Many readers were interested in the material “Migomobile — fantasy? Reality!” (1977, No. 11), tells about an unusual engine for transport — the flywheel developed by a group of young enthusiasts, members of the NTTM. To meet the wishes of readers to continue this topic, we begin today the publication of a series of articles about the transport of tomorrow. To keep this section we asked doctor of technical Sciences Professor N. V. Gulia.

Many readers were interested in the material “Migomobile — fantasy? Reality!” (1977, No. 11), tells about an unusual engine for transport — the flywheel developed by a group of young enthusiasts, members of the NTTM. To meet the wishes of readers to continue this topic, we begin today the publication of a series of articles about the transport of tomorrow. To keep this section we asked doctor of technical Sciences Professor N. V. Gulia.

Scientists dealing with the problems of the future — futurists today are trying to determine what will be the world around us, for example, by the end of the second Millennium or even 100 years. At the same time something can be seen relatively easy, something hard. But firmly we can say that in 50, 100 years or more the transportation will exist. And not only to exist, but to grow steadily.

Science fiction writers sometimes suggest that in the future most of the information can be transmitted mainly by means of communication — from video phones to laser channels. The role of transport as a carrier of not only goods, but information is not taken into account. But this is not so.

The advantage of transport in that it moves not only goods but also people — the most capacious media. The famous Soviet scientist-Transporter is Professor V. N. Ivanov emphasizes, “People need direct communication and not replace it can no phone, no TV, nothing else”. Not by chance, despite the significant progress of communication tools, today will continue to be improved and transport.

What are the ways to go its development in the future?

Most of the problems can be summarized as follows: transport machines, or rather their engines, should be harmless to the environment, or, as they say, “eco-friendly”. “Field of view of the Soviet scientists, — said in the report of the Central Committee of the CPSU XXV Congress of the party General Secretary of the CPSU Central Committee, Chairman of the Presidium of the Supreme Soviet of the USSR Leonid Brezhnev, — must not fall aggravated the problems of environment and population”.

In order to stretch” the consumption of fuel and energy resources of our planet, the engines should be the most economical. Great attention is paid to safety of machines, as well as such traditional issues as further improving the speed, maneuverability, comfort. Will be created and develop new, specialized types of transport for the national economy

However, what all the same it will be, future transport, its engines? If they are prototypes right now, today? All of these issues are devoted to these materials.

1. HEAT: “FOR” AND “AGAINST”!

Mankind blames. So we can formulate the current with respect to the mass of the engine — heat, and in particular to the internal combustion engine (ice).

The articles of “guilt” heat engines to humanity in two. The first is wasteful, barbaric expenditure of non-renewable natural resources of fuel. The second is the environmental pollution with toxic exhaust gases and other waste derived energy, including excessive heat, noise and smell. All this is now quite a lot to say. In the same way as on the ensuing inexorable conclusion: if not to improve heat engines (or abandon them altogether), then the planet in the foreseeable future, measured in tens of years, is threatened, first, fuel starvation due to exhaustion of reserves of natural fuel; second, the mass poisoning of humanity by the products of the combustion of this fuel, and possibly excessive (worse than in the hottest steam room!) atmospheric warming.

So, an improvement, or a complete failure. If you remember that heat engines are installed on hundreds of millions of cars, motorcycles, tractors, harvesters, aircraft, ships, motor boats and other machines, it will be clear that to completely abandon these people until you can. However, it is necessary to do so to extend their age, did not significantly reduce the century! How to reconcile the thermal engine and person?

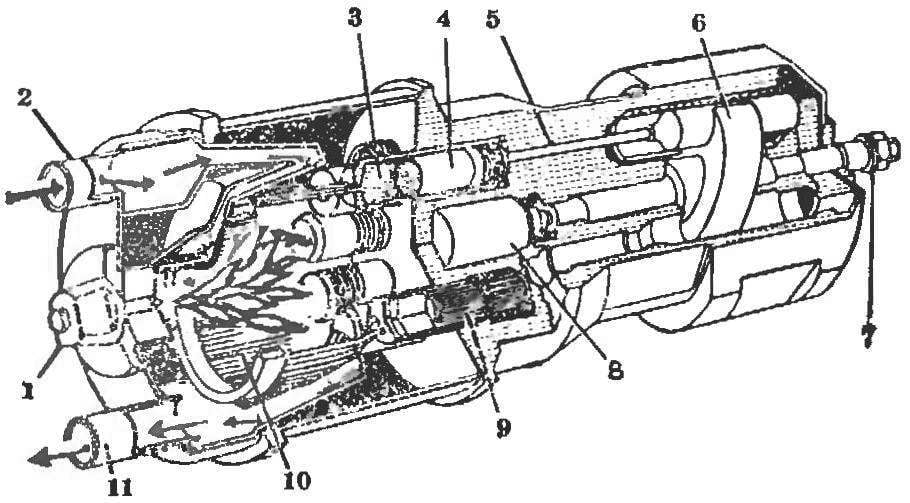

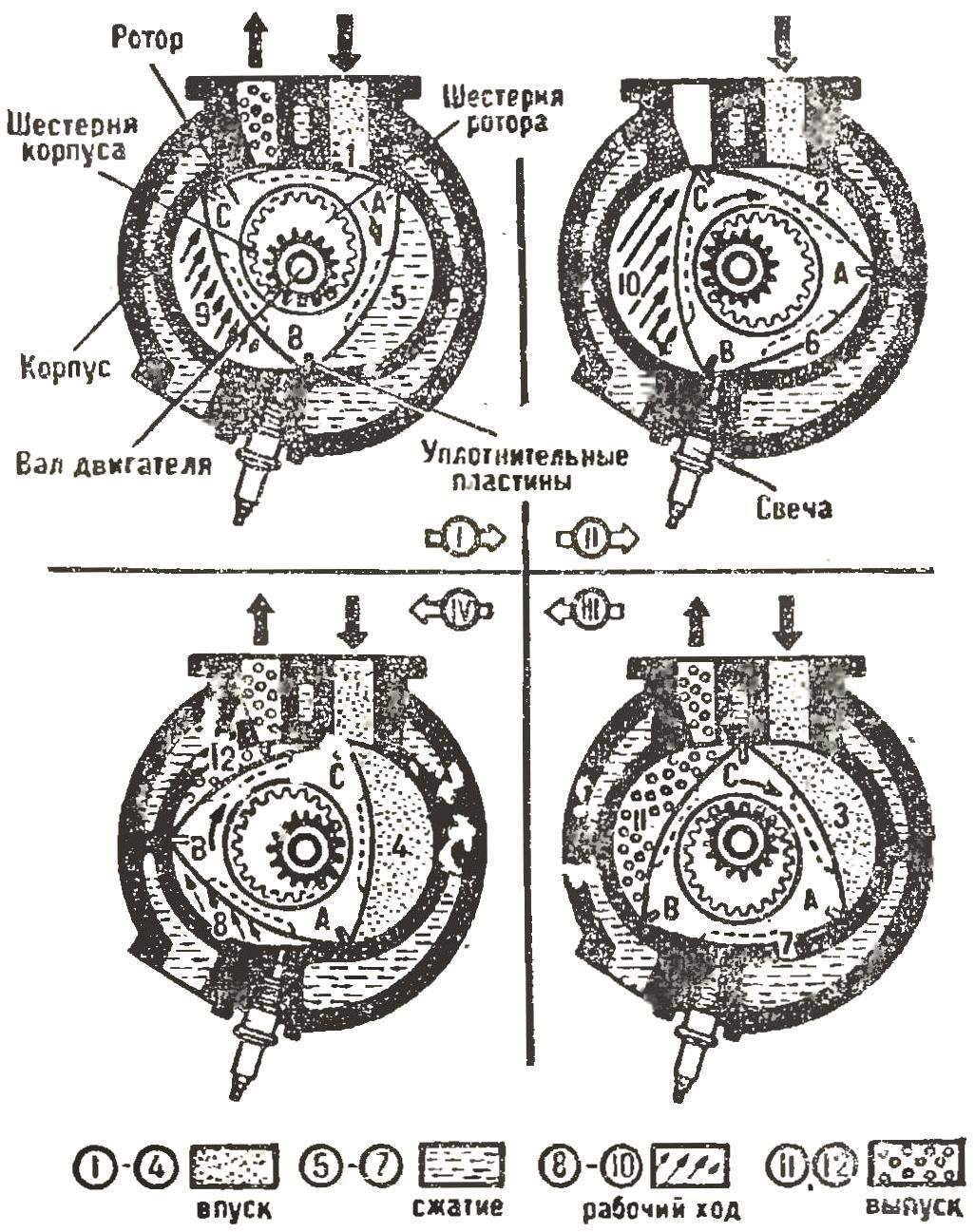

Fig. 1. The Wankel engine (in comparison with a conventional motor).

Fig. 2. The duty cycle of the Wankel engine.

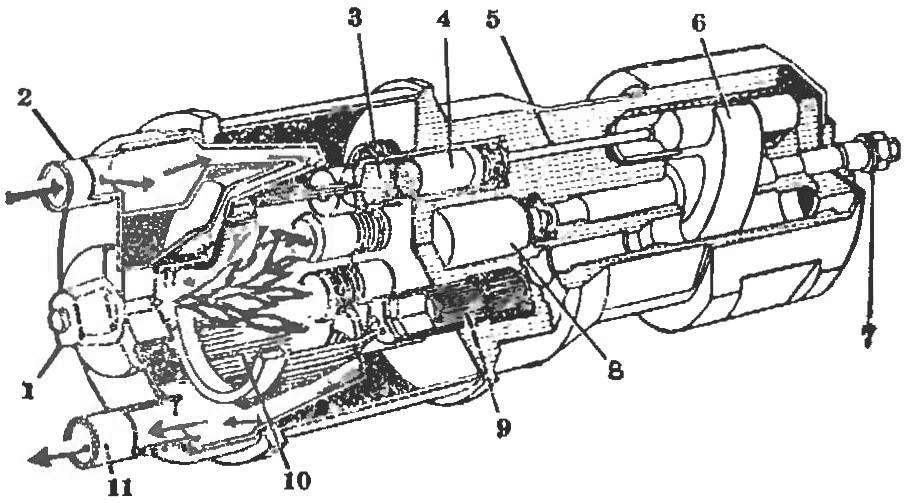

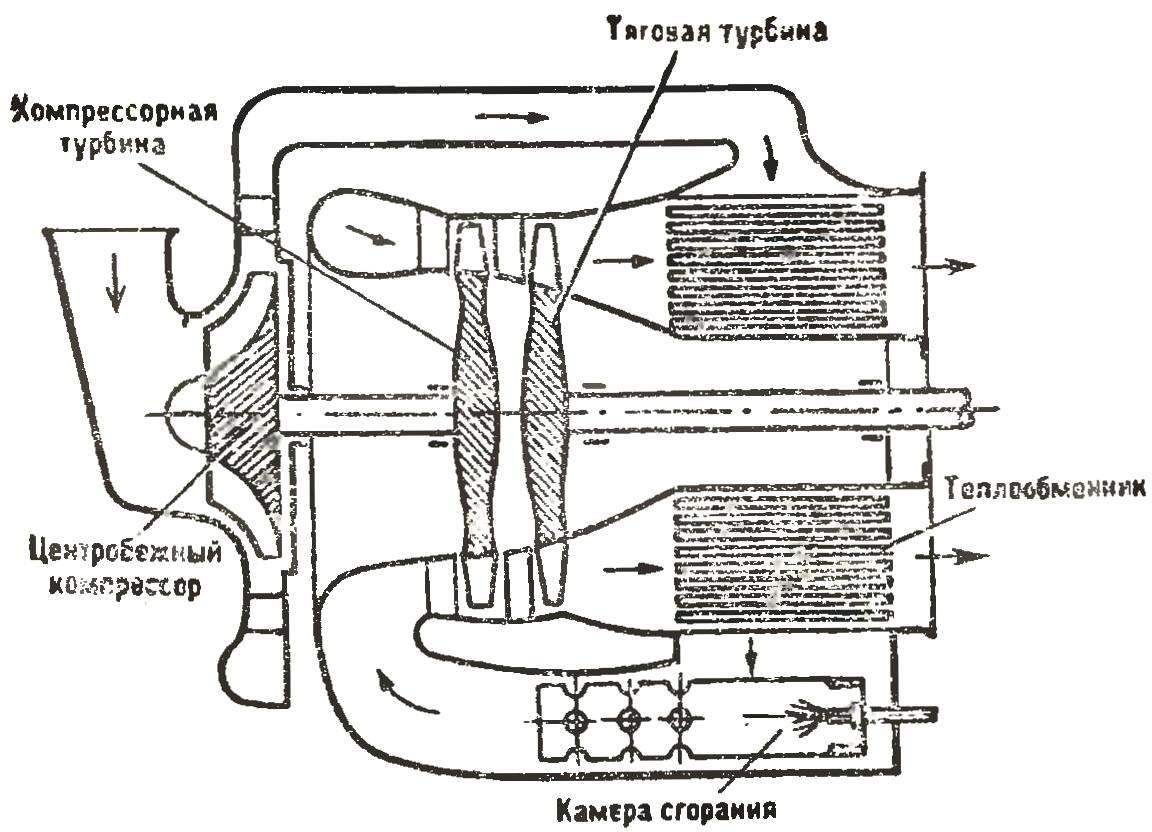

Fig. 3. Diagram of the two-shaft gas turbine engine.

The answer is simple and complicated: it is necessary to eliminate the toxicity of the exhaust gases of thermal engines and increase their efficiency. The main damage is done contained in the exhaust gases carbon monoxide, nitrogen oxides and hydrocarbons (aldehydes), and carcinogenic substances. But they, obviously, it is possible to catch? Yes, these traps-converters already created: liquid, plasma, catalytic and combined. They are usually on the exit of gases in the exhaust pipe of the engine.

However, all these devices provide only a partial resolution of the question: even if available, the engine itself remains the same voracious mechanical monster.

From the age of the dream experts on the engines was to build one where the pistons do reciprocating motion, but only rotated. It promised a significant reduction in size and weight of the engine, reducing fuel consumption and emission of toxic combustion products. Approached the solution of this problem more than anyone else, Professor F. Wankel. Many experts believe that its rotary engine could become a major automotive internal combustion engine.

Recall how the Wankel works. In its housing there is a cavity of complex configuration, which rotates the rotor-piston triangular shape connected to the shaft by means of toothed wheels. It sits freely on the eccentric shaft, the center of which coincides with the center of the fixed toothed gear. Omega it along a complex curve, the rotor-piston keeps touching the tops of the inner walls of the housing. For sealing tops installed in the movable plate the volume of the chambers formed by the surfaces of the rotor-piston and the walls of the housing, successively change. Here, the processes of intake, compression and ignition of the fuel, expansion, and exhaust Opening and closing the intake and exhaust ducts by the rotor-piston.

Thus, for one complete rotation in Wankel engine flows all the processes of a conventional four-stroke engine, and at the same time in different working chambers: outbreak fuels, flammable from a single candle, three working speed, three exhaust, three intake of fresh mixture. The Wankel engine was not only the most compact and the lightest (one of his first prototypes with a capacity of about 30 HP, weighed only 10 kg), but with the high number of revolutions. Add to this that it can run on cheap diesel fuel. It would seem, here it is — the solution of the problem. But… no matter how “wise” designers still failed to achieve reliability of sealing of the rotating rotor of This defect, mainly hampering further improvement of the engine, is a genuine scourge engines of this type.

Another direction of search — engines development, currently used in aviation gas turbine (GTE). They work much less the same power of the internal combustion engine, it is easier and safer to operate. Despite the slightly increased fuel consumption, produce less toxic by-products, especially nitrogen dioxide. This is explained by the fact that in the GTE combustion of fuel is continuous, at lower pressures and temperatures than in the piston. Gas turbine engine — the same engine. Only the compression of the combustible mixture carries out the compressor (usually centrifugal). The outer air entering the compressor rotates with its blades, is compressed under the action of centrifugal force, and then is heated in the heat exchanger and into the combustion chamber. Combustion of the mixture of hot gases pushing the turbine blades, the axis of which is located the compressor. Hitting next on the impeller blades of the turbine, they spend a major part of its energy to perform useful work.

This is a basic scheme of the so-called two-shaft gas turbine. It is different because both turbines, high (compressor) and low (working) pressure is kinematically totally independent. For vehicles designed for single-shaft and three-shaft turbine. It is still unknown which of these schemes will be the most promising. Most likely, depending on the required capacity and expertise of the car each of them will be eligible for further development.

All the above engines the fuel is burned in the combustion chamber — inside the cavity, where the rotor, piston or turbine. To control the combustion there is very difficult, so often the fuel is burned, not completely, there’s lots of toxic products. Next, consider such engines, where the fuel is oxidized outside the working chamber (cylinder). By analogy with the internal combustion engines they can be called internal combustion engines. Main of them — steam engines and Stirling engines.

The second era of steamers began only a few years ago, when their design on a modern basis, has engaged in major research centers. These motors have many attractive features: large starting torque, no complex the gearbox, the complete harmlessness of the exhaust. And the dynamism of the steam engine — one of the important advantages.

When improving old schemes have managed to overcome such Porsche classical steam engine, as the explosion of the boiler, excessive weight, complexity of starting and difficulties of using water as the evaporative liquid in the winter. Cumbrous and dangerous hot water boilers came compact tubular steam generators. Managed to successfully fit all of the units in the dimensions of the car.

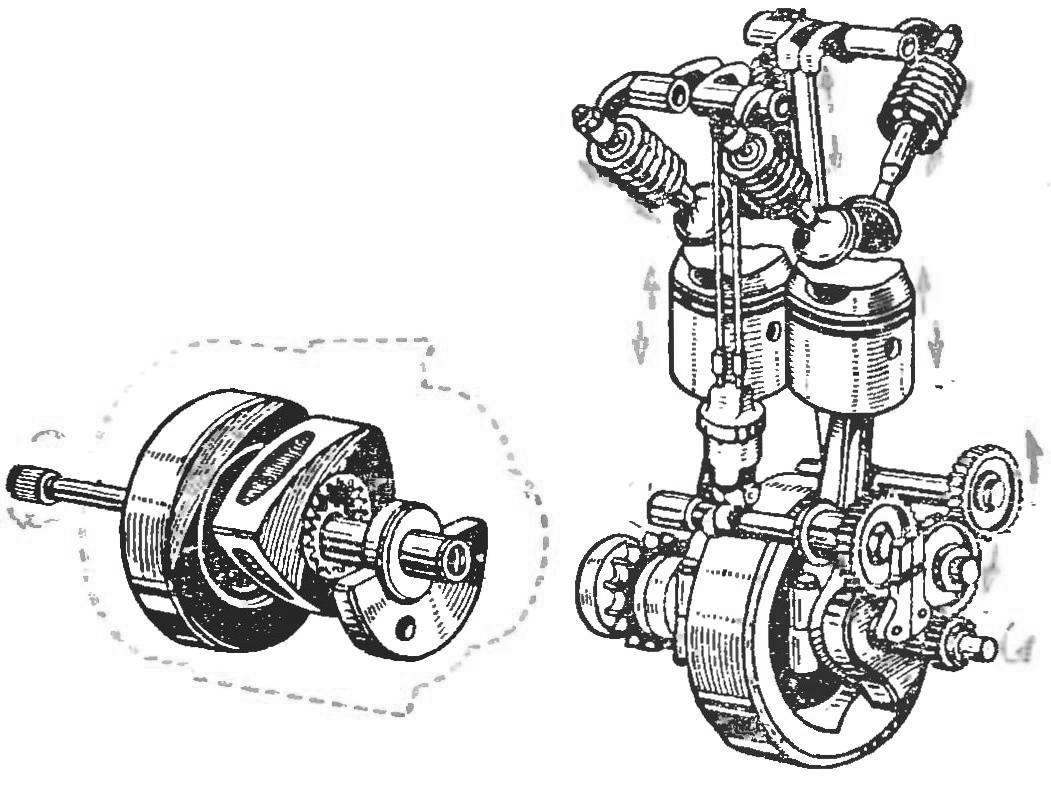

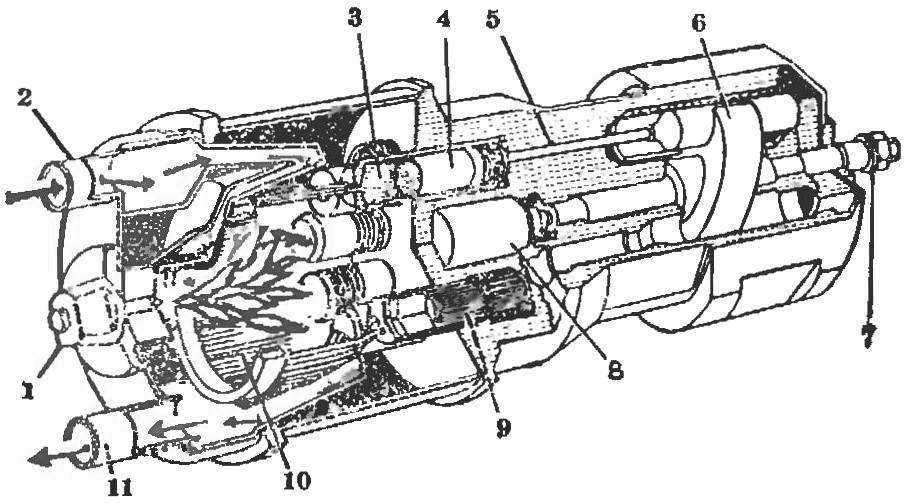

Another promising branch of research is connected with the motor, invented in 1816 by Scot Robert Stirling. This external combustion engine was a blanked off both ends of the pipe, which went the piston. The cavity on one side of the piston is continuously heated, the other cooled. Cool and liquefy gas is pumped into the hot cavity. Here, when a fixed piston, its temperature and pressure raised by heating. After reaching the maximum gas parameters, the piston moved up, making a working stroke. Then the expanded gas is pumped into the cold cavity, where it is continuously cooled, it was compressed by a moving piston. The cycle was repeated.

Fig. 4. Stirling Engine:

1 — atomizer, 2 — air injection valve, 3 — extension, 4 —piston, 5 — pusher, 6 — presenter oblique washer, 7 — shaft, 8 — oil pump 9 — tube gas cooler, 10 — pipe gazavtoservis, 11 edition.

Scheme of the working cycle of the engine.

Since compression of cold gas takes less mechanical work than is released when the expansion hot, the Stirling engine was allocated the excess mechanical energy.

Clearly, this engine could not be particularly Economical. However, if the compressed cold gas before it enters the hot cavity to heat the heat which was given during cooling of a hot gas Stirling can be a very economical engine, exceeding efficiency and gasoline and diesel.

Device for heating gas capacity, called a regenerator, is offered at the time, the author of the invention. B our days the effectiveness of such a heater is brought up to 98%. And the engine cavity began to fill with compressed to 100 — 200 ATM of hydrogen or helium. Improved drive piston of Stirling, making it similar to the axial drive piston pump with oblique washer. The result is a modernized Stirling fits most machines that use heat engines. Toxicity it hundreds of times less than gasoline, and it works almost silently. But while Stirling complex and expensive, and heavier than gasoline.

And yet the above engines the vast majority of active consumers of natural fuel. And its reserves are not unlimited. Therefore of great interest attempts to use as fuel artificially produced hydrogen. To extract it from water, decomposing it with electric current, sunlight, high temperature with catalysts.

The main advantage of this quadcopter is much smaller than that of gasoline, toxicity of combustion products. Of nitrogen oxides formed, for example, 200 times less and carbon monoxide and hydrocarbons in the exhaust at all. However, there are other problems — for example, storing gas in cylinders. However, scientists are proposing to saturate with hydrogen, the hydrides of certain metals, absorbing it like a sponge. It is interesting that the tanks are filled with hydride, contain 40 times more hydrogen than hollow.

The engines are also created, which uses the most unexpected natural factors — solar radiation, evaporation, osmosis. No coincidence they are called exotic: as long as they have a very small spread. But the growing interest in environmentally friendly sources of energy will certainly lead to an increase in their role. They come in handy and space transport — planetary Rovers, the service systems of orbital stations.

An example of exotic motors can serve as so-called motor light absorption. The working cylinder it has a transparent window, through which skipped the sun’s rays or a laser beam, heating the gas in the cylinder. Due to this, heat is made and stroke. The experimental sample of a laser engine gives up to 600 Rev/min when the equipment power is 30 watts. The efficiency of this engine, though was less than 2%. Known motors, powered by solar radiation. It is converted via photovoltaic cells into electric current.

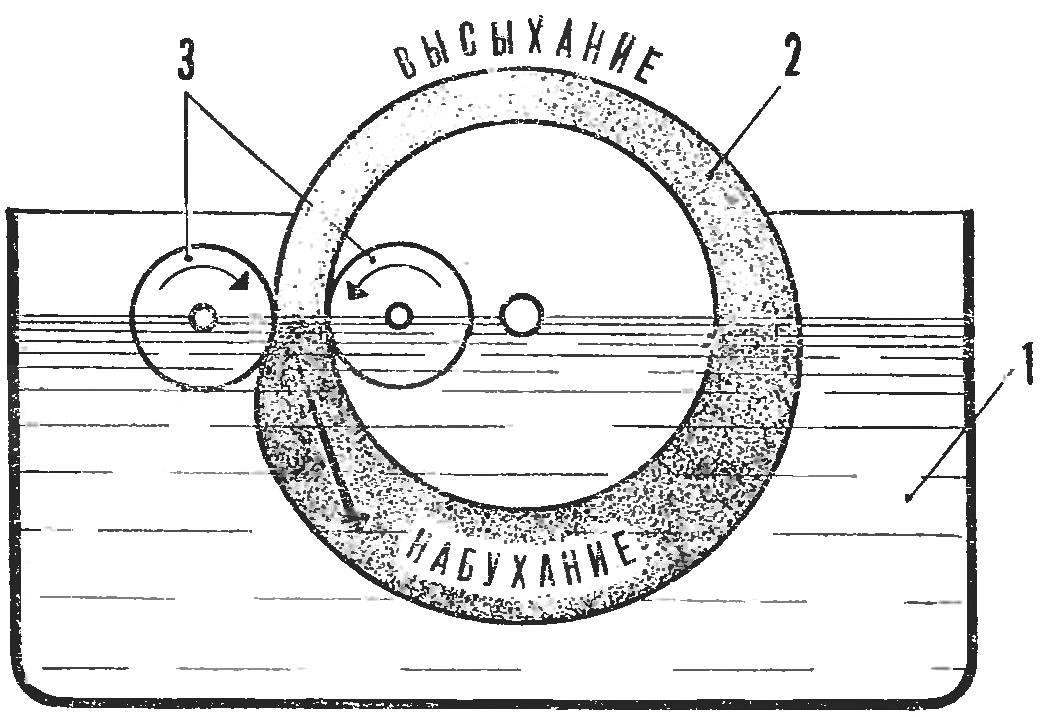

Fig. 5. Osmosis works:

1 — bath, 2 — disc swelling with ring, 3 — driven rolls.

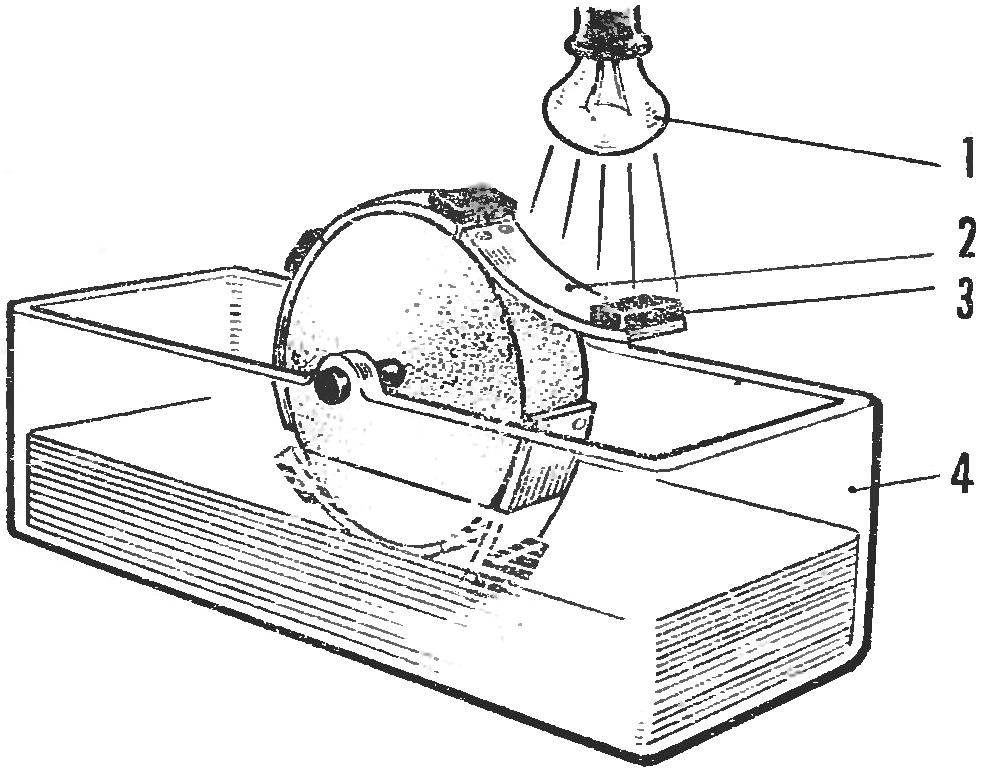

Fig. 6. “Perpetual motion machine”, working under the action of light rays:

1 — light source, 2 is a bimetallic plate, 3 — weight, 4 — cooling water bath.

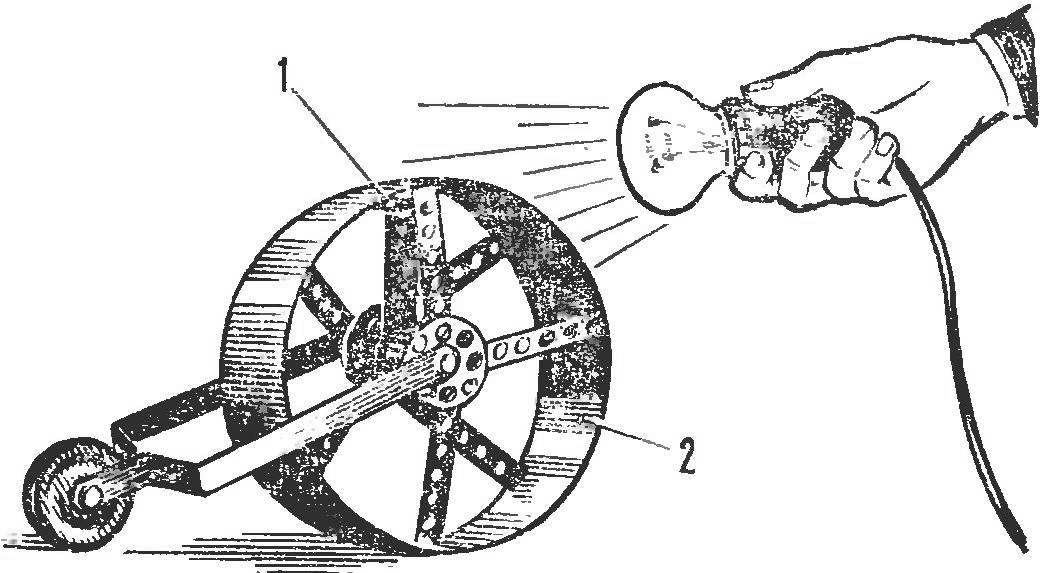

Fig. 7. “Solar” engine:

1 — magnet, 2 metal rim.

And it is quite unusual are the models of engines operating due to “memory”, open the alloy nitinol. Welded from Nickel and titanium, it has an unusual feature: to remember the form that it is given in the heated state. You can, for example, a strip of this alloy to spiral — alternately heated and cooled, it will again strip, then spun back, and so countless times. American engineers managed using this property to build the engine. Its basis is a wheel with curved spokes, which in the hot condition were the direct. When such a needle is immersed in a bath of warm water, she straightens up and pushes the wheel. Immediately the needle goes into the cold water and bent, and in its place a warm bath comes a brand new curved needle. The engine has enough temperature differential is only 23°. The inventors believe that this strange engine will help, for example, to use heat which is transferred by the cooling water of nuclear power plants.

Possible motors, where the sun (or any other) heat is used to change the magnetic properties of the metals. Due to this, it is also possible to obtain mechanical work. The illustration of that is the engine proposed by the inventor and journalist, A. G., Presnyakov. It is extremely simple, consists of a rim with spokes. The headband is made of a ferromagnetic alloy which loses its magnetic properties at +65 °C. (Today known alloys, where this loss occurs at lower temperatures.) Close enough to the rim to establish a strong permanent magnet and not even the heat, but only to cover any part of the rim to the loss of magnetic properties as the magnet will attract the adjacent portions of the rim, causing it to rotate. We should not think that this engine is very weak. Solar water built Presnyakov in the desert rocked up to 800 l of water per hour. Produced by Presnyakov and a cart rolling at a strong light bulbs. Such a model could, in principle, to build any young designer.

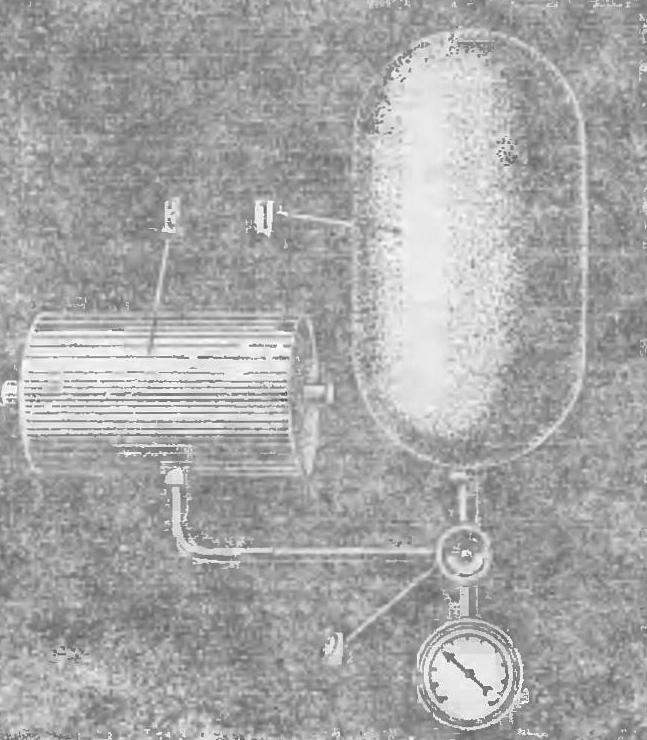

Fig. 8. Diagram of a pneumatic actuator:

1 — battery (compressed gas cylinders), 2 — valve, 3 — pneumatic motor.

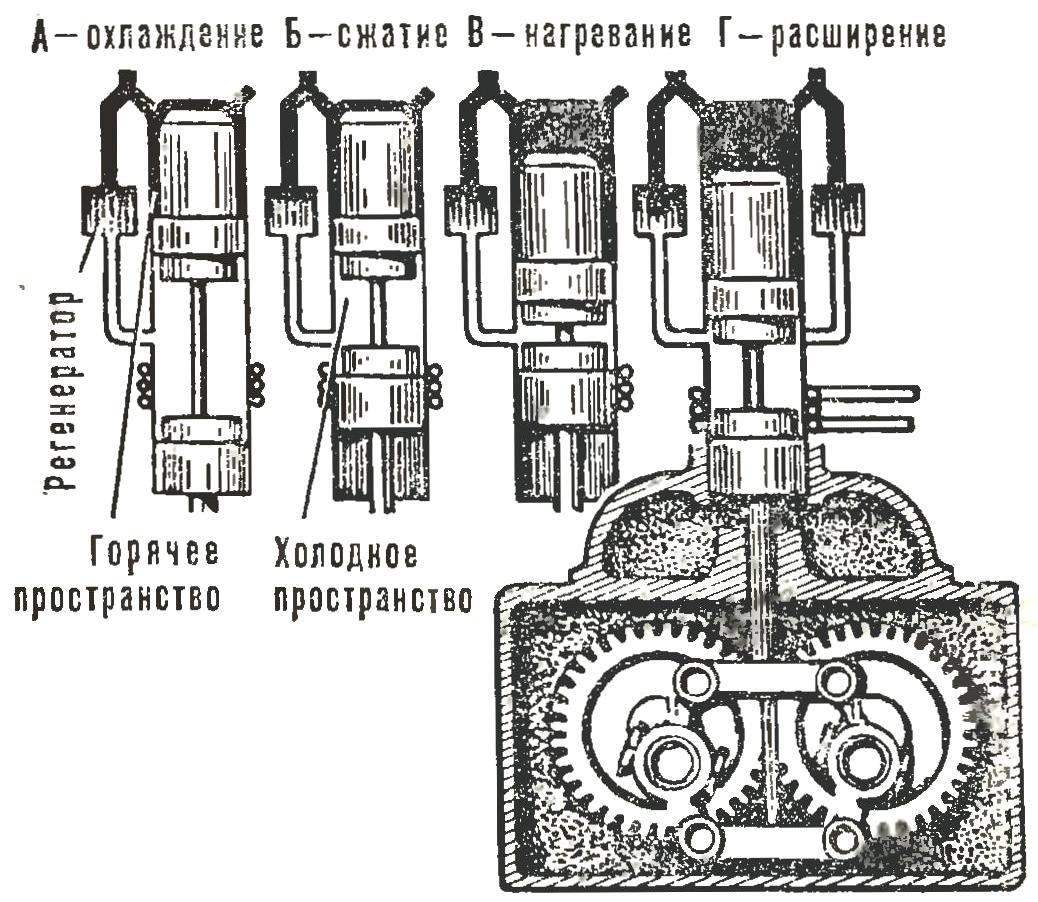

Fig. 9. Flywheel battery:

a — band super flywheel, the b — disk.

Some inventors are trying to use is for producing mechanical work, the phenomenon of osmosis. It is, as you know, is diffusion of a substance through a semipermeable wall, thereby creating excess osmotic pressure In the UK issued patent No. 1343391 on the osmotic engine, are quite complex, but appropriate, in the opinion of the inventors, for use on cars. Soviet engineer P. Rogovik from Makeyevka offers a very easy slow osmotic engine of small capacity, based on the swelling of the material when wet. So swell, for example, gelatin.

A ring of this material, the inventor clamped between two rollers, immersed in water to levels axis. Part of the ring beneath, diverging from the swelling and pressure on the rolls, bring them into rotation. Along with the rolls rotating slowly and the ring. His swollen part is gradually raised up, and the dry sink, absorb water, swell and put pressure on the rolls, continuing to rotate them. Part of the ring coming out of the water, dry out, and the cycle continues.

Young designers the strength to make another exotic model of the motor. It works on light energy the light bulb or the sun, focused through a lens. For its construction will take several bimetal plates, which are used in various thermal relay. It is known that bimetallic plate composed of two strips of metal with different coefficient of thermal expansion, when heated rather strongly bent.

Slave cylinder, made for example of plastic, “sheathed” on the perimeter of the bimetallic plates attached to the cylinder at one end. On the other end are weights. The cylinder is planted on the needle, mounted in two bushings on the edges of any vessel.

In the normal condition of the plate are curved around the circumference of the cylinder. When heating plate straightens and moves away from the wall, the balance of power weights is disturbed, and the cylinder rotates. Place this disc is new,

E straightened cooled and then is pressed against the cylinder wall. For fast cooling into a vessel you can pour cold water.

2. THE BANK HORSEPOWER

In a previous article talked about the fact that heat engines are constantly being improved: reduced fuel consumption, exhaust emissions. But a question arises: is it possible to do without these negative qualities?

This question can be answered positively: it is possible to obtain energy for transport means that do not require the burning of fuel, and then “trust” that energy to the consumer, accumulating it in the batteries.

Now most of the energy worldwide is produced by thermal power plants — thermal power plants. If you present them in the form of special engines of colossal dimensions, TS we see that they are the most economical, and the atmosphere suffers from them less on stationary devices more power is much easier to adjust the correct combustion of the fuel, than thousands of small engines, the work environment is also changing every minute. But… TES did not withstand the test of sustainability, the lack of harmful impact on natural processes occurring in the field of application of one or hoar-frost technology.

Humanity, however, puts himself at the service and environmentally friendly energy sources, and the sources are practically inexhaustible. It is the energy of the sun, rivers, tides, wind, internal heat of earth, heat and ocean currents. Relatively harmless atomic (later thermonuclear) station.

Obtained from these sources is energy in various ways to bring to the consumer. If the latter is stationary or tied to a specific route (train, tram, trolley bus), let them work and electrical wires. Led the consumer is movable, the energy will first have to accumulate to ass black thus “energy cans” to use when driving.

By the way, this energy is used since ancient times. The first batteries were, of course, the simplest mechanical devices, storing potential energy. Raised the goods, stretched a bunch, catapult — these types of batteries have been used since time immemorial. There are similar batteries now. They are used in a wider in a clockwork springs in clocks, appliances, children’s toys. Previously, they have found application in vehicles: built, for example, a huge crown on the chariot, which was made ceremonial visits of the emperors. The springs constantly pozabotilis hidden inside the cart slaves.

However, the spring batteries are low energy density, that is, the amount enclosed per unit mass. Much more it in the rubber elastic accumulators. Every Modeler knows that the engines of an elastic harness lift into the air model airplanes and helicopters. There are, of course, there are disadvantages: low KPC fragility.

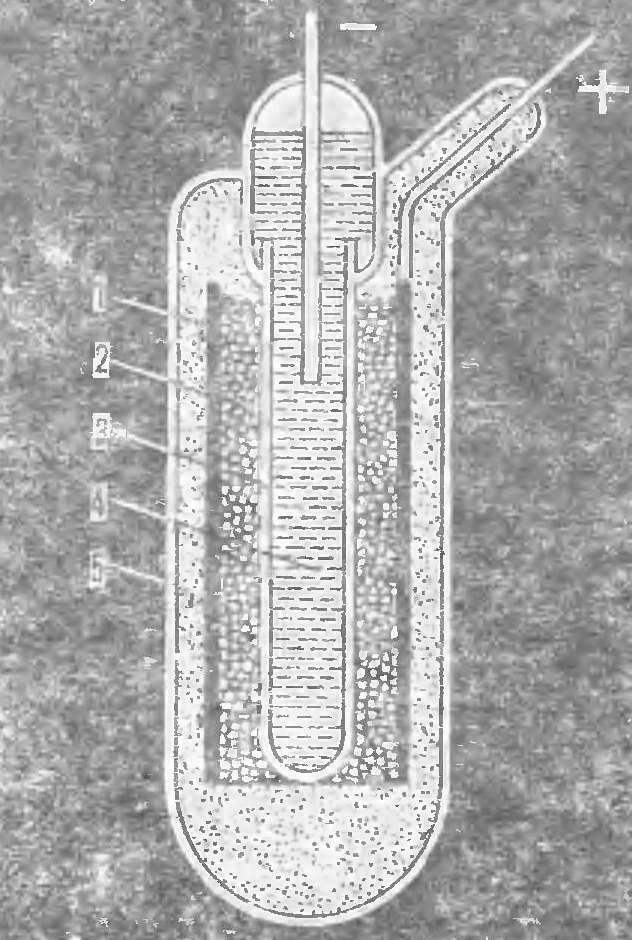

Fig. 10. Diagram of the sulfur-sodium battery:

1 — the current collector of positive electrode 2 and the molten sulfur, 3 — solid electrolyte, 4 is a molten sodium, 5 — body.

For the transport of cars more suitable another battery, which can accumulate so much energy that you will be able to ensure the move for tens and even hundreds of kilometers. It is a compressed gas. The accumulation of energy occurs when pumping gas in the balloon is under pressure; selection — when letting off the gas from the cylinder. Works here the air motor, similar to those used, for example, in pneumatic hand tools — wrenches, drills.

In 1876 in the French city of Nantes was built tramway, worked by compressed air. He overcame a six-kilometer route with one filling. Compressed to 30 ATM. the air was filled with ten cylinders with a total volume of 2800 L. the Flow rate was 8 kg of air per kilometer. The total stock is enough for 10 -12 km away. this Idea is not forgotten and today. Pneumotachometry appeared on vehicles operating in an urban environment: firm “Sorgeto” in Italy experimenting with the machine, is supplied by nine steel cylinders of compressed air. It is enough to walk about 100 km at the speed of 50 km/h. Weight of “pneumobilia” — about half a ton.

Pneumatic battery “charge” and other gases, most often with liquid nitrogen, 50 liters which is enough for 230 km mileage.

But the gas accumulator deficiencies, and substantial. So, when you fix the gas is heated, when the issue cools. And this is unproductive losses of thermal energy.

Another more promising energy storage flywheel. When rotating, it accumulates mechanical energy in the form of kinetic, and it is present in the flywheel as long as it rotates.

One of the most ancient flywheels age whiter 55 thousand years was discovered by archaeologist Leonard Woolley during the excavations in Iraq: a massive wheel, which served as the ancient master Potter’s wheel. Over time, the flywheel has undergone significant changes, turned into a steel disc, the form of which is dictated by the requirement of “equal strength” have increased because of the speed of promotion. Today it is placed in a vacuum chamber for openingscene very significant friction losses on the air. For the same purpose instead of bearings using magnetic supports, friction losses on them is practically impossible.

The skeptics brought long held its position, pointing out the main drawback of the flywheel as a battery — low energy density. With what it was connected! It would seem, all is simple: raising the rotation speed, say, half, we, as we know from physics, we increase the kinetic energy of the flywheel four times. However grow four times and the mechanical load on the body of the flywheel, leading to his break with the formation of fragments that represent a greater danger to others.

And then search for scientists and designers led to the creation of so-called super, made of thin fibers or tapes by winding. The fact that the modern neath – and ribbon-like materials have a greater strength — several times stronger than a monolith of the same material. Safer and rupture of super flywheel: thin fibers or ribbons do not produce fragments capable of causing severe destruction. The author of these lines had the gap band the super flywheel: he couldn’t punch through the casing two-millimeter thickness, while the solid flywheels transcend metre high wall.

The main thing is that the energy density of the super flywheel is much larger than monolithic. Theoretically, it is even much higher than electric batteries, and almost no way inferior to them.

However, the battery is characterized not only the energy density but also power density: that is, the power that develops every kilogram of mass. And by this measure, the flywheel is not equal.

Thus, the super flywheel is a promising battery (and engine) for the transport of the future. It provides a quick boost and less effective braking, is of great durability — in short, all those qualities which required the battery to the vehicle and which is so lacking right now. A particularly promising super flywheel to drive buses, subway trains, taxis and other means of public transport, working in a circular, tight schedule, with frequent acceleration and braking.

Modern super flywheels in a vacuum chamber rotation save energy even weeks, and special samples makovicky batteries can change it and years. In terms of conservation of energy there is only one worthy rival — electric, or, more correctly, Electromechanical, batteries. They were created relatively recently, although the date of their appearance can be considered 1799 when Alexander Volta, by placing copper and zinc electrodes in dilute sulphuric acid, received the first galvanic cell. After all, almost any cell can in principle be battery if using it to pass a current in the opposite direction, charging it. Even ordinary dry-cell batteries, used for flashlights and transistor receivers, it is possible for 8-10 times to charge as the battery. Another thing is that this “charge” is not economically particularly advantageous: the efficiency obtained is very small. But, it is still much higher than that of discarded batteries.

These same batteries, though more expensive than conventional electrochemical batteries can withstand 8-10 charge cycles, and a hundred times more. Therefore, energy storage in electric batteries is not very expensive too.

From the electric batteries are the most common lead-acid; they are installed on every car as starter batteries. This humble and hardworking, they aren’t energy and power metrics, but rather economical and have high efficiency. However, they do not tolerate frost, high currents, strong discharge. In contrast, the crack battery is unpretentious, but has a low efficiency: up to 0.4—0.5, compared to 0,75—0,8 at lead-acid.

From these two batteries, you cannot expect any prospects. Energy density and power of them is low, and the car with such a burden will carry mostly himself — so they are heavy.

Special hopes are pinned today, scientists at superaccumulation — sulfur-sodium, lithium-chlorine, etc. they maintained a high (300 — 600°), the temperature, the electrolyte is molten. Of course, the destruction of the battery when the car accident promises little good, and their efficiency is low, especially considering the need to warm up the contents. However, very high energy density — ten times more than lead acid, and the power density is twice higher — up to 150 watts per kilogram of tissue. It should be noted that such “superaccumulation” has not yet emerged from the walls of the laboratories and they have to work and work.

Finally, we should mention the so-called fuel cell to directly transfer the energy of fuel into electric current. The most interesting of sneeze are oxygen-hydrogen fuel cells, which use a process of decomposition of water directly on the element; it also has capacity to store the gases. Hydrogen and oxygen combine again into water, for example, by using catalysts, high temperature and so on. this releases the electrical energy expended in the decomposition of water, and battery — hydrogen and oxygen. Fuel cells are very promising for electric vehicles, however, still very heavy and expensive.

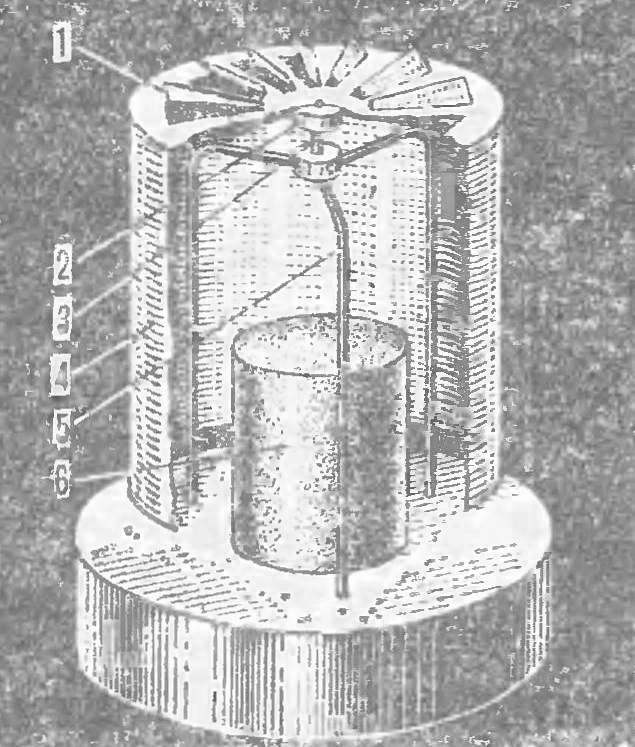

Fig. 11. Model running on accumulated thermal energy:

1 — cap-impeller, 2 — bearing, 3 — needle, 4 — cylinder, 5 — bearing, 6 — battery pack (heated body).

Stand accumulators of thermal energy. By themselves, they can’t get the machine to move, but in combination with a heat engine, for example, Stirling (see “M-K” No. 2, 1979) is able to provide good results. Previously mentioned on a scooter, working about five hours from a bucket of molten lithium fluoride battery heat.

A thermos of hot water, a warm stone in the sun, hot iron, in other words any heated body is an accumulator of energy. However, there are compounds able to accumulate it in tens times is more than just a body heated to the same temperature. From physics it is known that the melting of a crystalline substance the temperature will not rise a single degree, until you spent a certain, usually fairly large amount of heat called latent heat of melting. Solidification this heat is released, and also without changing the temperature of the material. Here on this phenomenon and constructed a so-called thermal batteries melting. If the required temperature is small, below 100°, as we focus on bringing the substances are different hydrates. For temperatures of 600-800° are best suited fluorides and hybrids lithium; above — silicides and borides of certain metals:

Thermal batteries store huge amounts of energy — more than any, the most promising type of battery. The only trouble is that when attempts are made to use this energy in the form of mechanical, electrical, and other “qualitative” types of the main amount of energy is lost going into heating the environment. In addition, the weight of a device that converts heat into “high quality” energy (e.g., Stirling engine, thermal elements, etc., significantly reduces this figure, the energy density of the entire device, bringing it closer to most ordinary types of battery energy. However, today a heat accumulator can have a good use, for example, heating of a transport car is Driven by another energy storage: electrical, makoveckogo.

Talk about batteries, we always refer to them, the main indicator is energy density. For different species, to Express it in kilojoules per kilogram of mass, it is this:

- the battery potential energy: steel springs — 0,32; rubber — 32; gas and hydrogasifier — 28. Heat storage with Stirling engine — 9.

- Electrochemical batteries: lead acid — 64; Nickel-cadmium (alkaline) — 110; sulfuric sodium — 800; fuel element at various terms interchange — 15-150.

- Batteries flywheel: steel disc with a hole 30; a solid disc of equal strength — 120 super flywheel of the tape — 150; super flywheel of a special fiber — 650 (model).

But we should not forget that flywheel batteries are very large reserves of energy. For example, if you make the super flywheel is made of quartz fiber, which exists only in the laboratories, you will be able to increase energy density up to 5000 kilojoules per kilogram. And if you use “sverhgigienichnoe” carbon fiber with diamond pattern, you will receive and is a fantastic figure — 15 000 kJ/kg! To such conclusion the Japanese scientists recently.

In conclusion, I would like to offer to build an interesting model of the “eternal” engine that runs on stored energy derived from simple thermal battery. This will produce a cylindrical cap, sticking it out of the stencil or other thin and strong paper with the top of drawing paper or hard aluminum foil. This cap will be in the form of an impeller formed by the cutouts with curved edges; the optimal angle of limb can be determined empirically. In the center of the impeller on glue is attached a light metal nest: a dispute with a conical recess, into which is inserted the tip of the needle. Blunt end needle goes into the tube, mounted on heavier non-combustible stand with tripod of thick wire. Do not warp the cap on the needle and easily rotates from a weak push or blow from the bottom.

To bring such a “perpetuummobile” in the motion to be put on a stand of a metal disc heated to 300-400°, and cover with its cap. Disc—battery heat will cause the movement of air inside the hood from the bottom up. Passing through the impeller, the air will rotate it the faster, the higher the temperature of the heat accumulator.

Even better results can be achieved if the disc is to be replaced by a jar of molten lead or zinc. Then we will get a real battery melting. Best of all, of course, use fluoride, or lithium hydride. Here you need to be very careful not to burn yourself, and not start a fire and experience to lead in a specially equipped physical laboratory or workshop.

Someone maybe will say that it is easier to cover this kollkom the light bulb. Then the cap-lampshade (which can be painted) will rotate as long as the lamp is lit. But we keep the usual heat engine without energy storage.

We spoke only of some of the types of heat engines developed for the cars of the future. Of course, it’s not even all of the principal engines of tomorrow. In their development can try their hand, of course, young designers and modelers. However, we must remember that the development of new engines is a complex and time-consuming, which requires a serious and specialized knowledge; one “invention” many do not reach. And the first test of the validity of your ideas can serve as built with his own hands the current model.

N. GULIA doctor of technical Sciences