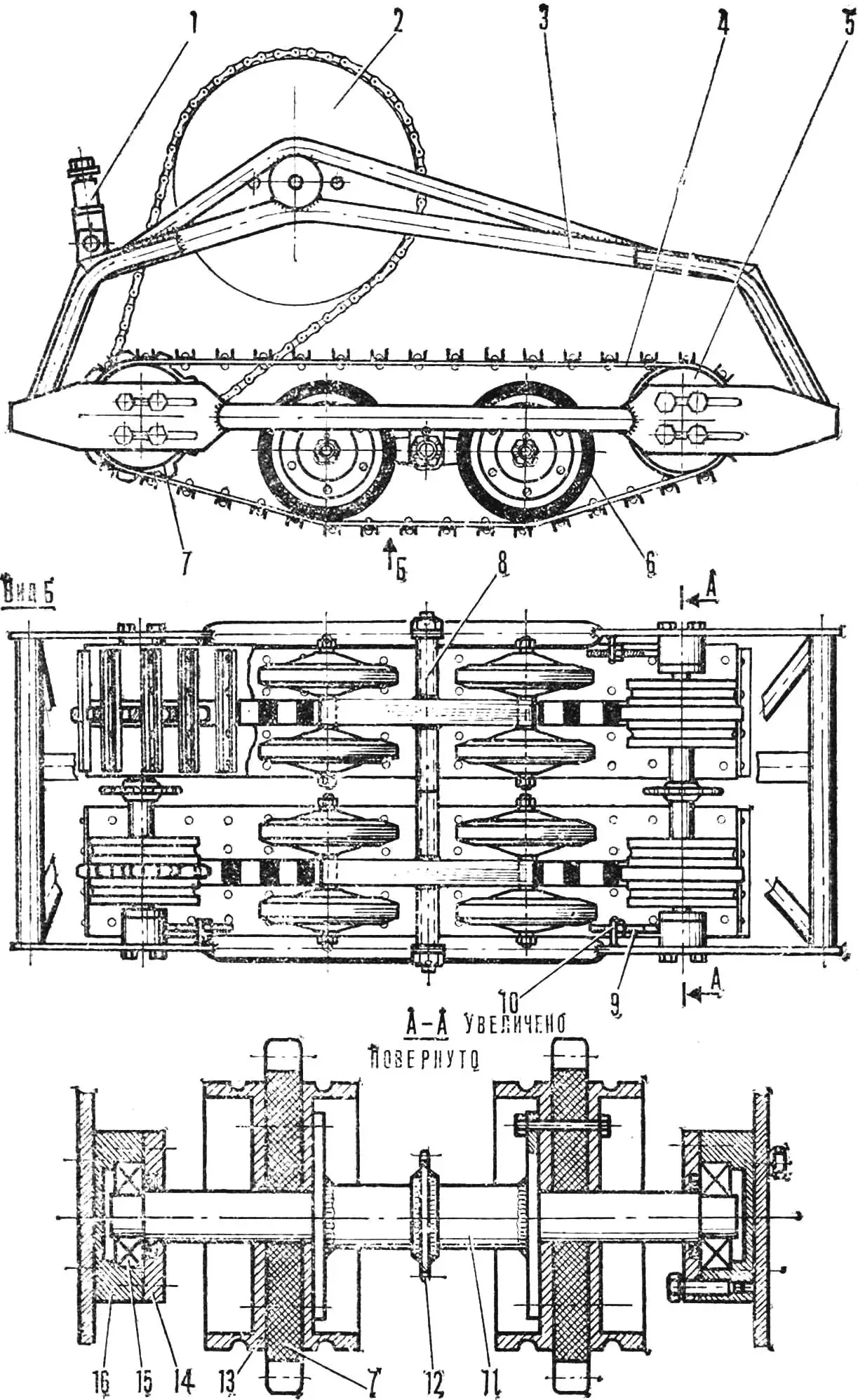

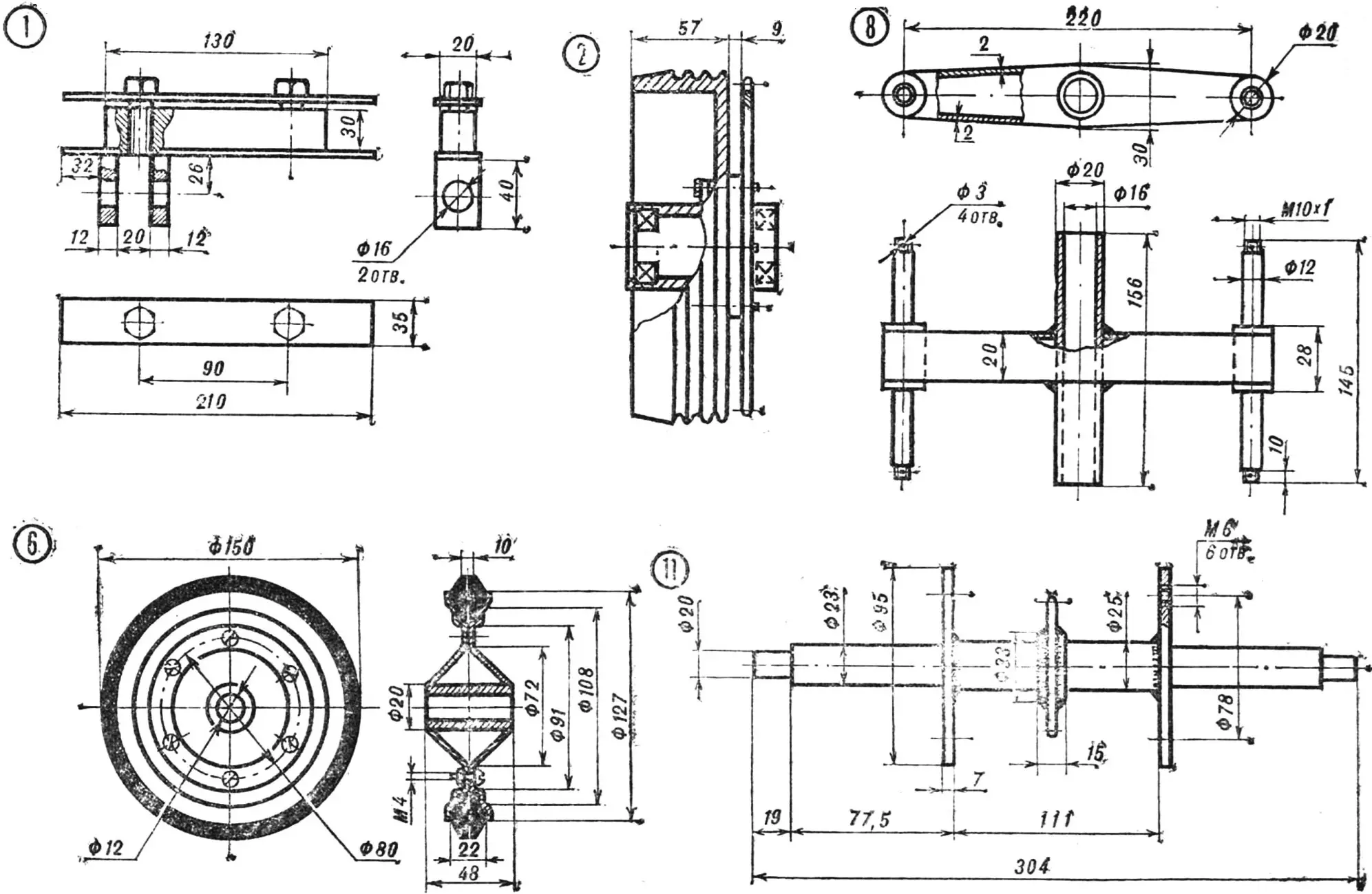

Its frame is welded from steel tubes Ø 30 and Ø 20 mm and four steel plates 8 mm thick. The longitudinal slots in the plates are intended for connecting the front and rear shafts of the track support drums and adjusting its tension. A steel bushing is welded to the vertical tubular arch. Through its hole, when installing on the motorcycle, passes the axle of the removed rear wheel. The lug in the front part of this arch serves to attach a special unit, with which the entire frame is fixed to the rear fork of the motorcycle. And two similar lugs, welded under the longitudinal tubes, are necessary for connecting the balance beam axle. In addition, these tubes have stops at the ends for the threaded track tensioner.

The shafts of the front and rear support drums of the track are turned from steel rod Ø 25 mm. At the ends of each, necks are turned for bearing No. 204, and in the middle part, sprockets (Z=17) of the chain drive and flanges of the support drums are welded. Since only the front shaft is driving, the rear sprocket is not used, but the shafts turn out to be fully interchangeable, which may be useful if the sprocket fails.

The bearing housings of these shafts are turned from steel blanks. In them, in addition to the bearing seat, axial holes are made for attachment to the frame plates and a radial hole (in place) — for a long stud used as the rod of the track tensioning device.

1 — drive unit mounting to motorcycle, 2 — drive sprocket (Z=42) with hub, 3 — frame, 4 — track, 5 — driven shaft disc, 6 — support roller, 7 — drive shaft sprocket, 8 — balance beam, 9 — tensioning device rod, 10 — tensioning device stop, 11 — shaft, 12 — drive sprocket (Z = 17), 13 — support drum, 14 — bearing cover, 15 — bearing No. 204, 16 — bearing housing.

The housing covers have a groove for installing a sealing ring and are attached to the housing with M5 bolts.

The track support drums are turned from duralumin blanks and assembled from two halves with six M6 bolts. During assembly, drive sprockets cut from thick rubber sheet are clamped between them — on the front shaft, and cylindrical rollers — on the rear. The teeth of the drive sprockets transmit force to the track, engaging with the ground cleats through the gap between the track belts. And the drums themselves roll along the inner side of the track. The semicircular grooves on their outer surface are made so that the screw heads, with which the ground cleats are attached to the belt, don’t interfere with operation.

The track consists of four strips 56 mm wide, cut from conveyor belt and joined together by common ground cleats — steel U-shaped profiles bent from 2 mm thick strips.

The front shaft of the track is driven by a chain drive from the drive sprocket (Z = 42), installed in place of the wheel. The sprocket itself is borrowed from an IZH-10 motorcycle. It is attached with six M6 bolts to the modified, as shown in the drawing, wheel hub. This part is mounted on the rear fork similarly to the rear wheel with the addition of a simple spacer bushing.

The intermediate supports of the tracked drive unit are balance beams — four two-arm levers installed on a common axle with roller axles fixed at their ends.

Not finding suitable wheels in size and strength for the balance beam, I made them myself. Using a simple die, I pressed out wheel disc halves from round steel plates, turned bronze hubs — plain bearings — and a mold for the roller tires. By joining the half-discs with six bolts, I got a strong wheel that is easily repairable in case of wear.