To build a simple, unpretentious, and reliable car, I was, one might say, forced by circumstances. Back in the memorable times of general shortages, I bought a well-worn “Zaporozhets” that spent more time in repair than on the road, waiting for me to find the necessary spare parts.

After several years of such torment, I began to be haunted by the thought of building my own repairable and affordable vehicle in terms of spare parts.

I had some experience in homemade construction by that time—before that I had made an aerosleigh, two walk-behind tractors, and a small tractor. But I was still afraid to approach building a car—I was aware that such a construction requires a higher level and quality of execution.

There were many options in my head. It took another year or two to realize what I wanted (or rather, what I could handle and afford).

In the end, I decided to build a small car in the “jeep” style with a non-deficit motorcycle engine from “Izh-Jupiter” even at that time. The engine power of 27 hp allowed me to count on the fact that it would pull a small car without problems at a decent speed.

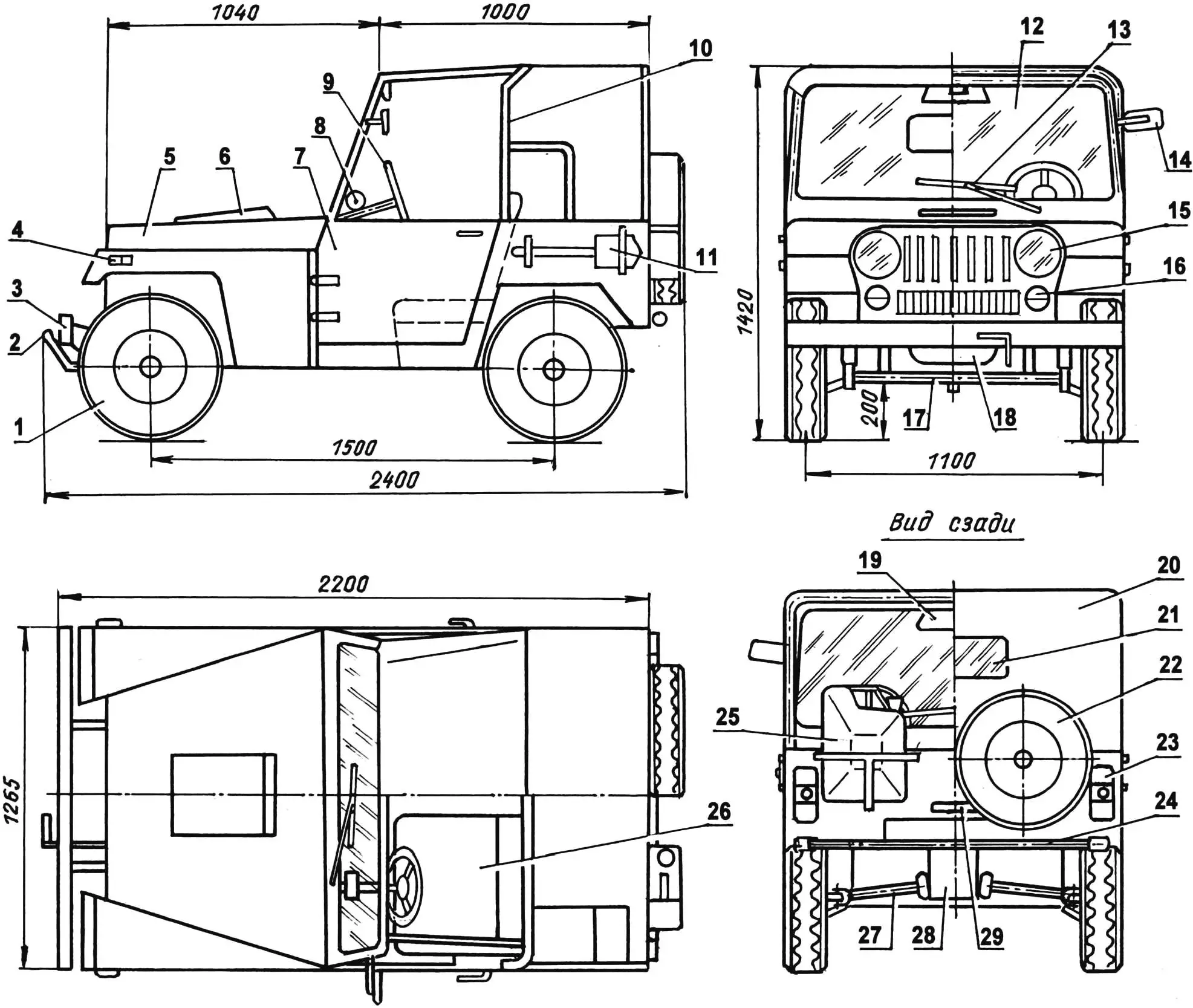

1 — wheel (from SZD motocart, 4 pcs.); 2 — kick starter (motorcycle, extended); 3 — bumper (steel pipe 60×40); 4 — turn signal repeater (2 pcs.); 5 — hood with fenders, radiator grille and partition (duralumin, sheet s2); 6 — removable cover (duralumin, sheet s2); 7 — door (from motocart, 2 pcs.); 8 — windshield wiper drive motor (from tractor); 9 — steering wheel (from motocart); 10 — frame; 11 — shovel; 12 — windshield (from motocart); 13 — wiper blade (from tractor); 14 — side rearview mirror; 15 — high and low beam headlight (from motocart, 2 pcs.); 16 — parking light and turn signal lamp (automotive, 2 pcs.); 17 — front axle beam (from motocart); 18 — power unit (from Izh-Jupiter motorcycle); 19 — rearview mirror (automotive); 20 — tent (from cargo truck); 21 — rear window (plexiglass); 22 — spare wheel (from motocart); 23 — rear signal lamp (automotive); 24 — crowbar; 25 — 20-liter canister; 26 — seat (from motocart, 2 pcs.); 27 — half-shaft (steering shaft from ZIL car, 2 pcs.); 28 — final drive (from Ant cargo scooter); 29 — license plate light (from motocart)

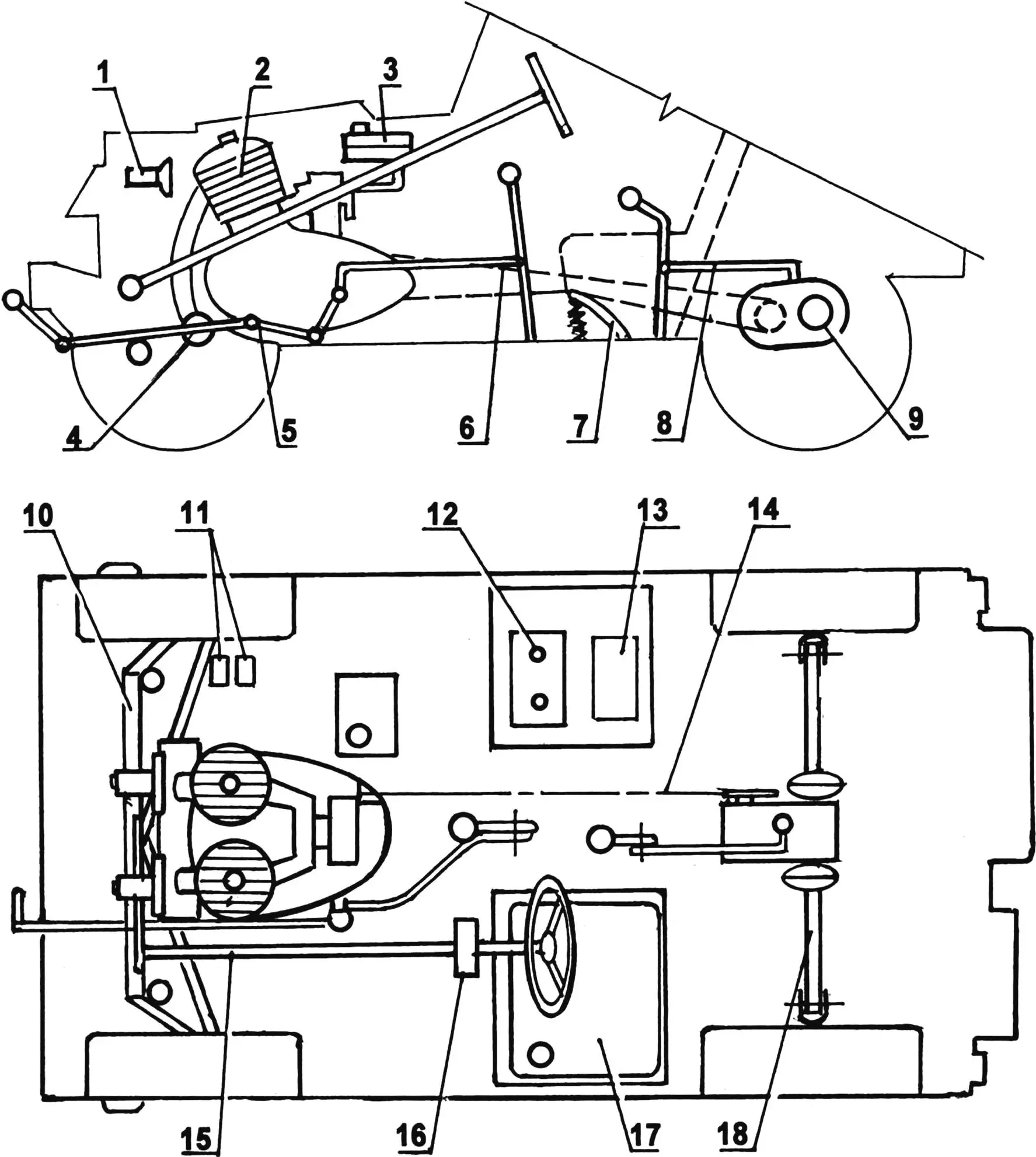

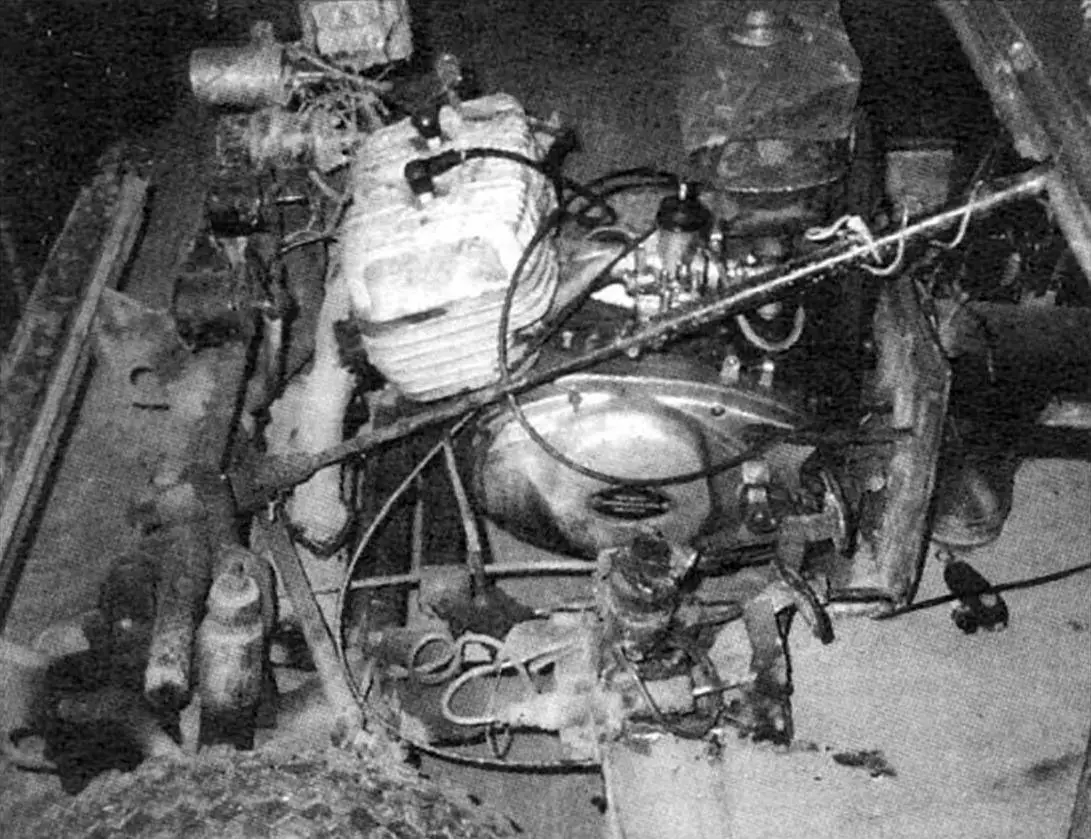

I used the chassis, steering system, and some other units from the SZD motocart: at that time, disabled people were already being given “Zaporozhets” by social protection agencies, and motocarts (even in quite decent condition) were sent for scrap metal. Such a decommissioned motocart served as the basis for my car, which car enthusiasts often call a mini-jeep, although it only has rear-wheel drive and, probably, it would be more correct to call it a motokar. But I placed the power unit in the front, unlike the prototype, and connected it to the final drive with a chain with a pitch of 15.875 mm from agricultural machinery. The final drive is from the Ant cargo scooter. At the point where the chain passes through the transverse frame beam, I fixed a tensioner on the latter that eliminates sagging of the lower branch. Additionally, the chain can be tensioned by moving the final drive in the slots of its mounting brackets. The chain is covered from above with a removable housing.

I initially installed all the half-shafts of the rear wheel drive from the same motocart, but then replaced them with driveshafts with joints from the steering shaft of a ZIL car. The steering mechanism, front axle, and its torsion bar suspension with shock absorbers are used completely (as assembled) from the motocart, as are the levers and suspensions of the rear wheels.

The engine muffler is homemade. Made from a pipe section with a diameter of 100 mm and a length of 350 mm. The engine is started with a kick starter, the extended and curved lever of which is brought out behind the front bumper.

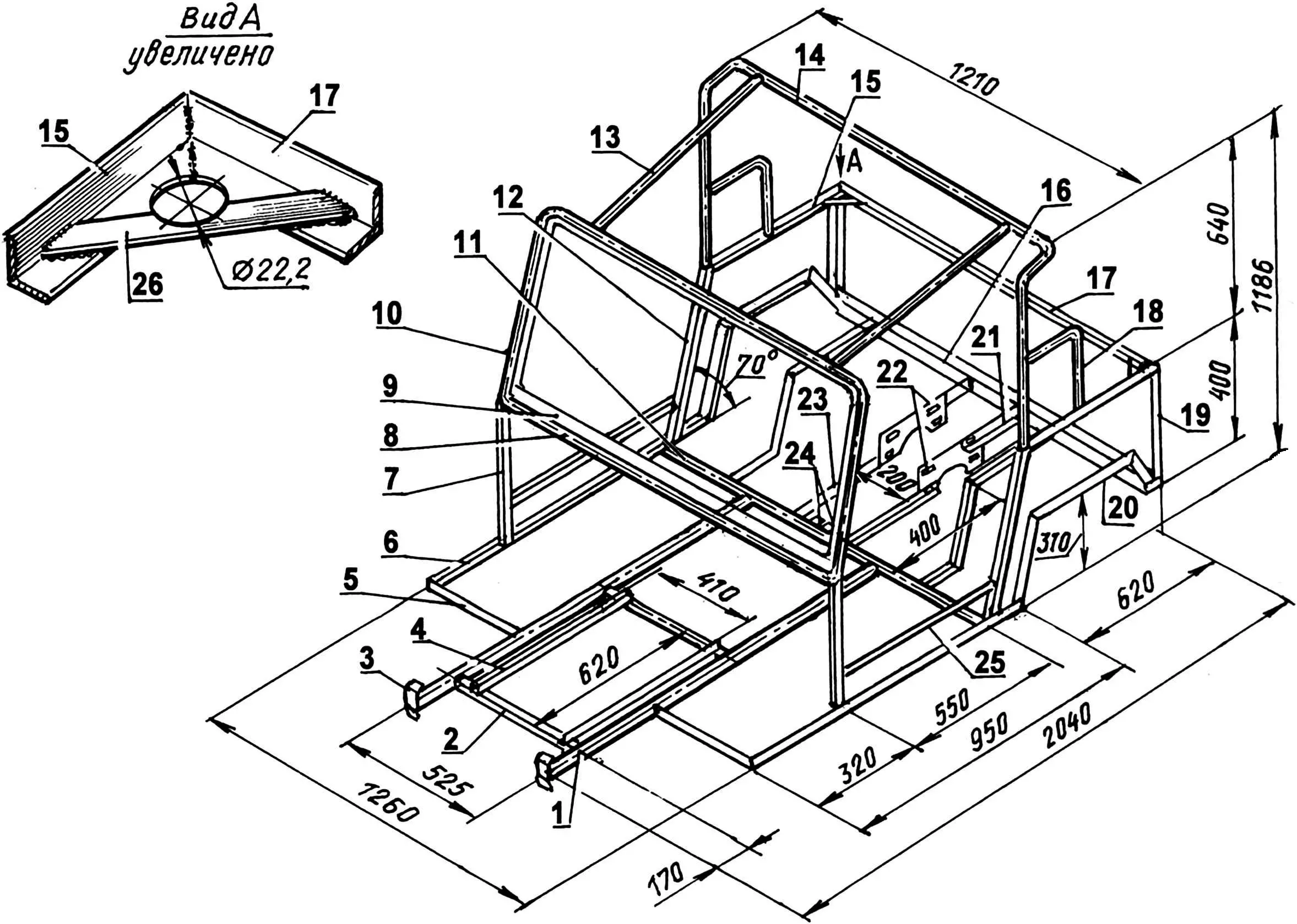

1 — main longitudinal member (1 1/2″ pipe, 2 pcs.); 2 — engine subframe crossmember (1/2″ pipe); 3 — bumper mounting flange (sheet s3, 2 pcs.); 4 — engine subframe longitudinal member (20×20 angle); 5 — floor crossmember (20×20 angle, 2 pcs.); 6 — additional longitudinal member (20×20 angle, 2 pcs.); 7 — front pillar (20×20 angle, 2 pcs.); 8 — sill (20×20 angle, 2 pcs.); 9 — windshield panel (sheet s2); 10 — windshield frame (1/2″ pipe); 11 — cross beam (1 1/2″ pipe); 12 — middle inclined pillar (1 1/2″ pipe, 2 pcs.); 13 — tie (1/2″ pipe, 2 pcs.); 14 — safety arch (1 1/2″ pipe); 15 — side panel stringer (20×20 angle, 2 pcs.); 16 — rear beam (60×40 pipe); 17 — rear crossmember (20×20 angle); 18 — strut (1/2″ pipe, 2 pcs.); 19 — rear pillar (20×20 angle, 2 pcs.); 20 — wheel arch arc (20×20 angle, 4 pcs.); 21 — rear bracket suspension; 22 — final drive mounting bracket (sheet s4, 2 pcs.); 23 — front bracket suspension (20×20 angle, 2 pcs.); 24 — control lever mounting bracket (sheet s4, 2 pcs.); 25 — sill (20×20 angle, 2 pcs.); 26 — gusset (sheet s3, 2 pcs.)

The mini-jeep body is also completely homemade. Its basis is a welded spatial frame assembled from various metal products: rectangular and round section pipes, angles—in general, from what was at hand at that moment—as long as the material provided proper strength and rigidity.

The composite elements of the frame can be considered both the engine subframe and various brackets for mounting transmission and suspension units, since they are welded to it. Most joints of the frame parts are reinforced with gussets, although they are not shown in the drawing. The frame element can also include the attached arc-shaped rear pillar—it is installed when a tent is stretched over the frame.

The body cladding is combined—from various materials. The front part: housing, fenders, radiator grille, and partition between the engine compartment and cabin are made as one part from 2-mm sheet duralumin. This part (let’s call it one word—hood) is easily removable and attached to the frame using spring latches from GAZ-69. By removing the hood, you can provide free access to the power unit, front axle, and even controls.

1 — fan (from GAZ-51, 2 pcs.); 2 — power unit (from Izh-Jupiter motorcycle); 3 — 3-liter fuel tank; 4 — muffler (homemade, Ø100 pipe); 5 — kick starter lever (from motocart, modified); 6 — gear shift mechanism (lever, rod and handle, from motocart); 7 — chain tensioner (shoe and spring, homemade); 8 — reverse engagement mechanism (handle, rod, lever—from motocart); 9 — final drive housing (from Ant cargo scooter); 10 — front axle beam (from motocart); 11 — ignition coils (from motocart); 12 — 12 V battery (automotive); 13 — tool box; 14 — drive chain (t = 15,785, from agricultural machinery); 15 — steering mechanism (from motocart); 16 — windshield wiper drive motor (from tractor); 17 — 18-liter reserve fuel tank (from motocart); 18 — half-shaft

On top of the hood there is also a removable cover with a rear slot opening. The cover serves for quick access to spark plugs, carburetor, fuel tank, electrical connector, and through the opening, the oncoming air flow, cooling the engine cylinders and heating up, blows on the windshield, preventing it from fogging even in cold weather. Two forced cooling fans for the engine are also mounted under the hood, necessary when the motokar moves slowly.

The doors are metal, made of steel sheet. They are also used from the motocart. The windshield is also from it, taken together with the drive mechanism of the single wiper blade.

The cabin floor under the driver’s and passenger’s feet is made of 3 mm thick duralumin sheet. The rear wheel niches behind the seats are closed with 0.8 mm thick galvanized roofing sheet, and the removable floor for access to the final drive, like the hood, is also made of 2 mm thick duralumin sheet.

The sides—side and rear—are sheathed with plywood covered with fiberglass impregnated with synthetic resin.

The car roof is a removable canvas tent with a rear window made of plexiglass.

The front bumper of the motokar is made of 60×40 mm rectangular pipe, removable. Instead of a rear bumper, a massive crowbar made of 25 mm diameter steel rod is installed. The car is equipped with a spare wheel, 20-liter water canister, and a shovel. All this is fixed on the car’s sides outside, and inside are also placed an axe, hammer, 18-liter spare fuel tank, tow rope, and jack.

The motokar cabin is not only without frills, but, one might say, ascetic: it has only two full-size seats—for the driver and one passenger. Behind their backs, on the wheel niches, two teenagers can (of course, without much comfort) be accommodated. Under the driver’s seat is a 20-liter reserve fuel tank, and under the passenger’s seat is a battery and tool box. On the instrument panel—only the most necessary instruments and sensors. Controls: clutch, brakes, and “gas”—like a regular car—using pedals. The brakes have hydraulic drive on all wheels. The hand brake drive is cable-operated and only on the rear wheels.

The total length of the motokar is only 2.2 m (400 mm less than the ancestor motocart), width—1265 mm, height 1420 mm, track—1150 mm, wheelbase—1500 mm, ground clearance—200 mm. Small dimensions, short wheelbase, high clearance provide the car with off-road capability like a real jeep. The engine allows reaching speeds up to 80 km/h, but it becomes too noisy, so the optimal speed is 55—60 km/h.

In the past, the motokar was even used for trips to neighboring regions many tens and even hundreds of kilometers away, which for such a car is not a short distance, but it withstood it every time.

Now “Nakhalenok” (as all acquaintances call the car by the nickname of a mischievous boy—one of the heroes of Sholokhov’s works) is mainly used for recreational trips by son Maxim. He also shows significant interest in automotive and motorcycle technology and has assembled himself a decent mini-moped from various units (son with wife next to the motokar—in the header photo).

The car has participated in “Samavto” festivals in recent years, where it was awarded diplomas and various prizes. But teenagers, of course, pay the most attention to it.

S. PANTYUKHIN