In the Arctic tundra and in Antarctica, the snow-capped mountain slopes and in the forest most of the year working tirelessly snowmobiles — reliable support person. The combination of a lightweight gasoline engine, V-belt CVT and rubber tracks — that is, essentially, the whole wisdom underlying most of these machines. At first glance, not too difficult combination. But it took a lot of time and labor to make this “Troika” to work together.

In the Arctic tundra and in Antarctica, the snow-capped mountain slopes and in the forest most of the year working tirelessly snowmobiles — reliable support person. The combination of a lightweight gasoline engine, V-belt CVT and rubber tracks — that is, essentially, the whole wisdom underlying most of these machines. At first glance, not too difficult combination. But it took a lot of time and labor to make this “Troika” to work together.

And the weakest was the caterpillar. Designers had to try many varieties of rubber, the various schemes of the drive devices to prevent the sticking of wet snow, etc. the Result is a number of ingenious solutions to the “problem tracks”.

Today we offer our readers an article of designer Y. I. Pavlushin, one of the founders motoart “Buran”, in which he shares with snowmobile enthusiasts equipment experience in the manufacture and repair of tracks. Recommended design and manufacturing technology are protected by the copyright certificate No. 553150. In the annotation to it emphasizes good remotepoint proposed by Pavlushina caterpillar and the ability to make it from one or more rubber-cord belts.

Many Amateur designers build motonarty their own, often achieving good results. But if the Assembly of the chassis and the engine does not cause much difficulty, but to make the caterpillar can not everyone. Because they will reliably operate in all weather conditions, without losing any longitudinal flexibility in peremanivanie on the stars, nor the lateral stiffness needed for maximum area and the uniformity of the pressure support surface.

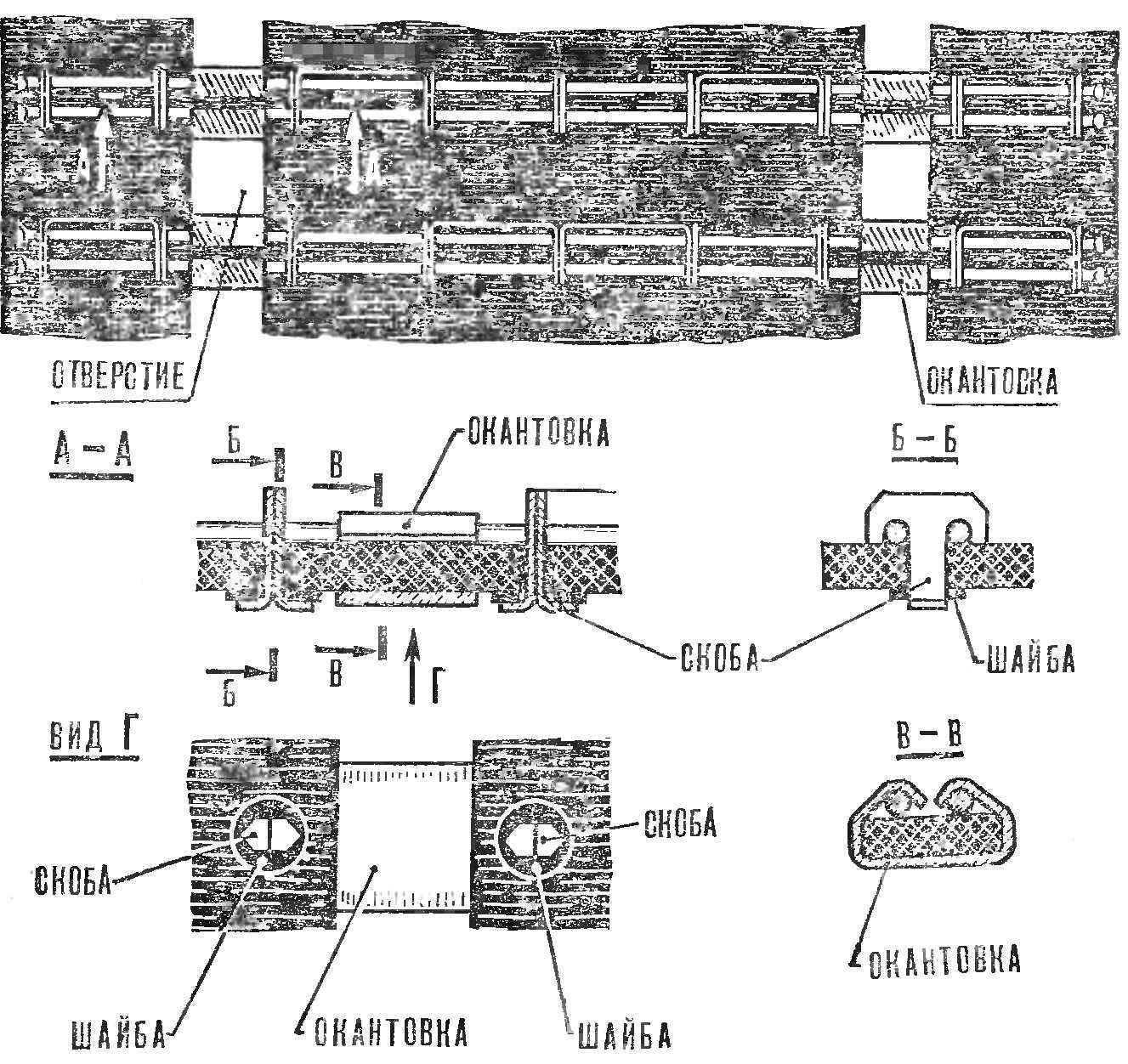

Fig. 1. The caterpillar of one of rubber-cord tape with T-shaped brackets.

3 serial snowmobile “Buran” this is achieved by using flexible rubber-cord tape, which is moulded into a transverse spring steel rods. But… the studs often break, and then the whole caterpillar out of order. In addition, some owners of “storms” are complaining that the grip of the caterpillar when driving on ice, smooth, hard ice, hard crust not enough.

The proposed design is also not immune from damage, however, its significant advantage is that the rods and other metal parts it can be easily replaced. Grip same tracks, for example, with ice — just like the horse, put across the movement. And the most eye — caterpillars can be manufactured at home again (or to remake the serial, following the published drawings).

In rubber-cord tape of selected size hole (as on film) two rows of rectangular holes. Step between them and the dimensions depend on the geometry of the leading stars. The distance from the edge of the tape up to the holes should be approximately 1/5 of its width. In between the Windows on the outside tape is applied to two rods of spring wire (OBC), which is attached to the ribbon at each point of the T-shaped double brackets. The latter have at the bottom of the legs recesses in which to place the rods, and the legs of the staple pass into the drilled in the tape holes and bend on the opposite (inner) side after putting them on the washer (Fig. 1). The ends of the rods to prevent axial movement flattened. Sections of rubber cord tape between the Windows with the rods okolcovannaya clamps from a metal strip in contact with the teeth of the sprockets, and caterpillar in the first version is ready. It will be of satisfactory good longitudinal and lateral grip with the snow and soil, however, can slip on ice.

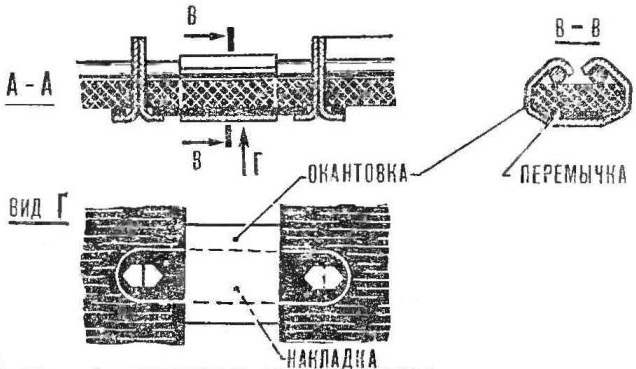

To avoid this, as well as to increase the longitudinal grip of the track on the ground can be bridged with jumpers, or all or a portion of the staple adjacent the holes. Jumpers should be parallel to the rods of each bracket when looking at the surface of the caterpillar will have the letter P, the sidewall of which is made in the design of the T-shaped brackets, and the bar is a jumper on the tape surface. Caterpillar with such staples has a good longitudinal and lateral grip on any surface.

Almost any combination of clips with jumpers and without jumpers. You can even typing, for example, of the combinations of clips his name or the name of the machine, and then, if necessary, on the trail in the snow it will be easy to know what was the snowmobile.

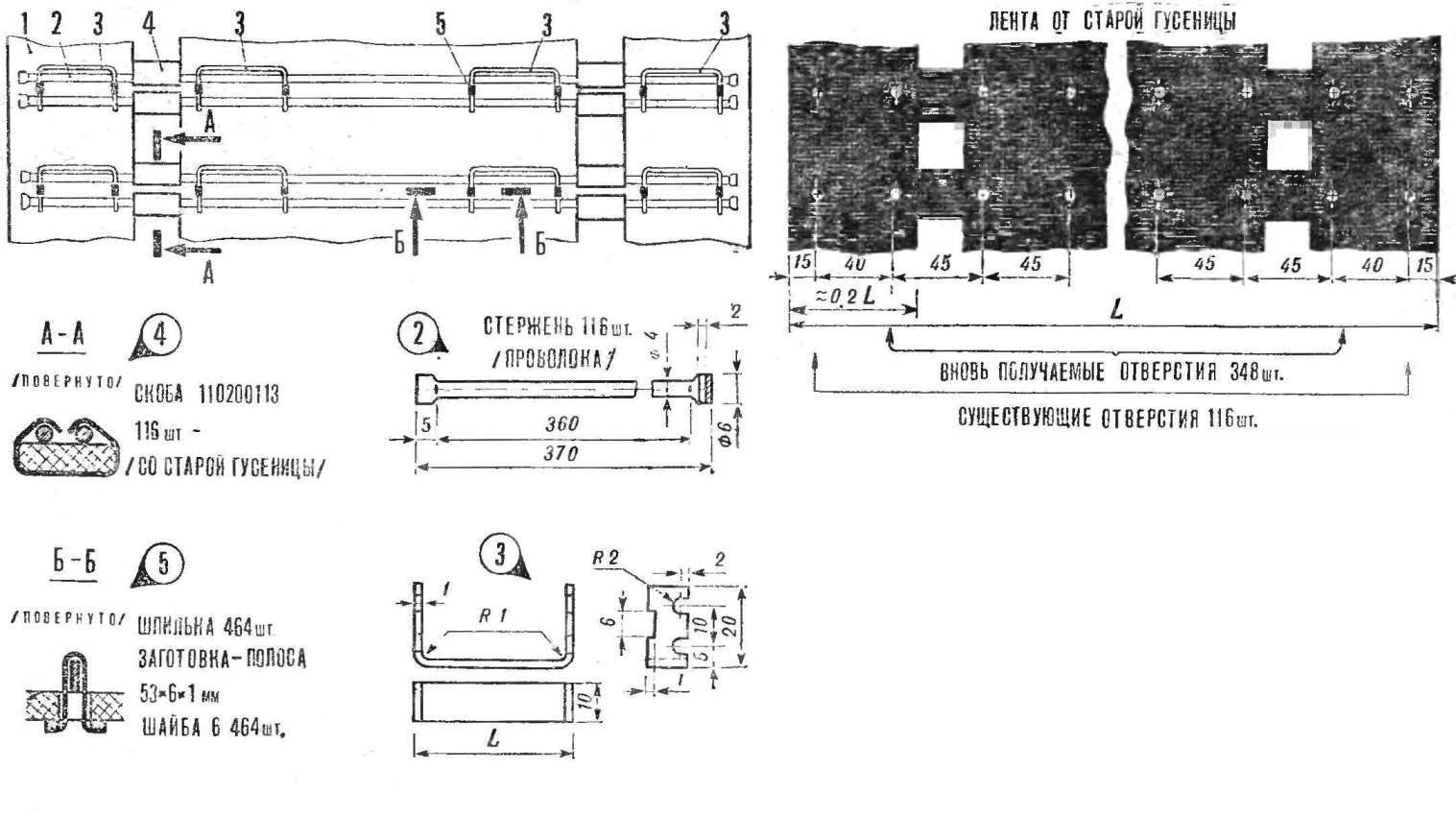

Fig. 2. The caterpillar of one strip with composite brackets and the option of remaking the old tracks of the construction of a snowmobile “Buran”:

1 — rubber-cord tape, 2 — steel rod, 3 —jumpered, 4 — clip edging, 5 — stud.

Fig. 3. The caterpillar of several tapes (joint tapes).

To get the perfect clutch caterpillars with a smooth icy surface, the working edges of the brackets necessary to make a gear. Preferably used for all metal parts corrosion-resistant coatings or stainless steel materials.

Well, what if there is no possibility to make a complex contour, T-bolt clamps? In this case, they are made of two parts — a bracket-rails with recesses for the bars and feet-the studs. This design of tracks shown in figure 2; at the same time he explains how to upgrade the regular tracks of the snowmobile “Buran”.

Finally, if the designer ran out of tapes of the desired width and caterpillars have to collect from a number of narrow, it is recommended to connect the strips at the location of the Windows, and the dock to execute, as shown in figure 3. Spacer between the strips is cut from the same tape, and the individual elements within are connected by laths, on which lie spacers, and all this together with rods ringed clamp. It is the least acceptable option; however, this caterpillar was on tests 300 km along spring road.

In the manufacture or repair of caterpillar you have to use a lot of detail. However, they are easy to manufacture, and their individual elements — the grooves, chamfer — can be treated in the kit. If there is a possibility to make the stamps, the work will be simplified and speeded up.

Yu PAVLUSHIN