(The end. Beginning at No. 2, 1975)

(The end. Beginning at No. 2, 1975)

Teacher Stanislav I. Pozdnyakov from the city of Berezina in the Minsk region, has been building snowmobiles for almost 10 years. He set himself the seemingly narrow task: to make a winter car for use on snow-covered roads — roads and country. In the process, the designer has found some original solutions of individual units. And although the appearance of his car is not very attractive, it is comfortable enough and that the basic, reliable in operation (see photo).

The snowmobile turned out light, only 85 kg. Mounted on the engine of the motorcycle IZH-49 with a nominal capacity of 12 HP develops with a homemade propeller pulling force in excess of 6 kg per unit of power.

This made snowmobile twin. Their payload, taking into account the supply of fuel, almost twice the weight of the structure itself.

Below are the operational and technical characteristics of the snowmobile.

ON TWO SKIS

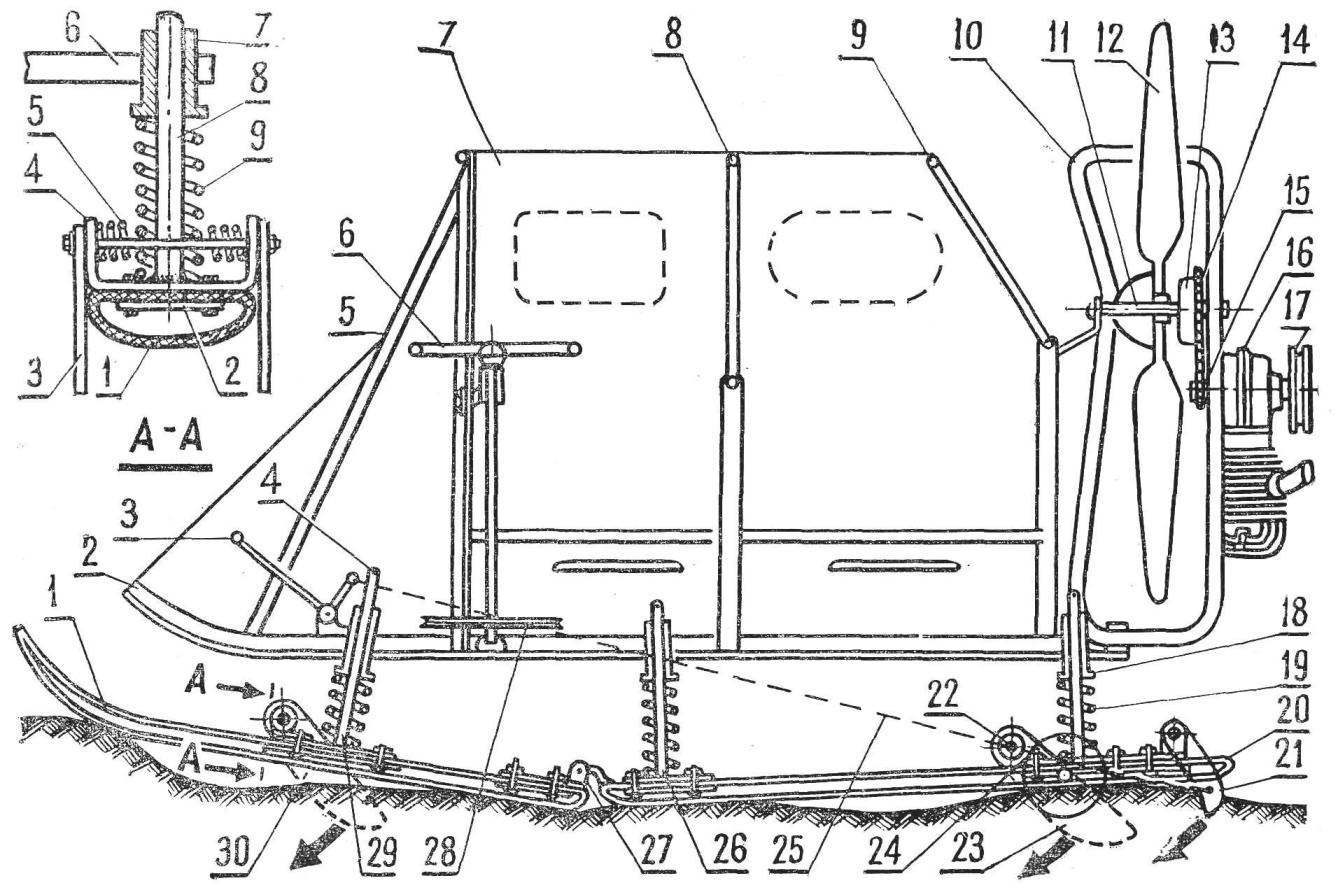

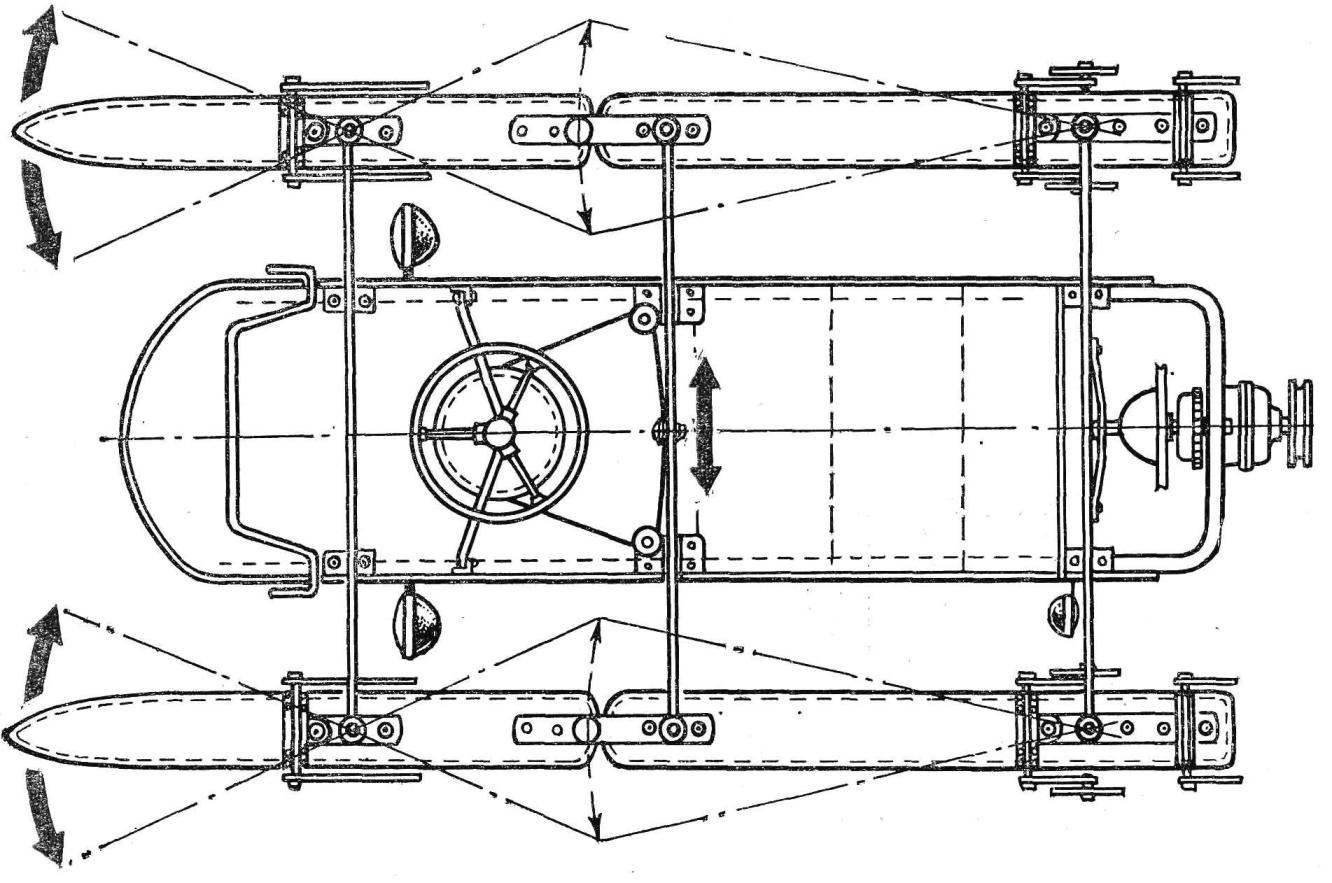

I built a snowmobile differ from the traditional schemes of his not quite normal suspension (Fig. 1), It consists of two “flexible” skis, made of a flattened ellipse in nylon tubes. Nylon provides good sliding on snow. Skis when driving leave only two tracks, which reduces the resistance to movement.

Each ski in the middle is cut crosswise and is pivotally connected. This joint allows them to bend in the vertical and horizontal planes, it is easy to adapt to the irregularities of the roadway and to take the right angle when making turns.

Fig. 1. Scheme snowmobiles (side view):

1 — the front section of the ski 2, the longitudinal side member of the body, 3 — brake pedal, 4 — strut of the front section of the ski, 5 — tube frame Ø 25 mm, 6 — steering wheel 7 — removable canopy with Windows made of Plexiglas, 8 — medium arc awning, 9 — back arc awning, 10 — the enclosing frame of the screw 11 — screw shaft, 12 — blade like, 13 — drum mechanism, the clutch 14, the leading chain, 15 — sprocket on the motor, 16 — engine IZH-59, 17 — starting pulley, 18 — guide sleeve rack, 19 — spring 20 — rear section of the ski, a 21 — brake hook, 22 — bracket mounts podraza, 23 — knife-like undercut, 24 — disc undercut, 25 — the brake cable, 26 — strut of the rear section of the ski, a 27 — swivel front and rear sections 28 — steering drum, a 29 — flange mounting of the strut to the ski, 30 — front knife-like undercut. View a—a: 1 — skiing, 2 — plate, strut, 3 — knife-like undercut, 4 — mount podraza, 5 — spring podraza, 6 — traverse 7 — guide sleeve, 8 — strut 9 — spring.

To prevent lateral sliding of the ski in curves because of their ellipsoid shape at the points of fastening it to the casing are guides undercuts: in front of the sliding skate, and the rear rotating disk undercut. They are pushed to the ground by the coil springs and, mixing with the snow, providing reliable stability speed and good handling of the snowmobile, at the same time without interfering with movement.

Change of direction is carried out from placed in the driver’s cab of the snowmobile of the steering wheel. When turning the cable coming from the steering drum, causes the cross tube tie rod connecting the Central rack of skis near their swivels. Both skis through the hinge at the same time bend in the horizontal plane, thus providing for the necessary rotation angle.

Racks are mounted to the ski by bolts, with the flanges mounted inside a nylon tube. Its upper part of the strut is included in the bushing tie rod, freely sliding in them.

On the rear ends of the ski brake is placed “nogtevogo” type: two steel hooks welded to the blades. They are connected by a rope with the foot brake lever.

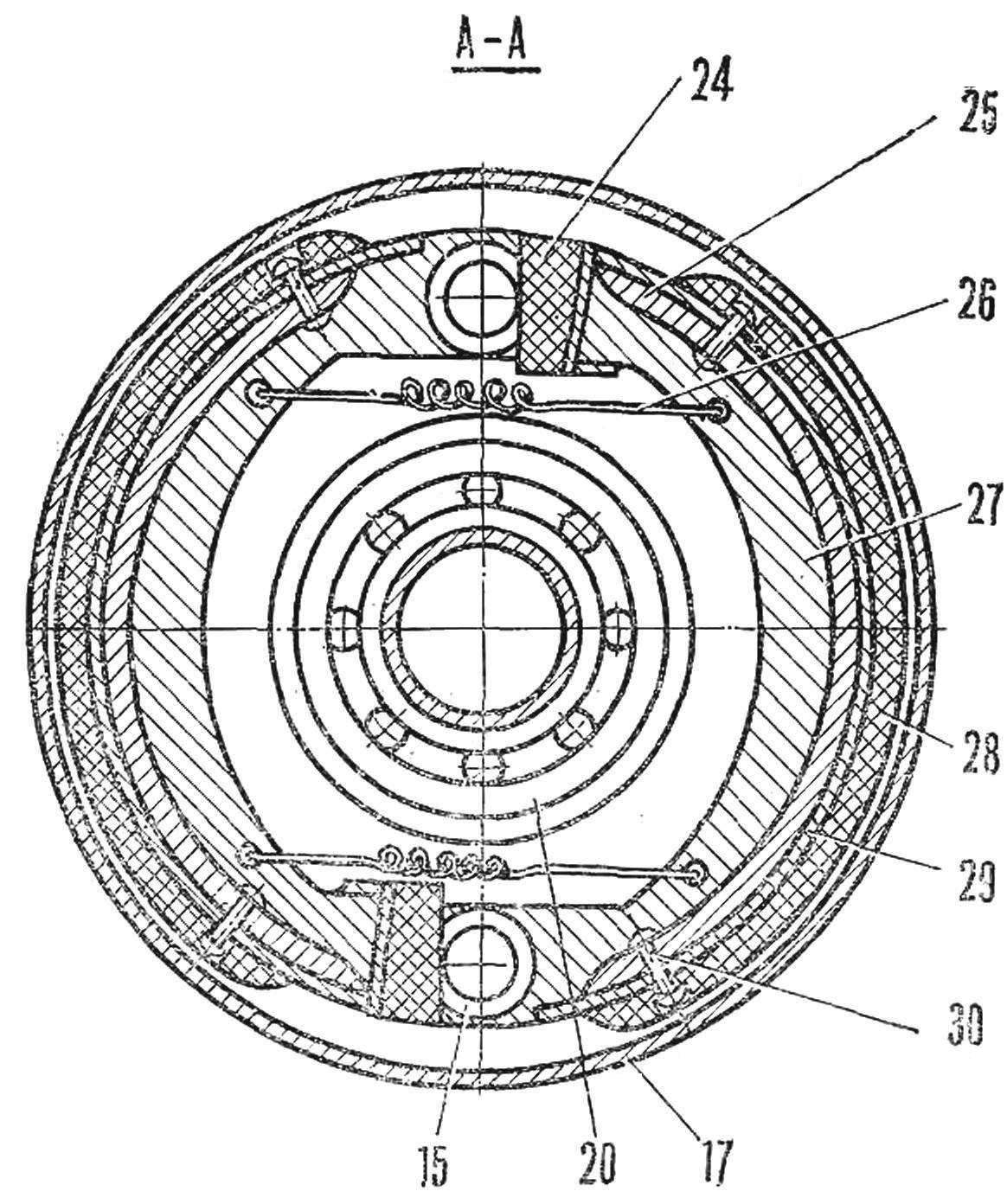

To improve the airflow to the engine placed behind the propeller (Fig. 2). This provided better access to it that creates great convenience when servicing the motor.

The motor is installed on motorhome down the cylinder. This allowed to shorten the chain reducer and the piping ventsistemy, to lower the center of gravity of the snowmobile.

Fig. 2. Rotor installation.

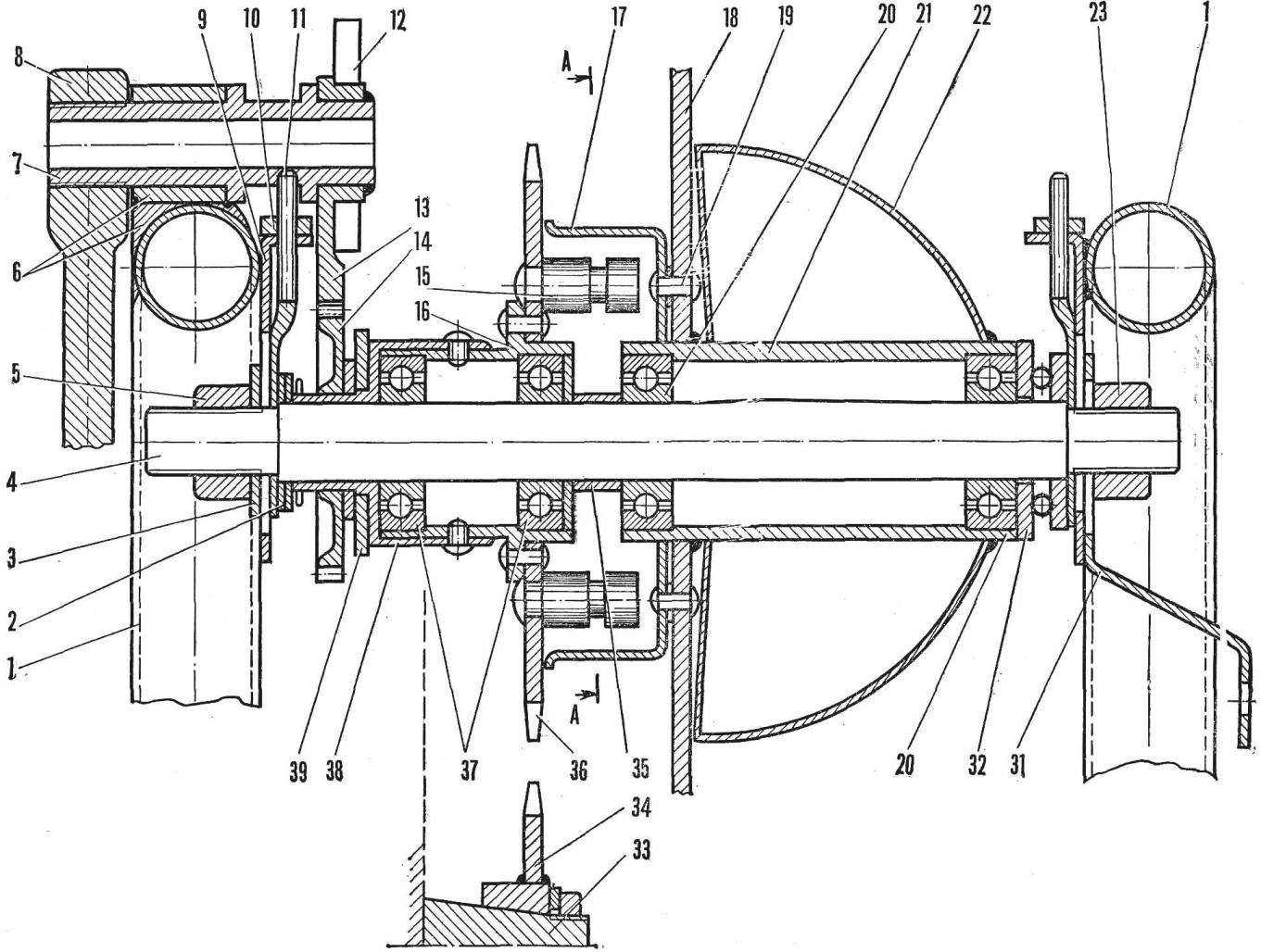

Fig. 3. The shaft Assembly propeller (And node centrifugal clutch):

1 — under engine frame; 2, 3 — washer; 4 — propeller shaft; 5 — nut; b — bracket-bushing; 7 — axis of a releaser; 8 — starting lever; 9 — panel on a motor frame; 10 — tensioning nut; 11 — tensioning bolt; 12 — a spring return stroke; 13 — launcher toothed sector 14 is the factory sprocket; 15 — front pads of the centrifugal clutch; 16 — hub motorcycle rear wheel; 17 — drum centrifugal clutch; 18 — spring of the blades of the propeller; 19 — rivet; 20 — ball bearing screw; 21 — hub screw; 22 — fairing of the propeller; 23 — a nut; 24 — a rubber shock absorber; 25 — lead plate; 26 — tension spring; 27 — Shoe centrifugal clutch; 28 — ferrodo; 29 — plate; 30 the rivet; 31 — mounting bracket; 32 bearing; 33 — the shank of the crankshaft of the engine; 34 — sprocket motor; 35 — spacer ring; 36 — sprocket driven; a 37 — ball bearings releaser; 38 — glass trigger mechanism; 39 — washer.

The engine is a boat diaphragm pump, pumping-up fuel from the tank, located underneath the passenger seat. There is also a pear of manual pumping of fuel.

The original installation on the shaft of the propeller a centrifugal clutch (Fig. 3). It allows you to run the engine without the propeller. The propeller is automatically activated upon achieving the required revolutions of the crankshaft of the engine. The value of the speed can be adjusted by changing the weight of lead plates, vkladyvanii pads in the clutch, and depending on the tension of the springs. Thus, the connection of the shaft with screw is only through friction pads on the inner surface of the clutch drum.

This grip makes the sledge more safe to operate. This is supported by the presence of a releaser, is almost entirely borrowed from the motorcycle. It is mounted on is welded to the engine frame bracket. The lever of a releaser accommodated, and the motor itself with the plane of rotation of the propeller.

Originally made in the sled and the propeller. It has sheet metal blades riveted to a spring strip, which in turn also riveted to the drum of the centrifugal clutch.

I applied on their snowmobiles screws two types of three-bladed and two-bladed, identical in design. The lower half of the screw is enclosed in a tubular protective frame.

TECHNICAL CHARACTERISTICS

General data: type of snowmobile — closed, twin, the engine of the motorcycle IZH-49 with a capacity of 12 HP at 4000 rpm type of propeller — three-bladed, Ø 1400 mm, speed 2000 Rev/min, reduction: 1 : 2, transmission of the screw — chain, traction screws 50 kg, weight — 85 kg, payload 140 kg, fuel weight — 14 kg.

Overall dimensions, mm: — length 3000, width — 1400 track — 1200, the base — 1500, ground clearance — 300, body height — 1300.

Operating data: maximum speed — 70 km/h operation 40 km/h.

S. POZDNYAKOV, Berezino, Minsk region