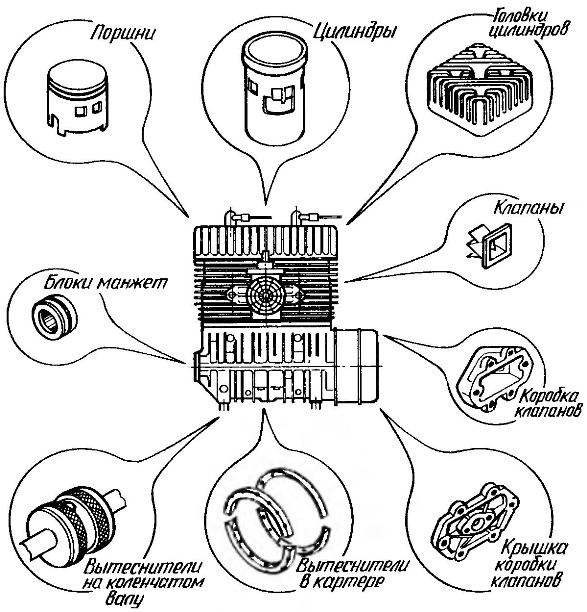

As the valves and boring the Windows of the cylinders increase the volume of the crank chamber of the crankcase 41 cm3 (which reduces the pressure of the purge and, as consequence, to decrease the maximum engine power), in the hollows of the cheeks of the crankshaft and in the corners of the crank camera to the so-called displacers harmful volume. On the crankshaft they are made of glass yarns on epoxy binders (for better grip winding cheeks a drill with a diameter of 4 mm they outline the wells with a depth of 0.5 mm). The Carter plungers are aluminum half-ring of triangular cross-section, attached with M4 screws.

The amount of volume displaced in the chamber along with the volume displaced by the cuff clip is 79 cm3, which more than compensates the increase from the placement of the valves and the bore of the Windows, which ultimately improves the purging.

However, the increase in pressure in the crankcase led to the fact that regular cuffs began to be extruded from cartridges. It showed up at the first engine start-up. Had to make new clips and to build in them cuffs from the axle of the car VAZ-2101, trimmed to 1 mm and facing each other face. To seal the clips used rubber rings from the shaft of the plug from the motor vehicle VAZ-2108.

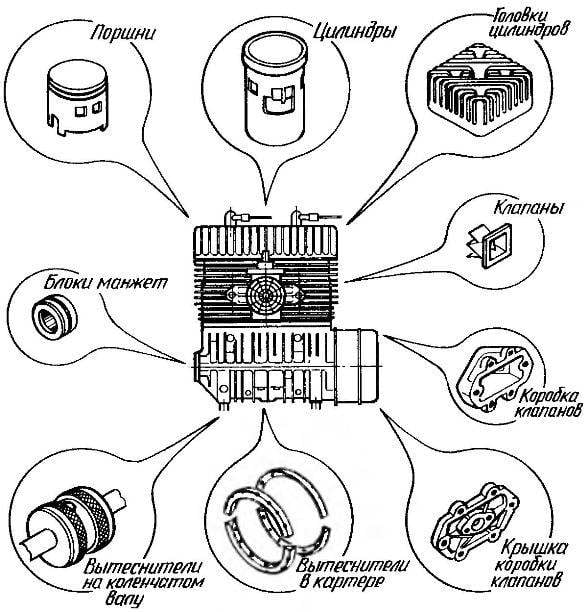

Fig. 8. Plate valve:

1 — saddle valve (organically Kevlar); 2 — M3 bolt (4 PCs); 3 limiter (steel, 2pcs); 4, the damper plate (laminate STEF-1, 2).

Before mounting the cuff holder was heated up to 200-250°C. Then, in the cavity of the cuff to fill the grease tsiatim-201 with disulfiram molybdenum, after which the cage is mounted on the crankshaft. Their shoulder tucked into the recess of the crankcase, and the regular thrust washer removed.

In addition to these works, a conventional two-stroke internal combustion engine for the procedure for improving internal surfaces, that is, the cleanup casting in channels and Windows and fit the lines of the pairing of the crankcase and cylinders. Read more about it in the book for THEM.Grigorieva (see references).

The third stage. During the re-test was measured the parameters of external, helical, flow characteristics and the maximum temperature of the cylinder head under the spark plug. The temperature and composition of exhaust gas has not indesirables. Power was given to normal conditions. The ignition system was not changed and was not regulated.

Test conditions: outside temperature — 8°C; atmospheric pressure — 748 mm Hg.St.; fuel and the external load are the same as before the upgrade; the diffuser of the carburettor dispersed to a diameter of 33.6 mm; main jet — diameter of 2.12 mm; LF = 7,2.

The results of the tests of the upgraded engine.

Screw feature: Ne = = 31,7 HP at 5316/min, CE = 0,321 kg/h HP; head temperature t°Cmax = 204°C; capacity increase of 22.8 per cent, efficiency is 25.8%.

Exterior feature: Ne = the 38.2 BHP at 5778 rpm, CE = 0,332 kg/h HP head Temperature — t°Cmax = 208°C; the capacity gain is 36.9 percent efficiency — 20.25%.

And finally, the fourth stage. In the configuration without a gearbox, blower motor spun up to 6840 rpm, the recorded capacity of 19.6 HP, CE = 42,2 HP at 5978 rpm, CE = 0,338 kg/h HP

Under the specifications of the upgraded motor was designed and manufactured a new air screw with the profile of Wortman PX-63-137 with a diameter of 1.6 m and 0.8 m step for flight speed of 72 km/h With it on a mooring was obtained 152 kg deadlift To pull this off on production engine with the standard screw has reached 112 kg, after the upgrade — 135 kg.

Climb double ultralights with the serial engine and the standard screw was 1 m/s After the upgrade, with the same screw is 2.5—2.8 m/s; and with the newly made — 3-3,2 m/s, while fuel consumption did not exceed 9 l.

The temperature of the head of hot cylinder upgraded engine when operating in the mode of takeoff and climb when the outside temperature is +28°C did not exceed 195°C.

Outcome: after completing these stages of upgrading the engine became more smooth and soft, much easier to run. Has improved almost all of its major characteristics: power, efficiency, continuity and, most importantly, reliability. At the end of September 1999, the engine operated in flights to deltaluca 32 hours without comment.

V. NOVOSELTSEV

LITERATURE

1. Kondrashov V. M., Grigoriev Yu. S., Tupov V. V., Sillat P. P.,Abramov V. I.,Strokin A. N. Two-stroke carburetor internal combustion engines. — M., Engineering, 1990.

2. Grigoriev I. M. Motorcycle without secrets. Moscow: DOSAAF, 1973.