Designers snowmobiles operating in rural areas, and most — often used parts of decommissioned tractor Puscuta PD-10 propeller systems for their cars. It is clear and logical: the engine PD-10 is widely distributed in agriculture, it is necessary to recast it we option is not the challenge. Accumulating the experience of operating planes with such engines, the designers achieve a very noticeable increase their performance by improving purging, selection of carburetors, etc. it is safe to say that at present, a single “rural” snowmobile engine, created on the basis of the PD-10 are the most proven and reliable machine. It should be added that in the construction of chassis, control systems, etc. in recent years also created a lot. According to the editorial, timely information about these updates can assist the novice builders.

Designers snowmobiles operating in rural areas, and most — often used parts of decommissioned tractor Puscuta PD-10 propeller systems for their cars. It is clear and logical: the engine PD-10 is widely distributed in agriculture, it is necessary to recast it we option is not the challenge. Accumulating the experience of operating planes with such engines, the designers achieve a very noticeable increase their performance by improving purging, selection of carburetors, etc. it is safe to say that at present, a single “rural” snowmobile engine, created on the basis of the PD-10 are the most proven and reliable machine. It should be added that in the construction of chassis, control systems, etc. in recent years also created a lot. According to the editorial, timely information about these updates can assist the novice builders.

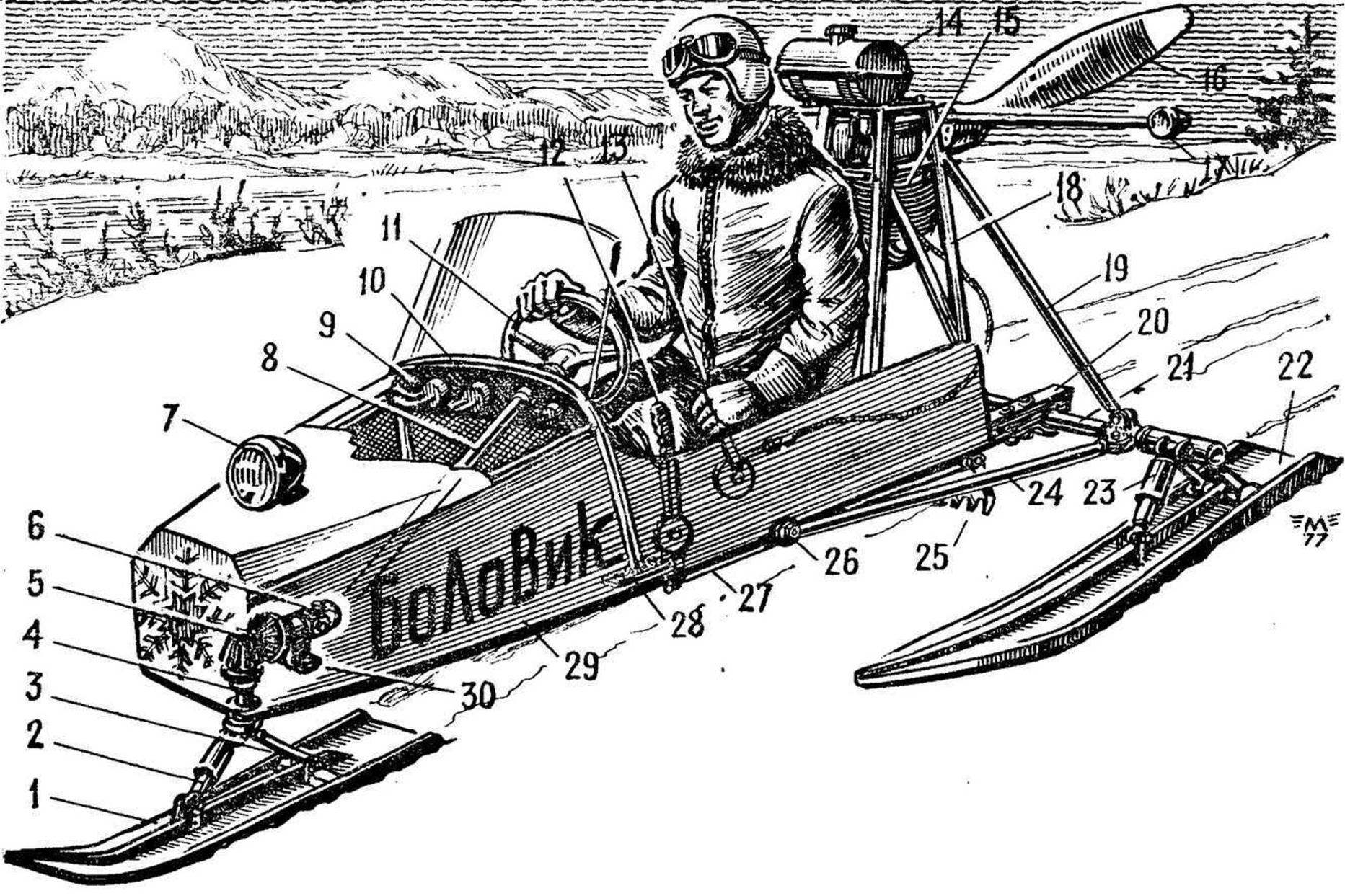

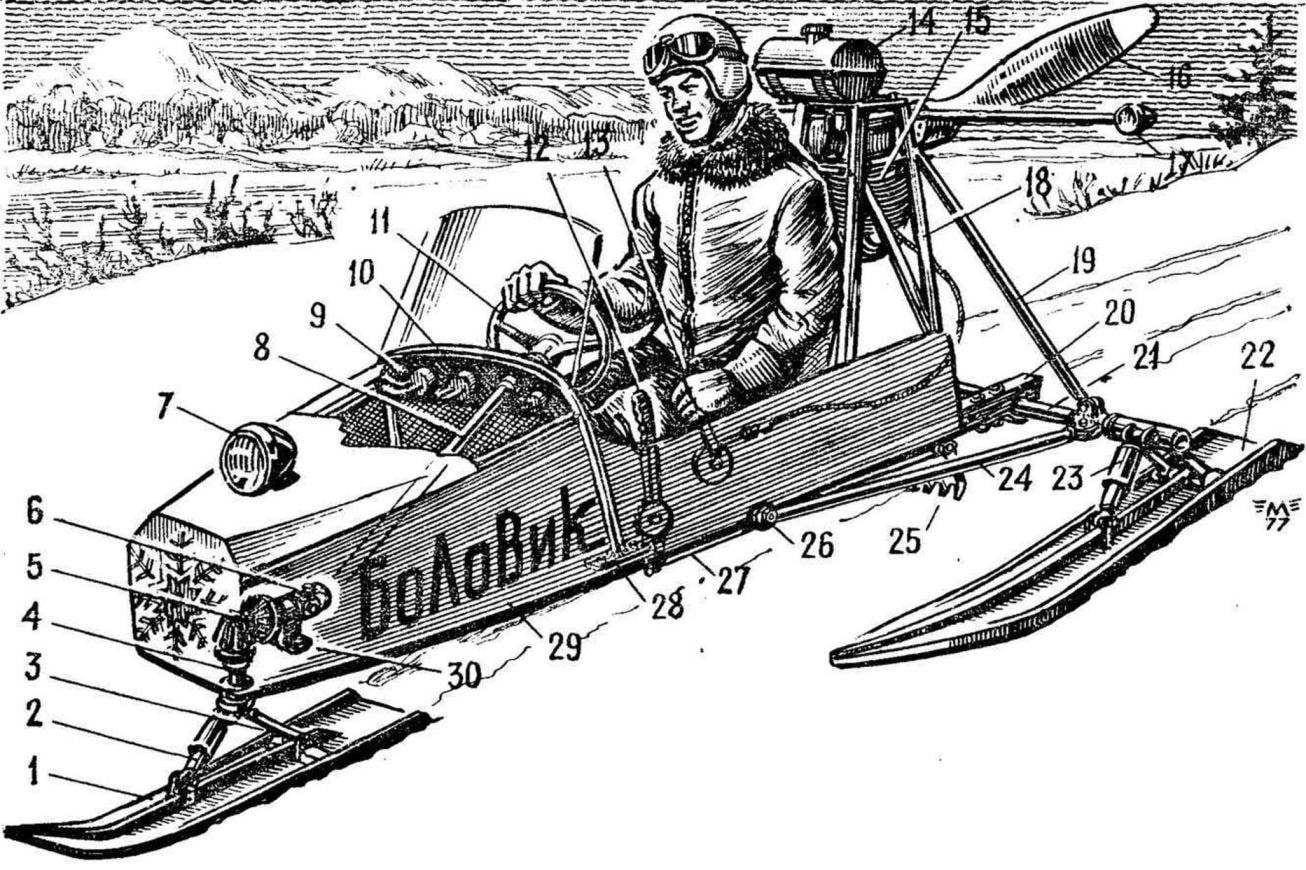

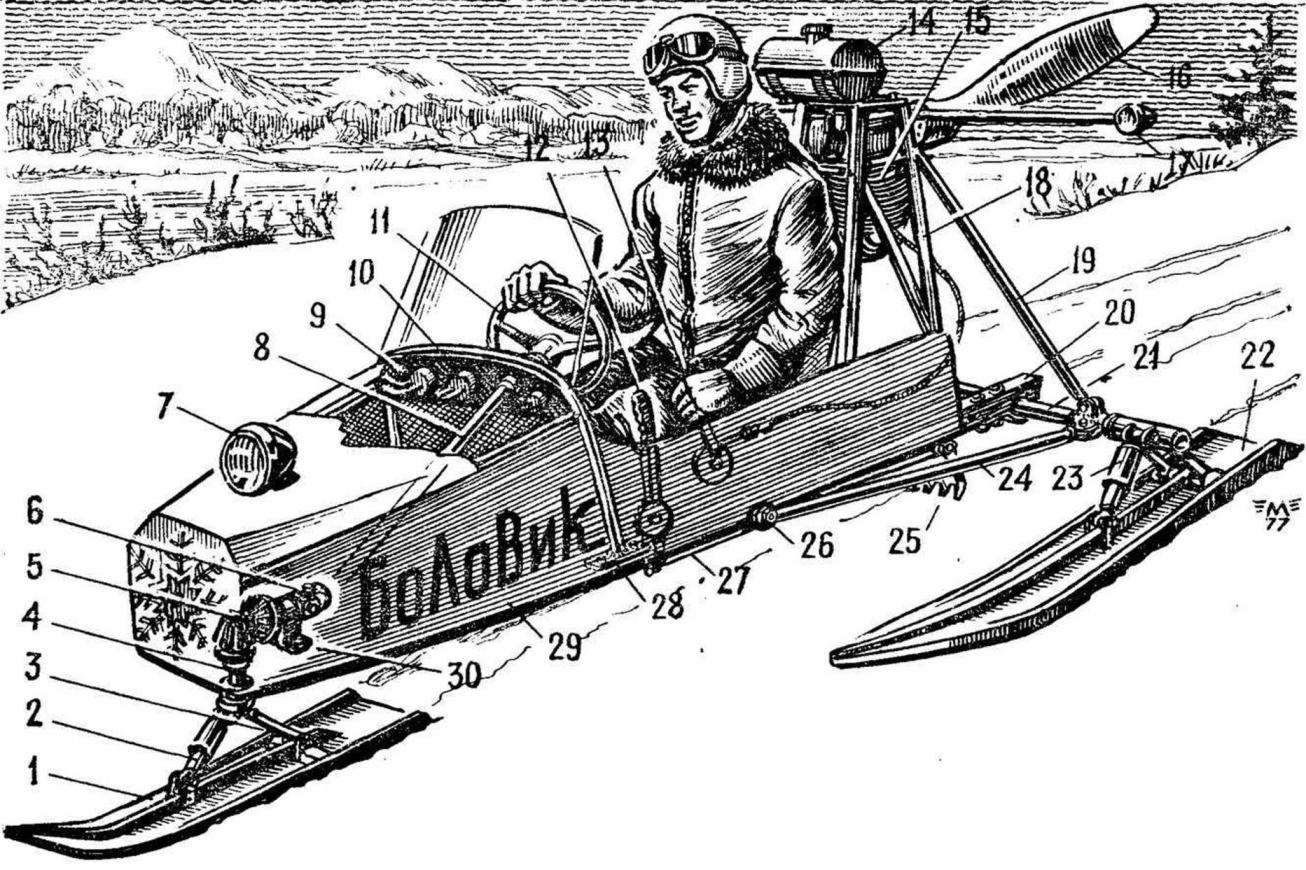

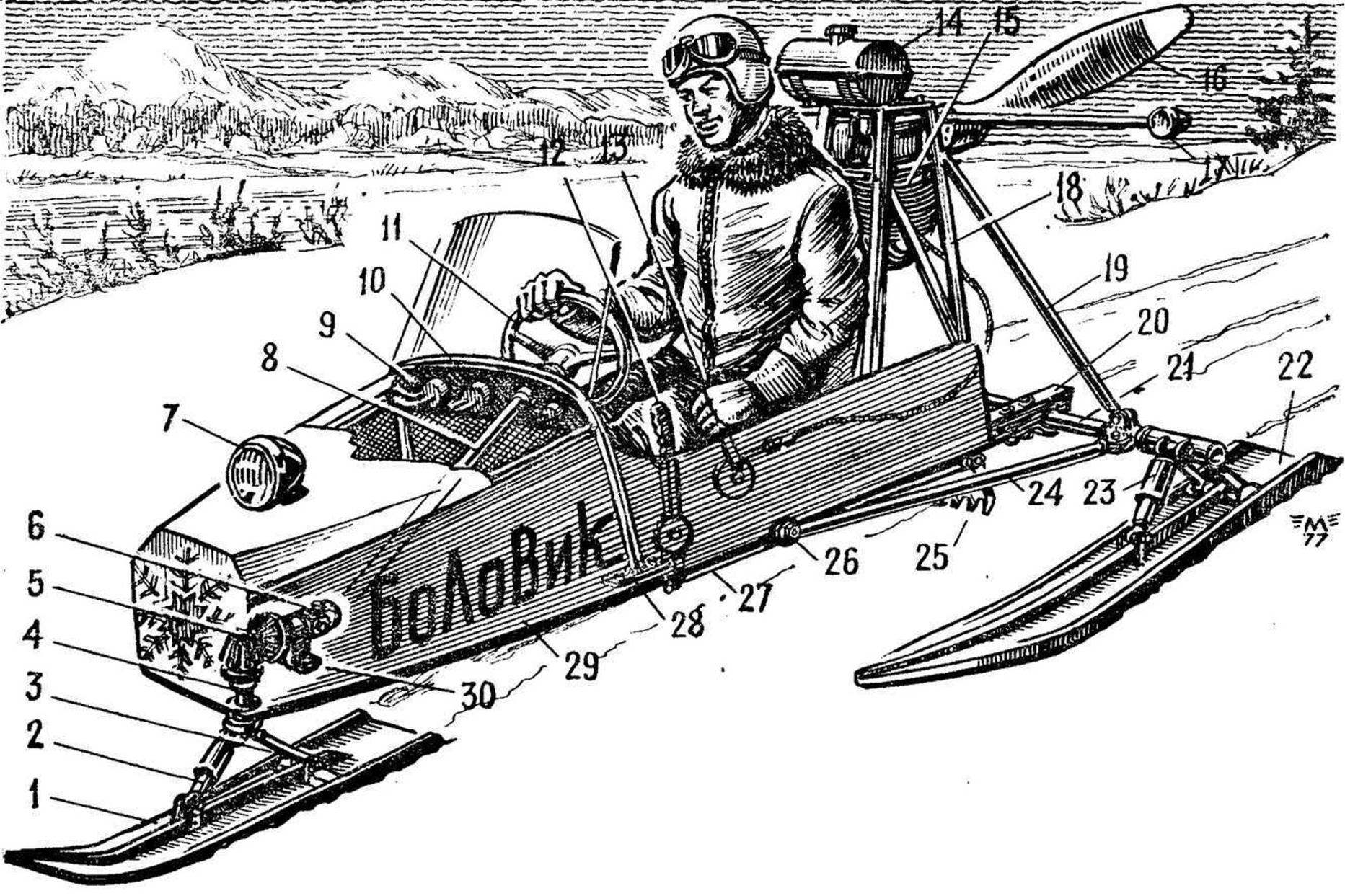

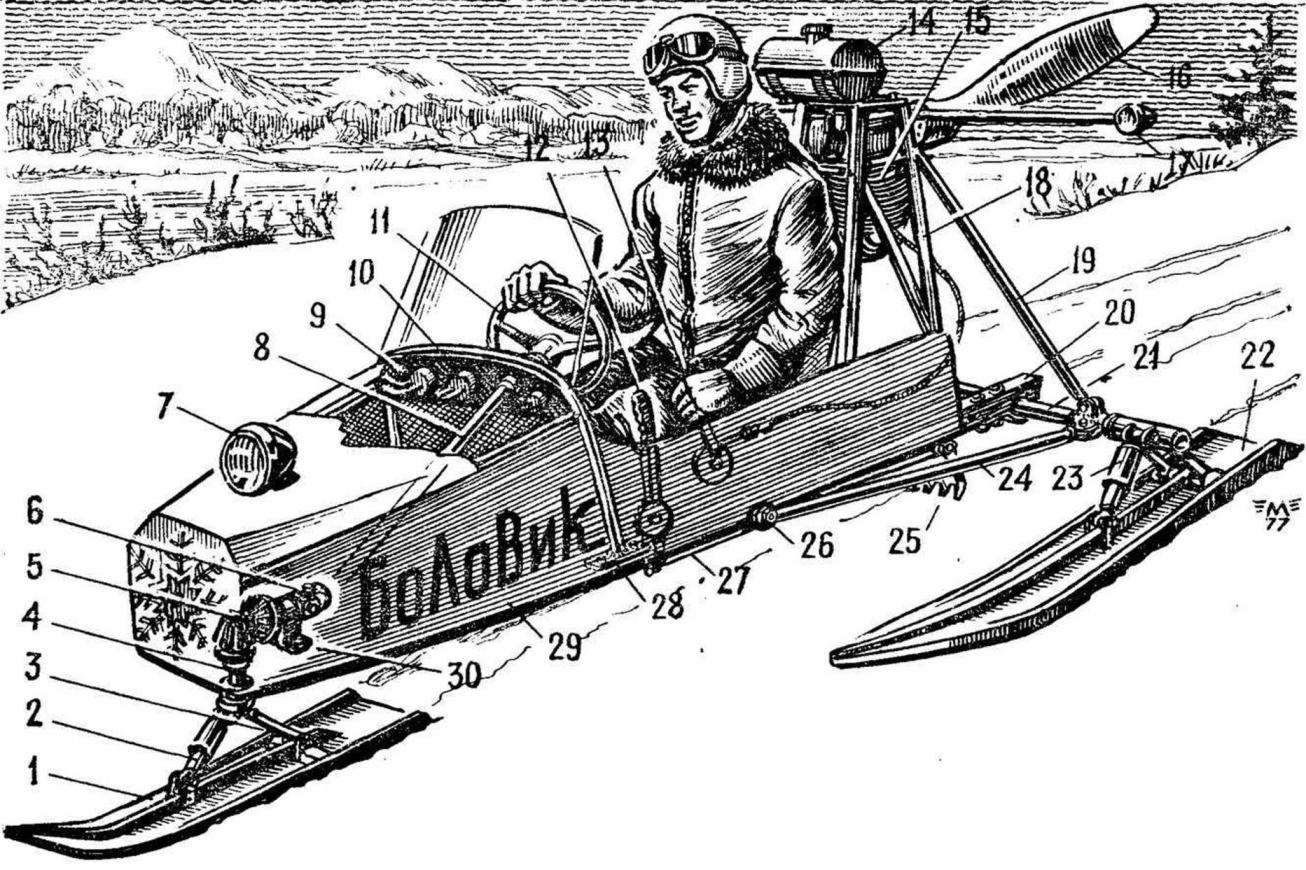

Snowmobile “Volovik”, the description of which we provide, belong to this class. They built accountant of the farm “rudawy” Obanikoro district of Kursk region and V. I. Bolotsky and now the third season properly serve him when traveling in the vast expanses of the state farm fields. The main principles of the designer in this machine: simplicity, Nezavisimosti applied materials, reliability and simplicity of operation.

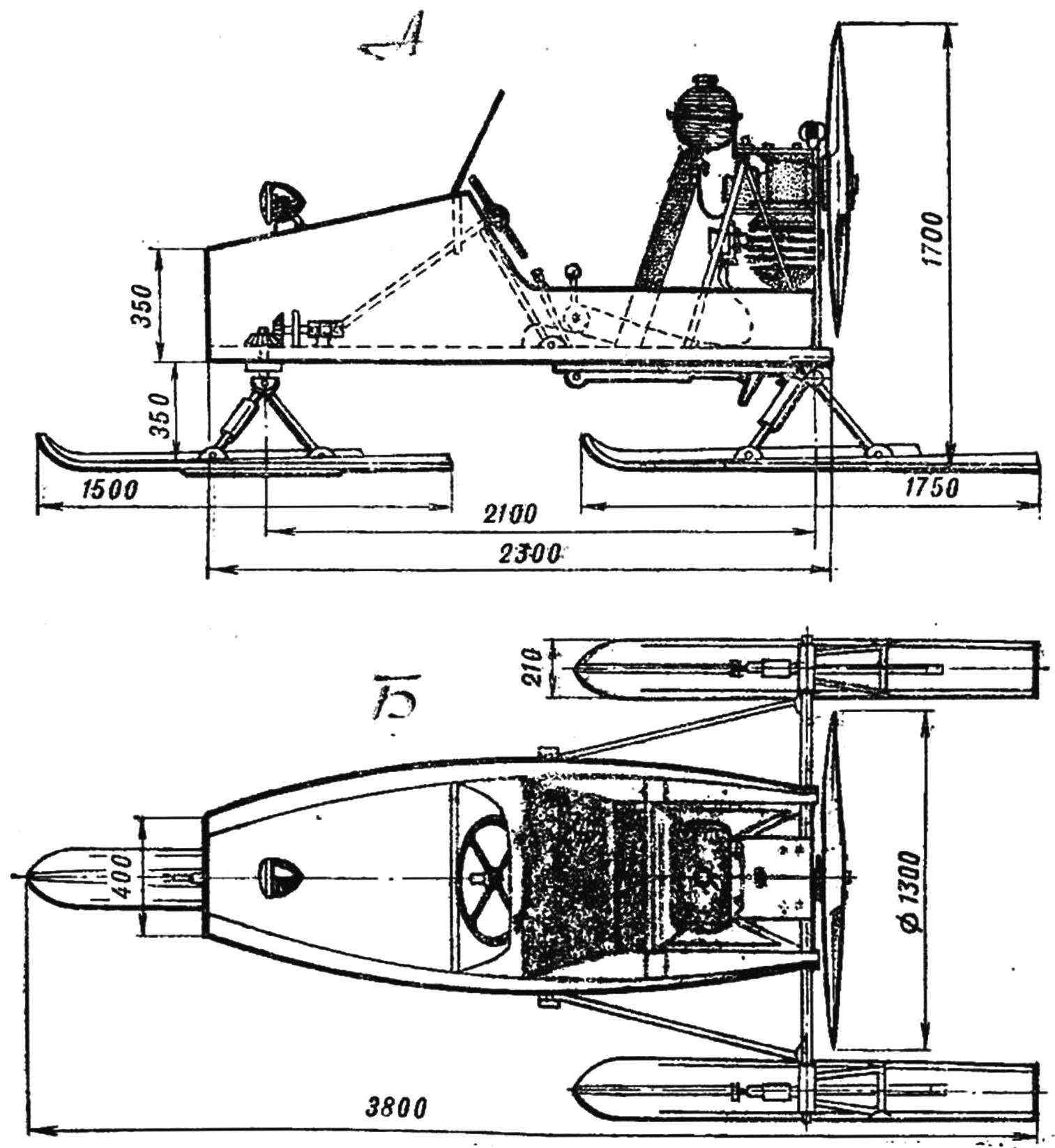

This single machine trehmernoi scheme with the front steering ski (Fig. 1). She weighs about 90 kg and develops a good crust speeds up to 60 km/h. a Semi-enclosed body with a sheathing of plywood mounted on a wooden frame the simplest type (“ladder”) collected on the gussets with glue and reinforced at the corners with metal plates. Rear frame with steel clamps fastened a tubular shaft on which are mounted the back of the ski; it is also equipped with the sub frame, welded from a steel angle 25X25 mm. Front (steering) ski has a vertical rotary rack associated bevel gears with the shaft of the steering wheel. All three ski suspension shock absorbers of the motorcycle M-1-M To save weight brackets of skis must be made from thin-walled steel tubes (e.g. from old bike frames).

Fig. 1. General view of the snowmobile:

1 — the front (steering) ski, 2 — attenuator, 3 — bracket, 4 — swivel stand, 5 — bevel gear, 6 — universal joint steering shaft, 7 light, 8 — steering shaft, 9 — panel, 10 — metal frame (cot), 11 — wheel, 12 — brake lever, 13 throttle lever, 14 — fuel tank 15 — drive, 16 — propeller, 17 — marker lamp on the fence post of screw 18 — front motor, 19 — brace, 20 — spar frame of the sleigh, 21 — rear axle, 22 — rear ski, a 23 — absorber, 24 — jet lever, 25 — comb brake, 26 front mount jet lever, 27 — pull brakes, 28 — flange bulkhead, 29 — sheathing body 30, the steering gear housing.

Steering wheel and shaft are taken from a wheelchair sidecar С3А. The shaft attached to the frame made from arc cot, appropriately cropped and fitted in place. The body is sheathed with plywood of 3 mm thickness and outside covered with one layer of calico. On the right (in the direction) side of the sled, the height of the body is 400 mm, the left for easy entry reduced to 200 mm. Seat and back have foam rubber cushions covered with leatherette.

In designing the engine used crankcase, piston group, crank shaft Assembly with roller bearings and magneto from the PD-10. Carter cropped from the side gear pinions magneto and Governor to the bearing seat. The neck of the crankshaft on the same side cropped to the drive gear, it made cuts under magneto M-24. For the latest on the shank of the shaft machined hub flange, on which nasverlennye holes and made the threads for mounting the magneto and adjust the ignition timing. The hub is placed on the bearing seat No. 2206 and fastened by three bolts. Then on the modified crankcase set cylinder, head, decompressor, carburetor K-28-E and control cables from the motorcycle IZH-56 IZH or”planet”, as their seats meet the Carter PD-10.

The sub frame is welded from steel angle 25X25 mm. It consists of the upper part, which is installed the engine, and the lower, connected with M8 bolts to the frame body. To increase the rigidity of the sub frame is enhanced by two tubular struts, the two horizontal pipes and one lateral square on the M8 bolts. The upper frame carries a fuel tank. The engine is bolted M8 with rubber lugs. It is a cylinder down to lower the center of gravity of the machine and securing fuel supply samotokom. Fuel tank from motor ZID, its capacity of 8 L. This quantity is enough for almost 2 hours of engine operation. Used fuel — gasoline A-72 mixed with oil AC-8 in the ratio of 1 : 25.

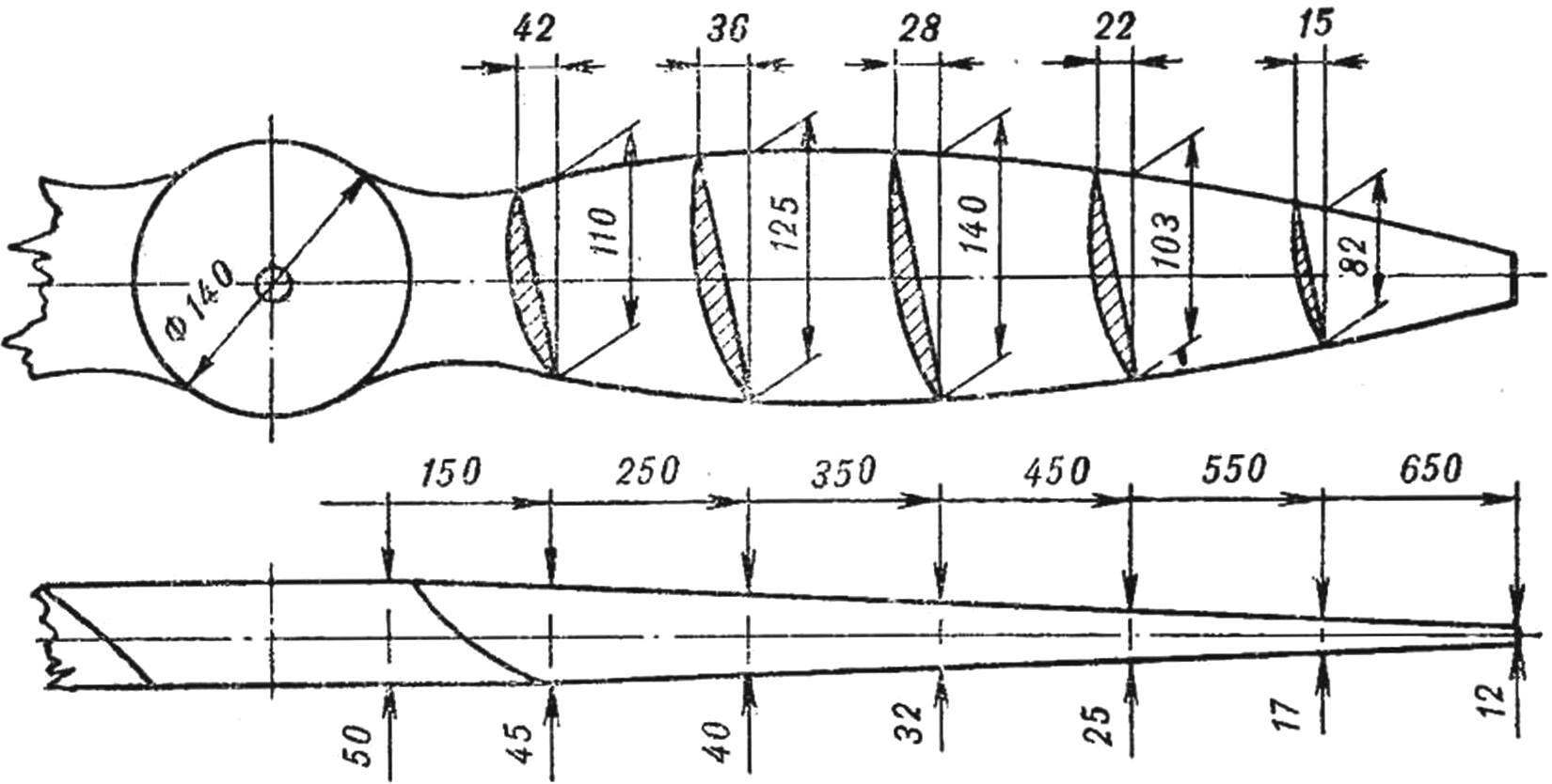

The propeller is made of a whole block of elm. It took dry, straight grained blank size 1300X140X50 mm. you Can also use red beech, birch good, and in an extreme case grained pine. In the latter case, the screw be sure to glue one layer of fiberglass, ASTT (b) epoxy resin. Billet of wood of solid rock before processing it is necessary to withstand a few hours on a hot pair. This with-Xitami wood high resistance against atmospheric influences.

Figure 2. Dimensions and cross section of the screw.

Fig. 3. Diagram in two projections:

A — side view; B — top view.

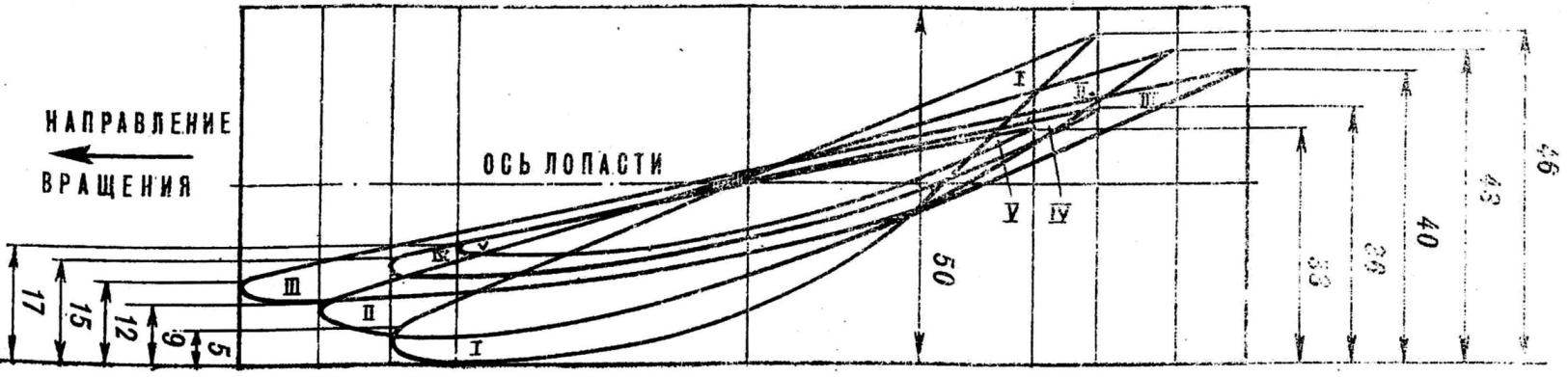

The technology of manufacturing of the propeller, as well as methods of calculation and selection of the propellers, described in our journal. Therefore, we present only theoretical cross sections of propeller blades, shown, according to Bootsgo, the better the results. After treatment both of the blades and balancing will be completed, ka Central part (location of the hub) must be affixed to the reinforcing circular plates made of plywood thickness of 5 mm, to prevent the possibility of breakage of the screw during operation. Then the screw is double-covered with hot linseed oil and painted with bright oil paint on natural drying oil. Remember: the proper selection and fabrication of the propeller depend largely on the driving performance!

Fastening screw on the motor shaft by using the hub, machined from steel St. 20. The holes for the mounting bolts in the lug should be drilled after the screw is seated properly into the bushing of the hub.

Skis made of Linden planks with thickness 15 mm in accordance with the drawing and the bottom bound after installation. roofing iron. The front steering ski has undercut steel area of 20X20, the curved form of the sole of the ski and is attached thereto by bolts M6 flat head screws.

Electrical equipment: ignition — magneto from an aggregate of M-24; the lighting, from battery (customers spotlight FY-38, portable lamps and side lights on the railings of the propeller). In the variant with mechanicznym maggino it is advisable to assemble the diode rectifier to charge the battery on the go.

The braking device of the scraper type. The Parking brake is fixed a hand lever with ratchet and pawl.

The location of the handles, and underwing skates are set individually. To do this, in his arms; lie on the sled and to determine the most comfortable position for the hands.

The last step of fabrication of the pillow, on which rests the athlete. At its core may be foam rubber or quilted with cotton wool (for example, a piece of an old jacket or blanket). The outer case should not be slippery, otherwise it will be difficult to control the “plane”. During operation of the sled it also emerged that in the heavily-Packed snow or hard crust ski there is sometimes Hughes and the design becomes unmanageable. In these cases, useful metal comb (“undercut”) fixed to the sole of the ski. It can be manufactured from steel of area 10X10 mm or slightly less (it will have “scalloping” the regiment to prepare a file to a height of 5-8 mm). The undercut to the ski it is necessary to strengthen as much as possible — it is best to use M4 screws with countersunk heads.

Technique drive has features that the athlete will feel after the first runs. The ability to maintain balance in people is different, it depends on the condition of the vestibular apparatus and reaction speed. So if one pilot offered beautiful sled from going down, the other is less prepared — long “pick your mountain” before you master the secrets of mastery. In all cases it is necessary to remember one mandatory rule: first, “to start” with small slides and only having mastered the simple slopes, go to steeper slopes. With a sharp touch of snow by the end of the wing, the sled can instantly turn around and reset the driver. During transportation to the subway or commuter train wing it is necessary to Unscrew and fold sled in the package, as shown in figure A. For this purpose the bolts that connect the wing with the ski, it is necessary to choose a set of wing nuts.

G. MALINOWSKI

Recommend to read

THE EXPRESS COMPASS

THE EXPRESS COMPASS

What if you need to draw a circle, and a compass at hand is not! To get out of this situation by making a simple compass of the bent and strapped to the pencil in the right place for a... AND THE STUMP WILL COME IN HANDY

AND THE STUMP WILL COME IN HANDY

The stump on the dacha is usually not only a hindrance but also a problem: to root out its not so easy. However, you can not get rid of it, but rather made to serve. For example, using...

Designers snowmobiles operating in rural areas, and most — often used parts of decommissioned tractor Puscuta PD-10 propeller systems for their cars. It is clear and logical: the engine PD-10 is widely distributed in agriculture, it is necessary to recast it we option is not the challenge. Accumulating the experience of operating planes with such engines, the designers achieve a very noticeable increase their performance by improving purging, selection of carburetors, etc. it is safe to say that at present, a single “rural” snowmobile engine, created on the basis of the PD-10 are the most proven and reliable machine. It should be added that in the construction of chassis, control systems, etc. in recent years also created a lot. According to the editorial, timely information about these updates can assist the novice builders.

Designers snowmobiles operating in rural areas, and most — often used parts of decommissioned tractor Puscuta PD-10 propeller systems for their cars. It is clear and logical: the engine PD-10 is widely distributed in agriculture, it is necessary to recast it we option is not the challenge. Accumulating the experience of operating planes with such engines, the designers achieve a very noticeable increase their performance by improving purging, selection of carburetors, etc. it is safe to say that at present, a single “rural” snowmobile engine, created on the basis of the PD-10 are the most proven and reliable machine. It should be added that in the construction of chassis, control systems, etc. in recent years also created a lot. According to the editorial, timely information about these updates can assist the novice builders.