In recent years, individual housing is a kind of “silent revolution”. Increasingly, private homes, whether villas, farmhouses or country cottages — built two-and even three-storey. The desire is quite justified: the reduced building area, housing is made more compact, to the same tiered structure looks many cuter than located in a single plane.

In recent years, individual housing is a kind of “silent revolution”. Increasingly, private homes, whether villas, farmhouses or country cottages — built two-and even three-storey. The desire is quite justified: the reduced building area, housing is made more compact, to the same tiered structure looks many cuter than located in a single plane.

However, multi-level house has a well-known feature — to get from one floor to another, the home must be equipped with ladders. Most often in our country are used for this purpose wooden straight stairs, They do not differ in the ease and attractiveness, however, due to the simplicity and plainness individual developer stops his gaze on them. Meanwhile, for the past many centuries successfully operated screw-down (or, as they are called, spiral) stairs. You can make them from almost any structural material, including from readily available wood and metal In this publication we introduce you to design spiral staircase, the materials which were published in the English magazine Practical Householder (“Practical homeowner”).

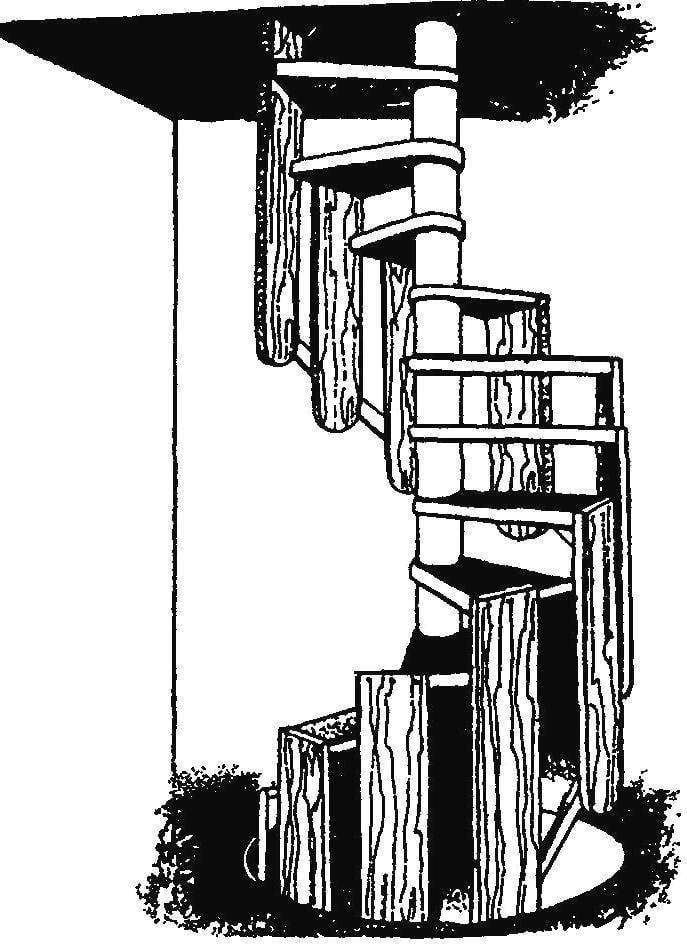

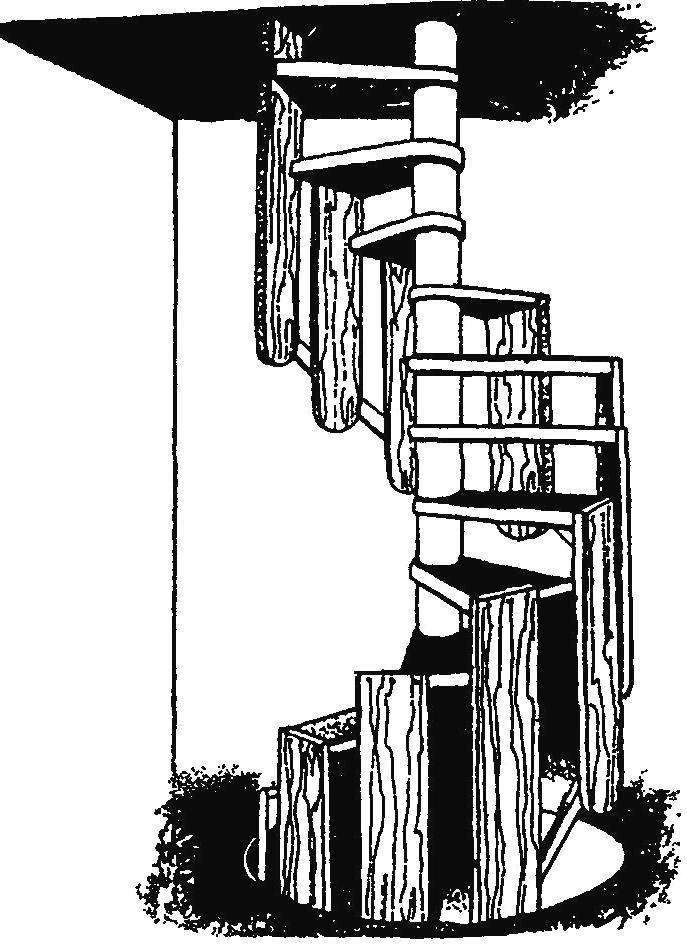

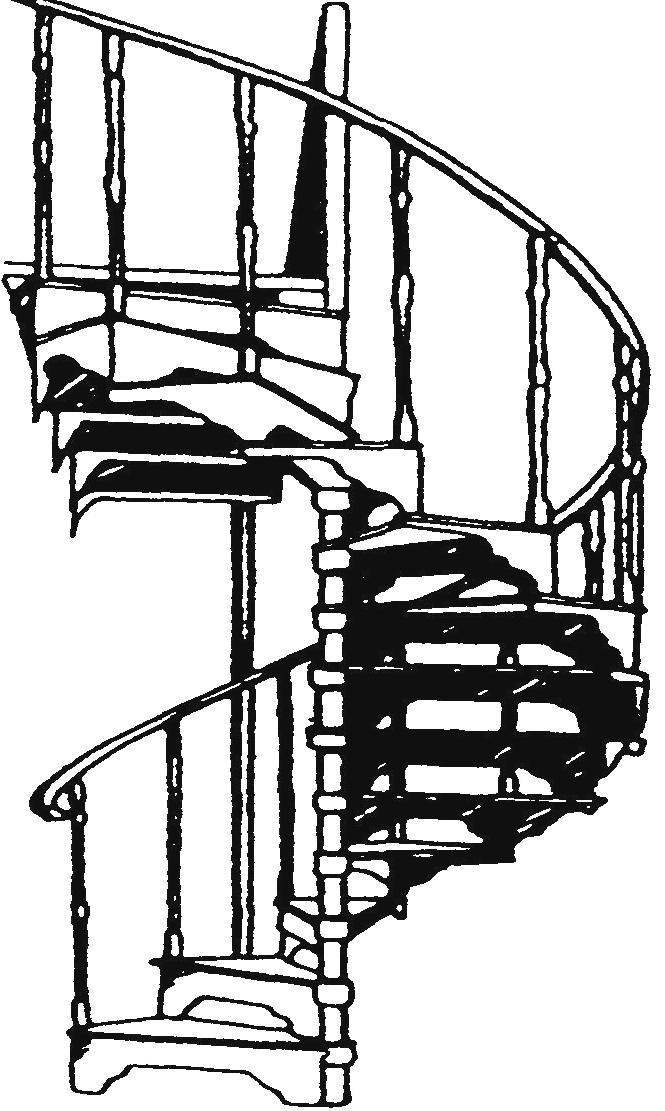

A spiral staircase is a decoration for your home! Unlike one – or multimid-flight wooden or metal structures, openwork spiral design, done with taste and respect for anthropometric standards, takes up minimal space in the premises and are sometimes organizing element of the layout of the dwelling. Look at the pictures — as you can see, spiral stairs significantly affects the design of the room in which it is located. But speech today not about it. The purpose of this publication is to acquaint readers with spiral staircases of various designs.

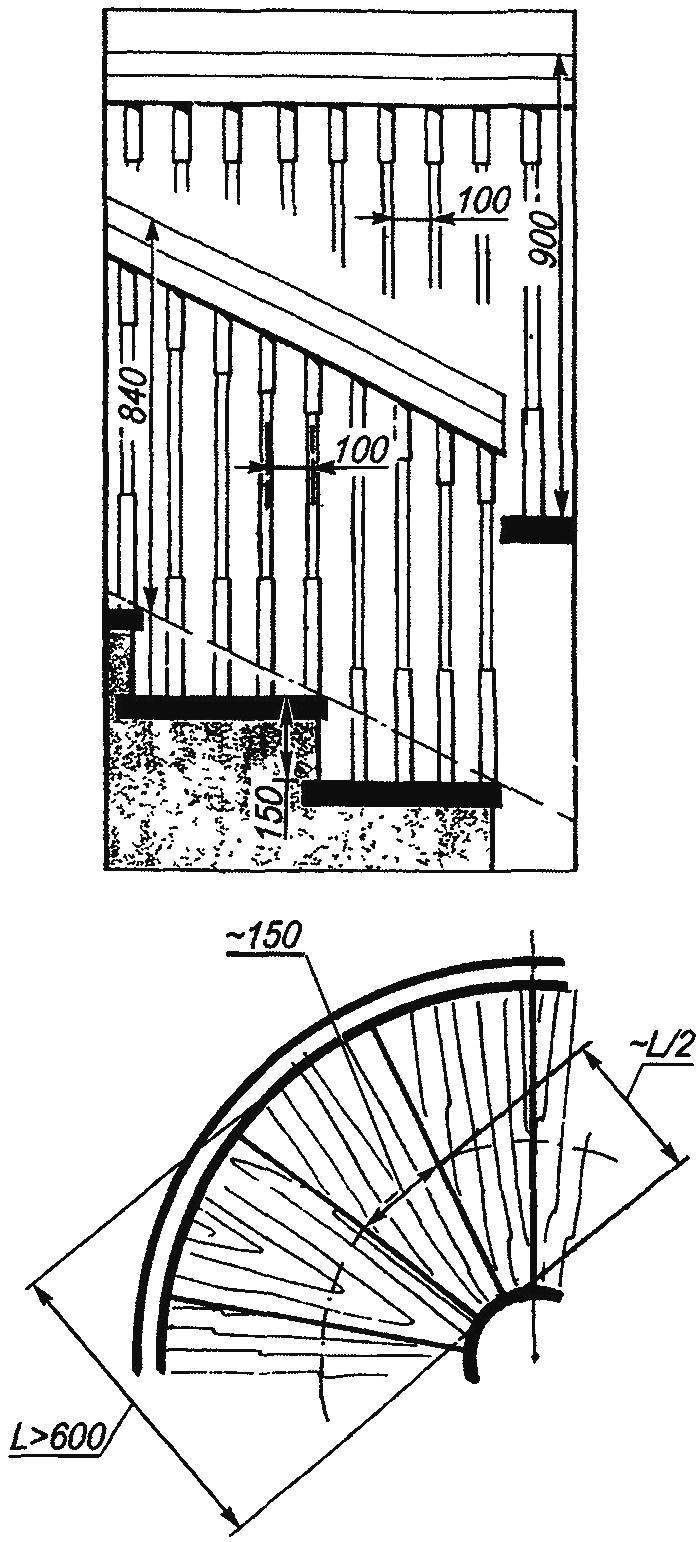

For starters — several geometrical parameters to be followed in the design and manufacture of spiral staircases. Thus, the width of a ladder March (excluding center column) should be not less than 600 mm, the average width of a step — 150 mm, minimum pitch “of the screw” (or if you want the height of steps per revolution) — not less than 2700 mm, height of stair handrail 840 mm, height of fence stair opening is 900 mm.

The main geometric dimensions of a spiral staircase

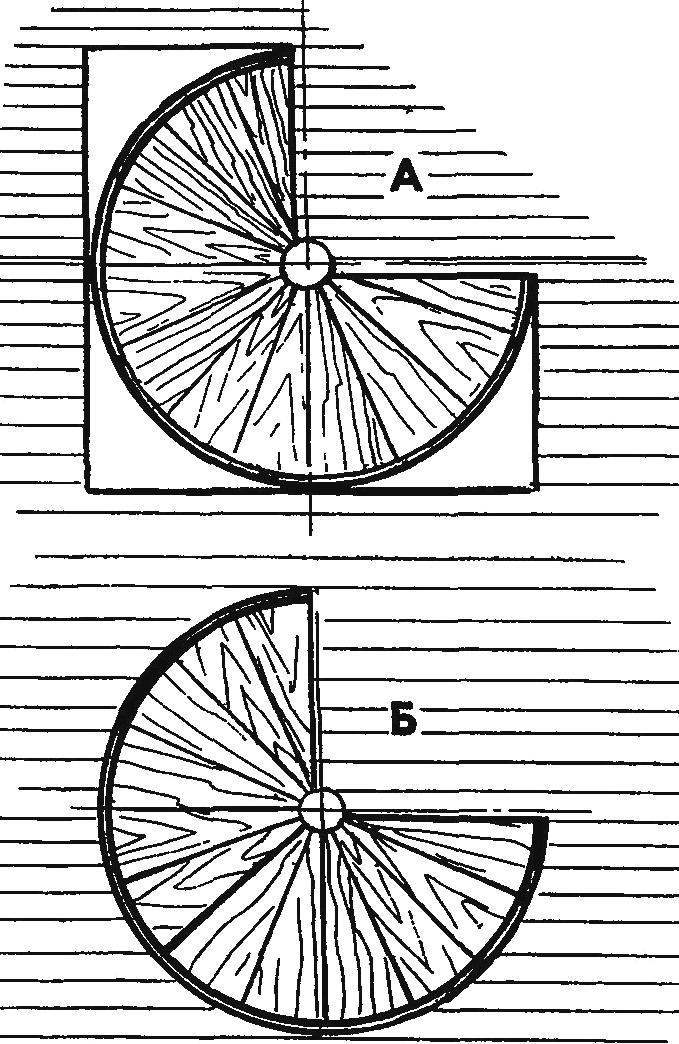

The basic configuration of the staircases:

A — square B — round

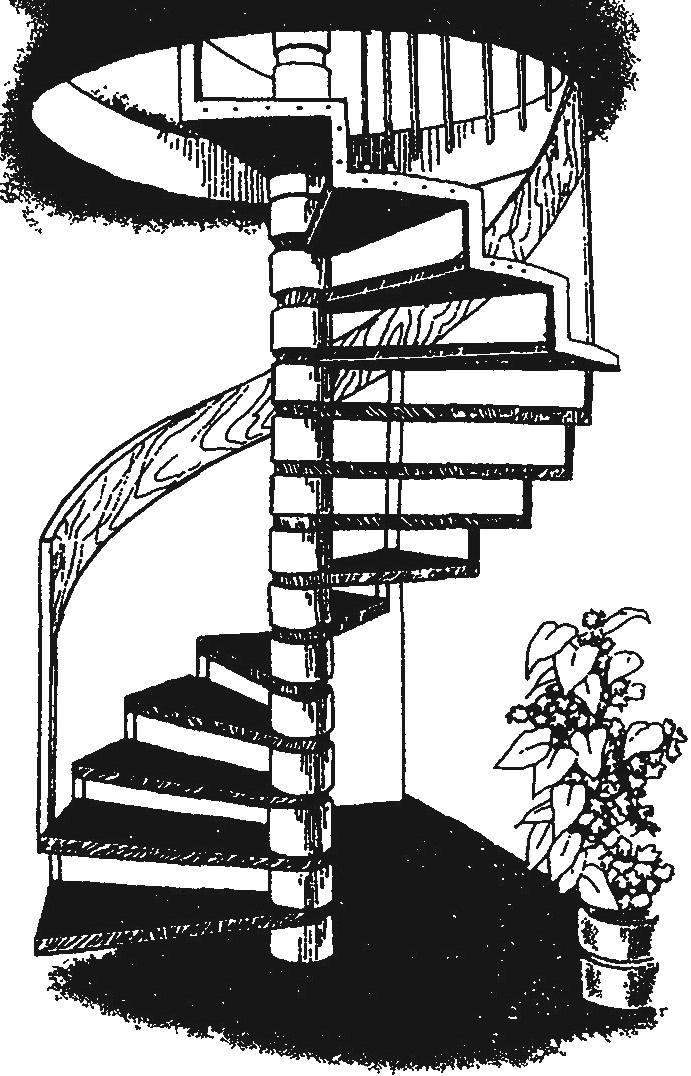

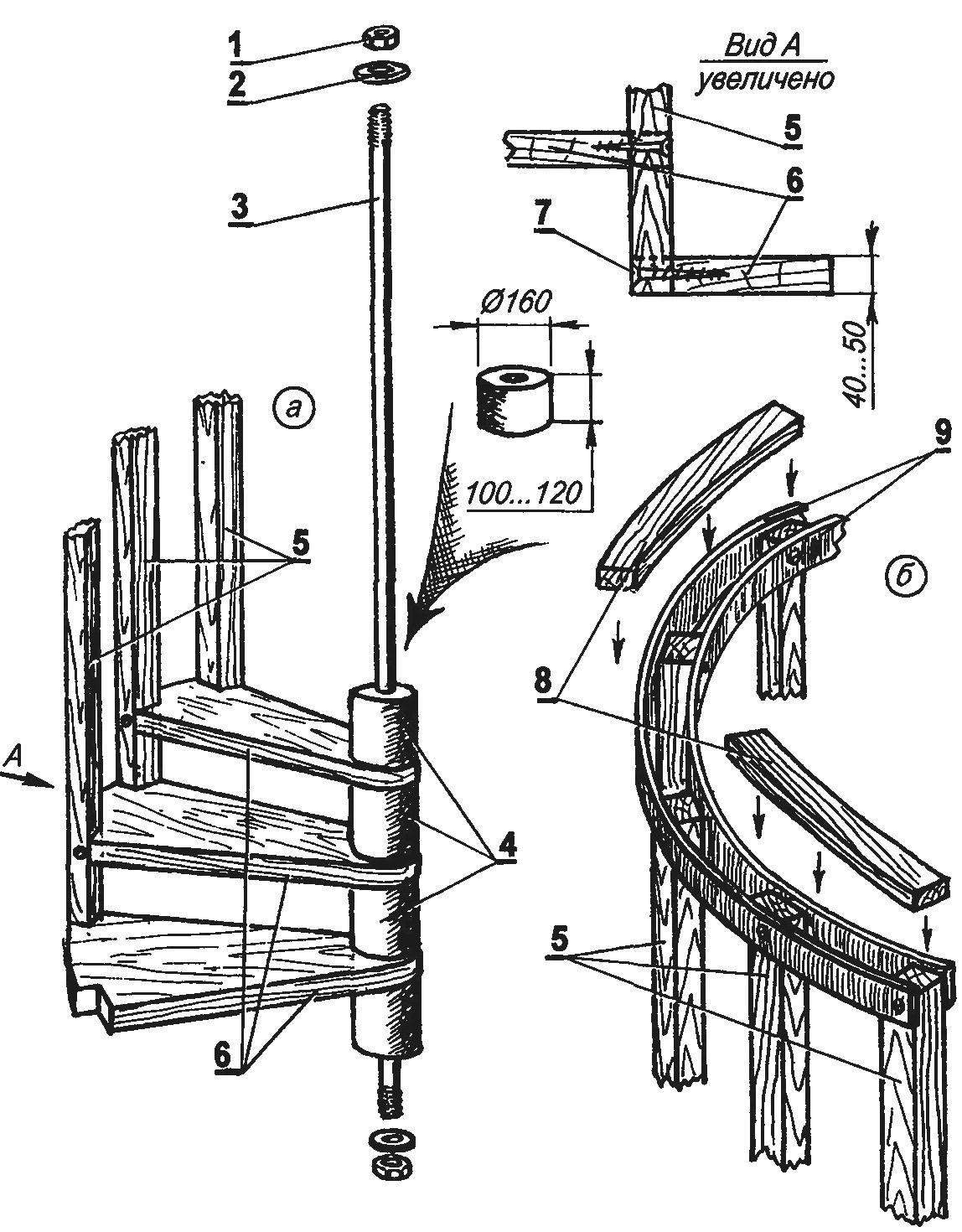

Solid wood construction is the most simple. In any case, in their manufacture does not require any welding or metal bending, nor his quite sophisticated processing can be done in a home workshop.

Here’s one of those ladders. Her steps are cut from boards with a thickness of about 50 mm, bushing-spacer defining the height of the steps — from round wood timber (logs) with a diameter of about 160 mm, the Entire Assembly into a single unit with the tie — a steel rod with a diameter of 10…12 mm, or a water pipe of suitable size, the ends of which are threaded. Pre-and in steps, and bushings drilled holes under the plate: during Assembly it is recommended to use epoxy glue.

Great care should be taken for installation of stair handrails. Of course, most will look turned balusters and carved from segments of the monolithic beam railing, but you can make them only good in carpentry. In home conditions, we can recommend the design and technology easier.

On each of the steps are cut square grooves of the same section that future stands (e.g., 50×50 or 60×60 mm). Then use epoxy glue and screws racks are fixed on two neighboring levels, each, connecting the most peripheral parts thereof into a single structure. Stand, if desired, you can decorate a simple thread or just make them square balusters.

A little bit harder to do rails, which is a spirally twisted bar. Here, perhaps, the most technologically advanced option. Made of plywood with a thickness of about 6 mm are cut strip width 80 mm (direction of the fibers of the outer layers of plywood — across the strip!) and workpiece are fixed with the outer and inner sides of the balusters on the screws and epoxy glue the Next cardboard or thin plywood cut pattern of Board thickness 20 mm cut elements to fill the groove between the plywood cheeks railings they are also Fixed with epoxy glue and screws.

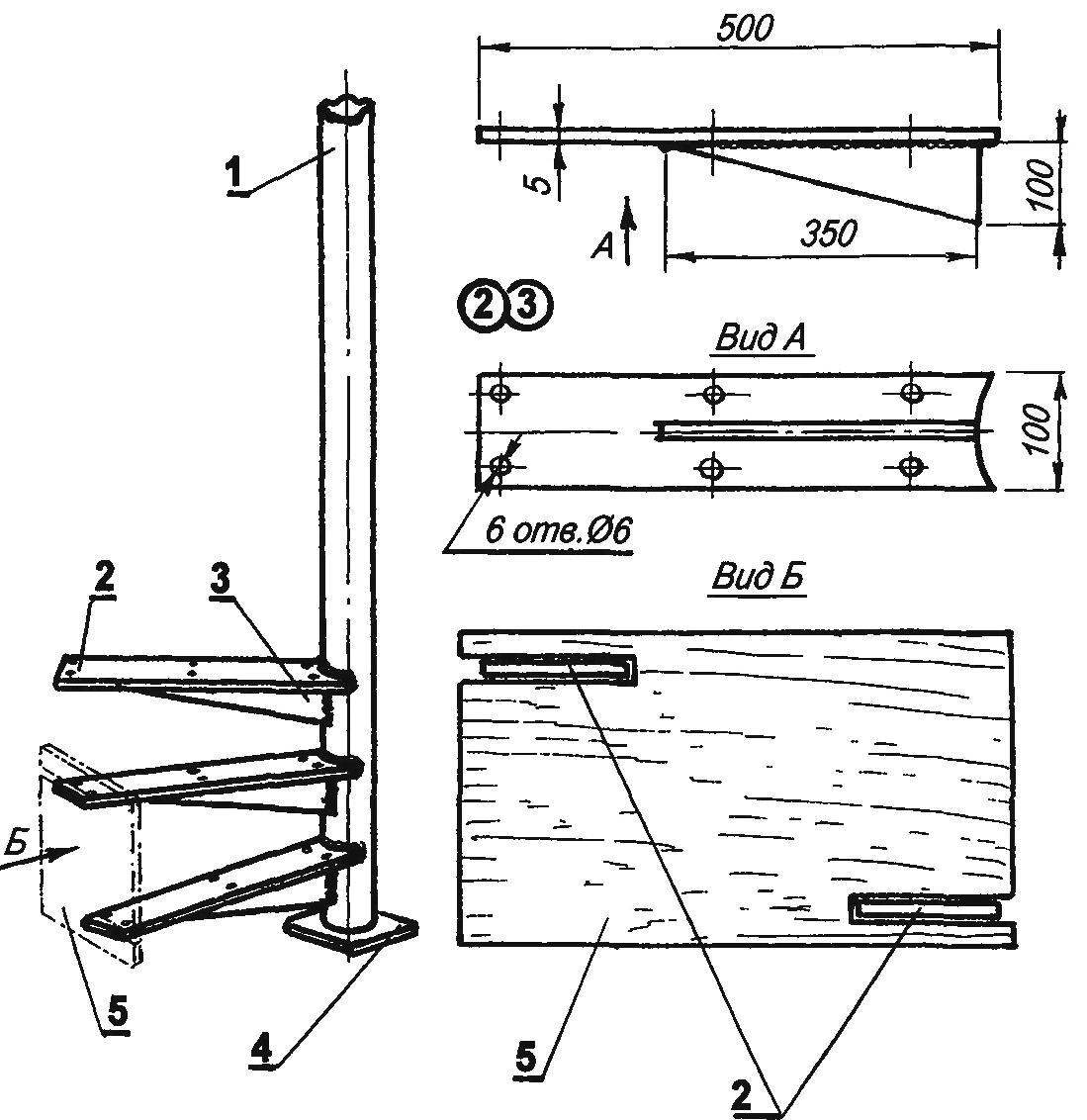

If you have the opportunity to use the welding machine for you is not too complicated and will be a combined version of the ladder with a steel welded frame and wooden steps.

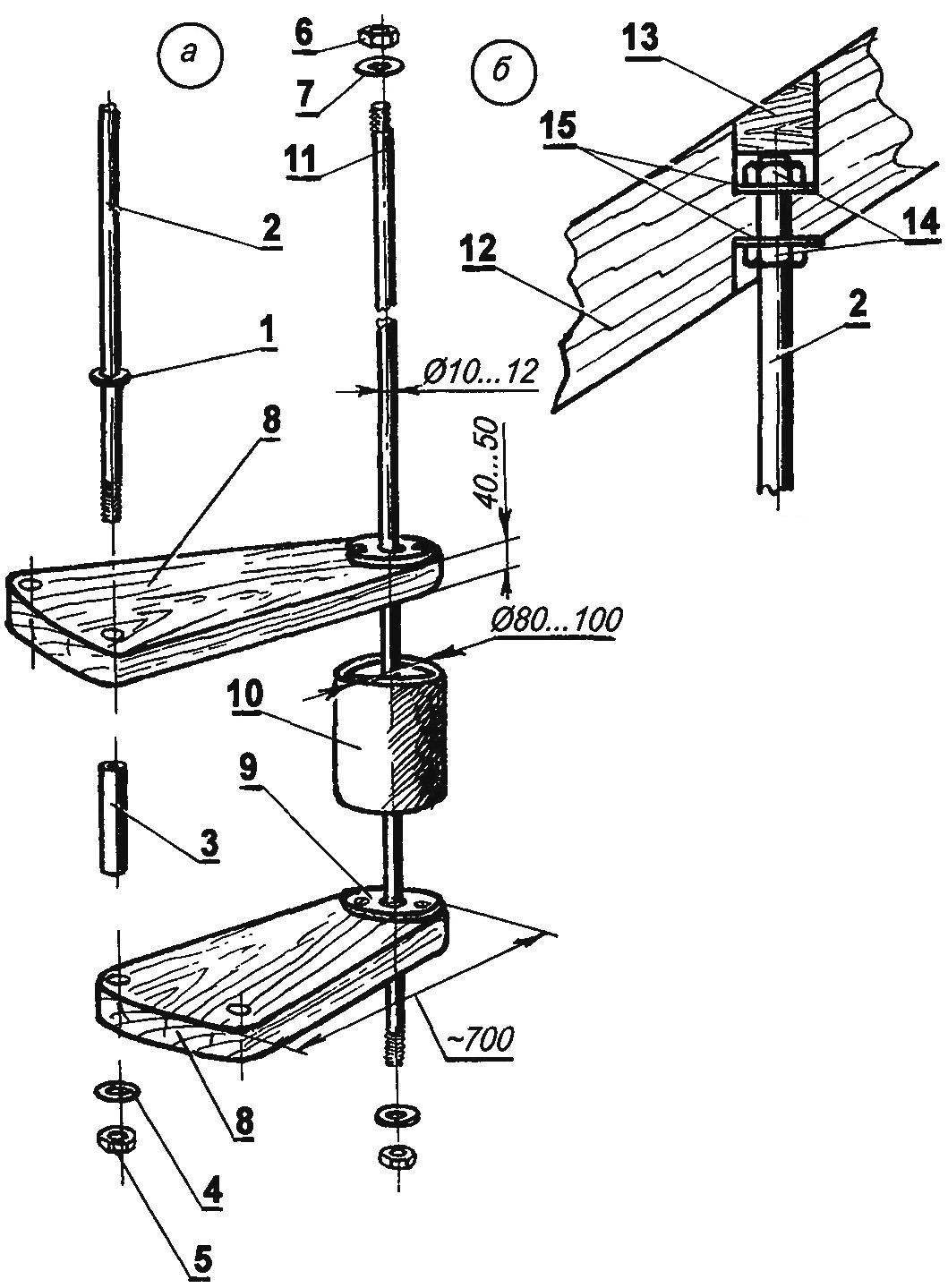

Design of wooden stairs (and — installation steps; — installation of railing):

1 — nut 2 — washer; 3 — coupler; 4 — bushings-spacers, 5 — rack enclosure, 6 — stairs; 7 — screw; 8 — filling in the screw groove 9 of the side railing (plywood)

Installation of steel stairs:

1 — Central stand; 2 — supporting ground stage; 3 — gusset plate-brace, 4 — supporting foot, 5 — conductor for welding support brackets

Installation of combination ladder with steel frame and wooden steps (a — basic stair components, b — mount stair railing):

1 — washer (welded to the rack); 2 — front fence; 3 — distance sleeve; 4 — washer; 5 — nut; 6 — a nut of a rod, 7 — washer; 8 — step; 9 — centering washer; 10 — bushing-spacer, 11 — coupling, 12 — handrail 13 — insert; 14 — nut, 15 — washer

For this ladder, you will need steel pipe diameter 60 — 80 mm steel strip with a thickness of 5 mm and a width of 100 mm. From the last machined bearing surfaces of the steps, and scarves-struts of which are welded the supporting brackets. To ensure uniform step between them when assembling, it is convenient to use a simple device — for example, a Board cut, which propisyvayutsya two of groove in accordance with the location of the reference sites.

Locking every time each relative to the bracket already welded, thereby to provide a constant step step as their height and angle.

For the steps as in the first (wooden) version will suit batten thickness of 40 — 50 mm. Fastening it to the base pads with screws

Stand stair railings — steel rods or pipes, with each need to weld supports which mutually connect the adjacent stages by means of screws. Between the uprights weld it good decorative grille, bent from steel strips.

You can offer another option of a combination ladder with steel frame and wooden steps For it will need a Central hub-spacers from lengths of steel pipe (length 100 — 120 mm depending on the step height), the steel rod-cement screed with a diameter of 10 -12 mm or cut plumbing pipe threaded on both ends, and the Board thickness 40 — 50 mm for the steps. Will also need steel rods with a diameter of 10 — 12mm for uprights stair railings and steel spacer sleeves of a water pipe.

This ladder can be assembled without welding. To ensure the alignment of screed with a Central bushing, you need to use plywood circles, the external diameter of which corresponds to the inner diameter of bushings-reducers, and the hole diameter is the same as the thickness of the screed. The circles are fixed on the steps with glue and a few nails.

Both ends of each strut stair railings — threaded. On the top two nuts fastened to the railing on the bottom using standoffs and a pair of nuts adjacent the foot.

The railing of this staircase are assembled from separate wooden wedges, which are joined to each other to spike.

To hide protruding from the rail nut around the hole under the rod rack enclosure with a chisel you select a rectangular groove, which after tightening the screws sealed flush with the surface of the handrail wooden block of appropriate size, and then processed together.

Form the stair opening is selected depending on the design of floor slabs. Of course, very beautiful looks like a hole in the form of a circle, but to equip it is far from easy, especially when talking about wooden house, More simple and technologically advanced in this case is a square aperture is not too difficult, using the space between the intermediate floor beams.

Finishing of wooden stairs consists in the careful polishing of their elements cloth, impregnated with hot linseed oil and coating in several passes oil, or pentaphthalic varnish. You can also use parquet varnish, in this case, the underlayer of varnish is not required

If you prefer a wood of dark tones, it is necessary before varnishing to use the stain or, in extreme cases, a strong solution of potassium permanganate. Good results are obtained by the treatment of the wood by the flame of a blowtorch or gas burner, however, this method is insecure, so work in this case is recommended together: partner with a bucket of water in hand has to insure you.

If you have enough patience and skill, can be recommended to decorate stand-balusters simple ornament or applique wooden sloping parts

I. SERGEEV