The idea of creating a small four-wheeled carriage with electric drive for pleasure trips in the picturesque surroundings of Peterhof came to us last year. Before that, we built two-wheeled machine as a drive unit used for electric drill, powered by a car battery through the transistor voltage Converter.

The idea of creating a small four-wheeled carriage with electric drive for pleasure trips in the picturesque surroundings of Peterhof came to us last year. Before that, we built two-wheeled machine as a drive unit used for electric drill, powered by a car battery through the transistor voltage Converter.

But this vehicle was difficult to keep in balance at low speed and with frequent stops, as it was installed the battery, comparable in mass with the chassis.

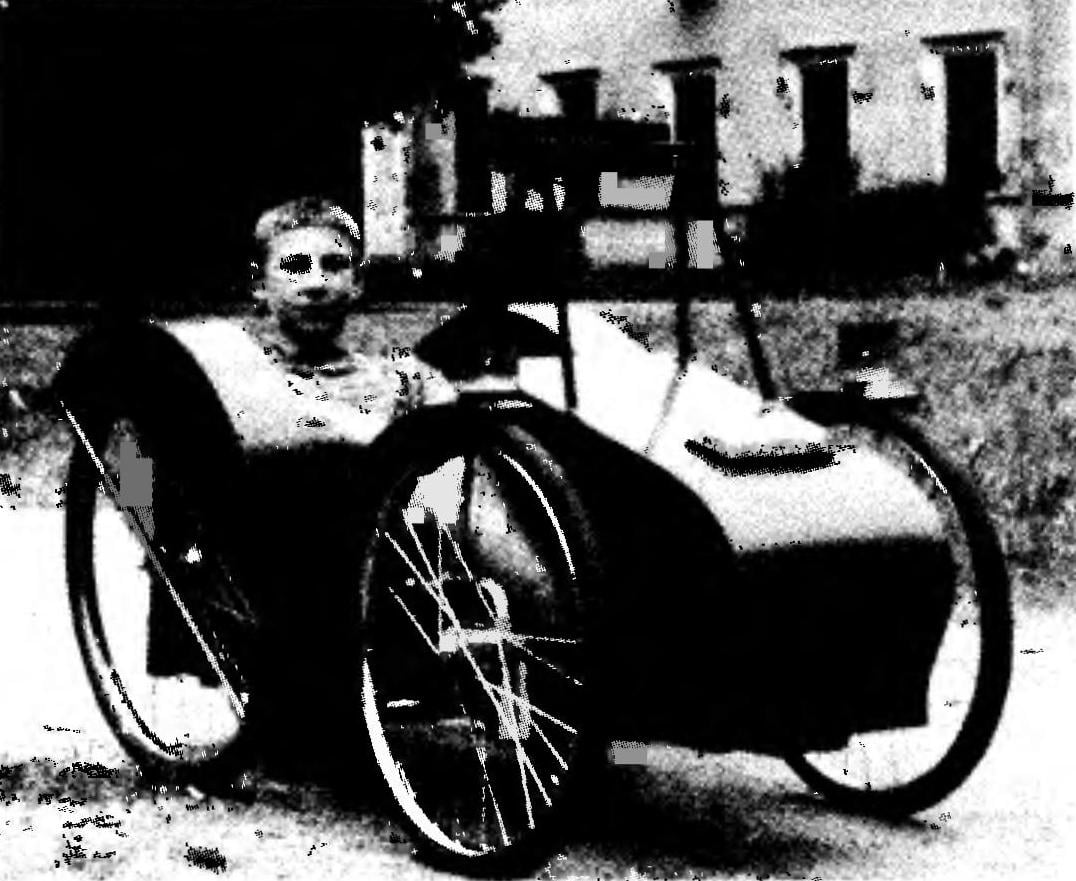

New electric car, called “Debut”, we did in three months, not counting the preparatory period, study design, procurement of materials, machinery, parts.

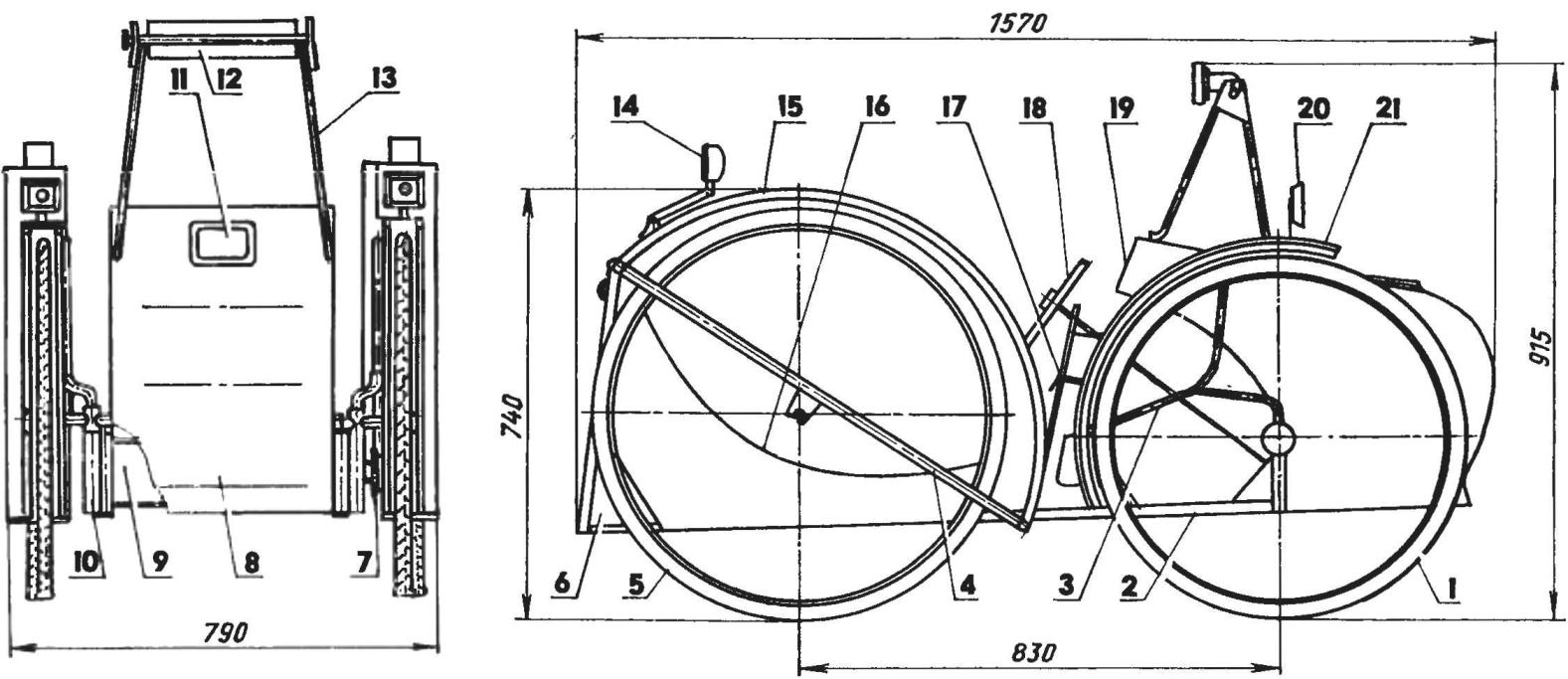

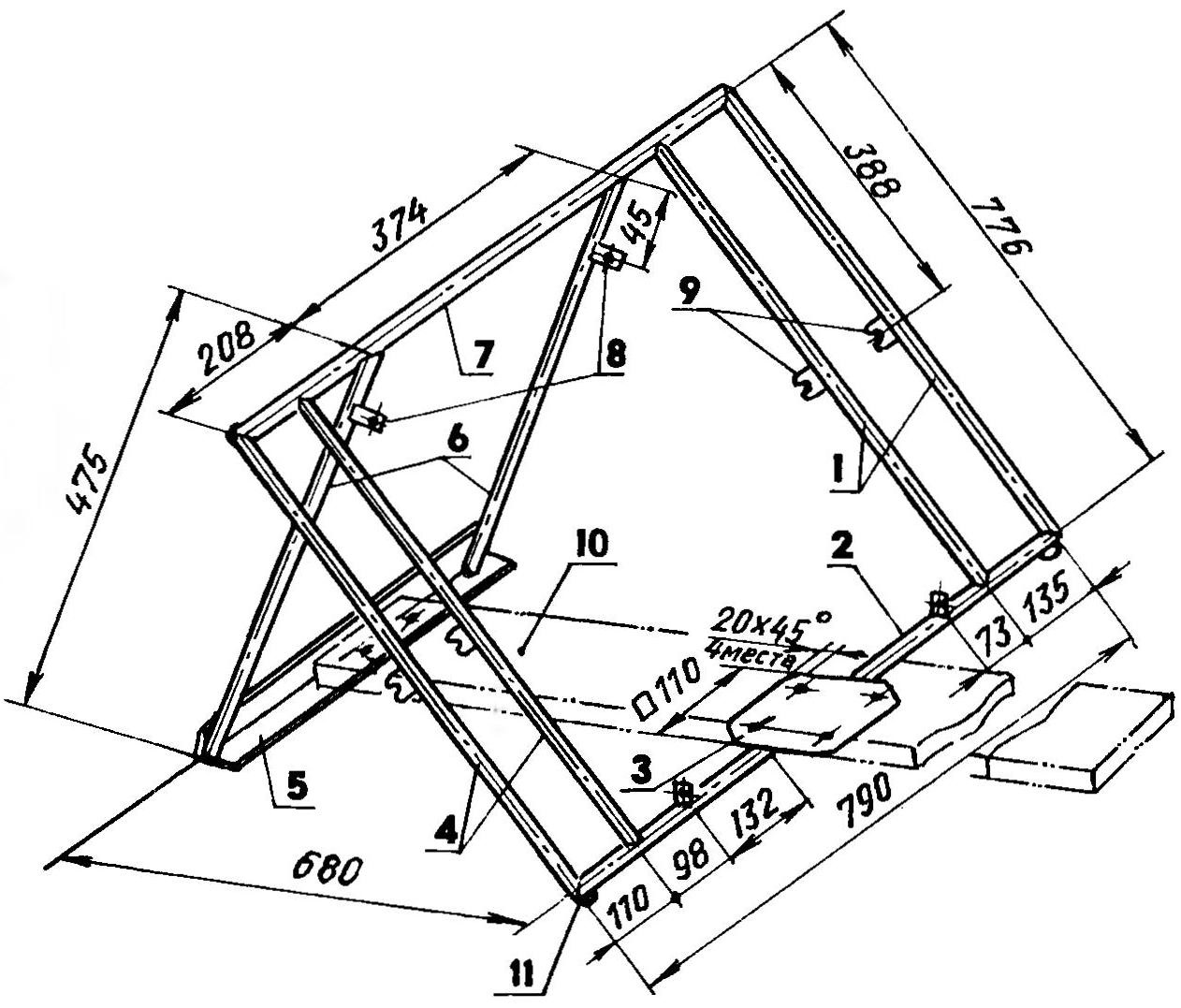

The main element of the chassis is a simple frame made of pine boards with a length of 1550 mm and a cross section 110×23 mm. It combines the front and rear of the machine. In the rear mounted subframe, welded mainly of half-inch water pipes in the form of a tent. This form was not chosen by chance: with a minimal number of parts sub-frame has the highest stiffness. And for him it is necessary, because it performs the role of the rear axle and bears the brunt of a massive battery and the driver.

Subframe welded Assembly. It consists of six sloping racks (two rear and two front pairs) and three cross members. All parts, except the rear crossmember, made of half-inch steel water pipe. At the top of the stand are connected by a common cross member, below front — his back is also his area of 40×40 mm, full steel strips with a thickness of 2 mm. the pair of the rear struts placed closer to the middle of the cross members, and front — on their edges.

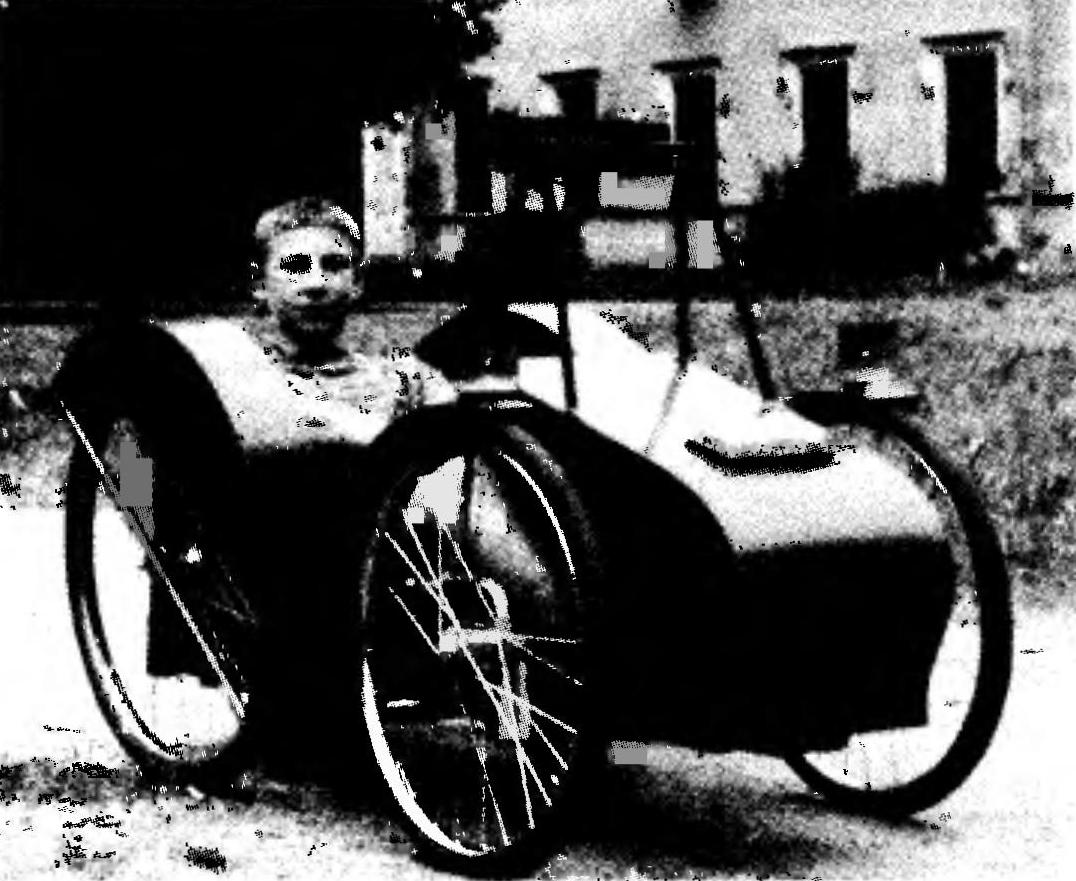

The raised headlight, Parking lights turned on. Visible gear: chain transmission sprocket and the leading of the left rear wheel

The battery compartment under the seat is closed. Brake lights and panoramic rear view mirror — from a real car

The distance between the pairs of front struts are different as between the left pillars is inserted into a rear Bicycle wheel with a large driven sprocket and the brake hub. On the right side is inserted into the same diameter wheel but with no bushings or sprocket.

For mounting the wheels in the frame to each front pillar in the middle of the welded lugs in the form of lugs bike forks. In addition, to the rear uprights at the top welded mounting brackets with holes for attachment thereto of the seat. Exactly the same brackets for the same width and with the same purpose and welded to the lower front crossmember. It is still welded to the: bottom end — rings to the pipe of the brake mechanism, and in mid-top — support — steel 2-mm plate with four holes with a diameter of 4 mm for screws fixing the Board frame. Two holes for this purpose are drilled in the horizontal shelf area of the rear lower cross member.

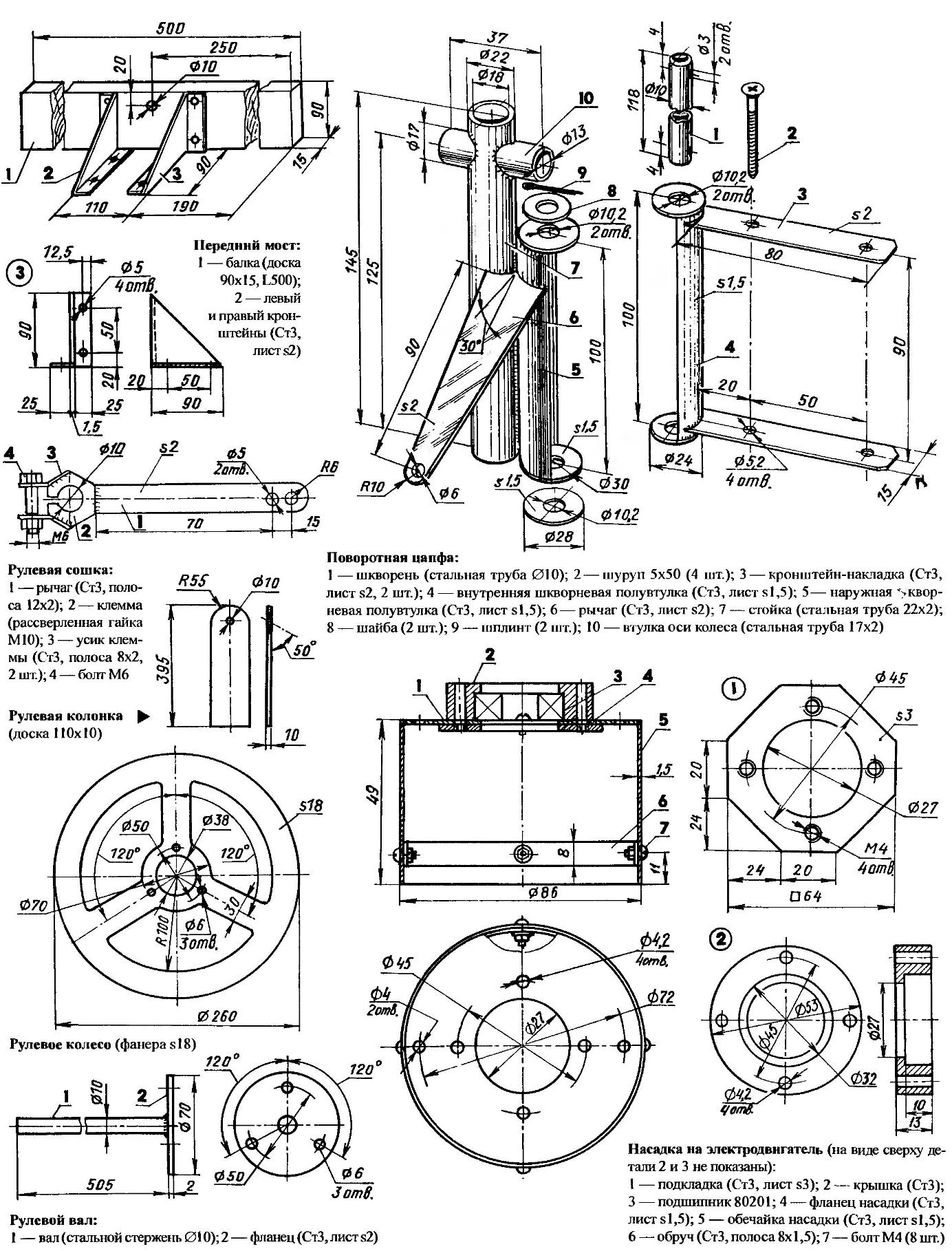

At the other end of the frame mounted front axle. He is also a Board cut section 90×15 mm and a length of 500 mm, set on edge across the frame. Intermediate connecting pieces — two arms, the curvature of 2 mm steel sheet. Fasteners — screws. Also the screws attached to the ends of the front axle and a homemade rotary axle of the wheels.

Crew management is carried out by the actuator, consisting of a steering wheel shaft with a bipod and steering linkage. Wheel is cut from a plywood sheet of thickness 18 mm. and is attached to the flange on the upper end of the steering shaft. On the lower end planted through the terminal clamp bipod. The shaft (steel rod 10 mm in diameter) inserted into the inclined holes in the column and front axle. Fry and left pivot arm, and levers (left and right) linked by a wooden tie-rods of a steering trapeze.

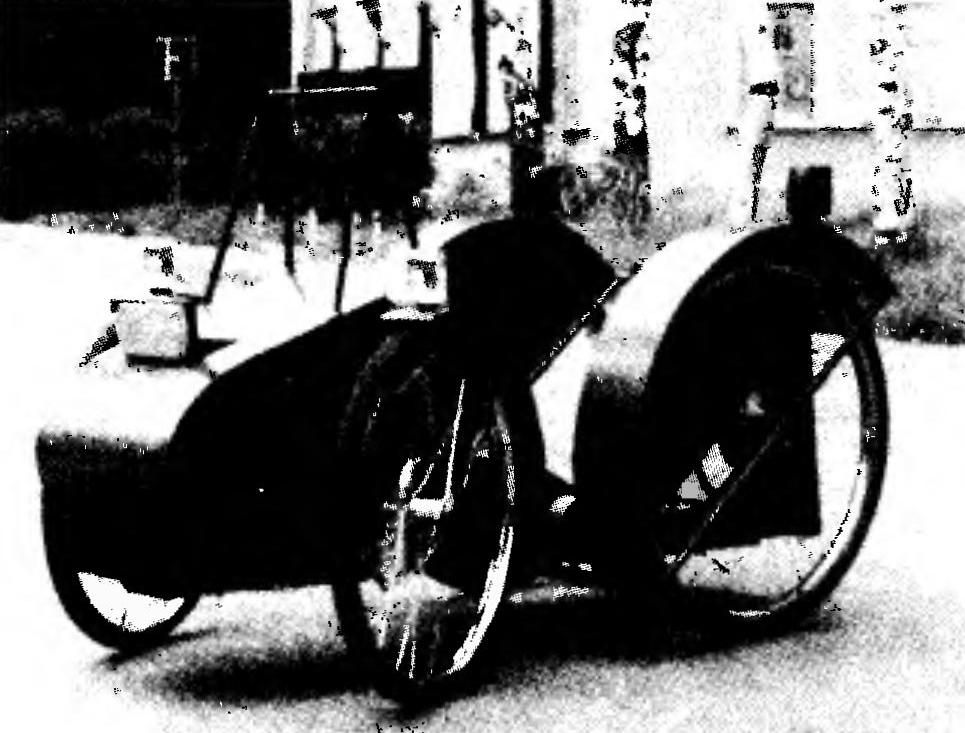

The Electric Car “Debut”:

1 — front castor wheel (Bicycle 37-533); 2 — the frame (Board Л10х23, ІЛ550); 3 —shackle mounts of the front wing (dural tube 22×2); 4 — stretcher; 5 — rear wheel (Cycling 40-622); 6 — battery; 7 — sprocket-drive (z = 6, t = 12,7); 8 — hood (hardboard, plywood s18); 9 — rear axle; 10 — rotary axle; 11 — retractable headlight; 12 — panoramic rear view mirror; 13 — stand mirror (steel pipe 17×2,2); 14 — brake (2); 15 — rear wing (hardboard, plywood s18, 2 PCs.); a 16 — seat (plywood s3 and s18); 17 — steering; 18 — drive; 19 — instrument panel; 20 — marker light (galvanized sheet s0,5, 2); 21 — front wing (hardboard, plywood s18, 2 PCs.)

Subframe:

1 —left pair of front struts; 2 — lower front cross-member; 3 — a support (St3, sheet s2); 4 — right pair of front struts; 5 — lower rear cross bar (40×40 area, is bent from steel strip s2); 6 — rear pair of struts; 7 — upper tie bar; 8 — brackets for seat mounting (St3, sheet s2, 4x); 9 — lugs axles of the rear wheels (St3, s2 sheet-4 pieces); 10—frame (Board 110×23); 11 — ring for pipe braking device (wire Ø5, 2); items 1,2,4,6,7 made of steel pipe 1/2″

The rear and front wheels of the chassis are different. 40-622 rear dimensions, front (swivel) 37-533 mm

The engine and drive. As the engine used a modified starter from the car “Oka”. He was cleared of all unnecessary items (to the body, which is the anchor): retractor relay, overrunning clutch pinion, etc., and in their place are installed new front end — a self-made nozzle with the bearing 80201. Shell nozzles are worn all the way to the Hoop on the starter housing and “stuck” to him multiple welded points.

I must admit that the efficiency of such a motor-starter due to the large current consumption is low, and if possible it will be replaced.

The most appropriate would be the motor Syu the following parameters: voltage 12 V, capacity 700-1000 W, the number of revolutions per minute to about 4000 (more undesirable, as it will have to significantly increase gear ratio chain transmission).

The power source for the electric motor — two batteries of 6 at a capacity of 75 amp-hours each. These batteries are obtained from the automobile, which cut and three left banks. Range — the distance traveled by the electric vehicle on a single battery charge when driving at cruising speed of 20 km/h is about 25 km away.

Toggle switch voltage 6/12 V, switching the battery in the first case parallel and in the second consistently, rated at 100 A (short-term, up to several minutes, up to 300 A), a homemade. It is fixed on the steering column under the “wheel”.

Torque of the electric motor on the rear left driving wheel is transmitted to the standard Bicycle chain with a pitch of 12.7 mm using a homemade star. Sprocket fitted on the motor shaft and welded to it, has six teeth, and the led welded to the head on the wheel, 70 teeth. It is easy to determine gear ratio: it’s pretty significant — more than 11.6.

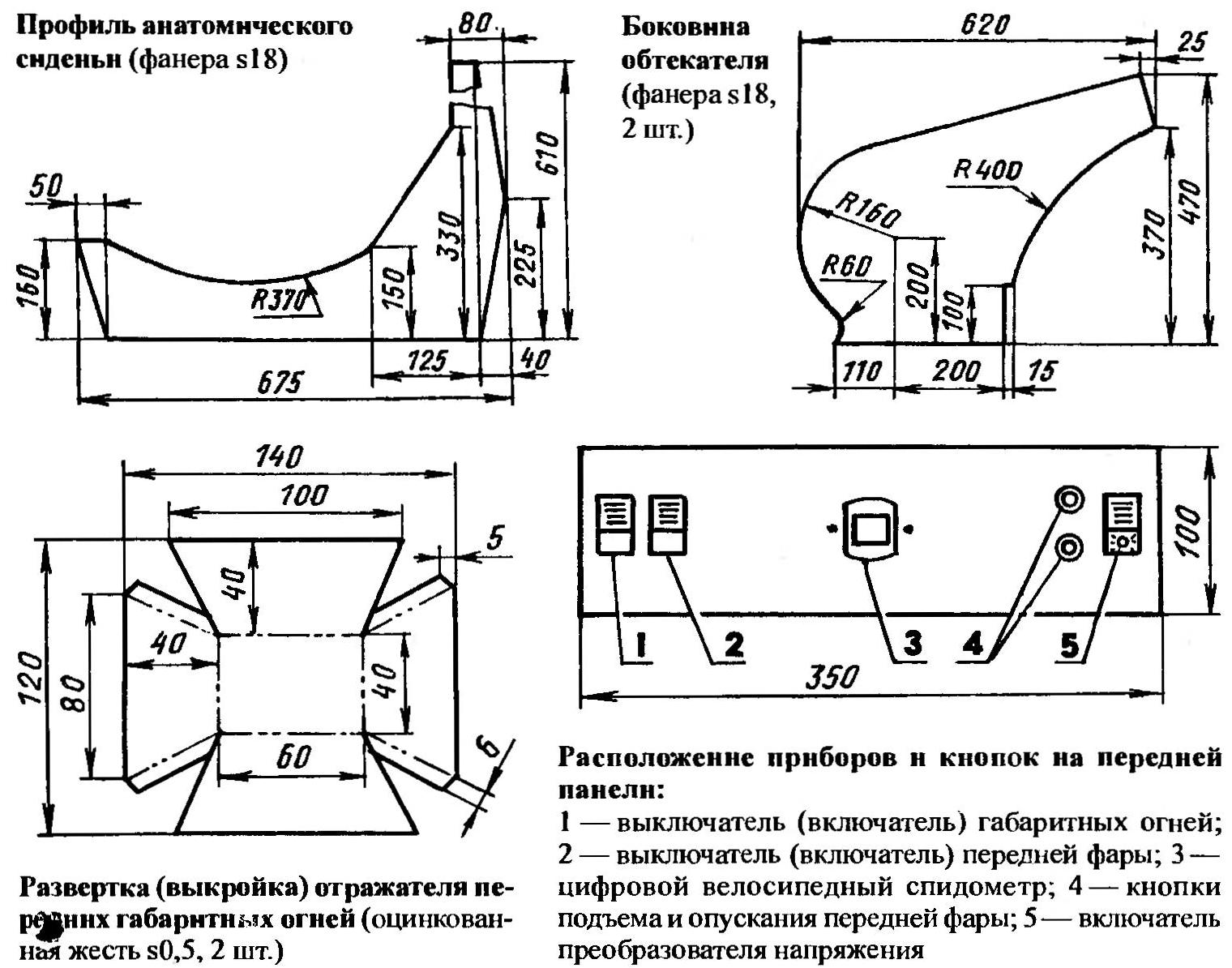

The wings are made from strips of hardboard and is connected by screws with cut of 18 mm plywood arcs. The hind wings are mounted on the front subframe. The front are mounted on special arms which are inserted in the rack of the rotary axles, and fenders turn with the wheels. From the same plywood and made side fairing-cowl. From above it is closed is also a sheet of hardboard. Between the side walls (in the upper back) has a dashboard.

Wiring diagram:

M1 is the drive motor (modified starter from the car “Oka”); SB1 — button switch of the drive motor (pedal “gas”); SA1 — the toggle switch connecting the drive motor and switching of the batteries; SA2— toggle switch control headlight; M2 — motor extension lights; EL1 — bulb lights; SA4 — hoist limit switch of the lights; SA3 — limit switch down lights; SB2— button on/off headlamps; SB3 — button horn switch (on the handlebars); SA5— on/off switch, front marker lights; SB4 — button switch brake (from brake pedal); HL1, HL2 — light bulb the Parking light; HL3, HL4 light bulbs of stop lamps; power wire from battery to the motor— section 15 mm2, others — 1 mm2

All related details are connected with screws. The hood to the frame drawn by five screws.

To the facing elements can be attributed to the seat, because the electric — cabriolet type. The seat is comfortable, anatomical. It is, as the fairing consists of two 18-mm plywood sidewalls, but not closed hardboard and a sheet of 3 mm plywood.

At the back of the seat is the battery compartment, an indoor climbing up the door, made of 18 mm plywood. All cladding details are covered in several layers of oil paint.

Under the seat front of him on the wall with two brackets with bolts fastened on the motor. Since the wall is sloping, by shifting the engine to adjust the chain tension.

On the rear wheels of the electric vehicle installed drum brakes. Brake pedal, through a pipe, which is welded to the pedal and the cable.

The crew is equipped with a digital bike speedometer with trip meter, front and rear Parking lights with stop lights, electronic horn, front headlight.

Brake lights commercial production and front marker lights — self-made from galvanized sheet.

Headlight retractable (retractable), has its own voltage Converter. It is mounted in the middle of the cowl fairing. On the hood there on the racks-arcs panoramic rear view mirror.

Main technical characteristics of the crew

Overall dimensions, mm:

length………………………………………………………………1570

width………………………………………………………………790

height (top of wings)………………………………….740

Maximum speed, km/h…………………………………..40

Operating speed, km/h…………………………….20

Capacity batteries, And h……………………150

Cruising at a speed of 20 km/h, km………………………..25

The size of the wheels, mm:

front……………………………………………………….37-533

rear…………………………………………………………..40-622

Track front/rear wheels, mm……………………650/680

Wheelbase, mm………………………………………………..830

A. POLIKARPOV, I. POLIKARPOV, Saint-Petersburg