To determine the structure was easy – because the experience was still not enough, they decided to build in the likeness of those that existed in a mug: truck mount (caterpillar wooden bars on two strips of conveyor belt and two front steering skis). To simplify the design, considered it appropriate, these reference nodes to run without shock-absorbing suspension. Summer has prepared the ribbon and bars for caterpillar, bought the “beushnye” (used) the power unit of the motorcycle “Minsk”. The motor had to replace the piston and rings. In the fall, when I bought the welder, the work on creation of the snowmobile came to life.

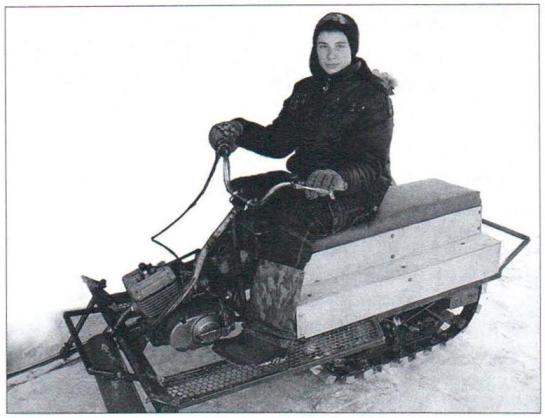

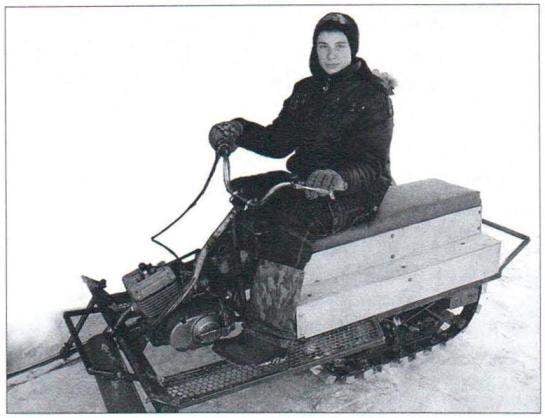

The snowmobile is under construction, and intermediate tests

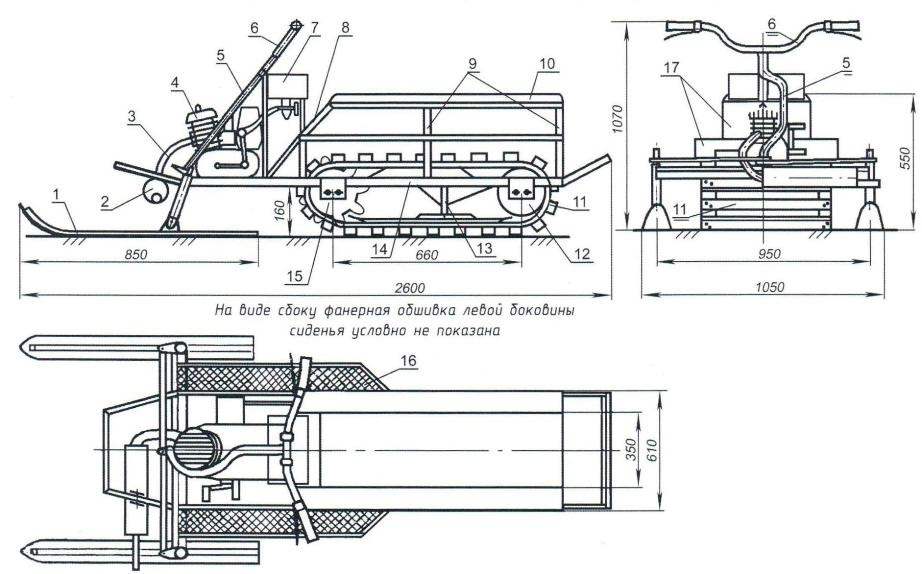

Although the frame of the snowmobile and spatial, but simple – rectangular in plan. Its main power elements (spars and cross-beams) are welded from steel pipes of rectangular section 40×20 mm, subsidiary – of square pipes 20×20 mm. the Front cross member is made of a tube section 60×30 mm and is welded to the front ends of the side members at an angle of 15 degrees (the angle between the longer wall of the pipe and the horizontal). In fact, all sleepers, except the first, made in the form of portals (U-shaped only for short racks). At first gantry rack cross bars made slightly inclined inwards (so it seemed to me more beautiful), but as it turned out on the test, they began to affect the ends of the tracks. It was necessary to shorten the already short tracks, so I decided that it is better to digest the portals, making them rectangular.

To detail frames can be attributed to the housing the steering knuckle managed ski. The case is made of steel pipe with outer diameter of 32 mm with a wall thickness of 5 mm and welded to the ends of the beam under an angle of 15 degrees to the vertical.

Frame:

1 – front bumper (steel tube 20×20); 2 – bushing, steering knuckle guide skis (pipe 022, 2); 3 – front eye mount of the power unit (sheet s4); 4 – spar (tube 40×20, 2); 5 – rear eye mounting the power unit (sheet s4); b – brace (steel tube 20×20); 7 – retaining front bushing steering shaft (tube 20×20); 8 – bushing the steering shaft (tube 028); 9 – spacer, seat (steel sheet s2); 10 – spinal jumper (tube 20×20); 11 – gantry stand (pipe 20×20, 6 PCs); 12 – rear bumper (tube 20×20); 13 – Klondike (steel sheet s4, 4 items); 14 – mounting bracket drive shaft and idler axis tracks (steel sheet s4, x4); 15 – framed footboard (pipe 20×20,2 pieces); 16 – portal jumper (pipe 20×20,3 PCs.); 17 – supporting cross member (tube 20×20); 18 – cross member (tube 50×30)

Ski reference:

1 – frame (steel area No. 2); 2 – sole (polyethylene s5); 3 – (sheet s2); 4 – bracket (2 PCs); 5 – rivets (bottom – head wpoty set)

Guide ski:

1 – the snake (sheet s3); 2 – ridge (steel tube 20×20); 3 – bushing (steel pipe d26x2)

Reference ski on the racks. Is clearly visible the stretch axis of the track rollers

Caterpillar mover similar to those used by most self-telsikom. Its caterpillar is a pair of parallel endless bands (with riveted ends) conveyor belt width 65 mm, combining tracks from wooden bruskov section 50×40 mm, attached with a step of 100 mm. the Total length of caterpillar – a little more than two meters, the number of tracks on it – 20 pieces. So the caterpillar not “slid” to the side, at the ends of the bars-truck (one or two) with the free side fixed angles. Each corner – piece welded, with vertical shelves-walls are made rounded (pipe) to the corners themselves are unable to support wedged on the ski or final drive gears.

Node of the drive shaft of the caterpillar:

1 – drive sprocket shaft-drive tracks (z=32); 2 – the bearing №205 (2); 3 – key; 4 – hub drive sprocket (tube d40x7,5); 5 toothed wheel z=8, t=50 (aluminum); 6 – flange of fastening of a cogwheel to the shaft (steel sheet s4, 2); 7 – shaft (steel, round 25); 8 – bolt М8х25 (8 PCs.); 9 – the bearing № 205 (2); 10 tracks; 11 – shaft bracket to the frame

The caterpillar (a-front view; b – abutment track; in the top view of the left during track):

1 – Trak (birch timber 50×40, compl.); 2-band (belt 65×10, 2 pieces); 3-limiter (steel sheet s4, compl.); 4 – plate (steel sheet s4, compl.); 5 – bolt M6 with plain and spring washers set).

The layout of the power unit

Crawler unit

Top runners preventing the sagging of the tracks

The lower branch of the caterpillar props supporting the ski, and the upper branches do not allow to SAG two runners from wooden bruskov by section 50×50 mm. the ends of the runners are beveled for easier entry to them, and a quiet gathering with their tracks. Support ski made of sheet polyethylene with a thickness of 5 mm on the basis of steel 2 mm sheet frame from area No. 2. Front and back it has the folds up. As a lubricant in the slide tracks for supporting the skis and runners is the snow, which, as practice shows, ensure the service life of parts in one or two seasons (depending on usage), then they have to change. Reference ski in the subframe is pivotally attached to a pair of uprights welded to the other ends of the cross member of the frame made of rolled corner 50×50 mm. But on the first test stand began to bend. They had to reinforce the struts of steel strip 30×4 mm section Rails mounted in parallel to the side members and attached to the crossmember frame is rigidly bolted M10.

The power unit, as mentioned above, used a motorcycle “Minsk” (two-stroke, the working volume of 125 cm3 and a power of 10 HP). It is located in front, in the middle of the frame. This arrangement made it possible to think about the weight of the unit, but was forced to do a “crooked” steering shaft, so that when the corners he went around the engine cylinder without touching it. The engine secured to the frame by a pair of brackets, lugs made from 4 mm steel sheet and cut to form a staff, which is welded to the frame of the motorcycle. Motor no alterations were not exposed, even the sprocket output shaft remained full-time, toe-ndcategory.

Steering:

1 – the wheel (from a motorcycle “Minsk”); 2 – steering shaft (steel pipe d22x2); 3 – a Pitman arm (sheet s4); 4 – knuckle (steel sheet s4, 2); 5 – transverse thrust (steel sheet s4,2); 6 – pin plug (2); 7 – casing the knuckle (steel pipe d32x5,2); 8 – bearing (nylon, 4x); 9 – traverse

The knuckle housing:

1 – the case of the steering knuckle; 2 – pins (steel, round 16, 2); 3 – plug (channel No. 5); 4 – axis fist (steel, circle 16,2 PCs); 5 – bearing axis (kapron. 2); 6 – nut M16 spring washer fixing axis (2 compl.); 7-knuckle (steel sheet s4); 8 – nut M16 spring washer of fastening of the lever; 9 – the bearing of the king pin (nylon, 4 PCs); 10 – frame cross member; 11 – rib skiing (ski ridge); 12 – runner skis; 13 – sleeve ski

Instrumental-stowage compartment under seat cushion

Fuel (gasoline mixed with motor oil for two-stroke engines) is supplied to the carburetor of the engine by gravity from a homemade gas tank volume of 5 liters, is located on the engine between the wheel and the seat.

Transmission of a snowmobile is also the simplest – without intermediate shaft and gear. Chain transmission with the output shaft transmits the rotation directly to the drive sprocket shaft caterpillar, which is fixed a pair of drive gears of the belt. Gear wheels were cast in a circle of melted in an electric furnace of aluminium in cast iron form. They are connected to the shaft via welded to a round steel flanges, each with four bolts M8.

The shaft rotates in two bearings No. 203, which is fixed on intended for them (welded to the longerons) of the vane brackets of the frame. In the likeness of a drive shaft made and the stretch axis, but instead of driving gear wheels it is fitted with two rubber roller, diameter is smaller.

The chain is tensioned (or weakened for disassembly) bias the drive shaft away from the power unit, a track offset rear axle stretch even further back.

Guides skis (two of them) made of steel sheet 3 mm thick and reinforced welded from the top longitudinal stiffener of the steel pipe section of 20×20 mm. With stand knuckle is pivotally connected to the ski and has the ability to turn in a vertical plane to run into obstacles and run in them. In the horizontal plane of the ski is rotated together with the knuckle from the action rods when turning the steering wheel. Undercut (or, as they are often called, “knives”) skis do not have, but the handling is not affected much because the ski is quite narrow.

Steering is a typical snowmobile with two skis and administering kvadratikov: the wheel of the stag motorcycle type steering shaft with bipod, well cross rod with steering knuckles on the car. The feature of the steering shaft was noted above – it “curve”.

Brakes snowmobile, but stops quite quickly due to friction of parts and components in the crawler block and transmission when you reset the “gas”.

And although my snowmobile made in a simplified version, has a lot of drawbacks, but to me it pleases with its enviable cross virgin snow and snowdrifts. Therefore, the snowmobile I call “Shreber KM-125” – conqueror of the drifts.

SOROKIN, p. Ust-Kamenka, Altai Krai

Recommend to read TO HELP VALVE For lifting of drinking water from boreholes and wells, often used external centrifugal pumps of the type "don" or "Kama". It is a reliable and high-performance mechanisms, but they have... TRACTOR-“WOLFY” The idea is to make a mini-tractor ripe at once: an allotment I have a small, but because I was without equipment. In General, it was more a desire to test their capabilities. In the...