Requirements for the car are pretty liberal and mostly relate to the safety of the pilot. The rest of the space for creativity. And the more the design of original solutions, the higher the score.

The rally runs for three days (in three stages) on the first day the participants present and defend their projects, the technical solutions adopted in them, and the authoritative Commission evaluates them.

The layout of the racing car “Adrenaline”:

1—the bump (made of anodized aluminum, the sheet s2, 3 pieces is one in another);

2 — frame (round tubes of steel 30KHGSA);

3 — of the control pedals (3 pieces gas, brake and clutch);

4 — front idler (13, 2);

5 — arm suspension front wheels (2 PCs.);

6 — the steering wheel;

7— the pilot seat;

8 — the power unit (from a snowmobile “Yamaha”);

9 — front drive wheel (13, 2);

10 — arm suspension and rear wheels;

11 — rear wheel drive (drive axle shaft 2 PCs.);

12 — damper;

13 — bracket of the hood.

On the second day of the technical inspection checks built car according to their rules (competition requirements) and individual dynamic tests (tests).

The third day is the final stage — the 22-kilometer race with a driver change at one of the tracks of the legendary “Formula 1”. Overall assessment the project will be billed for the total score. obtained during all three phases.

In the end can not win the fastest car and not even the most successful design, and the balanced project as a whole; in technical and in economic terms (price/quality) given correct and full documentation.

Welded space frame (mounting brackets parts, components and mechanisms is conventionally not shown).

Until recently, this car competition for Russian students was exotic, about which few people heard. It was held abroad, attracted participants from Europe, America, Australia and even Africa, but not from Russia.

We have the same “Formula Student” first “showed up” a few years ago (in 2005) in the walls of the Moscow road Institute (MADI), when a group of his students decided to try their luck and participate in this contest. They had a hard time.

As you know, talents in Russia, the mass, and “to Shoe a flea,” for many of them — no problem. But to create the conditions in which Russian left-hander will be able to “Shoe fleas”, this is in our country always had problems. But, fortunately, there were among the teachers of those who agreed to assist. Team MADI has at its disposal the computers for the calculations, the ability to communicate with foreign colleagues via the Internet, and then, as expected under the terms of the contest. — all by yourself. The search for sponsors, long evenings, flowing in carried out at the computer monitors, night, multiple calculations, disputes themselves hoarse, the development of many specialties working for the realization of structures — in General, all that accompanies a real creative process.

Front axle and steering:

1 — brake disc (2 PCs.);

2 — caliper brake cylinder (2 PCs.);

3 — steering knuckle (2 PCs.);

4 — lower control arm suspension wheel (2 PCs.);

5 — upper suspension arm (2 PCs.);

6 — rod (2 PCs.);

7—shock(off the bike, 2 PCs.);

8 — rocking chair (2 PCs.);

9 — steering wheel;

10 — basic steering bearing;

11 — steering driveshaft;

12 — intermediate steering bearing;

13 — a Pitman arm;

14 — tie-rod (2 PCs.);

15 — the support of the steering mechanism;

16 — the hub of the wheel (2 PCs.);

17 — axle (2 pieces).

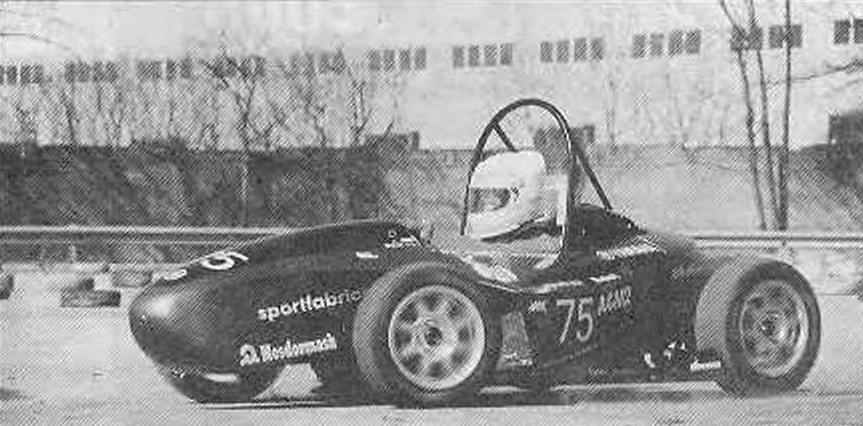

Usually teams who begin performances in the “Formula Student”, had already been in the competition as spectators and knew firsthand that represents this event. Our team has prepared for it only by avaricious messages in the media on the dry pages of rules However, Moscow’s students are still designed and built in less than a year a racing car with a motorcycle engine Yamaha and was able to perform at all stages “Formula Student 2006” held in Germany.

If a couple of years ago the first performance of our compatriots in the “Formula Student” in Germany created a furor — the Russians have arrived! now the program will not look timid beginners that can make concessions. Of course, the material base of the Moscow student teams and their foreign competitors is incomparable. But after saving one of the conditions of victory, and, at least according to this indicator, Russian students is able to give odds to any other parties because as you know, necessity is the mother of invention.

Design description

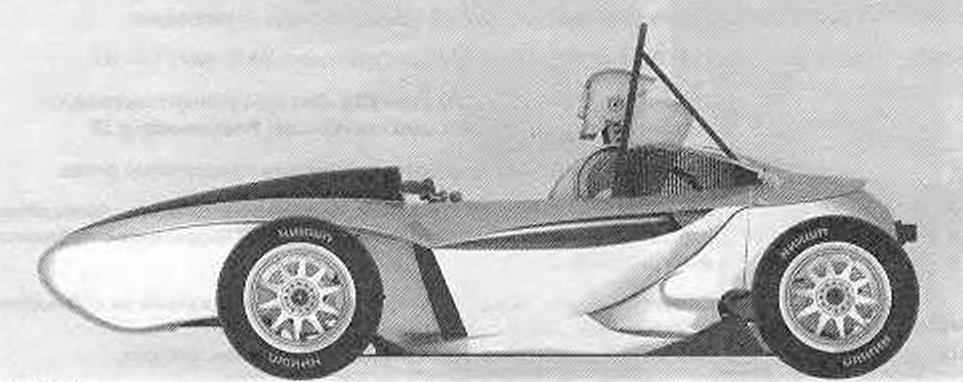

The frame of the car — dimensional, welded, made of steel (30KHGSA) pipes. The major parts diameter of 25 mm with a wall thickness of 2.5 mm from the support, 20×2 mm. These gross stipulated in the regulations of the competition, as, indeed, and the allowable intervals between them, and the distance from them to the ground and to the pilot. Weight frame only 33,5 kg, but it provides the design loads for torsion and bending, and most importantly — the safety pilot.

Rear axle and transmission:

1 — brake disc (2 PCs.);

2 — caliper brake cylinder (2 PCs.);

3 — Cam (2 PCs.);

4 — top growl pendants (2 PCs.);

5 — lower suspension arm (2 PCs.);

6 — rod (2 PCs.);

7 — shock (off the bike, 2 PCs.);

8 — rocking chair (2 PCs.);

9 — presenter (sliding) pulley variator;

10 — driven pulley of the CVT;

11 — intermediate shaft;

12 — sprocket of the chain transmission;

13 — sprocket driven chain transmission;

14—the left arm;

15 — right arm;

16 —differential;

17 — the axle shaft (2 PCs.);

18–the hub;

19 — axle.

Most teams also made of a welded tubular frame, which is later hung the body panels. For definition of its sizes or use the high pilot or 95 percentile is adopted in the design of cars option when 95 of the hundreds of adults will be quite comfortable and only a five crowded in here. In the case of using any other steel, you must provide the calculation to prove the equivalence of structural strength.

Calculation frame on the strength of the students is carried out, usually in the SolidWorks program, which is a sponsor of “Formula Student”. Created especially for engineers, it allows you to “draw” accurate computer model of any part, set the material and calculate the stress at various loads. simplifies the creation and optimization of design even at the development stage. Naturally, requirements to the frame come primarily for reasons of security it is also necessary, and the front bumper, the design of which the machines of different teams varies greatly. Importantly, to meet the requirements, according to which the barrier, being loaded up to 300 kg, should reduce the overload on impact with a solid obstacle at a speed of about 25 km/h to a maximum of 20 g. This calculation is one of the most complex due to the nonlinear deformations at impact. Therefore, allowed and the option of a crash-gest copy with measured accelerations, which is used by many teams.

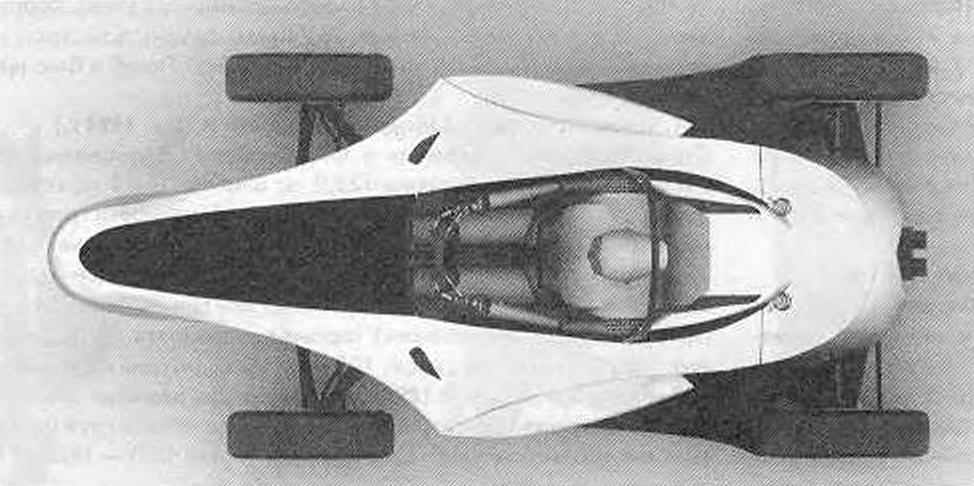

The splitting of the fiberglass body:

1 — fairing;

2 — front side panels (right and left mirrored);

3 — pontoon ( right and left mirrored);

4 — rear side panels ( right and left mirrored);

5 — the hood of the engine compartment;

6 — chassis.

Bump “Adrenaline” is a “doll” made of three, placed one within the other truncated pyramids welded from 2-mm aluminum sheet.

In addition, the frame should meet other requirements. In the first place — to be as light as possible, but to provide the necessary strength.

It is also important to provide quick access to basic and frequently serviced parts. By the way, on stage in Germany in 2007, the team SEG-MADI has taken on this parameter 2-e a place among the machines with metal tubular frames — in curb with a pilot car weighed about 330 lbs.

The carbon budget order monokote on the side. This design is more expensive and at the stage of gaining less points (due to “bought” and not own production), but significantly lighter and stronger, not to mention the aesthetic side.

Engine

The restrictor is not just inserted before the usual intake manifold washer — all teams made the intake system yourself. If as an example, take our car SEG-MADI, a new collector, designed and “purged” all in the same program SolidWorks, specially cast at the factory. The cost of this reservoir was about a thousand euros, but this is caused primarily by single manufacturer. In the pros, in addition as simple and short “geometry” (which reduces resistance) — three times less weight. In this regard, the required and finalize the the throttle. Motor itself, the latest four-stroke two-cylinder 500-CC Yamaha 500сс with distributed injection, by the way, used snowmobile from the latest model. Thus, the Japanese company is sponsoring our team. Engine power 82 HP (maximum torque of 250 NMS 11 at 11 750 rpm). Idle is about 2500 per minute

Electrical — 12-volt, standard snowmobile, as well, and the dashboard. Not even had to change the speedometer, the maximum speed was comparable.

Some teams set for engine with turbocharger no. as practice shows, the effect of them a bit — on the impact of such engines do not always exceed atmospheric, not to mention spojnosci built Although perhaps the depot’s just a lack of experience among the students for the solution of such complex tasks.

Separately want to mention a case that occurred in 2003 with an American team who came to the stage with the machine, which was the engine of his own design. Its volume — regulated -0,6 l, but it was V-shaped eight-cylinder motor! Unfortunately, before the race it was not made because of the failure of another of the rules: the car was removable starter, and were permitted to use only stationary. However, these guys left their mark in the history of the competition.

Transmission

Often teams use the transmission that comes with a motorcycle (or, as we have snegohodnyh) motor. Therefore, there is a variety of small — or Cam transmission, or CVT. On our car is the CVT. From it on the main gear torque is transmitted through a chain transmission. The principle of operation and design of the variator is known. It requires only the adjustment by selecting springs with the desired stiffness. Among the advantages of infinitely variable transmission — a constant smooth pull and ease of driving, due to the lack of grip. Reversing the car is not. The rear axle features a limited slip differential (Torsen T2) and half shafts with constant velocity joints from the car “Moskvich-2141”.

According to the regulations, the concept of the project is the order for the construction of 1000 racing cars for a special class, so maximum ease of driving and maintenance are taken into account, not least.

Suspension

The four-wheeled car, the wheels are 13-inch tires with an outer diameter of 540 mm. Suspension of all wheels — an independent without stabilizers and similar conventional “formula” front and rear on each are double wishbones. Third, “push” or “pull” (depending on load), the lever rests in a rocking chair, which is associated with hydraulic spring shock absorber Bicycle brand DNM. Move suspension up and down from the middle position to 30 mm.

Steering

Idlers car front. Steering shaft — gimbal, two-stage. The steering gear from the map. And finally, the tie rod on the front and an additional lever in the back — they are governed by the toe Minimum turning radius — 5.2 m.

The calculation of the kinematics of the suspension and the choice of attachment points of the levers — a very difficult job, requiring otlichnoe knowledge of both theory and software. In the Russian team, for example, use the program from Adams MSCSoftware.

Brake

Disc on all wheels hydraulic, with separate front and rear circuits.

The competition test in the passage of which the braking must block all wheels — to prove the efficiency of the system. This is the only requirement. On the other hand, all the same problems: the minimum weight, which is especially important to reduce the unsprung mass, and cost. So many teams are PR-yut brake discs themselves, cutting them from special steel sheets on videobrazilian or laser machine. Because the machines are very light, and the particular overheating of the drives do not. All teams use and controls the brake forces in different structures. The most common and easiest-controlled via the drive bearing under the brake pedal, shifting her to one side. Thereby shifting the shoulder of the impact on one of the brake cylinders, each of which is associated with its contour.

Body

When it comes to body design and material for its manufacture, in its resolution the main role played by the financial possibilities of the teams. Most (and we them) on their own produced plastic panels. Technology there are two “blank” or “matrix”. Since the production of the piece, the easier and cheaper the first option. The manufacturing process is technologically very difficult, but it requires experience and time. First, cut one longitudinal (let’s call him “spar”) and transverse (“ribs”) of the forming sections of plywood. “Rib” exposed symmetrically relative to “spar” with a laser. Free space between them is filled with foam and level, then clay put on top of the separating layer of wax.

Next is Vileika shell body made of layers of glass Mat, each of which is impregnated and coated with polyester oil (resin) and hardener (ideally this is done in a vacuum, but because of the lack of such opportunity many teams neglect it). After you put the putty, paint and varnish.

In the embodiment with the inverse matrix do the same form that in the same way fill the same components, but from the inside. On the same matrix it is possible to make a few bodies. If the budget allows, the team sometimes order a carbon bearing body-monocoque — a strong, lightweight, beautiful, but expensive.

Competition

The competition the competition is becoming tougher, the number of participants is constantly growing. If three years ago on stage in Germany came 10 to 15 teams, but this year there were 60. In England, the figure exceeded 100. A variety of tests and presentations increases, the demands on the quality of reports increase, but the experience is accumulated. If last year the team from MADI performed in dynamic tests due to technical problems and lack of experience, but this year the focus was on the preparation of documentation and presentations.

The judges were pleasantly surprised by such a qualitative leap for example, the cost report (Cost report), in which were painted all the details, up to the number of bolts and washers, and their price had more than three hundred pages. In another discipline, it was necessary to prove the feasibility and benefit of some technical solutions, not only from the point of view of the maximum speed, but the ratio quality/price, and to offer alternative solutions if requested “customers”. Leading foreign companies have realized that such projects — a great school of engineers and managers, acquiring valuable experience during his studies at the Institute. In Russia, unfortunately, there is no such a scale of production — automakers are lagging behind Europe and America, but foreign companies are learning we only have Assembly. The demand for automotive engineers and designers in our country is small, this explains the complexity in the support and development project in Russia. But only communicate when their projects with leading specialists from the largest companies “Ludi”, “BMW”, “Porsche” and “Toyota” engineers and managers of the teams Formapi-1. with other reputable people, one way or another related to cars — is a very valuable experience that you can hardly get anywhere else.

Recommend to read “PEAR” WITH THE SINKER An important detail of the toilet tank — the so-called "pear", covering the outlet. If its walls are deformed, it will not seal against the seat and close the drain hole. In this case,... Screwdriver with clip Help out in cases where the assembly of various designs have to screw the screw in a remote place. On a regular screwdriver, I pulled the rubber stopper, and strapped her bent at the...

Before you start talking about the car “Adrenaline” – built student engineering group of Moscow automobile and road Institute (MADI) to participate in the international competition “Formula Student”, it is necessary to say a few words about the history of this event.

Before you start talking about the car “Adrenaline” – built student engineering group of Moscow automobile and road Institute (MADI) to participate in the international competition “Formula Student”, it is necessary to say a few words about the history of this event. Since 1981, this contest has become an annual and international.

Since 1981, this contest has become an annual and international. To prepare for the competition “Formula Student” created a student working group, the purpose of which is to create from scratch a race car. The group is a small but perfectly functioning copy of the automotive company. This team consists not only of engineers, but also programmers, testers, managers, etc. or a combination (distribution) of these duties. The work includes the search of computers and software design, issues with premises and equipment, material supply, financial support I. most importantly, of course, build and test of avtomobila.

To prepare for the competition “Formula Student” created a student working group, the purpose of which is to create from scratch a race car. The group is a small but perfectly functioning copy of the automotive company. This team consists not only of engineers, but also programmers, testers, managers, etc. or a combination (distribution) of these duties. The work includes the search of computers and software design, issues with premises and equipment, material supply, financial support I. most importantly, of course, build and test of avtomobila.