Two years of hard work in their spare time (evenings and weekends) spent on the creation of design calculations and design drawings. In the end we made a good car for getting around sturdy Amur ice with snow dunes.

The frame of the snowmobile is easy and simple, consists of two side members and four cross members. And those and others are made of spruce wood spars — from 100×50 timber section, and the crossbar — boards 140×30 mm Spars on the bottom and on the outside is edged dural area 50×50 mm All frame parts fastened together with M10 steel bolts with a length of 130-150 mm. Under the bolt heads placed steel washers with a diameter of 50×10,5 mm and 3 mm thick. the Top frame lined with waterproof plywood with a thickness of 5 mm, which serves as the floor.

Under engine frame — spatial (frame), made from duralumin tubes with a diameter of 22 mm from the old cots with railings propeller. Attached to the frame of the snowmobile at the rear part thereof by the same bolts that held together the side members and the cross member.

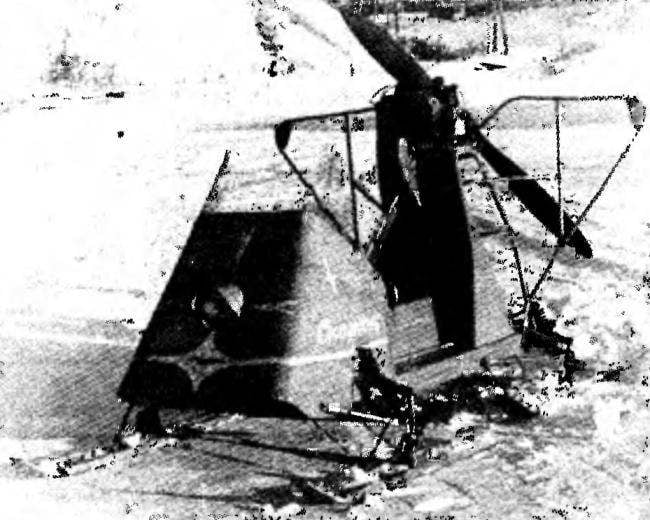

General view of the snowmobile:

1 —fairing (aluminium, sheet s0,3); 2 — windshield (plexiglass); 3 — wheel (road bike); 4— frame; 5 — sub frame (aluminum pipe 22×3); 6 — motor; 7 — reduction gear (I = 3); 8— propeller (bakelite plywood is waterproof, s70); 9 — clutch (motorcycle Voskhod); 10—right (green) marker light; 11 — fencing of the propeller (dural tube 22×1,5; 12 — left (red) marker light; 13 light; 14 — suspension the front of the ski; 15 — tie rod (020 dural tube); 16 — suspension rear ski; 17 — strut suspension rear skis (dural tube 22×1,5); 18— ski (aluminum, sheet s4, s5 plastic); 19 — mine duct (aluminum, sheet s0,5); 20— seat-trunk; 21— strut front suspension skis; 22— spring and cable.

Frame:

1 —spars (spruce, timber 100×50); 2— cross (spruce, Board 140×30, 4 pieces); 3— amplifiers spars (aluminum, area 50×50); 4— M10 through-bolts with two washers (8 PCs.)

Longitudinal section of modernized engine:

1,16,17,24,25 —side of the crankcase; 2 — ball bearing 205 (3). 3 — the sealing cuff (2); 4 — flange (aluminum); 5 — crankshaft; 6 — gasket set; 7 — rod; 8 — cylinder; 9 — asbestos gasket; 10 — piston with two rings; 11 — cylinder head; 12 — fin air cooling; 13— the bearing 36205; 14 — flywheel magneto; 15 —base of magneto; 18 — pinch bolt detachable parts of the crankshaft; 19 — segment dowel (2 PCs); 20 — spool spring steel (2 PCs); 21 — a nut of fastening of the valve (2 PCs); 22 — bushing spool (2); 23 — sealing ring (2 pieces)

Front cowl-fairing and rear air shaft is made of aluminum sheet of 0.3 mm thickness. On the fairing mounted windshield, under the mine — barred rumble strips that protect the screw from passivhauses chunks of ice rising into the air from under the front of the ski.

In the middle of the frame mounted Luggage box with a frame made of aluminum angles, sheathed 4 mm plywood. The trunk lid is lined with foam and leatherette and serves as a seat for the driver and passenger. On the right side of the trunk fixed lever cutoffs of coupling. Part of the cargo placed in front, under the hood, canister with extra fuel in the back under the engine frame.

Powertrain. The engine of the outboard motor “hi-22” reworked the description and drawings, given in the mentioned publication of the journal. But since the article is old and to see her readers is not always possible even in libraries, I think will not be superfluous to publish once again the drawing of the longitudinal section converted engine. The fact that such upgrading is, we think, the practical meaning today. Moreover, the industry these “hybrid” motors are not released, and the demand for them probably would have been, because the motor is very compact and at the same time is powerful enough (up to 30 HP at 5800-6000 rpm).

For the installation of “voshodyaschih” cylinders “privateusa” the Carter in its detail (it consists of several parts) was switched dural threaded plugs the old holes for studs M8 and next in accordance with the drawing (Fig.4) the holes in the cylinders with holes a depth of 25 mm under the same studs.

In the magazine was mentioned is another way of securing cylinders to the crankcase with the help of pins, each of which consists of two rods with thread M8 on the ends, welded lapped to each other. Maybe someone such a mounting method would be more acceptable, so driven and drawing of the special studs. Only at the bottom edges of the cylinders are at a height of 35 mm with oval holes dual part of the studs.

For installation in series of two cylinders with a centre distance of 142 mm for the fins to their heads with the opposing sides were shortened by 10 mm. In places of connection of the exhaust nozzles of the jumper between the ribs propylene for through passage of air.

The cylinder sleeves are cropped from the bottom to 5 mm, and the cut-outs in them increased to 35 mm in width and 25 mm in height (to match with the edges of the vent channels in the crankcase).

± ½ “Installation dimensions for threaded rods M8 for crankcase motor “hi-22″ under the cylinders of the engine Voskhod” src=”http://modelist-konstruktor.com/img/1564/5.jpg” style=”width: 408px; height: 300px” />

Installation dimensions for threaded rods M8 for crankcase motor “hi-22” under the engine “Rising”:

1 —axis closed up the holes in the crankcase “Hello”; 2—the contour of the purge channel “Sunrise”; 3 — contour of the venting channel, “Hi”; 4 — additional purge channel “Hello”; 5 — new holes in crankcase (holes in the cylinders “Sunrise”)

Special stud cylinder mounting “Sunrise” to the crankcase “Hello”

The transitional strip of fastening the carb to the engine

Dural flange crankcase

Crankshaft seal for “outboards” is not in the crankcase, and on the sub plate of the deadwood. As the need for the stove disappeared, the hole in the crankcase closed new dural flange, in which is mounted a lip seal under the root diameter of the supports of the crankshaft (25 mm).

In our case, the alteration was subjected to another and the output end (square cross section) of the crankshaft. He was simply cut off, and the shaft end is made of the axial threaded hole M18 x 1 depth of 20 mm.

When installed on a motor “hi-22” cylinder engine “Sunrise” between the cylinders and their heads set strip, which stood on the “Hi”, otherwise the motor would overheat even in the winter, because the volume of the combustion chamber is small.

We have had a compact gear with a gear ratio of i = 3 of the internal combustion engine, D-300, which we used in the transmission of the power unit to reduce the number of revolutions of the propeller. But first some details of the reducer is also altered. Thus, the shaft of the small gear was replaced with a more long and slender, Second from the gearbox end of the thread PI thread M18 x 1 20 mm long and combined it with the crankshaft of the engine. The shaft of the large gear is also machined the other is under the grip of the motorcycle “Voskhod”. The drum of the clutch disks and springs mounted on the hub of the propeller. “Squeezing” the clutch — lever via Bowden cable from the driver’s seat. Engine now warms up without rotation of the screw, which is especially useful in extreme cold. Besides increased safety.

Puck cutoffs of coupling rotates together with the shaft gear and crankshaft. We made washer eccentric and connected to it a lever of the fuel pump. The carburetor from a motorcycle “IZH-u-3” was connected to the engine via the aluminum transition spacer. Because the snowmobile is a winter form of transport, the carb has provided a heated, sending him the flow of air through the aluminium tube 40 mm diameter cylinder. This provides good mixing, and the carb is not covered with frost even in frost.

The power unit is mounted on under engine frame. The exhaust pipe lowered through the shaft of the engine coolant under the floor frame, which has a simple flat muffler.

The standard fuel tank from the boat motor, removable. To refuel, you can move it, not driving there snowmobiles, and then reinstall by connecting the hose of the fuel pipe. The pump— boat engine Neptune, operated via a lever arrangement from a Cam on the shaft.

Propulsion — propeller. It is made of plywood billets with dimensions mm. 2000x100x70 Processing, in turn, glued under pressure from 4 mm strips of a ship bakelizirovannoj plywood. The screw was calculated independently for publication in the journal “modelist-Konstruktor” No. 8 for 1979 But it would be nice if the help in this question had a specialist. Suffice it to say that we did five propellers before they got to meet us mover on optimal weight and good traction. Its parameters and given: diameter of 1860 mm, H = 900 mm R = 600 mm.

The suspension of the skis of the snowmobile (a — the front of the ski, b — back skis):

1 plate-trim (St3, sheet s6); 2 — eye (St3, the sheet s4,6 PCs); 3 — Teflon washer (s3, 10 PCs); 4 — absorber with coil spring (of the scooter); 5 — M10 bolt; 6 — the lower and upper pendulums; 7 — stand with clamps (steel pipe 22×3); 8 — pins (45 steel, rod d16); 9 — bearing (PTFE s5, 2 PCs); 10—bracket (St3, sheet s4); 11 — pivot arm (St3, sheet s4); 12 — axis skis (bolt M16); 13 — hog (St3, sheet s4); 14—ski; 15 — undercut the front of the ski;

The design of the ski:

1 — sole (plastic, sheet s5); 2 — (aluminium, sheet s4); 3 — rib (wood, timber, 30×30, 2 PCs.); 4 — mount of the pylon (steel, area 50×50, 2); 5 — rivet

It is probably superfluous to describe the craftsmanship of screw — machining and finishing of each size and profile of the blades, their polishing and colouring balancing. The ends of the blades are bound by copper sheets of thickness 0.5 mm.

The chassis and suspension. For snowmobiles, we chose chetyrehosnuju scheme. It provides the best stability in corners, compared with trehmernoi, and has only two tracks, the rear skis are on the track already laid to the front, which is important when driving on virgin snow. Ski made of sheet aluminium with a thickness of 4 mm and lined with plastic. The strength of the ski is provided with the mounting bracket bore and the two wooden bars 30×30 mm. All skis are proportionate: length 1400 mm, and the average width is 210 mm (the front is 10 mm wider than the rear). Suspension each ski independent, and their rotation axis in the vertical plane is limited by the wires attached to the frame, and springs reverse. The shocks on the front skis from the scooter, and on the back, given that they load much more from the motorcycle “IZH” with springs from a motorcycle “Ural”. Each ski with a suspension mounted on a vertical plate-lining, and the lining is attached to the frame rails. The front steering skis. Ski racks have the ability to turn in the brackets, connecting them with cover.

The front ski is made with handlebars. The tie rod connecting the swivel brackets of skis, made of aluminum pipe with a diameter of 20 mm. the Snowmobile is equipped with a lever brake.

Electrical equipment only the most necessary front — motorcycle headlight, left — red, right — green lights (mounted on the ends of the pipe fence of the propeller). Their power from a flywheel magneto with a power of 40 watts, which is enough. On the dashboard are: button engine stop and an audible signal; a switch headlights and tail lights; remote thermometer with a scale from 0 to 120 °C (inlet capillary wire to it — a length of 4 m).

Length with skis, mm 33002 12 712

N. PAKHOMOV-the-father, N. PAKHOMOV-son, the city of Nikolaevsk-on-Amur, Khabarovsk Krai

Recommend to read FIREPLACE FOR BEES Research scientists and experience of beekeepers show that with a good supply of benign feed and caring the contents of a winged honey bee plants can stand the winter even when severe... DISAPPEARING STAIRS Now, not only in large suburban homes or cottages tend to use pokrysheva space as the attic, even in small garden houses are cut in the ceiling hatch and equip the bedroom there (see a...

Scroll back to top

It all started long ago, with one of the publications in the journal “modelist-Konstruktor” No. 5 of 1981, a binder which we keep, and from time to time viewed. In the article it was about the alteration of the outboard motor “hi-22” with water cooling for air. This upgrade gave us the idea to use a similar engine to create a snowmobile as a motor, although not new, we have had, and the need for such a machine was considerable. A good helper, the magazine has become and also, the design of the snowmobile.

It all started long ago, with one of the publications in the journal “modelist-Konstruktor” No. 5 of 1981, a binder which we keep, and from time to time viewed. In the article it was about the alteration of the outboard motor “hi-22” with water cooling for air. This upgrade gave us the idea to use a similar engine to create a snowmobile as a motor, although not new, we have had, and the need for such a machine was considerable. A good helper, the magazine has become and also, the design of the snowmobile.