Foundation drive chair is self-propelled engine type In-50 or previously produced by the plant in Siauliai, engine type “W” with different digital indexes. The design of the power unit is simple. The engine is attached to a tubular frame, equipped with front and rear docking ports (the last one with the attachment point of the bridge). Blanks for both nodes are cut from springing sheet with a thickness of 3 mm and attached to the frame by means of a gas or argon arc welding. Bearing Assembly — a Bicycle carriage: it is also fixed to the frame by welding.

The axle is machined from steel rod on the model of the pedal axis of the Bicycle. Of course, it needs to be longer — after all, it will be planted with two wheels.

Homemade wheels, tires and cameras (205×56) from a child’s Bicycle. Disks are cut from sheet aluminum and are connected using stud bolts and nuts M6 with washers and remote plugs — pipe sections with an inner diameter of 7…8 mm and a length of 50 mm is laid on Top of bushing aluminum tape with a thickness of 1…1.5 mm and a width of 50 mm and is fixed on the disk with a rubber ring cut from a steel inner tube.

On one of the wheels is necessary to provide a sprocket of any bike. Pregnant bushings with flanges are fastened by screws and nuts. Records all wheels on the axle with the bolts, a tight fit in axle and bushing. Best fit the bolts of the second and third class of accuracy, and a hole under them to 0 6 mm is cut in two passes — first with a 5.8 mm drill bit to 0, then scan 0 6 mm. In tan case wheels will sit securely and without backlash, the connection will get loose.

Control cables, throttle carb, clutch and gearing mechanism are selected of such length that it will last for any turning of the chair.

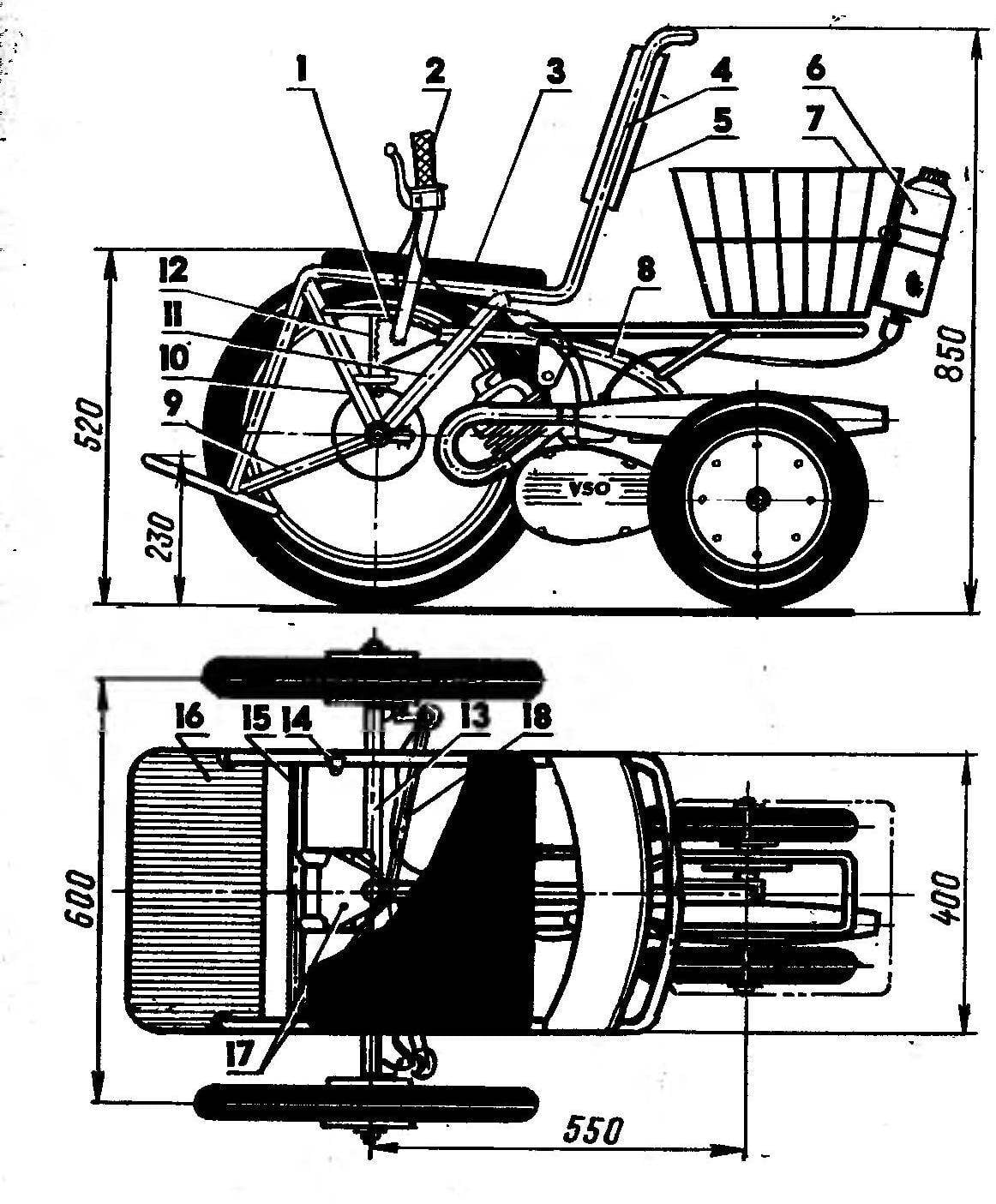

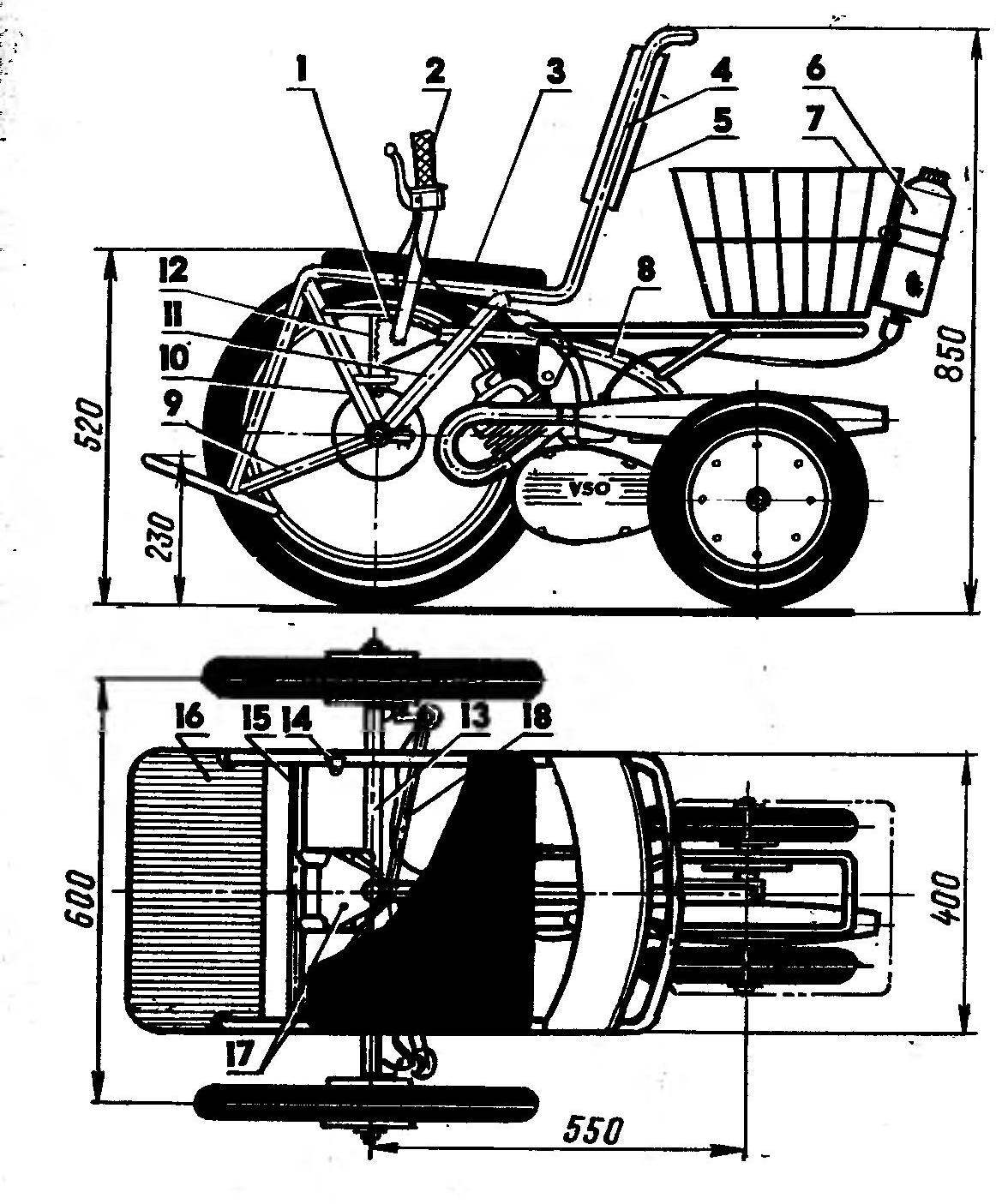

Fig. 1. Wheelchair motociclo:

1 — reinforcing the gusset plate, 2 — steering wheel with controls, 3 — seat (plywood, lined with foam rubber and artificial leather), 4 — frame chair, 5 — back (plywood, lined with foam rubber and artificial leather), 6 — fuel tank (canister with a capacity of 2.5 l), 7 — basket, 8 — power unit, 9,10,11 — struts, 12 — steering column, 13 — front axle, 14 — bracket, seat mounting, 15 — cross, 16 — a platform for the feet, 17 — upper and lower bridges 18 — the wheel.

,

Fig. 2. The power unit matarrese:

1 — brace the trunk, 2 — trunk, 3 — front bracket engine mounts, 4 — frame of the power unit, 5th wheel, 6 — engine type In-50 (At-501), 7 — damper, 8 — axis power unit, 9 — sprocket driven, 10 — exhaust tube 11 — bolt with nut and spring washer, 12 — flange 13 — wheel 14 — rear docking port.

Fig. 3. The frame of the power unit:

1 — wheel (steel pipe 22×2. 5 mm), 2 — spinal tube frame (steel tube 36×3 mm), 3 — the trunk (steel pipe 16×2 mm), 4 — brace trunk (steel pipe 16×2 mm), 5 — rear bracket engine mounts (steel sheet thickness 2.5 mm), 6 — front bracket engine mounts (steel Lis 2.5 mm thick), 7 — reinforcing the gusset plate (steel sheet thickness 2.5 mm), 8 — the right flange drive shaft 9 — asterisk (of a motor scooter of any type), 10 — bearing unit-rear axle (from any “adult” bike), 11 —the left flange of the axle and 12 — axle power unit, 13 — bolt with nut and spring washer, 14 — sleeve (bronze or PTFE), 15 — steering column (steel pipe 30×2,5 mm). Sizes designation * Refine the engine.

Fig. 4. The frame of the chair:

1 — rear brace (steel pipe 22×2,5 mm) 2 — front strut (steel pipe 22×2. 5 mm), 3 — lower brace (steel pipe 22×2. 5 mm), 4 — frame platform (steel pipe 18×2. 5 mm), 5 — cross bar (steel pipe 22×2,5 mm), 6 — bracket for seat mounting .(steel strip with a thickness of 3 mm), 7 — nut and washer, 8 — axis, 9 — the emphasis of the brake drum, 10 — axis (steel pipe 30×2,5 mm), 11 — an arm of fastening of a back seat (steel strip with a thickness of 3 mm), 12 — upper and lower bridges (steel Lis thickness of 3 mm). Size 90 to clarify the used wheel.

The frame of the chair bent and welded steel pipes 0 25×2,5 mm. Seat and backrest is of duralumin sheet thickness of 2.5 mm; cushion back and seat — foam with a thickness of about 50 mm lining — made artificial knives, or leatherette. At the bottom of the seat is fixed by welding platform for the feet. It consists of a tubular rectangular frame, where the screws are fixed cladding of duralumin sheet thickness of 2…2.5 mm, covered with grooved rubber Mat.

Self-propelled chair is a machine and an articulated schema: front axle connects to power unit with a hinge. The hinge is like a steering column of a moped or motorcycle: it is a steel pipe pressed into it with a bronze or PTFE bushings, which with the help of two steel rails is fixed by welding on the frame of the power unit. Counterpart of a hinge made according to the type of steering bridges the front fork of the bike. These bridges are cut from steel sheet of thickness 2.5 mm and are welded to the front tray of the chair. Connection of bridges with the steering column of the Central hinge using steel studs with a diameter of 10…12 mm; steering column and bridges you can borrow from any old moped — they are still better than homemade, because “branded” hinge equipped with ball bearings.

The chair connects with the front axle of our vehicle with the two front trays (which have already been mentioned: n they are bridges Central hinge) and two rear. Additionally, two tubular braces fixed and a Playground for the feet.

The axis chair is a steel tube 30×2,5 mm, connected by welding with two axles — speed rollers, the larger diameter of which is equal to the inner diameter of the tubular shaft, and a smaller — diameter landing the front wheel bearings. At the end of the cushion threaded for fixing the wheel on the axle shaft washer and nut.

Front wheel self-propelled chairs from any moped. For fixing fixed part of the brake drum of each wheel to the axle are welded lugs bent from a steel strip in the form of the letter P.

Self-propelled chair is controlled using the steering wheel, is rigidly connected to the rear portion of an articulated vehicle. Characteristically, kolacna turns right when the steering wheel turns to the left, the right arm goes forward, and the left — back. Accordingly, a left rotation is performed when there is forward the left arm and the right ago. Such features control the driver usually gets used quickly enough.

Mounted on the steering wheel and all other controls wheelchair: on the right handle grip control throttle overshadow the carb (throttle) and the brake handle; left handle control clutch and lever transmission.

Engine starting is accomplished using a modified kick: place the pedal pad of the device is fixed machined aluminum pulley on which is wound two or three turns of the nylon cord with a thickness of about 8 mm. the Free end of the cord is equipped with a comfortable grip. To start the engine, enough for the driver to pull the lever of the starting device approximately a quarter turn to turn the handle of gas.

If you intend to use the chair on city streets, it should be equipped with light devices: how low — headlight, rear “dimensions” and reflectors-reflectors. Also nice install on the machine and the sound of the bike.

The speed such a vehicle will be about 20 nm^h. Note that this is still too much for such a short one that does not have depreciation of the machine; so fast you can move only on smooth asphalt.

Braking is via two front wheels driven by one lever on the right handlebar grip. It will have to mounted on the brake lever gaiter and focus so you can install the two brake cable.

Recommend to read SPROCKET FOR CHAIN TRANSMISSION the Designers often have to choose the right transmission ratio, and in this regard to look for suitable veins. The case is ungrateful, requiring large expenditures of time. It is much... NIGHT TRAP Suspended in the area, it will distract on itself, annoying insects, and gardening can be destructive to pests. The secret simple trap, judge for yourself. In a flat... Scroll back to top

Sincerely hope that this vehicle will never need you. But this does not mean that it does not need anyone. There are many people with disorders of the musculoskeletal system, or simply are not able to move independently. Meanwhile, in many cases, the position of the immobilized people can be considerably easier with the help of a self-propelled chair. We offer a simplified version of this design. For the creation of such a vehicle for those in need could come from technical clubs and cooperatives, small and large businesses, and for funding numerous charities.

Sincerely hope that this vehicle will never need you. But this does not mean that it does not need anyone. There are many people with disorders of the musculoskeletal system, or simply are not able to move independently. Meanwhile, in many cases, the position of the immobilized people can be considerably easier with the help of a self-propelled chair. We offer a simplified version of this design. For the creation of such a vehicle for those in need could come from technical clubs and cooperatives, small and large businesses, and for funding numerous charities.