There is near Moscow, Serpukhov district, well-known vegetable farm “zaoksky”. Here, in high school, already DEA works student design bureaus, organized from the students of high schools teacher of Evgeny by Diligently. A quarter of a century he gave to the beloved work with children. Many of his pupils-modelers repeatedly took the first places of ka of the regional and national competitions were the winners of the all-Union competition; 12 masters of sports prepared them for this time. Experienced youth mentor bears the honorary title of honored coach of the RSFSR.

There is near Moscow, Serpukhov district, well-known vegetable farm “zaoksky”. Here, in high school, already DEA works student design bureaus, organized from the students of high schools teacher of Evgeny by Diligently. A quarter of a century he gave to the beloved work with children. Many of his pupils-modelers repeatedly took the first places of ka of the regional and national competitions were the winners of the all-Union competition; 12 masters of sports prepared them for this time. Experienced youth mentor bears the honorary title of honored coach of the RSFSR.

Recently appeared at Yevgeny’s new hobby — the construction of machines and devices for mechanization of agricultural labor.

Last year the workers of state farm “zaoksky” was marked by high production rates. “Fruitful” can be considered members of the student design Bureau N. Koukin, V. Kalinin, V. Burobin, S. Volodin, S. Sakharov and head E. N. Deligent. They became laureates of the Central NTTM exhibition, held at ENEA USSR. An original device for harvesting cabbage, a kind of manual food processor, they are submitted to this exhibition. The harvester has interested many visitors of agriculture.

Today we put this exhibit on our booth in absentia exhibition “TVP-75” (see No. 3, 1975).

In developing its original harvester the boys had to take into account a number of specific requirements: working with the device standing; to cut the sprouts need no additional treatment of the stump, to give the head a “trademark”; the device should put the heads separate piles — so it’s easier to load; it is necessary to exclude the possibility of injuries.

Created student KB device resembles a pitchfork. It is the basis of the dural tube an outer diameter of 33 mm and a wall thickness of 1 mm. pipe Length — 1260 mm, with grip — 1460 mm. the Pipe has a hinge-rod connecting with working parts. The lower end of the pipe is attached to each of the cutting head, which is a viloobraznym frame made of wire OVS Ø 5 mm with welded on steel plate for mounting the knife-cutter.

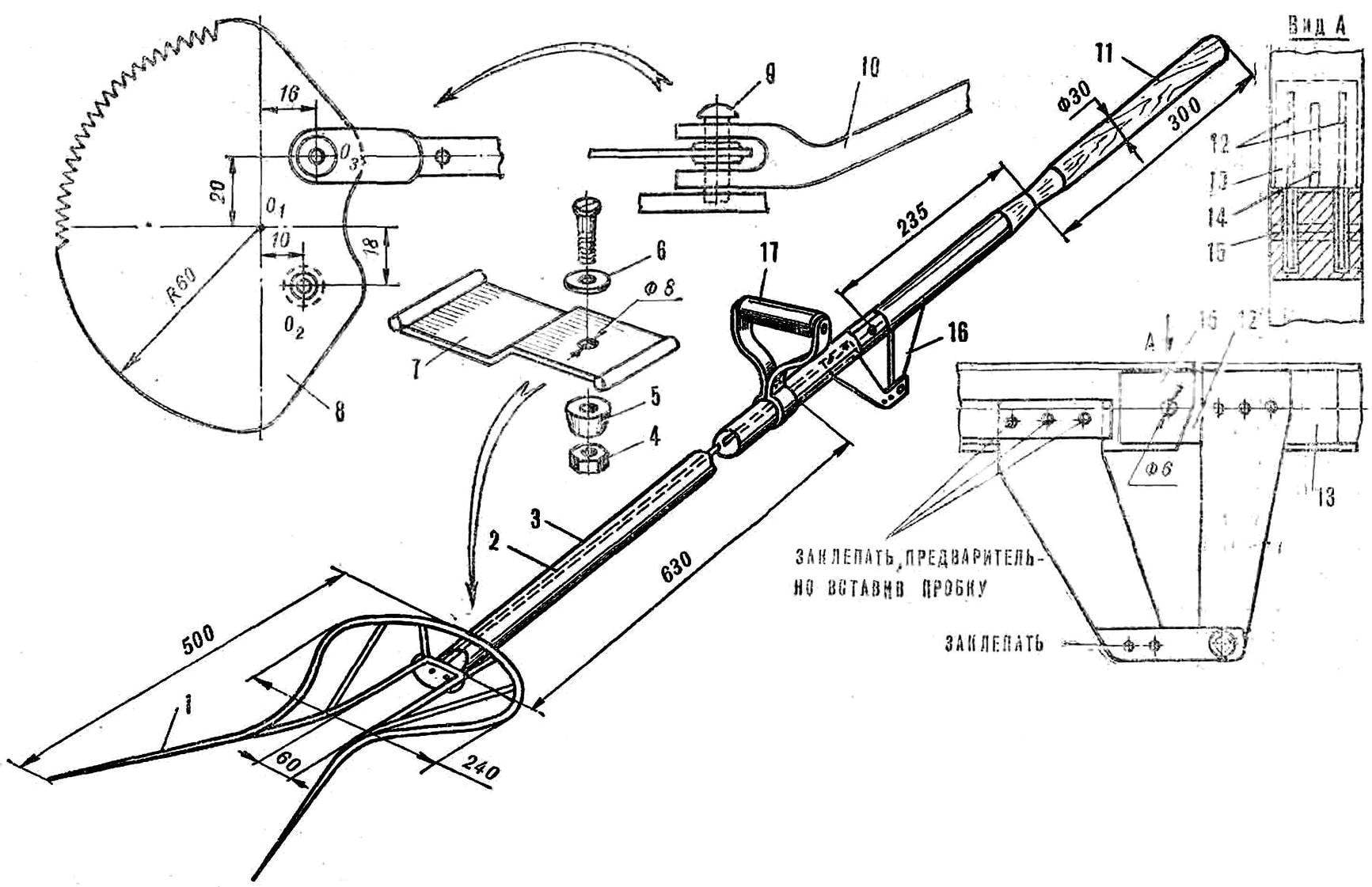

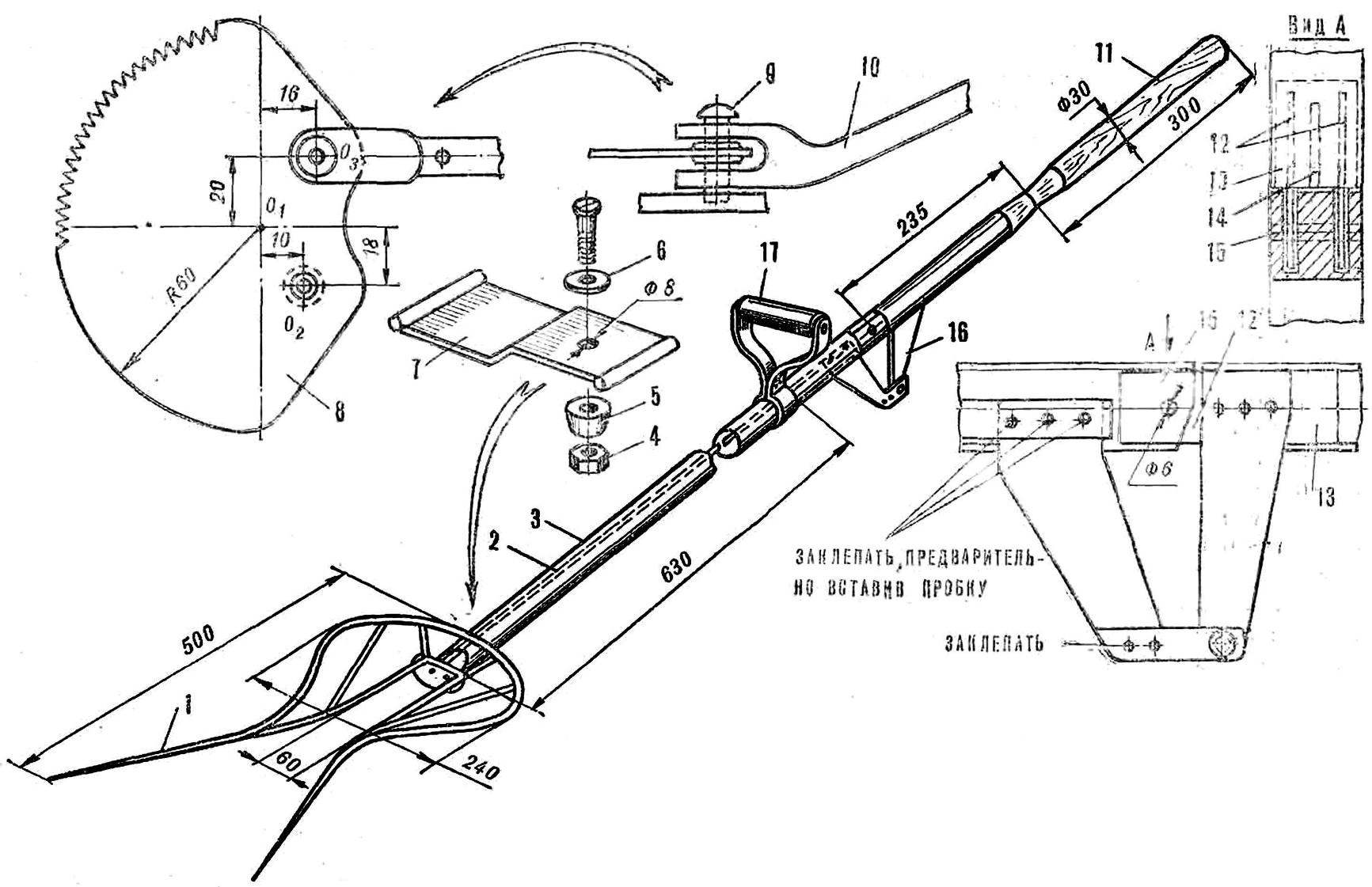

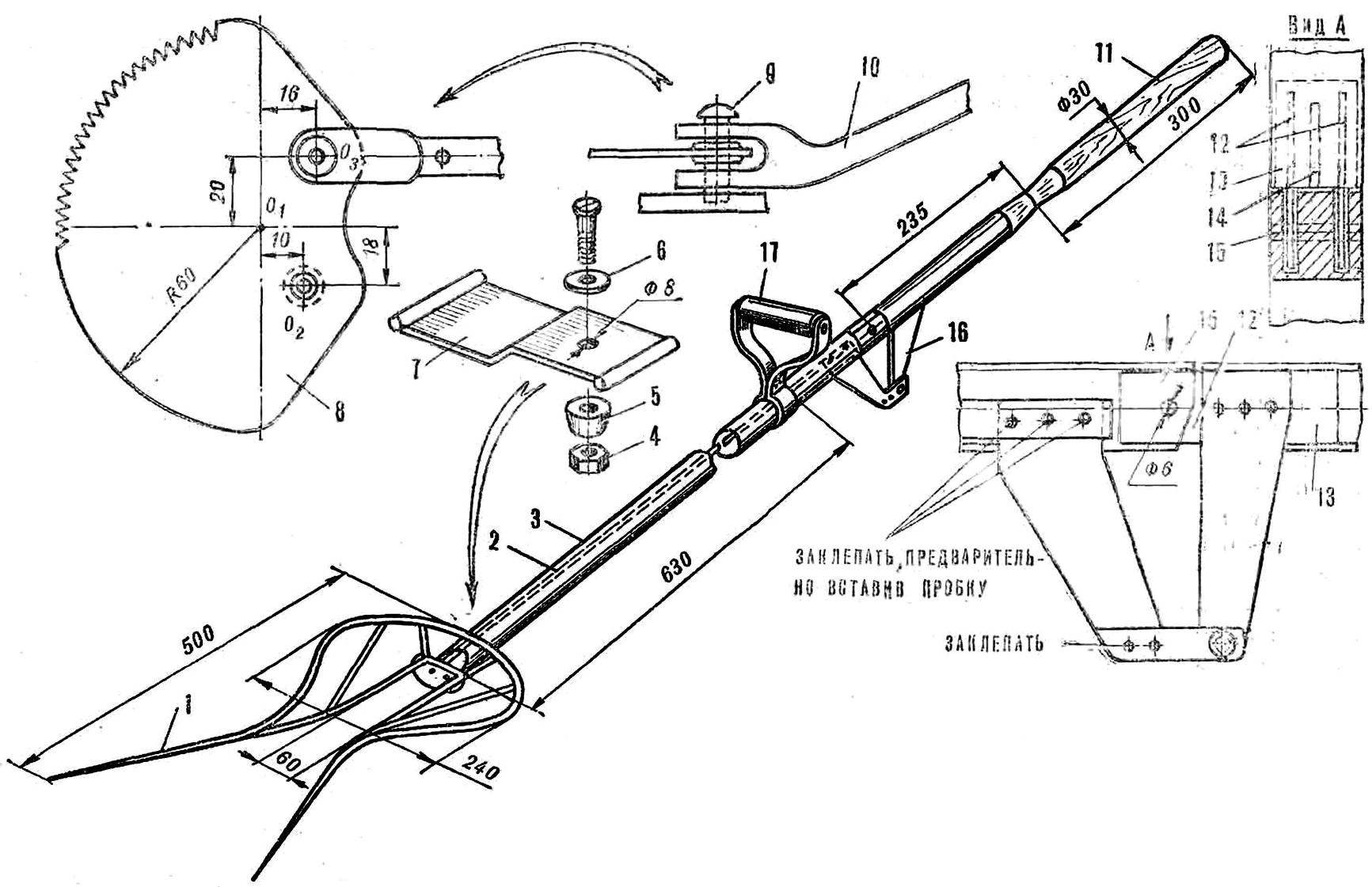

Scheme vil-harvester:

1 — receiving portion, 2 — rod, 3 — pipe, 4 to 6 — securing plate 7 — plate 8 — the knife-mill, 9 — bolt, 10 — head stem, 11 — arm, 12-15 — the elements of the hinge arm 16 is pivotally the lever 17 is a handle.

The knife-mill, of spring sheet steel 1.5 mm thick. the Left part it has a sharp cutting edge, and then sliced straight teeth like a hacksaw. The center of rotation (point O2) offset that allows the cutting edge simultaneously with the rotation to perform the translational motion. At the point O3 fixed stock. They used dural tube Ø 15 mm, passing inside the tube. The second end of the rod is connected to the top, “breaking” part of the pipe (see figure).

The force of action of the cutting knife of the cutter is approximately four times more force exerted on the handle.

Fixture viloobraznym part is overlaid on cabbage trees, bending leaves. Then sharp movement is sent forward, while the cutting edge of the cutter will enter the stump. Now it is characteristic of work with a pitchfork movement if lifted pry the head out. You need to click on the handle that stick breaks in two, goes down and through the swivel lever pushes the stem. He leans forward and turns the knife-cutter — is a cutting head. Then pry “up” and cut off the head easily discarded in a heap.

V. ROZHKOV