In the journal “modelist-Konstruktor” No. 11’1991 I met the description motoart — tracked snowmobile, designed by brothers Matveichuk of Zavodoukovsk Tyumen region and named them “Idea-2”. The car I liked. For me, a villager, she seemed an indispensable means of transport in winter, but as for the homebrew — it is executable, even with my poor equipment of the home workshop. And there are in it: welding machine, grinding machine, drill, Yes, the usual bench tools.

In the journal “modelist-Konstruktor” No. 11’1991 I met the description motoart — tracked snowmobile, designed by brothers Matveichuk of Zavodoukovsk Tyumen region and named them “Idea-2”. The car I liked. For me, a villager, she seemed an indispensable means of transport in winter, but as for the homebrew — it is executable, even with my poor equipment of the home workshop. And there are in it: welding machine, grinding machine, drill, Yes, the usual bench tools.

Experience of manufacturing all-terrain vehicles I already had — I built the wheel (on the tires) and wheel-ski ATV. A photograph of one of them was published in the “Modeller-designer” № 1, 1991 in category “Panorama photos of readers ‘letters”.

However, the manufacturer Motonari was delayed for years — that there were better things to do, the times were such that they could not buy even the electrodes. Tried for a long time and the design to be improved so that the machine was versatile for any time of year: it is enough to change gear, and motonarty would turn to a pneumatic or Quad. But this greatly complicates the design and implementation of it at home is not possible. In the end decided to make two machines: motonarty and the Quad, moving from one to another, only the engine.

Circuit of the snowmobile is used the same as in the machine of the brothers Matveychuk: tricycle with two front control ski and one caterpillar leading from behind. This arrangement promised the car a good permeability and stability, which is important when driving on rough terrain without roads. Only here the driver’s “Idea-2”, as on the Vespa, I was not satisfied. I was more familiar, and easier to drive the bike, sitting on it as the motorcycle — riding. But because the layout of the power unit with the transmission of the snowmobile ran the same, like a motorcycle, with even the controls to alter is not required.

The frame of my car, in contrast to the spatial frame of the snowmobile of the brothers, a simple — motor (spinal) type with cantilever beams (traverses). The material of the main longitudinal steel channel 40x40x4 mm. the Upper part (bolt) matched finished (moped “Carpathians”), It is quite a complex configuration. But it is not caused by any necessity. Therefore, in the figures of her form simplified.

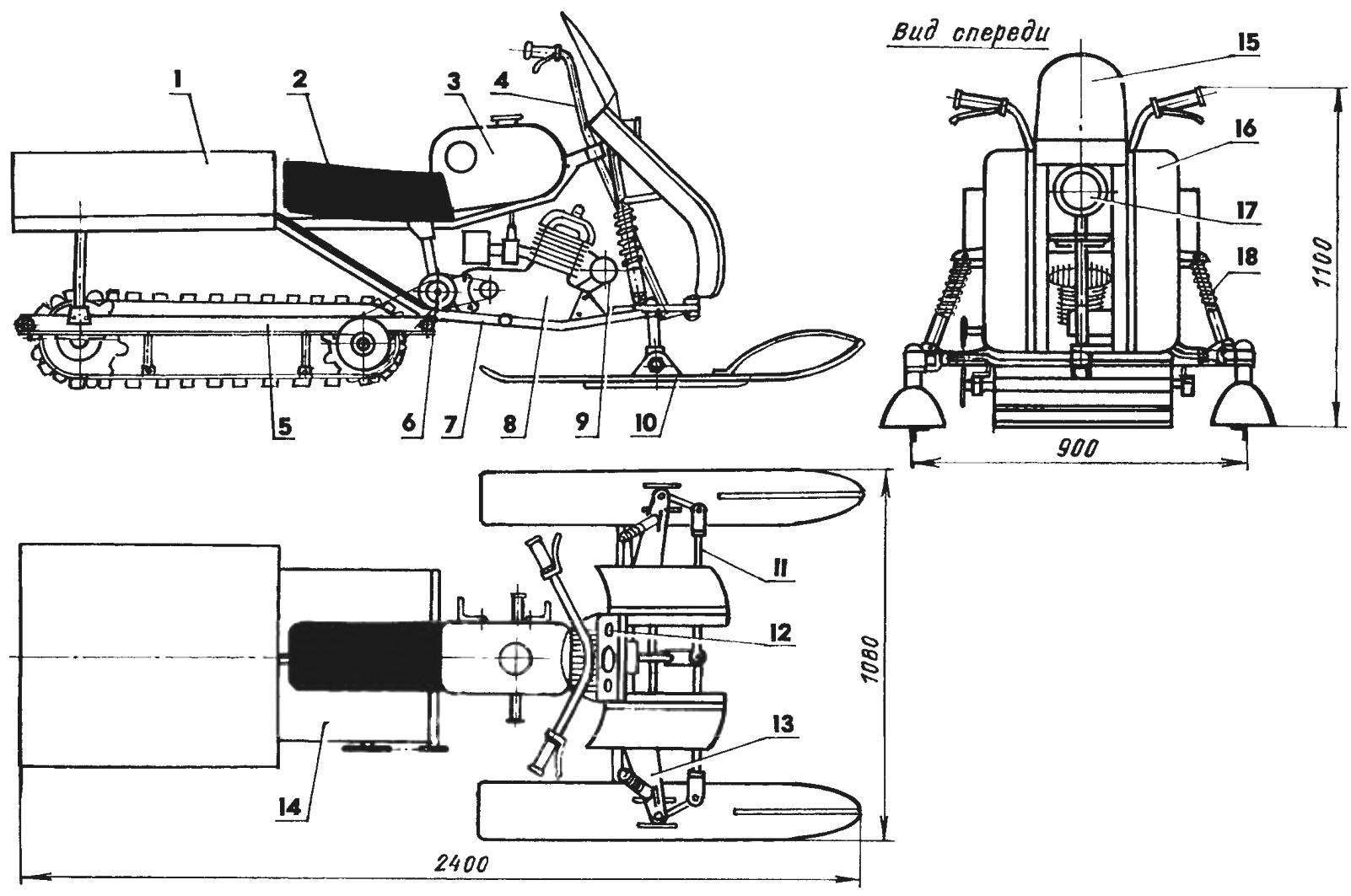

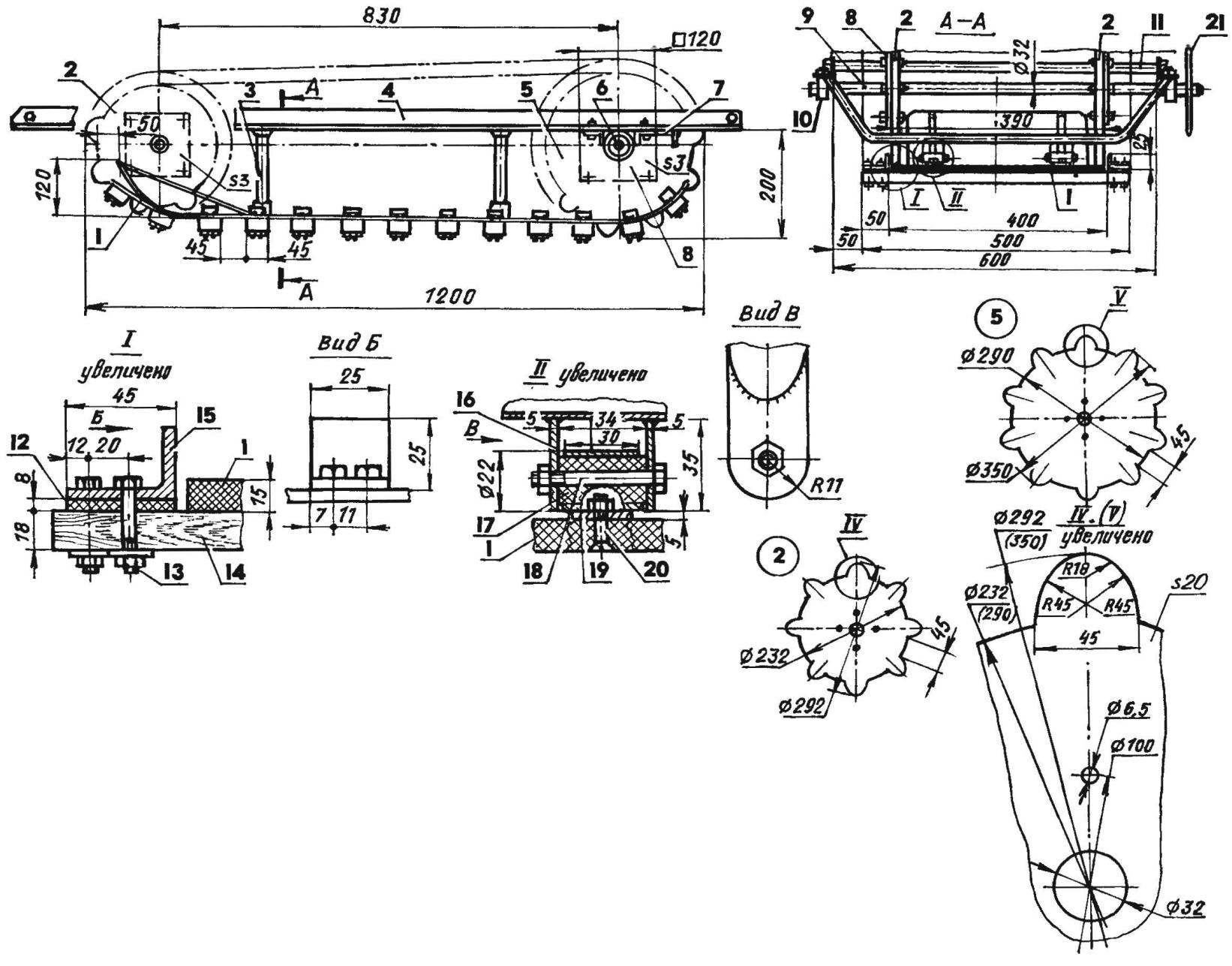

Motonarty:

1 — body (St3, sheet s0,8, border – area 25×25); 2 – seat (from a motorcycle “Voskhod-3M”); 3 — fuel tank capacity 6 liter (from moped “Karpaty”); 4 — steering wheel (from a motorcycle “Voskhod-3M”); 5 — tractor unit (mover); 6 — intermediate shaft; 7 frame; 8 — power unit (from a motorcycle “Voskhod-3M”); 9 — the muffler; 10 — the management of the ski (2); 11 — tie rod (from sidecar С3Д); 12 — instrument panel (from a motorcycle “Voskhod-3M”); 13 — arm (motorized С3Д); 14 — snegozaderzhateli shield (made of anodized aluminum, sheet s1); 15 — windshield (plexiglass); 16 — wind deflector (made of anodized aluminum, the sheet s1, 2 PCs.); 17 — headlight (from a motorcycle “Voskhod-3M”); 18 — shock absorber (from a moped “Karpaty”)

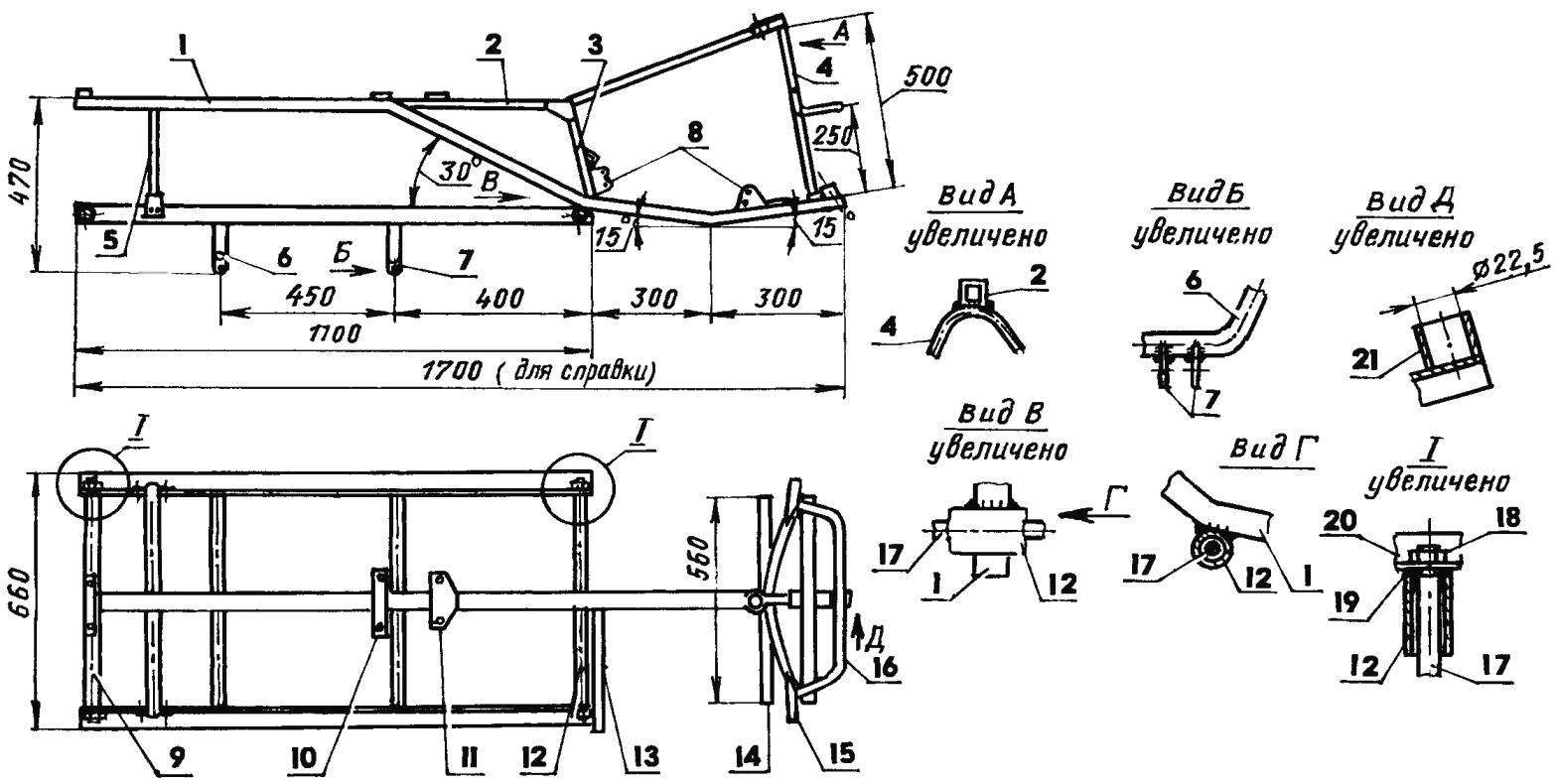

The frame of the snowmobile and sub-frame of the tracked unit:

1 — the main spar (channel 40x40x4); 2 — the upper bolt (from the moped “Verhovina”); 3 — front seat (tube 30×30); 4 — front (tube Ø28); 5 — podgotovka reference loss (pipe 1/2″); 6 — front support ski (tube 1/2″, 2); 7 — eyelet bracket for supporting ski (St3, the sheet s5, 8 pieces); 8 — mounting brackets of the power unit; 9,12 — back and front crossmember (tube 1″); 10 — mounting bracket of the body (St3, sheet s4. 2); 11-bracket for seat mounting (St3, sheet s4); 13 console mounting the intermediate shaft (area 60×60); 14 — front of the beam (from cars 2); 15 — mounting bracket of the shock absorber (passenger car, 2 PCs); 16 — arc (pipe 1/2″); 17 — coupling (stud Ø18, 2); 18 — a nut M22 (4 PCs); 19 — nylon bushing (4 PCs.); 20 — the spar of the subframe crawler block (area 60×60, 2); 21 — glass steering shaft (pipe Øвн. 22,5)

Crawler unit:

1 — reference of the ski (nylon, sheet s15); 2 — sprocket drive caterpillar; 3 — support skiing; 4 — longitudinal subframe crawler unit; 5 — driven (idler) sprocket (nylon s20, z = 10, 2); 6 — axis of the driven tension stars (pipe Ø32); 7 — tensioner caterpillar; 8 — sprocket flange (St3 sheet s3, 4x); 9 — drive shaft caterpillars (pipe Ø32); 10 — bearing 80204 in the housing (4 PCs); 11 — front cross member of the subframe and axle crawler unit; 12 — fastening tape (rubber conveyor belt 45×8, 2); 13 — М6х40 bolt with washer (112 pieces); 14 — sagaseta (birch plank 45×18,L500, 28 pieces); 15 — guide (made of anodized aluminum, area 45×25, 56 PCs.); 16 — lug bracket-reference of the ski (St3, the sheet s5, 8); 17 — a rubber bushing (4 PCs.); 18— axis (bolt М8х50, 4 valves); 19 — bracket-reference of the ski (4 PCs); 20 — a bolt М6х35 flat head screws (8 PCs.); 21 — sprocket (z = 32, motor)

The front Desk is made of steel pipe with a diameter of 28 mm in the form of forks, the lower ends rest on the front beam, taken together with the suspension arms from the car (a beam shortened, and the levers used only the bottom). Crossmember sub-frame of the crawler block of steel. Ties are inserted into them through a nylon bushing. The console under the intermediate shaft is made of area 60×60 mm. brackets for mounting the seat and body — steel 4-mm strips.

Subframe crawler unit is also of simple design based on two longitudinal members made of a steel angle 60×60 mm. the side walls are drawn together with crossbars; front welded to the frame of the snowmobile. From the bottom to the side members are also welded two curved legs skiing crawler block, and the top is attached with bolts M8 curved Luggage rack. All racks are made of half-inch steel water pipe.

According to initial estimates, a snowmobile as a power plant supposed to use the engine of the motorcycle terrain “Tula” working volume of 200 cm3 and a power of 13 HP with forced air cooling.

In this case it would be the front of the snowmobile close to the traditional machines of this type the hood-cowling, which significantly improved the ride comfort, especially in the cold and with a headwind.

However, the “Tula” engine at a reasonable price for me to purchase failed and the car had to match an old, renovated power unit (motor with transmission) from a motorcycle “Voskhod-3M”. The power even a little more (14 HP), while the displacement less (175 cm3). However, forced cooling had not. So the hood had to be abandoned, but instead to install two wind shield (like mud) with a gap therebetween, which passes airflow for engine cooling.

The transmission on my motonartah a bit more complicated than on a snowmobile “Idea-2”, — with intermediate shaft. But the shaft was not more than a link — having sprockets with a different number of teeth (22 and 12), it performs the role of the gearbox (or as the locals call it the homebrew, “Horomerice”). Rotation from the gearbox to the power unit on the intermediate shaft and the drive shaft of the crawler block is effected by a chain gear. The tension of the chains is governed by the plates, placed under the bearing housings of the intermediate and drive shafts.

Crawler block is the most difficult of improvised knots. Experience of manufacture I had, therefore, focused on the design and dimensions of the details given in the journal. Since the publication of old and young readers-homebrew this magazine is not, I think, is to give pictures of the unit, its main components and parts again.

Of course, some differences in design and materials from my crawler unit is, and although they are not

so important and significant to focus attention to them, I think I should.

Thus, the shaft bearings and axles in my crawler unit no 203, 80204 — they are bigger, and have on both sides of the separator shields. Reference ski — fully nylon. I did not include the side rails brass — with the correct (parallel) setting axis relative to the drive shaft and a good tension of the caterpillar to the side of not taking. Operation of a snowmobile showed that instead of the rear sprocket is better to use rollers, which can be easily manufactured of the same veins, cutting off their teeth, which I subsequently did. Bolts planks-tracks to tape is protruding ends with nuts to the outside; now they work like spikes the tires of motorcycles for ice Speedway — provide good grip and with Packed snow on the road, and with the solid present in the field, and with ice on the river or lake.

Front control skis made from wooden boards with a thickness of 15 mm and a width of 180 mm. Socks ski the steam out in boiling water and bent in the template to dry. Then impregnated with varnish and sheathed lower aluminum sheet. To the sole attached in the middle of the guide slider of duralumin corner 25×25 mm.

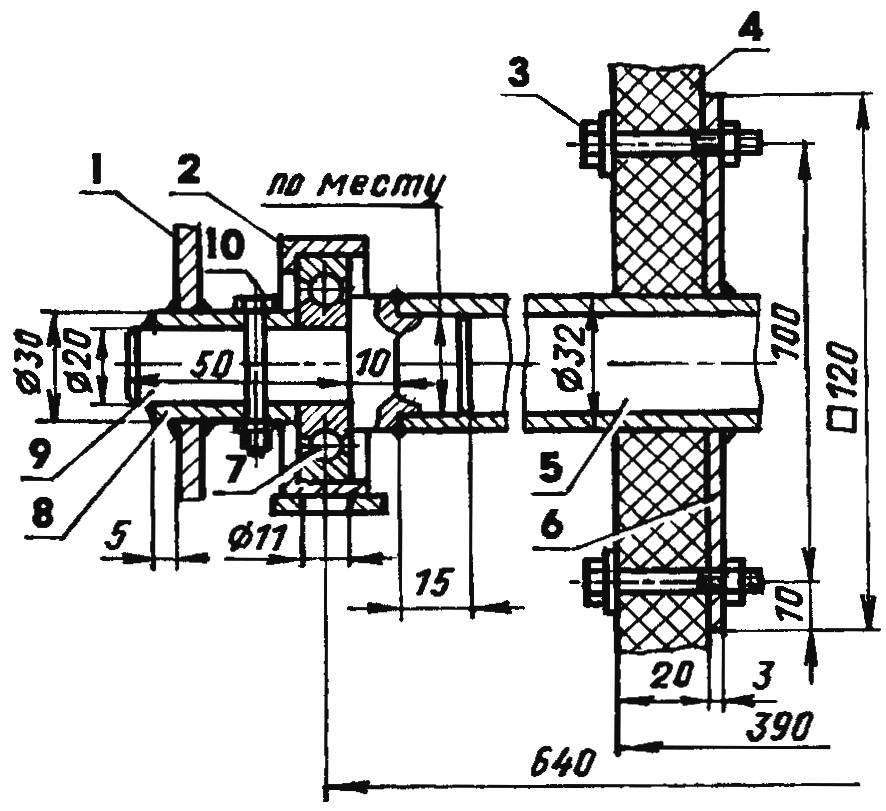

Drive tracks:

1 — chain sprocket (z = 32, motor); 2 — bearing; 3 — bolt M6 fixing crawler sprocket to the flange (4 PCs); 4 — leading crawler sprocket (z = 8, 2); 5 — tubular shaft of a driving axle; 6 — flange caterpillar sprocket; 7 — the bearing № 80204; 8 — hub sprockets (St3, pipe Ø30×5); 9 insert (St3, circle Ø32); 10 — pin (bolt M8)

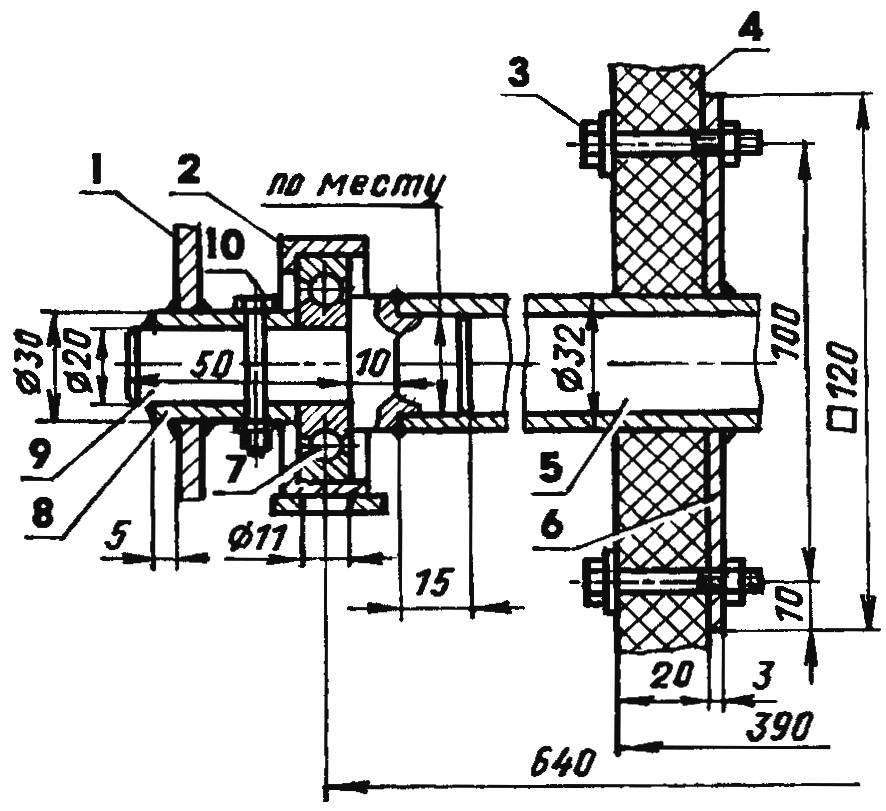

Steering ski:

1 — ski (aspen Board 180×15); 2 — sole (aluminium, sheet s1); 3 — guide (dural area 25×25); 4 — clip (steel tube Ø10); 5 — support bracket (St3 sheet s3); 6 — fork rack (u-joint); 7 — (St3, circle Ø32); 8 — casing the knuckle (St3, rough Ø32); 9 plug tie rod (u-joint); 10 — hinge (bolt M8); 11 — knuckle with bushing; 12 — pin (bolt M8); 13 — bushing (bronze, 2 pieces); 14 — axis (M12 stud with two nuts); 15 — Bush (nylon, 2); 16 — the case of the hinge (tube 1/2″)

Ski reference:

1 — screed dural tube Ø10 4 pieces); 2 — bracket (4 pieces); 3 — ski (nylon, s15); 4 — M6 bolts with countersunk heads mounting brackets (8 PCs)

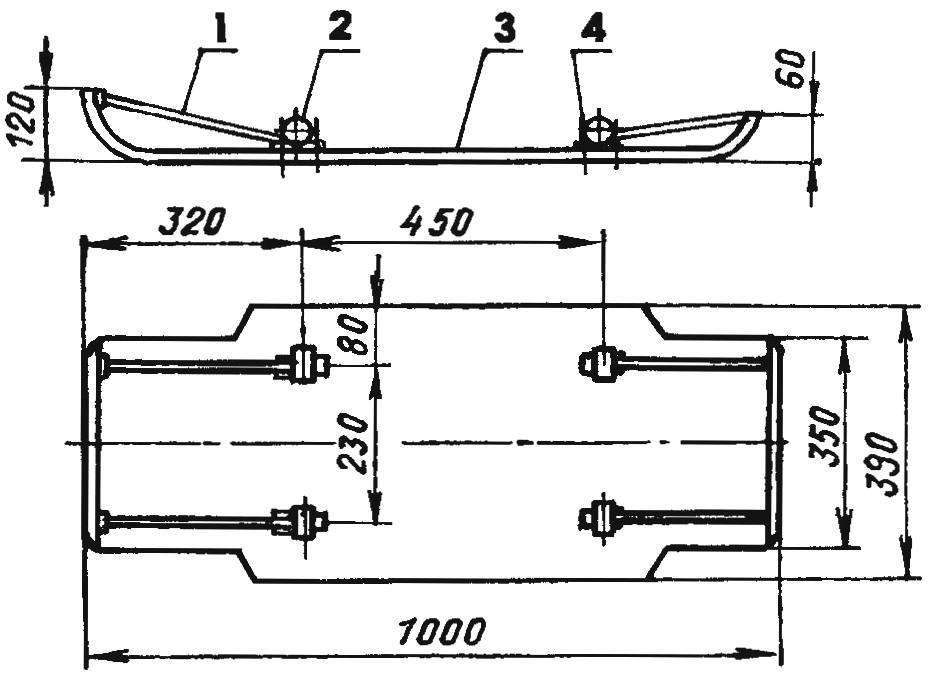

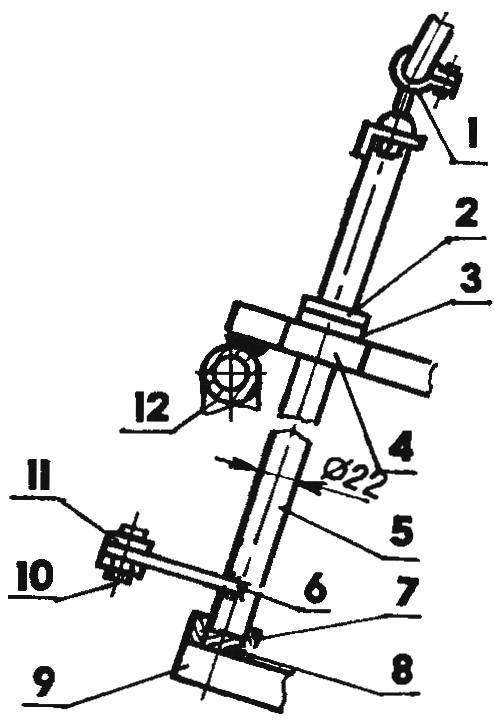

Steering:

1 — steering bracket (from a motorcycle “Voskhod-3M”); 2 — collar of the steering shaft; 3 — washer (bronze); 4 — bushing; 5 — steering shaft (pipe Ø22); 6 — a Pitman arm (St3, the sheet s10); 7 — glass (tube Øвн. 22,5); 8 — thrust bearing (bronze); 9 — the main spar of the frame; 10 — joint (M10); 11 — tie rod (2 PCs); 12 — front support leg frame

Rack steering ski mounted in the housings-bushings attached to the ends of the steering knuckle arms, taken from a passenger car. Levers are sprung shock absorbers with springs from an old moped. Ski control is carried out using the modified rods from the sidecar (regular tips from rods replaced plugs universal joints) connected to a bipod attached to the end of the steering shaft.

All the equipment of the snowmobile; a seat, handlebars, headlight, signal, electrical appliances, as well as the power unit from an old motorcycle “Voskhod-3M”.

The trunk — welded sheet steel 1 mm thickness bottom for rigidity banded area 25×25 mm fuel Tank capacity 6 liter — bike. Under-seat mounted tool kit. Caterpillar under the seat to the driver’s legs got less snow, covered with duralumin sheet. For protection from the oncoming air flow to the torso and face in addition to the front flaps over them strengthened windshield.

The construction of the transmission and propeller allows the machine to do without brakes, rolling almost none.

Cost accounting for the construction of a snowmobile is not produced — it would have to do quite carefully, because spent not a lot, because basically used someone once thrown (and I selected) units, units and mechanisms, waiting for their hour in the yard Arsenal.

Spent time dead is not considered, since in addition to design experience, additional skills for working with metal and moral satisfaction from made with his own hands machines the result is a vehicle that is much needed in agriculture for transportation of various cargoes and in General to quickly overcome large distances, even in the deep snows of our Northern region in a long winter.

A. STARTSEV, p/o Monastyrskaya Pashnya, Arkhangelsk region.