The power plant made the type of those that are widely used in light aircraft. Its basis is suspended 22-HP engine “Whirlwind-30” equipped with chetyrehluchevoy V-belt gear with a ratio of 1.6. The use of a reducer to substantially increase the thrust of the screw rpm at maximum engine power.

Driving and driven pulleys are machined from aluminum alloy; the engine flywheel drive pulley secured with ten bolts and M5 self-locking nuts. Cantilever axis of the driven pulley are fixed by bolts on the spacer, steel 5 mm plate. Himself driven pulley rotates in three ball bearings.

Plate-spacer, in turn, is mounted on the crankcase of the engine; the tension of V-belts is manufactured using welded to the spacer sleeve and bolt with nut.

Engine cooling – liquid, as applied to the radiator oil cooler from the car GAZ-53A, mounted on the frame of the snowmobile tubular struts. Pump – improvised, with the impeller from the water pump “Kama”. Silencer – homemade, assembled from blocks of used car oil filters with the filling in their “drain” chips or thin wire with thread waste.

Fig. 7. V-belt gear power plant:

1 – bolt M10; 2 – washer; 3 – propeller (Vileika of pine boards); 4, 17 – bolts M8; 5 – lock washer; 6 – thrust bearing 8204; 7 – ball-bearing 204; 8 – cantilever axis; 9, 10 – sleeve; 11 – ball bearing 205; 12 – a remote washer; 13 – a lock ring; 14 – nut M8; 15 – a bolt mechanism for the belt tensioning; 16 – driven pulley; 18 – bolts-adapters; 19 – bracket reducer (2 PCs); 20 – V-belts (4 PCs); 21 – drive pulley; 22 – rivet (steel, diameter 5 mm); 23 – spacer; 24 – engine “Whirlwind-30”

Fig. 8. Pusher propeller

The engine is mounted on the skin-vector frame, and that, in turn, on the frame of the snowmobile. The stiffness of the engine mounting provided by a pair of tubular struts.

Propeller planes made of well seasoned pine wood. Billet screw is laminated on the epoxy adhesive of the four boards in the thickness of 11 mm; in the process of curing, it is desirable to withstand under pressure or, in extreme cases, to pull the workpiece through a dozen traverse from scraps of steel channel and bolts M12 nuts.

After curing the resin in the blank, drill a center hole, then it is labelled in accordance with the drawing of a propeller.

For further processing of the screw must be made of sheet aluminum 2 mm thick templates of the control cross-sections screw – separately for the upper and lower bow sections. Next on the templates by round bastard a file on the workpiece propisyvayutsya grooves, which then use the plow and plane are combined in the specified control surface sections. When fine-tuning screw, the main thing – to achieve symmetry: both mass and aerodynamic. After finishing the screw is balanced, glued by a layer of fiberglass, sanded and finally painted.

The fence of the propeller is a ring, is laminated from three layers of 3-mm plywood. Bakpaka is made on particle Board, which is circumferential with a diameter of 1400 mm in increments of about 10° fixed “triangles”, assembled from wooden bars 40×40 mm. Plywood strips with a width of 200 mm, cut across the layers are lubricated with epoxy glue and are fastened by clamps to the “triangles”. After curing the binder ring is cleaned, puttied, painted in the body colour and mounted on a snowmobile. From the back of the ring is tightened rare wire-mesh cell is approximately 100×100 mm.

Igor KARAMYSHEV

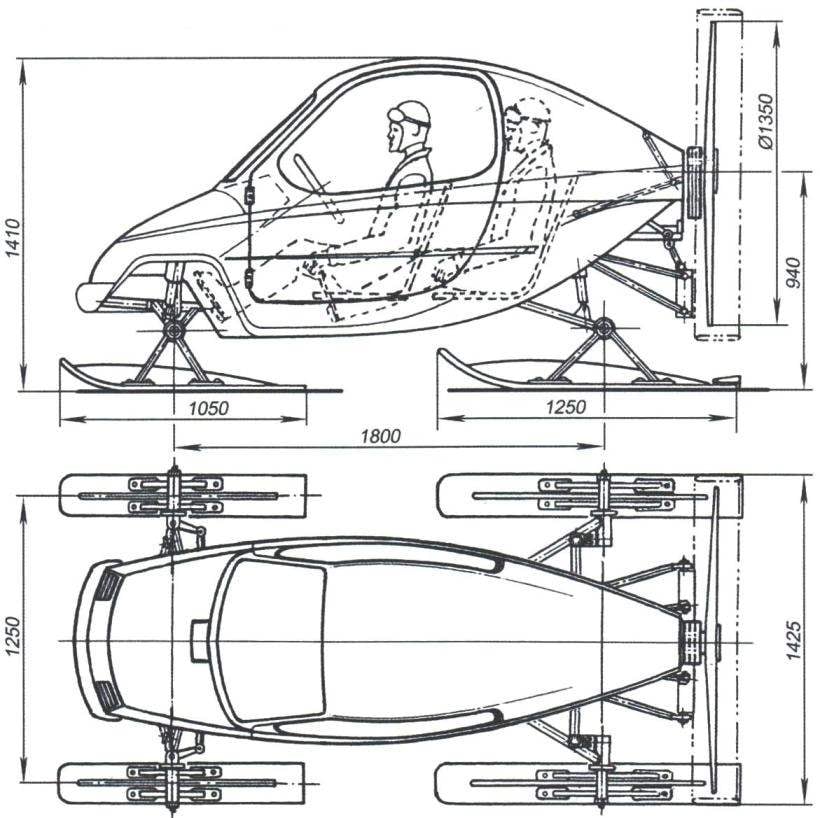

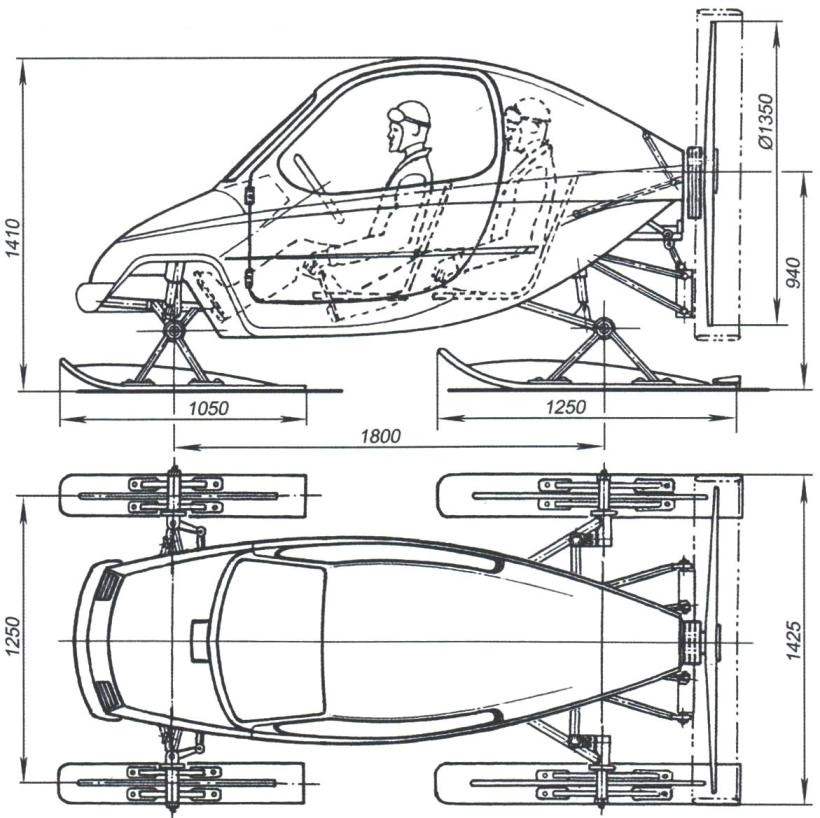

Double snowmobile “SQUALL-3”. With the advent of motoparaplane and trikes culture of designing power plants with propellers significantly increased, and today Amateur designers create rotor setup with decent traction engines using relatively small power. Accordingly, began to appear more frequently and wingless versions of these vehicles – hovercraft, snowmobile and aerolizer.

Double snowmobile “SQUALL-3”. With the advent of motoparaplane and trikes culture of designing power plants with propellers significantly increased, and today Amateur designers create rotor setup with decent traction engines using relatively small power. Accordingly, began to appear more frequently and wingless versions of these vehicles – hovercraft, snowmobile and aerolizer.