Our magazine has repeatedly written about the works of children’s technical club at HCS Institute of inorganic materials, which for many years was headed by engineer A. S. Abramov. Here young designers have created many original vehicles from using the bike and boat engines.

Our magazine has repeatedly written about the works of children’s technical club at HCS Institute of inorganic materials, which for many years was headed by engineer A. S. Abramov. Here young designers have created many original vehicles from using the bike and boat engines.

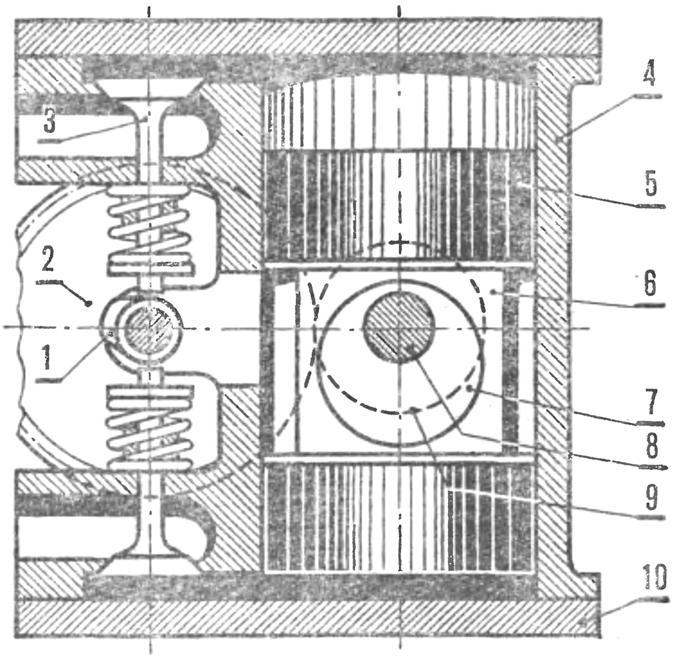

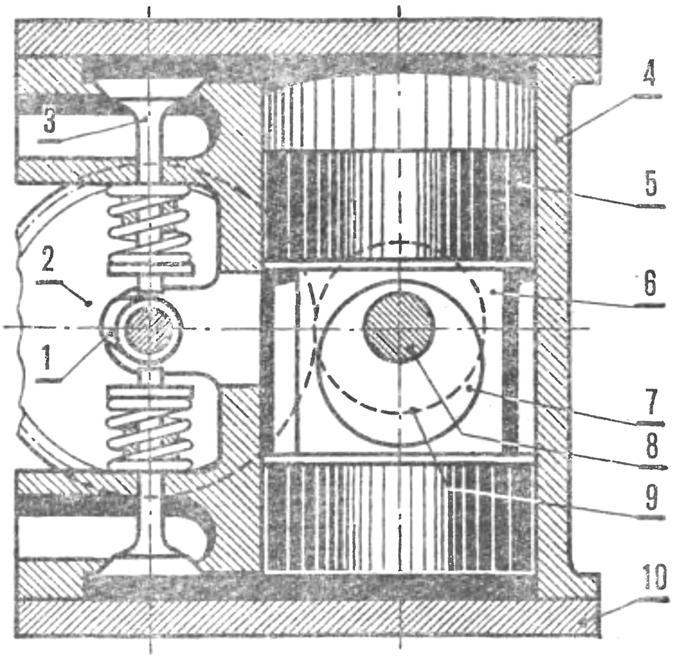

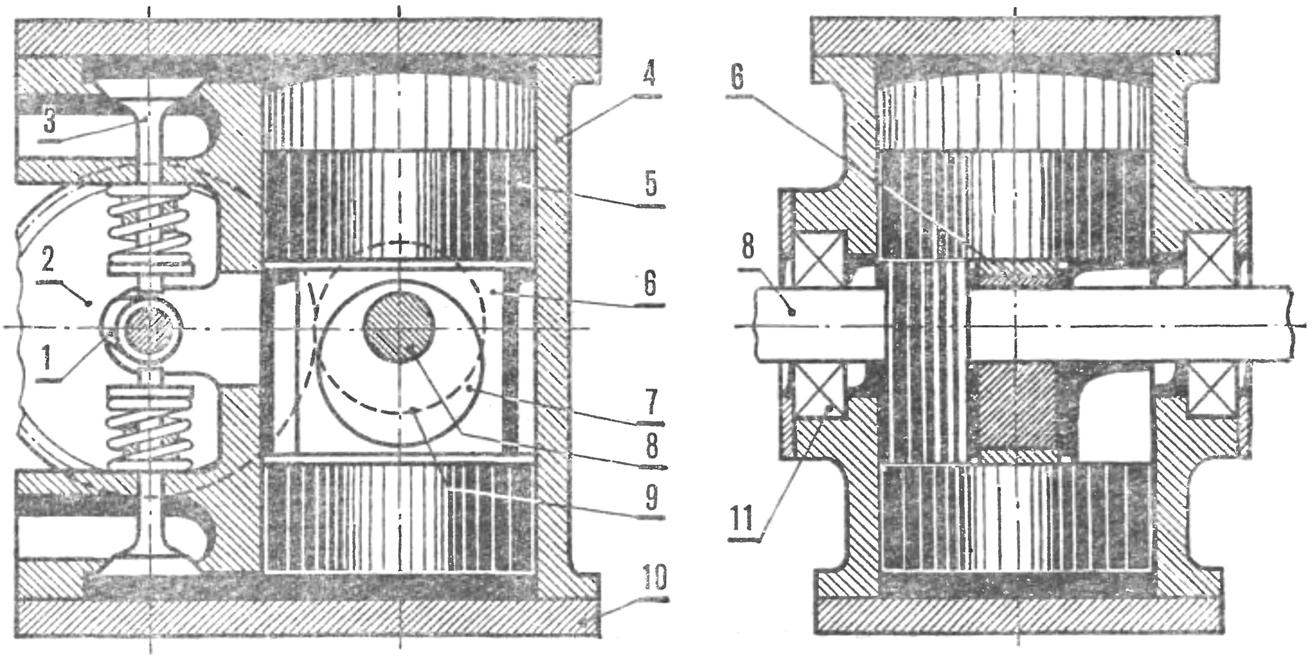

Today, readers are another interesting development — internal combustion engine with connecting rod free of the crank mechanism. The absence of the rod, and the unusual design of the piston left a mark on the whole scheme of the motor. Within the cylinder is a piston with two heads and two combustion chambers. Reducing the number of parts and simplification of the layout will give the opportunity to, according to the authors of the project, to increase the reliability of the engine as a whole.

Interesting design of the piston (see diagram). It consists of two heads connected by a strap. In its Central part has a hole for the passage of the shaft eccentric. With the opposite sides of the piston heads progressirovanii the guide grooves of the supporting cracker.

The Cam performs the role of the crankshaft. It consists of a small pinion gear drive timing. Large gear mounted on the Cam shaft. The ratio of transmission of 1 : 2. If we consider one of the combustion chambers, for example the top, you will find that it is no different from the usual “classic” cameras of a four-stroke internal combustion engine.

Diagram of engine with connecting rod free of the crank mechanism:

1 — Cam distribution shaft; 2 — the driven gear; 3 — valve; 4 — cylinder; 5 — piston; 6 — a support cracker; 7 — Cam; 8 — eccentric shaft; 9 — a leading gear; 10 — cylinder head; 11 — bearing.

The originality of the same kinematic scheme is to combine the functions of several parts into one. This is especially true of reference biscuit, which allowed to get rid of connecting rods, piston pins, etc., acting as the main liaison of the engine. Its location and design greatly reduce the lateral force acting through the piston to the cylinder wall.

Carter’s absence (it replaces the block-cylinder) reduces weight and reduces the size of the structure. The system of protection against dust and storage capacity for oil (sump) can now be made of light metal negligible thickness.

All other engine systems — ignition, intake manifold, carburetor, oil pump, etc. — are the same as that of conventional engines.

To build and carry out comprehensive tests is the task ahead, the young experimenters.

A. ABRAMOV, engineer