The experience of potato growers shows: Dutch technology for growing root crops is the most effective, with minimal labor costs. The rows are clean and even, and the harvest is excellent. The foundation of everything is properly organized planting and, naturally, good equipment.

I offer readers a brief account of the technology itself, as well as the design of a small hand-operated combine harvester—a proven assistant for the potato grower. Any beginning DIYer can make it.

After the garden is cultivated, furrows are cut across the entire area for potatoes. For example, with the same hand-operated combine. Seed tubers are placed in them, preferably sprouted, but you can also use ones that have simply been kept in the light for 3–5 days. Then the combine or plow-hiller (the design was published in the journal “Modelist-Konstruktor” No. 5’97) is run between the furrows—and all the potatoes end up covered as agrotechnics requires.

Some, when covering the seed material, try to use the very common disks instead of the combine or plow-hiller. However, they soon abandon them, because with soft tillage, the disks, cutting deep into the ground, turn up huge clods.

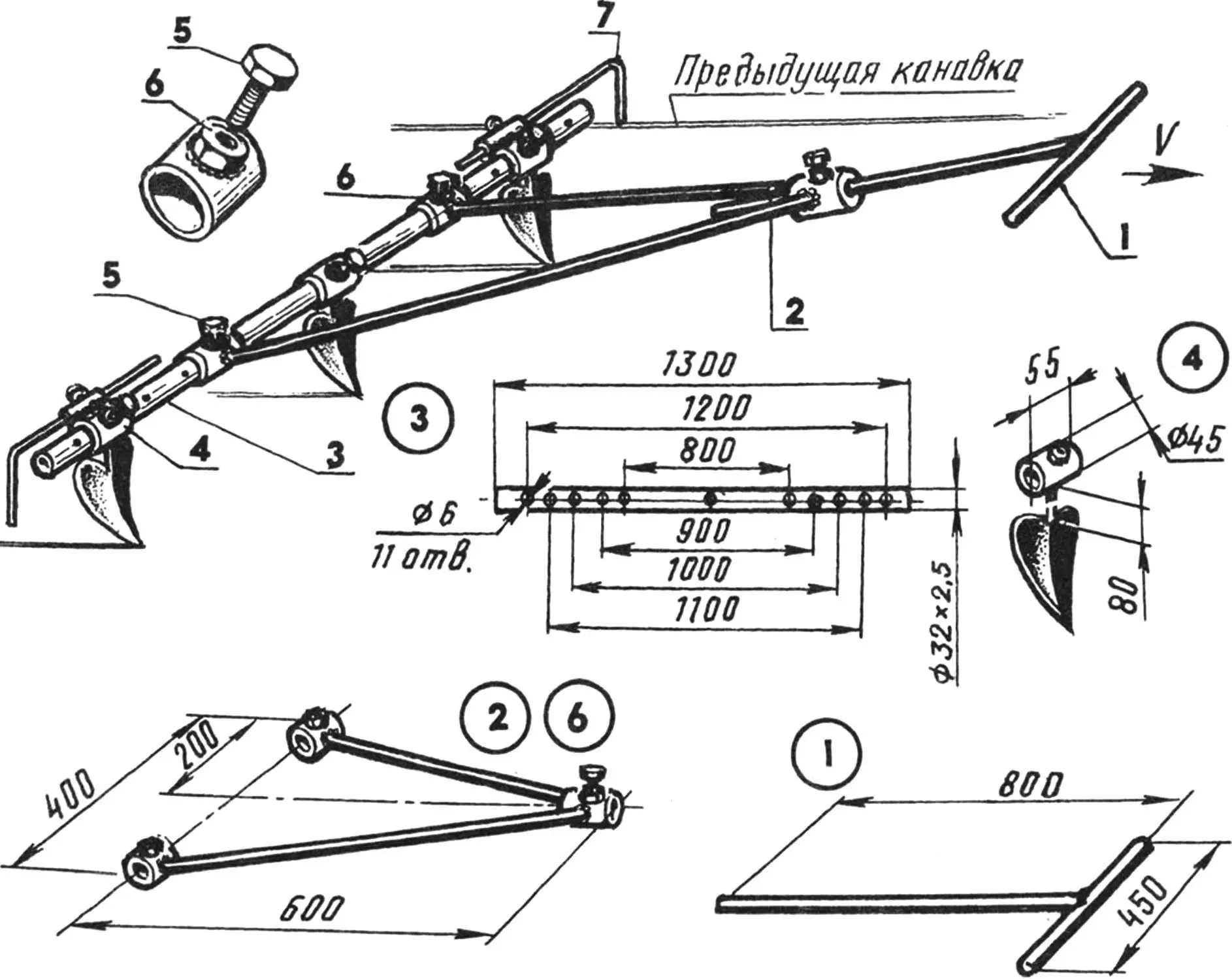

1 — handle (tube 21×2.5), 2 — beam (tubes 21×2.5, 27×2.5 and 45×7.5), 3 — mounting axle (tube 32×2.5), 4 — furrow opener (from agricultural machinery, modified, 3 pcs.), 5 — M12 set screw (6 pcs.), 6 — M12 nut (6 pcs.), 7 — marker (2 pcs.).

When processed with the combine or plow, the tubers end up in favorable conditions, as they are surrounded on all sides by well-loosened, soft soil. In terms of speed and uniformity of germination, the seed material far outperforms the shoots on control plots using the old, classical method. Moreover, heavy rains “clog” potatoes planted “the classic way.” The Dutch method successfully resists the elements—water concentrates at the bottom, in the inter-row spaces, while the rows themselves remain in ideal condition.

When the potatoes sprout and small weeds appear, weeding is needed. For this, small rakes or a cultivator (hoe) are suitable, descriptions and sketches of which have been repeatedly published in the pages of “Modelist-Konstruktor.”

But the weeds won’t give up; after some time they’ll come back. And when they reach a height of several centimeters—then you can’t do without a plow or disk hiller. You need to run them across the entire field, leaving behind only even rows of potatoes. Their stems at the base are slightly covered with soil, and the garden immediately takes on a well-tended appearance.

After some time, hilling the plantation should be repeated more thoroughly. The main thing is not to let the weeds overrun the entire field.

Digging up the potato harvest using Dutch technology is also more convenient. Moreover, this operation can easily be mechanized.

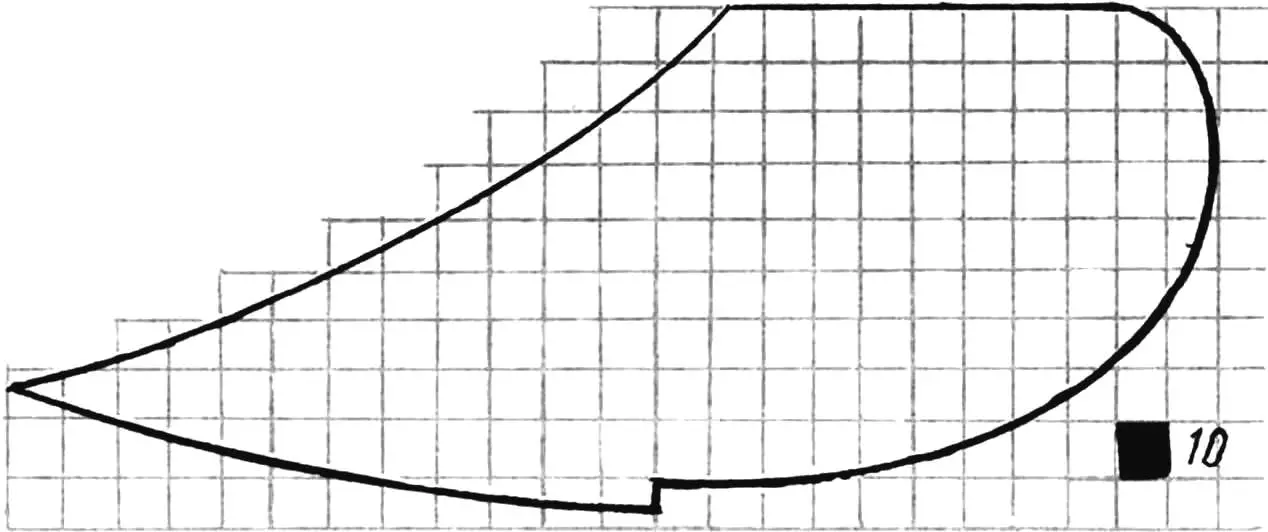

Now about the combine itself. This is a three-blade agricultural implement that, if there’s no walk-behind tractor, is pulled by two people. But with light soil, one person is enough. The working parts of such a hand-operated combine are replaceable and are fastened with set screws to the mounting axle. As the main ones, arrow-shaped furrow openers are used, similar to the mentioned plow-hiller. They can be taken ready-made (from decommissioned agricultural machinery) or made from a 3-mm sheet of high-strength, wear-resistant steel according to the provided development drawing. The furrow depth will be about 90 mm, and the width—sufficient for placing seed tubers.

At the connection points, the beam is fixed with set screws, which allows rotating the mounting axle relative to the handle and thus ensuring optimal (agrotechnical) depth of the furrow openers. The inter-row width is also easily adjustable.

On the mounting axle, on both sides of the beam, there are L-shaped markers with bushing-screw fixation—special beacons. The signal end of one of them, extended to the required distance, moves during furrow cutting and potato planting strictly along the previous furrow. The combine makes three new “beds” for tubers.

The other marker (with the first one retracted) is used when the combine is pulled in the opposite direction. This change happens quite quickly—for this, wing screws are provided on the bushings with wire beacons. Moreover, the bushings are slightly bent before welding so that the markers made of high-strength steel rod enter them with slight friction.

You can, by retracting and not using the markers at all, pull the combine so that one furrow opener follows the previous furrow. However, only two new furrows will be cut.

M. VALUY, Mena, Chernihiv Oblast