Each compartment of the boat consists of two identical plywood sidewalls, joined at the keel rojalnoj a loop length of 600 mm. Loop riveted to the sidewalls, but can also be used short screws with subsequent raskladyvanii them all. In addition, stacked along the sidewall on three sides of the perimeter (except for the top — flanges) are covered with a strip of rubberized fabric (can be covered and dense tarpaulin) width of 60 mm Strip is a sort of fabric hinge allows the sides of the compartment to spread out.

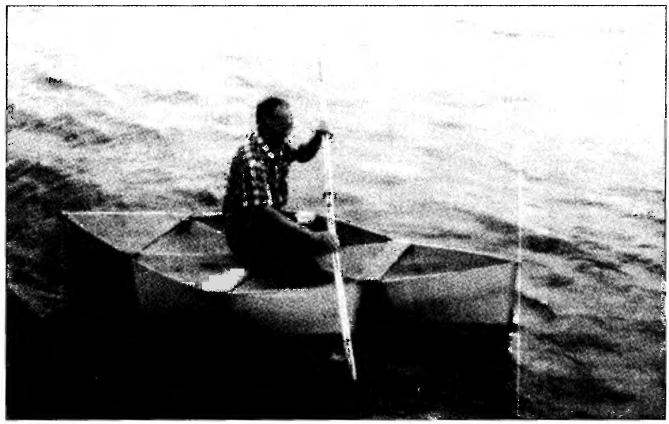

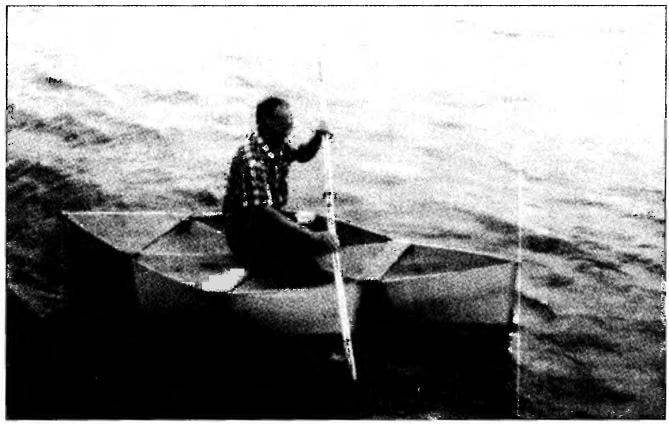

Foldable boat in ready to sail:

1,6 — bow and stern compartments; 2,5 — struts; 3,7 -4 — Bank

Option the boat three compartments

Press for gluing sections:

1 panels (particle Board, sheet s16); 2 — clamp (steel area 36x36x4, 10 items); 3 — bolt М10х70 (10 PCs); 4 — glue compartment

Compartment Assembly:

1 —the eye (D16T, strip s4, 2); 2 — sides (plywood s4); 3 — upper piping (fabric, 4 pieces); 4 — lining (rubberized fabric, 2 pieces); 5 — lining (D16T, band, 1.5, 2); 6 — M5 screw (4 PCs); 7 — tissue hinge (rubberized fabric); 8 — bottom trim (rubber); 9 — piano loop

The Central connection node compartments:

1,7 — bow and stern compartments; 2,8— side compartments; 3 — an overlay of rubberized fabric; 4 — Central М6х110 bolt; 5 — a washer 9x32x2,5 (2); 6 — eye

The hinge in the open state feels stunnah significant loads directed to the separation of the fabric from the sidewalls. Therefore, stevne reinforced — stitched synthetic pinned thread through the awl holes in increments of 8-10 mm and the seams are coated with waterproof glue. And again. To protect joint tissue from abrasion keel compartment is further covered with a narrow strip of rubber cut from old Bicycle inner tube.

The side compartment in the middle — in the areas of maximum fracture when disclosure is slotted with a hacksaw to a depth of 130 mm. Slots taped pads made of the same rubberized fabric. To pads when you repeatedly opening the compartment was cut from plywood, they, like stevne stitched with synthetic threads with the same step 8— 10 mm and the seams are coated with waterproof glue.

Edges of the boards are covered with narrow strips of dense fabric, which give the bays a finished look and protects the edges from damage.

Glued compartments sanded, impregnated with linseed oil and painted outside and inside with two layers of enamel PF-115.

Between the compartments are connected with eyelets, curved duralumin plates are available in the “nose” and “stern” of each compartment. The eyelets attached to the sides with countersunk screws through the dural lining.

For production boats it took me three standard sheet of 4 mm construction plywood size 1525×1525 mm. All the blanks of the sides I cut one circular saw. To do this, sheets of plywood were first dissolved into strips of a width of 500 mm so that the fibers of its external layers were oriented in the longitudinal direction. Eight bands folded in a pile, bonded at the corners by nails, on the top caused by drawing the contours of the side plates and drilled side holes and the holes for the screws on the lugs. According to the planned contour cut blanks with a hacksaw and made two parallel cutting in the sides.

Manufacturer compartments of the plywood side panels and rubber strips, using waterproof glue for wood and fabric more efficiently under pressure. So I used the simplest press: glue each compartment clamped with corners and screws between two sheets of chipboard, cut to the contour of the sidewall with a small allowance. Plywood, particle Board separated by plastic film.

On the shore the boat I’m building in the following order. First, all four compartments are fastened by one Central bolt. For that the side compartments are put together, and the end (bow and stern) placed between them so that the inner side holes and side holes of the lugs of the limit match. Through these holes pass the center bolt with washers and tighten nut. Pushing his foot into the opposite Board of the far side of the compartment, pulled the middle Board and put yourself between the Bank, aligning its pins with the outer side holes. Then breed the side of the end compartments and insert the spacers. Bolts on the struts wear eyes side compartments and tighten the nut. To banks or struts do not accidentally slipped and did not cause serious injury, insert the pins first next to his hole, and then in the future. The center bolt of the bolts and spacers are not experiencing heavy loads, so much of wing nuts do not tighten.

Bank:

1 —timber 2 — handle (aluminium tube 16×1,5); 3 — side panel (plywood s5, 2 pieces); 4 — pin M8 (2 PCs.)

Strut:

1 — beam; 2 — focus (2); Z — bolt M8 (2 PCs); 4 — screws 4×20 (2); 5 — bracket suspension paddle (steel, strip s2, 2 PC.)

The boat is Packed:

1 — package of stacked compartments; 2,6— halves of split paddles; 3 — bow brace (aft — the back of the pack); 4 — center bolt with washers and nut-lamb; 5 — Bank (between the compartments)

Rail truck:

1 — carrier (steel pipe 28x25x1,5); 2 — steel rivet (d5, 2); 3 — spacer (aluminum tube 22×2); 4 — handle (aluminum tube 18×2)

Collapsible trolley for transportation of boats:

1 — plug; 2 — strut; 3 — rail; 4 — a bolt of M6 with nut-lamb; 5 — handrail

At known skill build of a trimaran takes only a few minutes.

Disassemble it in the reverse order. When all are disconnected, the brackets of the braces hang the halves of the paddle. Compartments are folded flat in the package; in the middle (between the compartments) put jar and outside, along the sides of the spacers, aligning the side openings of the compartments with holes cans and spreaders. The whole package fasten the Central bolt.

Packed mass of boats with oars — 18 kg. to Carry the pack for short distances, you can use handles made of dural tube, attached with screws to the edge of the jar.

Fork truck:

1 — bolt M5 (2 PCs); 2 — pen (aluminum tube 22×2, 2); 3 — casing (steel channel No. 5); 4 — M6 bolt (round head, square neck and nut-lamb)

The strut truck (aluminum tube 22×2, 2 PCs.)

Cross member of the truck:

1 — reference site (D16T, 2); 2 — screw M6 (4 PCs); 3 — beam (steel pipe 28x25x1,5); 4 — lock nut M6 (4 PCs.)

The position of the Packed boat on the truck:

1 — package of stacked compartments; 2 truck; 3 — front mounting point (the center bolt М6х110); 4 — rear attachment point (bolt М6х60)

Collapsible paddle:

1 aluminum rivet; 2 — blade (D16T, sheet 1.5); 3 — clamp; 4 — spindle (D16T, pipe 16×1,5, 2); 5 — coupling (D16T); 6 — M3 screw (2 PCs.) Shows the left half of the paddle. Right mirror

At large distance the package moves on a makeshift collapsible two-wheeled cart. The package it is attached by two bolts: the Central (through the slits in the tubular struts) and rear (through the eyelet of one of the compartments to the loop on the handrail).

In the manufacture of truck I used the wheels and handle from a children’s stroller, aluminum pipe legs of the bed-a cot and a steel pipe of rectangular cross section from the frame of the Desk.

Wheel fork and the cross member of the truck are connected by two horizontal conduits M6 bolts round head, square neck and nut-lamb. In turn, the cross-member and the leash handle in one vertical bolt MB with a simple pan head.

The capacity of the trimaran on the water about 100 kg. At its aft and forward compartments is sufficient space for placement of camping equipment. In addition, the design allows you to assemble from three sections, leaving the fourth (say, corrupted) on the beach. In this case, the draught of the boat increases a lot.

The boat is suitable for walking, fishing and hunting on small lakes, rivers and in the coastal zone of large reservoirs. In the past six years, she operated in the Volgograd reservoir in the vicinity of Saratov. The boat is easy to overcome waves up to a third of meter away from boats and ships. Emergency buoyancy in open water her provide two slightly inflated motorcycle camera. They are placed in the ends of the boat horizontally and securely held under the struts without additional fastening.

P. USOV, Saratov

Recommend to read “COMBINE” SOLDERING IRON A good soldering iron stand is necessary for the radio Amateurs and all those who deal with soldering. Description of just such a fixture and is offered to attention of readers. The... SMOKING WITHOUT SMOKE… No, we are not talking about the latter-day method of processing products using existing industry liquid smoke (to taste qualities of such meats to speak of). For natural smoked...