The accumulated experience showed us another path of development. For several years the young operators engaged in the construction of units that have only one purpose, adapted to perform only a well-defined work: plowing, harrowing, cultivation etc. In the end, the lack of engines made me think: it’s time to think about the creation of a universal machine or series of mechanisms with a portable engine. This idea radically changed the direction of their creative search.

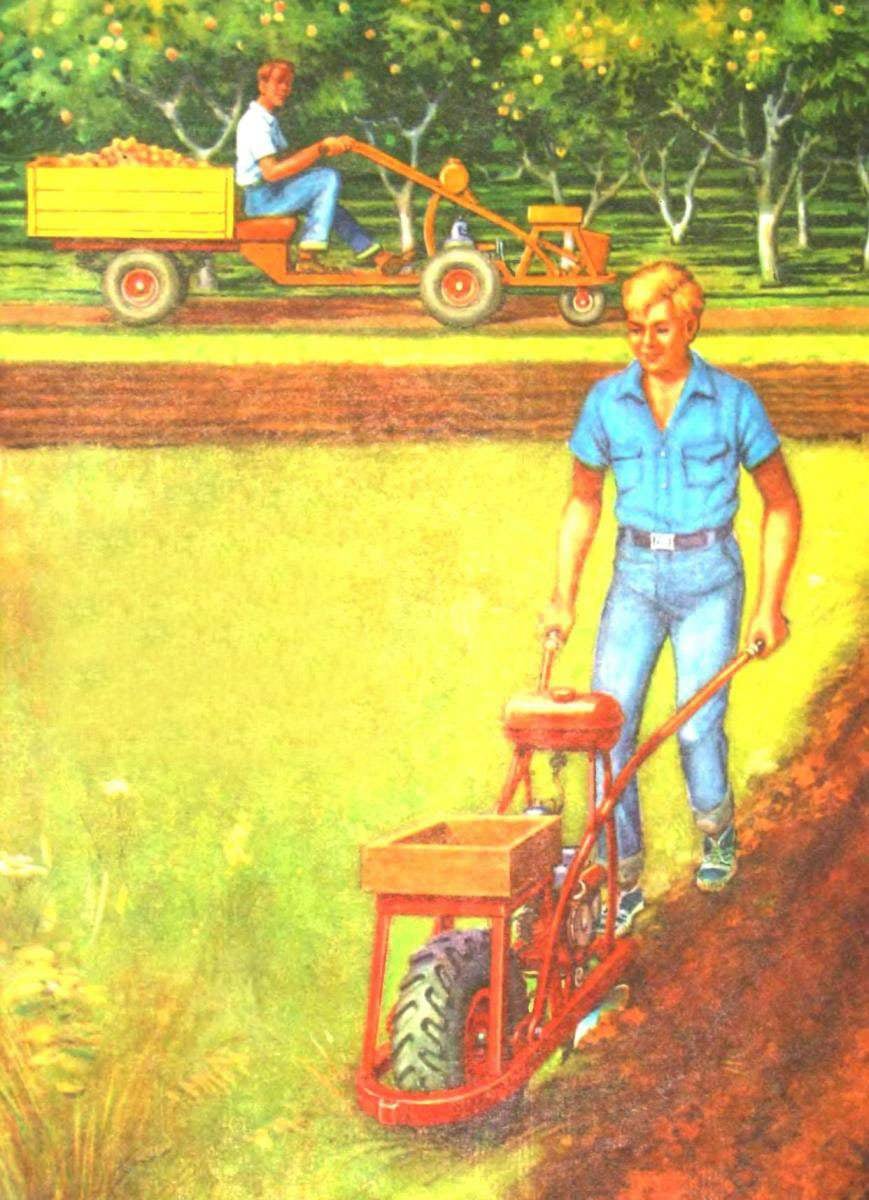

Figure 1. Universal agricultural machine, USM-2 “Cinderella” (base model) with a set of trailers and attachments:

1 — rotary mower, 2 transport cart, 3 — unit for planting potatoes, a 4 seeder, 5 — mechanical hoe Ripper, 6 Ripper with rotating knives.

Fig. 2. The layout of “Cinderella” in a three-wheeled version:

1 — engine from a chainsaw “Friendship”, 2 — worm gear, 3 — frame, 4 — front wheel 5 — cover wheel 6 — fork 7 — PTO, 8 — tool kit, 9 — Cam, 10 — intermediate shaft, 11 — driving wheel, 12 — clutch, 13 — sliding handle, 14 — control cable, 15 — steering arm (on the planned projection of the fuel tank conventionally not shown).

Fig. 3. Unit for thinning beet (for unicycle) version of “Cinderella”).

First tried to build a universal one-wheel tractor, which could plow moldboard plow, perform seedbed tillage of the soil cutter or cultivator, cultivating, hilling potatoes and even to carry small loads. For this “Gnome” (so-called tractor) was attached to a set of mounted and trailed implements. Did and made sure that the mini-tractor was successful and, moreover, can be applied on several agricultural activities, to twenty.

The search for further universalization of the structure led to the decision to transform the chassis of the tractor in the base that can easily adapt to various uses. In particular, the “Dwarf” instead of one wheel might be two or even three. After this dosourceroute tractor has become a universal small-sized agricultural machine (WSM-2), and instead of “Dwarf” he was rated as more suitable, in the opinion of the guys name — “Cinderella”.

We would have sinned against the truth, claiming that OSM-2 “Cinderella” design is solved the machine that fully meets all technical requirements. That’s why now our work will be aimed at its modernization: the increase in the size of the frame, a new configuration, replacement of the engine on more powerful equipment “Cinderella” of the hydraulic device, improve the power transmission and controls.

Thus, “Cinderella” will help to educate a new generation of technology enthusiasts, creative, irrepressible and design-minded guys who in the near future will become excellent specialists of agriculture.

Universal small-sized agricultural machine WSM-2 “Cinderella” can be used on the school experimental plot. in the farm economy, some state and collective farm greenhouses, student production brigades.

With its help, are moldboard plowing, hoeing, cultivation, sowing of grain and vegetable crops, thinning, planting potatoes and ridging, mowing of weeds, digging pits to a depth of 50 cm, the transportation of goods and other work.

Fig. 4. Kinematics (three-wheeled version):

1 — engine, 2 — gear reducer, 3 — worm gear. 4 — star, 5 — rear axle 6 — wheel, 7 — Bush roller chain, 3 — V-belt transmission, 9 — PTO shaft, 10 — track rod 11, the lever 12 is fork front wheel, 13 — steering gear, 14 — reel Kozachok, 15 — sprocket wheel drive with Cam clutch, 16, 17 — the star 18 — the cable actuator drive pin clutch.

Fig. 5. Location of main components on the universal agricultural machine USLS-2 Assembly with the vibratory cultivator (dashed line shows the nodes of “Cinderella” in unicycle).

Fig. 6. “Cinderella” (the one-wheeled version) the machine for planting potatoes:

1 — closing unit, 2 — bunker, 3 — circuit mixer, 4 — wheel seeders, 5 — plow, 6 — wheel depth controller, 7 — drive wheel 8 to the sprocket drive of the agitator, 9 — sprocket drive agitator, 10 — visaginase the rotor 11 and the motor of the agitator.

The machine is made in the form of a kind of unified chassis with a variety of mounted and trailed the working mechanisms. Depending on the nature of the work suspension of “Cinderella” is based on one, two or three wheels. For example, when thinning beets or hilling potatoes used unicycle option, mowing or two, and the carriage of goods, digging pits and other works — tricycle.

The car has an engine type of “Friendship”, leading worm gearbox (gear ratio 40:1). The drive shaft of the last gear actuator connected with the mechanism of the mower. Shaft worm wheel has two outputs, it is equipped with a ratchet clutch, designed for different variants of the chassis. Below the gear is a Cam drum which actuates some hanging mechanisms. Over the engine of a tank of fuel.

Management of “Cinderella” is performed by the levers, planted on the arm. The latter is made of sliding, consisting of water tubes 3/4 and 1/2 inch. Height adjustable arms with special brackets. Changing the length and height of the handles depends on which operating mechanism is hung on the tractor. Depth of tillage is regulated by the mechanism of penetration, located at the rear of the machine body. It consists of a bracket with attached wheel and locking slats.

In front of the vehicle, above the wheel, is a tool box and ballast which is laid to increase the strength of adhesion of wheel with soil.

Me years members Vorovskogo mug Seversk high school № 44 of Krasnodar territory are engaged in constructing a small-sized agricultural machines. The guys understand the importance of this kind of creative search, because has experienced the difficulties associated with manual tillage. Collective and state farms simply: to handle their huge fields of a set of mechanisms. For small parcels such cars practically does not exist a shovel, a hoe, a rake here, perhaps, and all the mechanization on the school or piticescu plot.

Me years members Vorovskogo mug Seversk high school № 44 of Krasnodar territory are engaged in constructing a small-sized agricultural machines. The guys understand the importance of this kind of creative search, because has experienced the difficulties associated with manual tillage. Collective and state farms simply: to handle their huge fields of a set of mechanisms. For small parcels such cars practically does not exist a shovel, a hoe, a rake here, perhaps, and all the mechanization on the school or piticescu plot.