The brace is made of rectangular tube 40X25 mm and is welded to the second strut lower side members and the transverse element of the upper part of the frame.

On the rack and the strut has a plate and the corner attachment points of engine “T-200”. The third node, the channel with the groove under the bolt adjustment is located on the plate of steel sheet of thickness 3 mm, welded to the lower longerons.

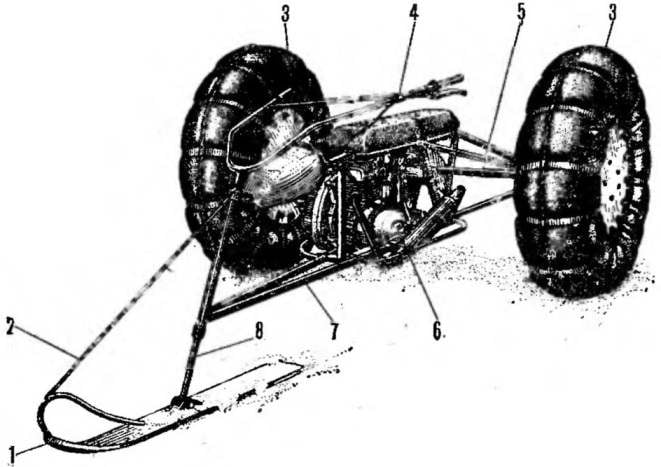

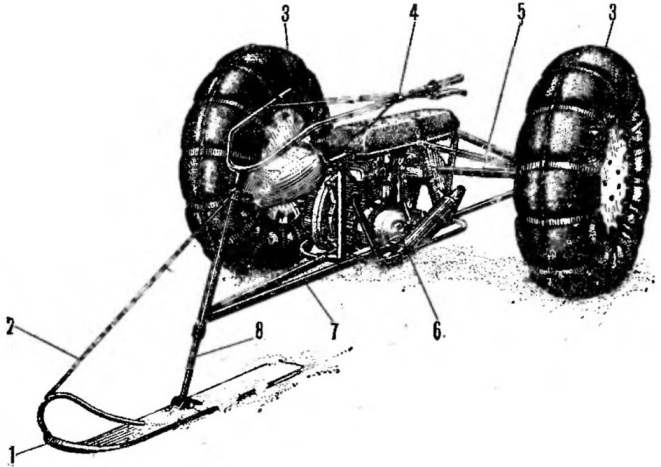

General view of the snowmobile:

1 — ski with shock absorber, 2 — elastic cord, 3 — camera low-pressure, 4 — rudder, 5 — rear axle, 6 — motor, 7 — frame, 8 — steering linkage.

Frame with the rear axle:

1 — bottom rails, 2 — step, 3 — first strut, 4 — pole adjustable mount engine, 5 — second spacer, 6 — steering bushing with bearings, 7, 9 — the point of attachment of the petrol tank, 8 — longitudinal pipe, 10, 11 — kerchiefs, 12—, 13, 14, 15 — knots motor mounts, 16 — brace, 17 — pipe of the pyramid base of the bridge, 18 — cheek, the 19 — lower bunch of 20 — cross member, 21 — bolt M12, 22, 25 — upper cords, a 23 — axle flange, 24 — edges of the pyramid, 26 — asterisk bridge.

Ski with the steering rod:

1 — pen-absorber, 2 — ski, 3 — the steering rod, 4 — thrust washer 5 — stud, 6 — axis, 7 — bracket 8 — edge 9 — axis thing.

Fuel tank capacity 20 l (from a motorcycle “Lang”) installed on the longitudinal pipe.

Frame rear axle are made largely from tubes 25X25 mm in two stages. First I welded the right and left of the pyramid, and then they were joined by ligaments: lower (steel strip 3 mm thick) and upper (segments of rectangular pipe 25 X 25 mm).

In the top of the pyramids welded the bearing housings beneath the axles of the car “Moskvich-407” and the reason cheek is welded (steel strip of 3 mm thickness), between which is a differential from the “Moskvich-407” with a homemade cover and band brake.

The differential bearings pressed into the aluminum case is screwed to the cheeks, and the driven gear replaced a sprocket with 72 teeth. 10-bevel sprocket of the engine it connects the chain with a pitch of 15.9 mm Flanges axle shafts machined to a thickness of 5 mm.

Frame and rear axle have four butt knot or two on top and two on the lower spar and are connected by three bolts M12. A single bolt tightens upper cross member of the frame and the first bunch of bridge, the rest bottom rails and bushings, welded in the corner of the base of the pyramids.

The wheels of a snowmobile are a combination of cameras from the trailer to the tractor K-700 and discs made from plywood 10 mm thick and tubular steel axles and aluminum cradle. Camera strapped, rubber-fabric belts conveyor belt thickness of 8 mm.

External disks with a diameter slightly larger than the inner, as when riding along the slopes of the driver of the snowmobile, trying to maintain the vertical position of the body, is deflected in the direction of the wheel going up the hill, and it loads in addition. On the wheel with a smaller disc camera turned for it, and “izdevalis”, because the air pressure is only about 0.3—0.4 kgf/cm2 . Here this does not happen. To the flanges of the axle the wheels are attached with five bolts M10.

Ski is curved from plywood and equipped with axial ridge, edge, shock absorber and steering rod.

The skate is made of steel strip thickness of 3 mm; the ski is attached with pins M3, welded thereto with a step 200 mm. Protect the plywood from abrasion edges screwed by screws.

Shock absorber (tube Ø18X1,5 mm) performs two functions: it protects the toe of the ski from damage when hitting an obstacle and when carrying the snowmobile serves as a handle. To it is attached an elastic cord that keeps the ski in a good condition.

Install differential (casing removed):

1, 10 — left and right axle shafts, 2, 9 — cheek, 3 — bearing, 4, 7 — screws M8, 5 — bearing, 6 — differential housing, 8 — stars.

Install the axle shaft:

1 — bearing housing, 2 — o-cuff, 3 — axis, 4 — edge of the pyramid (tube 25×25 mm), 5 — mounting flange, 6 — bearing cover, 7 — screw M8, 8 — axle flange, 9 — worn part of the flange.

Steering wheel:

1 — sleeve, 2 — tube, 3 — strut, 4 — rope of gas, 5 — clutch cable.

Wheel:

1 — external drive 2 — spindle, 3 — bed, 4 — rubber-fabric belt, 5 — internal disk.

The steering rod is machined from steel rod, has a flatted for the helm, neck, under the sliding bearings, thrust washer and end of axle.

The steering wheel twisted from steel pipe. In its center at an angle of 30° is welded on the bushing with two holes: a dull and through. In the first part of the top steering rod flatted in the second retaining bracket pin. Half the rudder is connected to the rigidity of the spacer pipe Ø18X1,5 mm and provided with control handles of the scooter: on the right the Gaza strip, the tear is the clutch lever.

The driver sits on the seat, which is installed on the upper spars over the engine.

A. TIMCHENKO

Recommend to read “Pocket” velomobile Most velomobile designs feature a rigid connection between the frame and wheel axles. This places increased demands on the quality of a number of parts that cannot be produced at home. The... MINIMAX: BIGGER ON THE INSIDE CAR — FOR WHAT? You need a car? What? This question confronts everyone who intends to buy a car manufactured in the factory. But as you know, choosing the right type of machine is...  Simplicity of design “Harp” is perhaps unique. In the car a total of six main parts: frame, engine, rear axle, wheels, ski with the steering rod and steering wheel. Reliability and simplicity of the snowmobile complies with the standards that apply to vehicles intended for Autonomous runs over a vast and desolate regions of the Arctic. “The harp” easy to disassemble and in the back of a truck or in the baggage car to transport to the launch site, and there is to collect hours. and a half and to travel.

Simplicity of design “Harp” is perhaps unique. In the car a total of six main parts: frame, engine, rear axle, wheels, ski with the steering rod and steering wheel. Reliability and simplicity of the snowmobile complies with the standards that apply to vehicles intended for Autonomous runs over a vast and desolate regions of the Arctic. “The harp” easy to disassemble and in the back of a truck or in the baggage car to transport to the launch site, and there is to collect hours. and a half and to travel.