Readers of “M-K” have already had the opportunity to meet with a student design Bureau Mari Polytechnic Institute (see No. 8, 1977). This team is many years engaged in the original design of snowmobiles, including many snowmobiles amphibians. During the time elapsed after the publication at SKB have developed two more such machines.

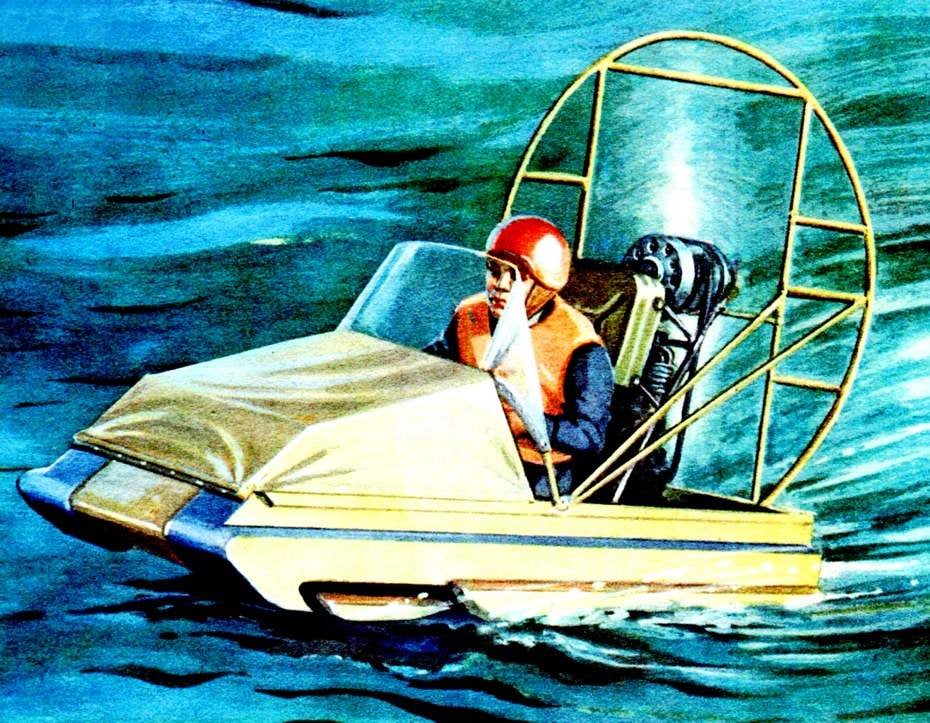

Readers of “M-K” have already had the opportunity to meet with a student design Bureau Mari Polytechnic Institute (see No. 8, 1977). This team is many years engaged in the original design of snowmobiles, including many snowmobiles amphibians. During the time elapsed after the publication at SKB have developed two more such machines. The first amphibious MPI-8 is to move snow and ice, and clean water, and sludge. The machine was successfully tested on the Caspian sea. Second — SAVR-1 (snowmobile-amphibian original structural diagram of the air unloading the skis) prepared for him.

The need to create snowmobiles that can move through snow and ice, overcome glades and gullies, to sail on open water and through the broken ice, is long overdue. The fact that such complex conditions exist in our country almost everywhere: in the far North, in the tundra and in the taiga, and in the middle lane, where there is a freezing swamp and rivers. Regular vehicles — cars, tracked ATVs, and snowmobiles motonarty — in such circumstances, often helpless.

In addition, young designers student design bureaus, MPI set out to create a machine that is able to move in forest clearings, small bushes and on the hillsides (with more roll). Therefore, the main task in developing the concepts was the ultimate relief of amphibians, lowering its centre of gravity and decrease the size. It was necessary to create a structurally simple, cheap to manufacture and simple to operate in harsh winter conditions aerohod.

The creation of MPI-8 was preceded by extensive experimental work SKB: the construction and comprehensive testing of amphibians has allowed to identify and correct many design errors, reduce the resistance and increase the reliability of propeller installation.

A story about the work of SKB MPI aroused a keen reader’s interest. The newspaper received hundreds of letters with the request more to describe the work of the students, particularly in light snowmobile-amphibian MPI-8. We offer you the drawings and the description of this interesting device.

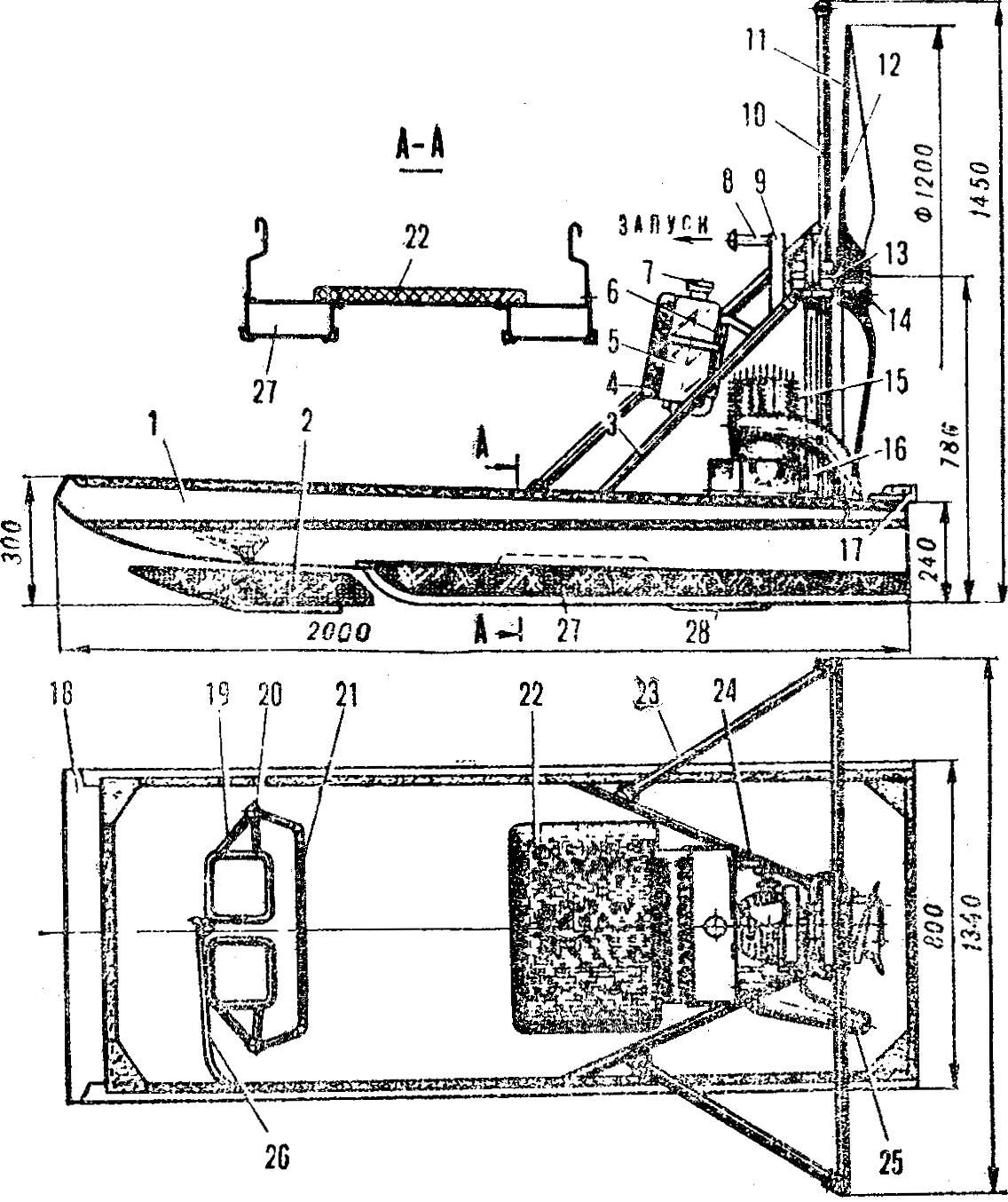

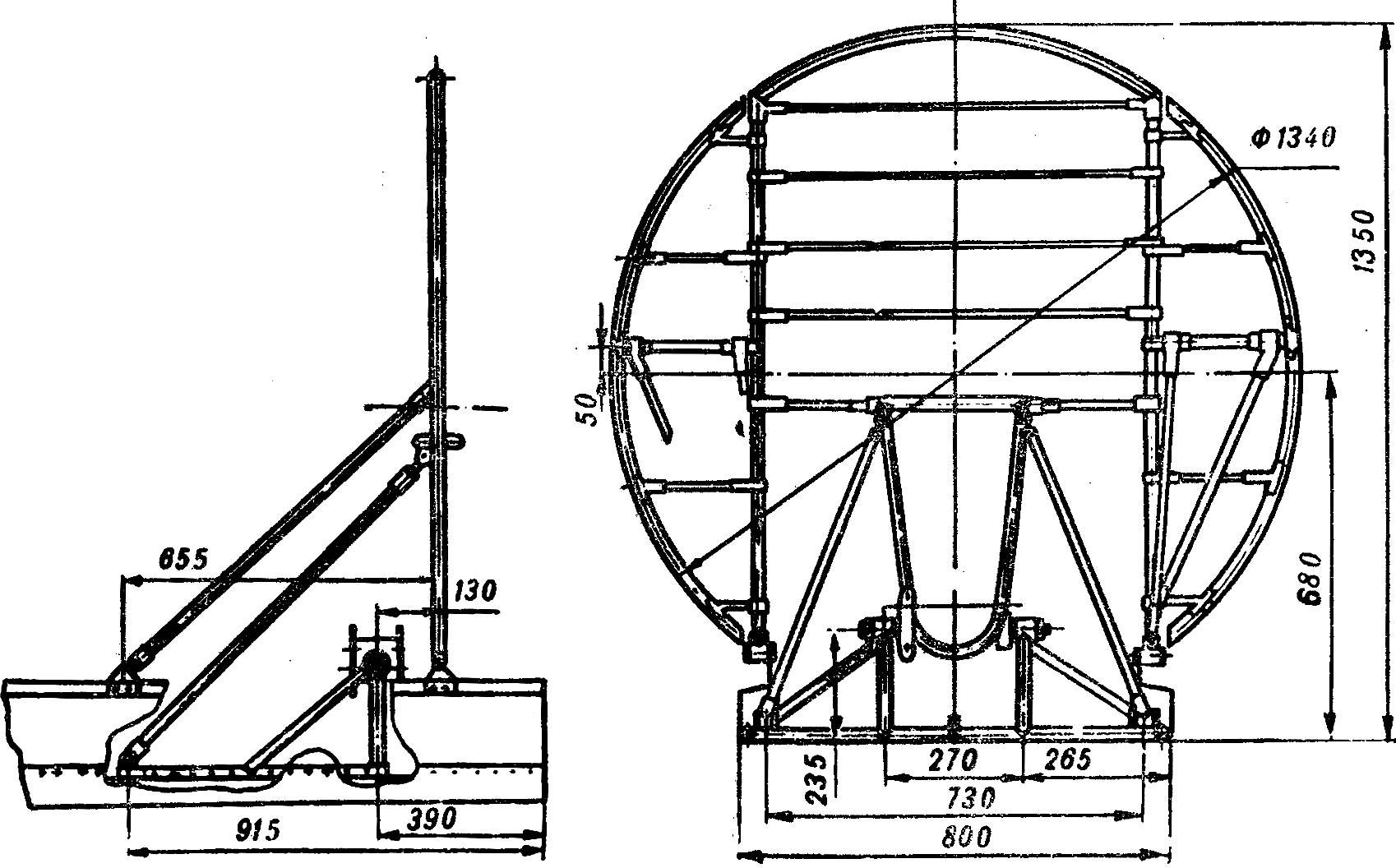

Fig. 1. Snowmobile amphibious MPI-8:

1 — body, 2 — front ski, 3 — strut, 4 — cushion backrest, 5 — fuel tank 6 — bracket, 7 — neck tank, 8 — starter motor 9 — starter motor case 10 — fencing of the propeller 11 — propeller 12 — bearing housing, 13 — shaft propeller, 14 — bushing screw, 15 — drive, 16 — toothed belt transmission, 17 — tow-node, 18 — hull plating, 19 — pedal control, 20 is a vertical turning axis of the ski, 21 — rod of a steering trapeze, the 22 — seat cushion, 23 — brace fence screws 24 to the carburetor of the engine, the 25 — exhaust pipe, 26 — control cable-throttle carburetor, a 27 — ledge-ski 28 is undercut.

Amphibian MPI-8 — single machine. It can carry loads up to 80 kg, placed on the shares.

The body of the amphibian is a flat-bottomed boat with aft U-shaped (in cross section) shape, formed by two ledges-skiing. The ratio between the width and length of the ski (1/8) is selected so to provide minimal resistance to movement but the snow of average density.

Two guided skiing, located in the front of the case, in the mode rectilinear motion have the same track as the rear. This significantly increases the throughput and reduces the resistance to movement.

The material of plating of the hull — duralumin brand D16T with a thickness of 0.8 mm. the hardness of the Board is provided with longitudinal ribs and reinforced frames. The bearings of the uprights of the steering ski mounted on the front bulkhead, on average, a fixed brake system and struts motor installation, and surround rear frame serves as the sub frame.

Tabs-skiing in the stern of the boat is made of duralumin D16T sheet thickness of 1.5 mm. Crenata them to the hull with screws with countersunk head, with a mandatory prietom sealing of threaded connections. On the external side of each ski is mounted a short steel undercuts that increase the stability of the course amphibians and to prevent “hunting” when driving at high speed, especially on a hard crust or ice.

The hull plating riveted to the frame member. At the connection of the housing with the struts and engine mounts and the front fence of the propeller, a steel connecting nodes with the bolt holes. To gain the upper edges of the sides of the raised wooden boss.

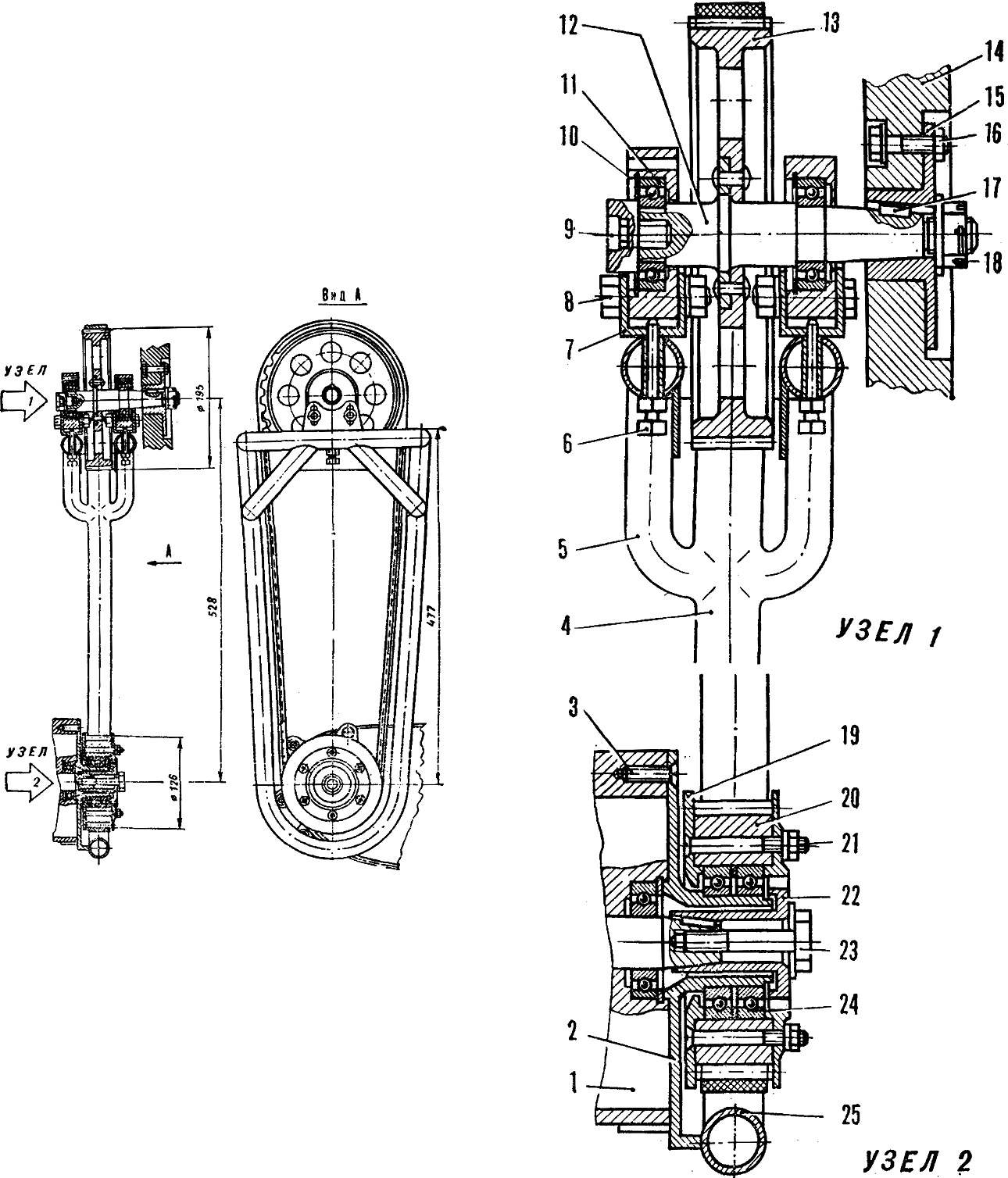

Fig. 2. Transmission snowmobile-amphibian MPI-8:

1 — crankcase 2 — fixed half-coupling 3 — bolt coupling half, 4 — the main Desk, 5 — fork rack shaft of the propeller 6 — tension bolt, 7 — guides cheeks, 8 — bolt, 9 — ratchet releaser, 10 — housing, 11 — bearings of the propeller shaft, 12 — shaft of the propeller 13 is driven sprocket 14 — propeller, 15 — flange propeller, 16 — bolt with nut and split-pin, 17 — key, 18 — a nut of fastening of a propeller, 19 — movable cover halves of the coupling, 20 — lead sprocket, 21 — bolt 22 — seal and the flange of the movable coupling half, 23 — bolt coupling half, 24 — bearing, 25 — tubular strut shaft propeller.

The front skis amphibians are associated with the control pedals, welded of steel thin-walled tubes. Tubular transverse thrust ensures the synchronism of rotation. On the right was in charge of a control lever throttle carburetor: thus, all Snowmobiling is focused only on the pedals of the driver.

The front ski has a box-like shape and made of sheet aluminum. Sole boxes are connected by screws with countersunk heads. The outer side of each box, a steel undercuts. The internal cavity of each ski is foam-filled. The soles of the skis, as well as the bottom of the case lined with polyethylene to adhesive PU-2: this reduces the resistance to movement and allows the body and the skis to freeze to the ice.

Propeller installation (including fencing of the propeller) is connected to the case hinge, which allows, if necessary, by disconnecting only the motor struts of the frame, move the engine so that it lay on the bottom of the case. In this position, the amphibious vehicle has minimal dimensions and can be transported by any other mode of transport.

The power plant consists of a serial engine IZH-P with capacity of 25 HP, belt-drive transmission, propeller. Last fence.

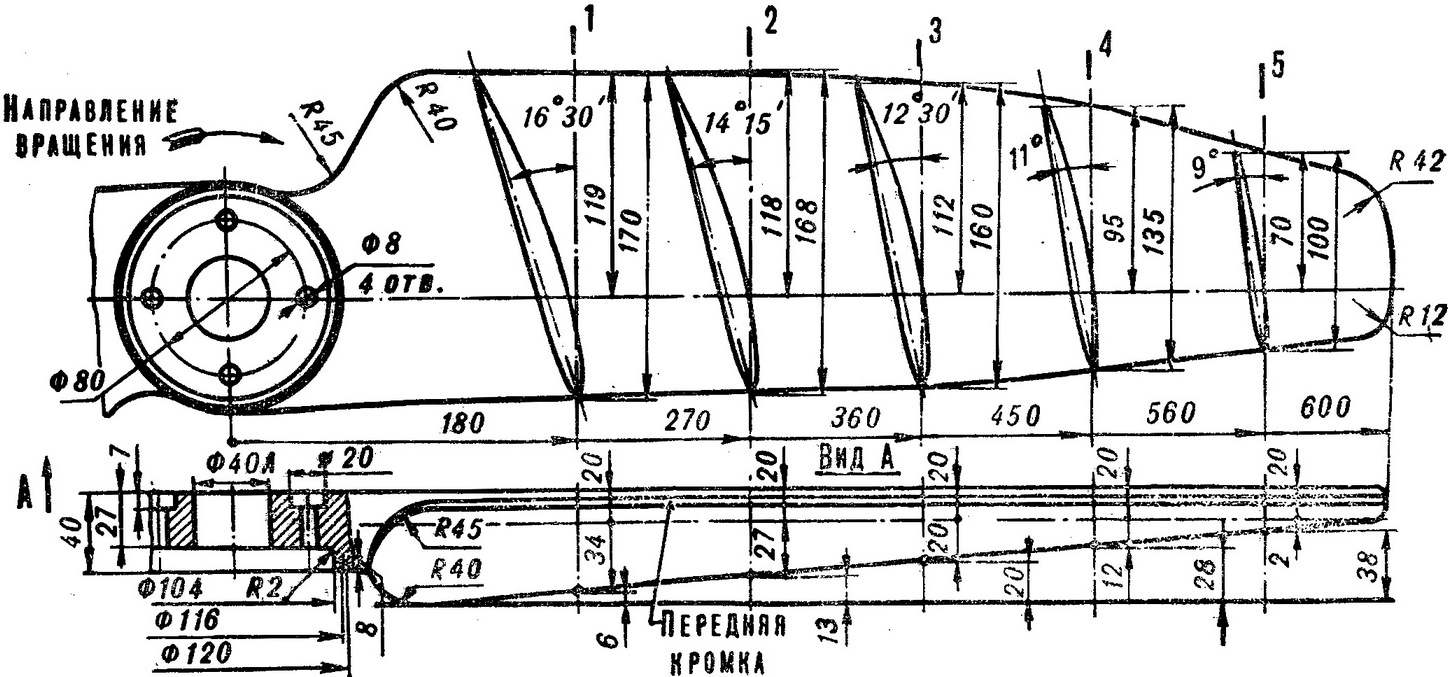

In preliminary tests the amphibians of the first and second models it was found that the action of the crankshaft of the engine alternating transverse loading (tension chain or belt), that can only handle 100-120 hours of work. Had to specifically create mechanisms for unloading of the shaft, to eliminate the influence of side forces on the overall life of the engine.

This mechanism is arranged as follows. On the crankcase with screws fixed fixed half-coupling, a bushing whose inner races planted two ball bearings. On the outer race of the bearings is mounted a drive pulley is assembled together with the movable coupling and cap. The latter has a sleeve with reverse taper and keyway, which correspond to the Seating cone of the engine crankshaft. Under the center bolt of the movable half-coupling to the crankshaft is placed spring washer. The coupling consists of two parts the hub and flange, interconnected slots. This design of this site allowed us to eliminate unwanted load on the crankshaft of the engine arising from inaccuracies of Assembly and warps when docking.

Torque from the engine to the propeller is transmitted by toothed belt. Practice has shown that such transfer is much more reliable than chain or belt.

The driven pulley of its internal groove is installed on the flange of the propeller and fixed with rivets. The screw shaft rotates in two bearings located in the movable housings. The latter have the option of using adjustment screws to move along the guide cheeks that allows you to change the belt tension. The final fixing of tightening bolts, the bearing housings are clamped between the guide cheeks.

The shaft of the air shield is mounted tubular bracket welded to the edge of the stationary coupling half. Bracket pipe and perform the function of fence timing belt.

The propeller is mounted on the cone shaft. Fixation sleeve screw on the cone — nut screwed on the threaded shank of the shaft. The locking of this nut is required.

On the opposite side of the screw shaft has a threaded hole for mounting the ratchet starting mechanism constituting the recoil starter spring return. To ensure driver safety and ease of launch cord thrown through the block: this allows the driver to start the engine directly from the corps amphibious.

Security reasons and to protect from damage in front of the air screw has a tubular fence. As well as the motor, it is mounted on the body hinge and the folding propeller installation rests on the housing Board.

Fig. 3. Structural diagram of the fencing of the propeller.

Fig. 4. Propeller-to-engine IZH-P.

Propeller Ø 1200 mm made of magnesium alloy MA-3. The maximum width of the blade — 170 mm. pitch on a radius of 450 mm 540 mm. To the flange of the bushing screw is fastened by four bolts M8 with mandatory locking nuts soft wire.

Fuel supply by gravity. The fuel tank is hung on the brackets of the braces of the frame.

Interesting solution to the braking device amphibians. The brake proper blade type: scraper is in a box, embedded in the bottom of the case. To avoid clogging it with snow, in the box displayed the exhaust pipe of the engine. This measure ensures reliable operation of the braking device even in the most severe frosts.

The driver’s seat consists of soft foam cushions installed on the bottom of amphibians, and back — similar to the pillow attached to the gas tank. The machine is also equipped with seat belts.

S. KIRKIN, supervisor of salvage and Mari Polytechnical Institute, Yoshkar-Ola