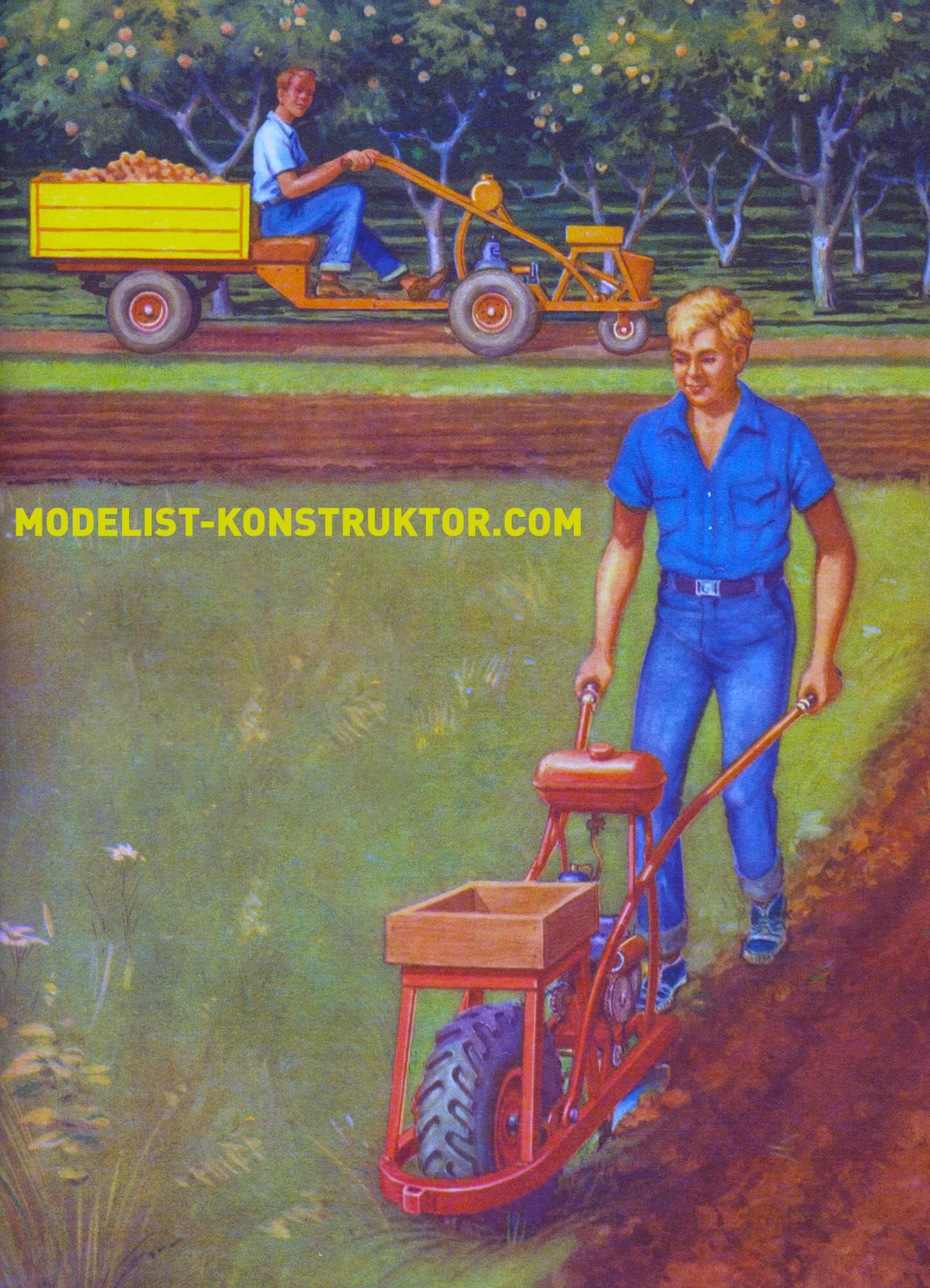

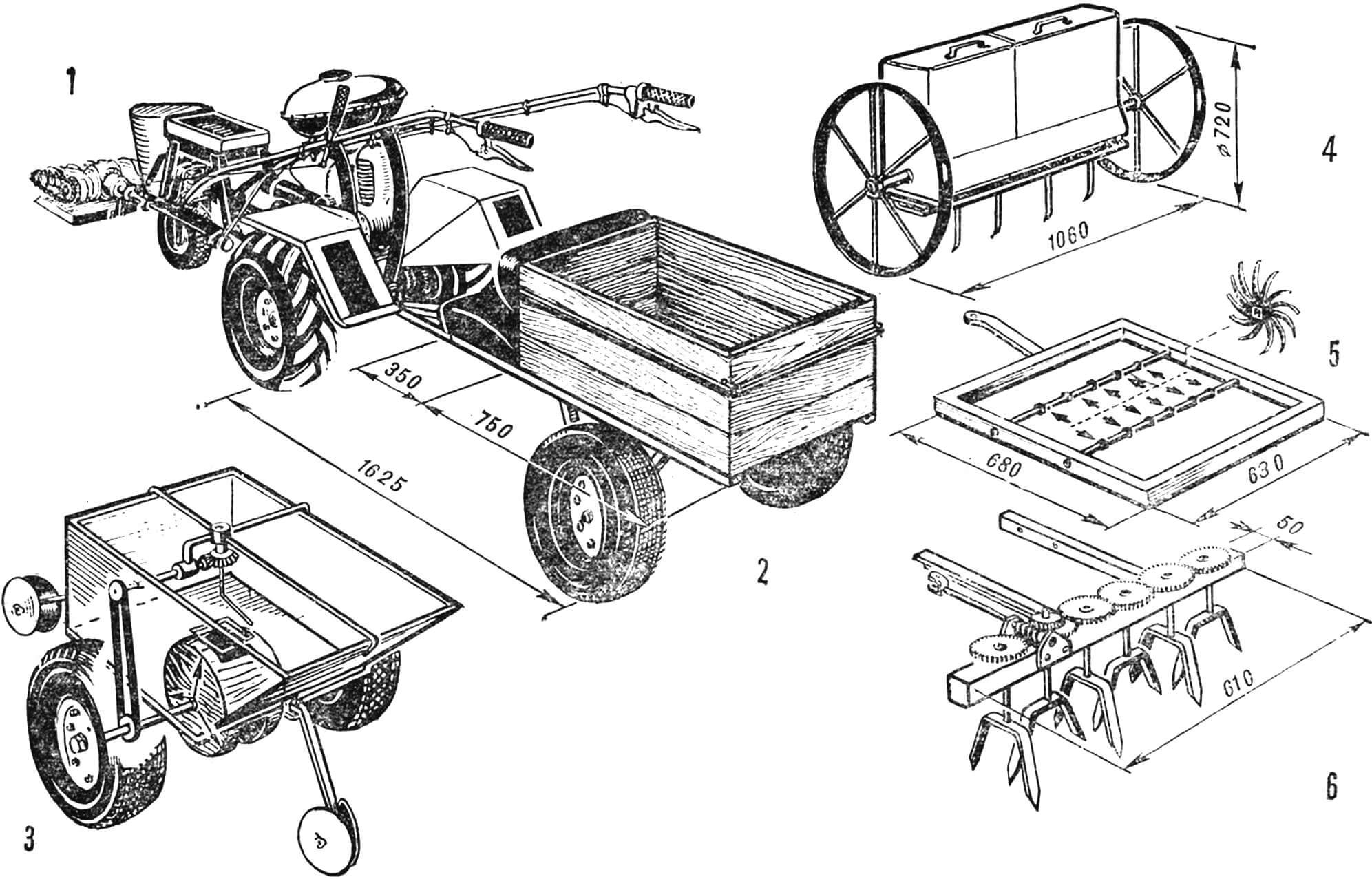

“CINDERELLA” — that’s what the creators, students of the Sever School, named this versatile agricultural machine. The microtractor can perform over a dozen various operations: plowing, seeding, planting potatoes, thinning beets, mowing, and more. Improvements to “CINDERELLA” are ongoing as the students learn to operate it with other agricultural tools.

The versatile small-sized agricultural machine (USMM-2) “CINDERELLA” can be used in experimental school plots, in household farming, in some collective and state farm greenhouses, and in student production brigades.

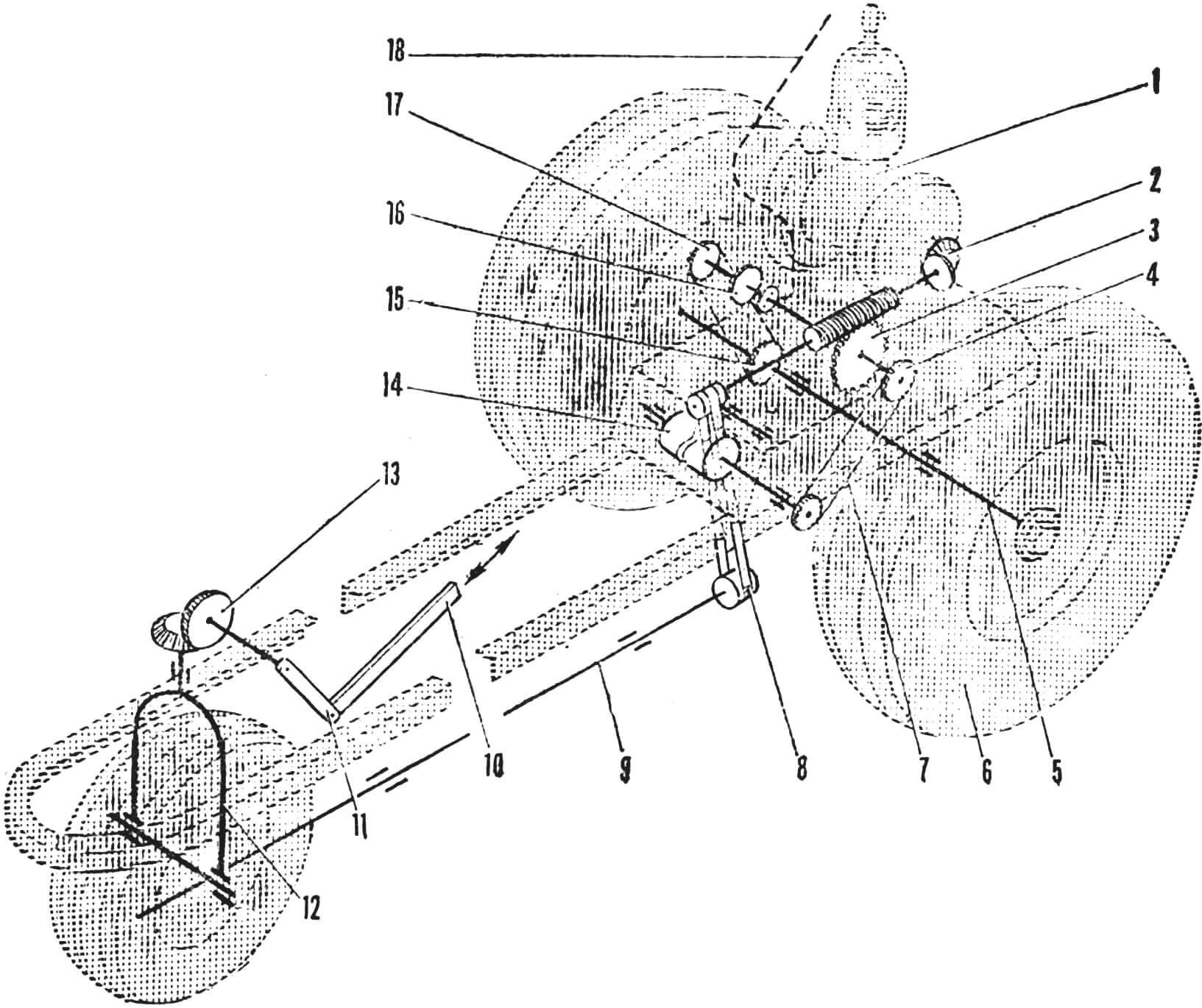

1 — rotary mower, 2 — transport cart, 3 — potato planting unit, 4 — grain seeder, 5 — mechanical hoe-cultivator, 6 — cultivator with rotating blades.

For many years, members of the technical creativity club have been involved in designing compact agricultural machines. The students understand the importance of such creative searches since they have experienced the difficulties of manual soil cultivation. Large collective and state farms have mechanized equipment for their vast fields, but there are almost no such machines for small plots; shovel, hoe, rake — that’s all the mechanization on a school or experimental plot. Bringing this work in line with modern agricultural technology is the main perspective of the young inventors’ design developments. This work is complex and labor-intensive. The students not only delve into the specifics of mechanizing agricultural production and agrotechnics problems but also spend a lot of effort searching for the necessary materials, parts, and engines for the intended mechanisms. Due to this, they often have to adapt the idea to the aggregates and parts that are available. This significantly affects the final result. But… there is a positive aspect in this continuous “war” with obstacles. The students learn to experiment boldly. They repeatedly test the quality of the devised mechanisms in practice, evaluate their pros and cons, and then set themselves new, more complex tasks.

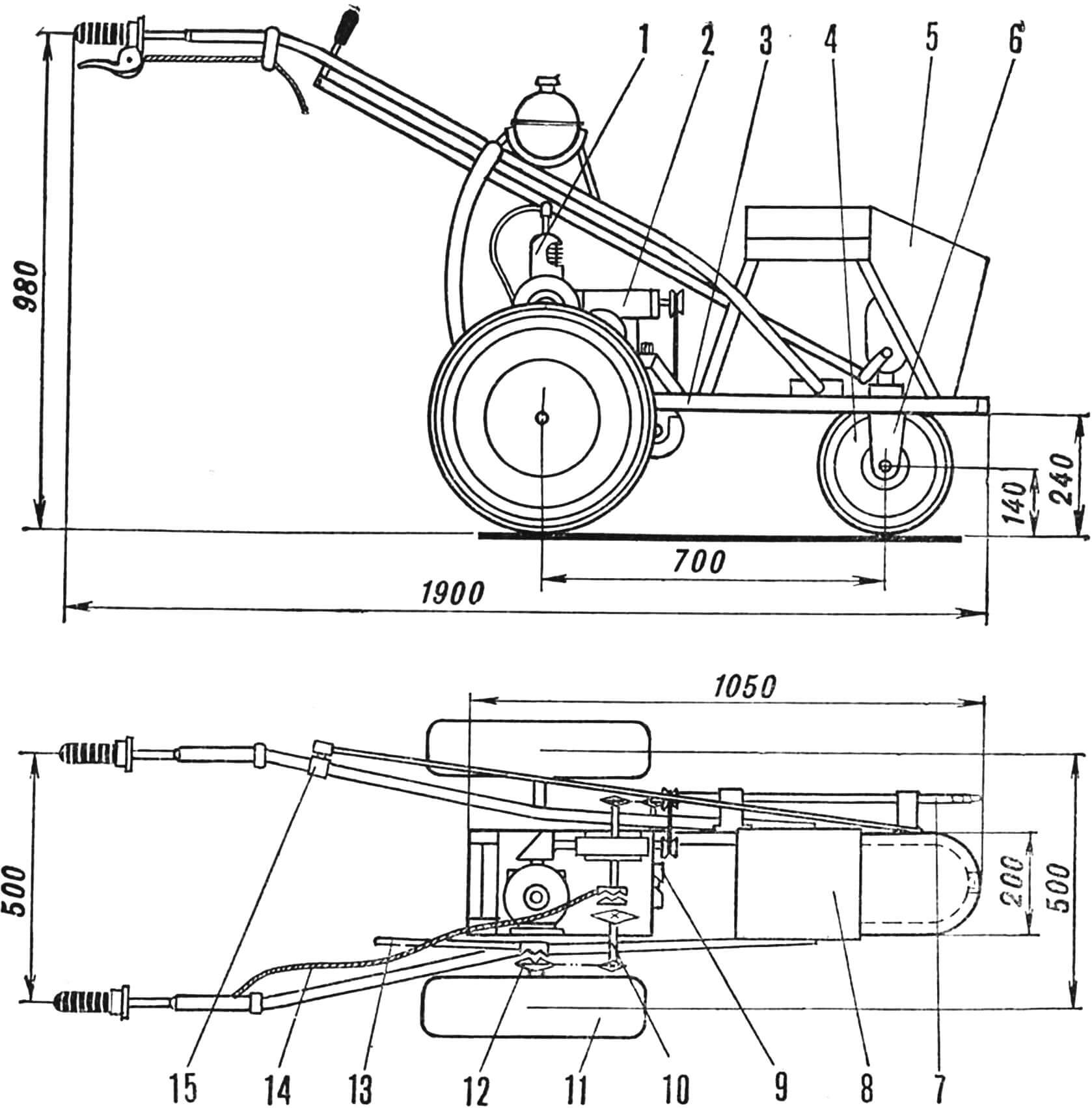

1 — engine from the ‘Friendship’ chainsaw, 2 — worm gear, 3 — frame, 4 — front wheel, 5 — wheel housing, 6 — fork, 7 — power take-off shaft, 8 — tool box, 9 — cam, 10 — intermediate shaft, 11 — driving wheel, 12 — clutch, 13 — sliding handle, 14 — control cable, 15 — steering lever (the fuel tank is not shown in the plan projection).

It is characteristic that of all the works carried out over the past years, the most successful were those that initially contained the greatest number of design mistakes. The point, as it seems to us, is that the identified error always suggests on which direction to focus further search. For example, when testing a self-propelled plow, the students concluded that the resistance of the soil when plowing with a bulldozer plow can only be overcome by opposing the weight of the mechanism. However, with an increase in weight, it ceases to be compact, let alone manual. Consequently, a fundamentally new design of the plowing unit is needed. And it was found: instead of a plow, a rotating blade, curved according to a special scheme, began to work.

The accumulated experience has also suggested another path of development. For several years, young mechanizers have been designing units that have only one specific purpose, adapted to perform strictly defined tasks: plowing, harrowing, cultivating, hilling, etc. In the end, a lack of engines prompted the idea: it’s time to think about creating a universal agricultural machine or a series of mechanisms with a portable engine. This idea radically changed the direction of their creative search.

Initially, they tried to build a universal single-wheeled tractor that could plow with a bulldozer plow, perform pre-sowing soil loosening with a tiller or cultivator, cultivate, hill potatoes, and even transport small loads. For this purpose, a set of mounted and trailer tools was attached to “Gnome” (as they called the tractor). They built it and found that the mini-tractor turned out to be successful and, moreover, can be applied to a number of agricultural works — up to twenty.

Further searches for universalizing the design led to the decision to turn the chassis of this tractor into a basic one, capable of easily adapting to various usage scenarios. In particular, for “Gnome,” instead of one wheel, there can be two or even three. After this improvement, the tractor became a universal small-sized agricultural machine (USMM-2), and instead of “Gnome,” it was given a more suitable name according to the students — “CINDERELLA.”

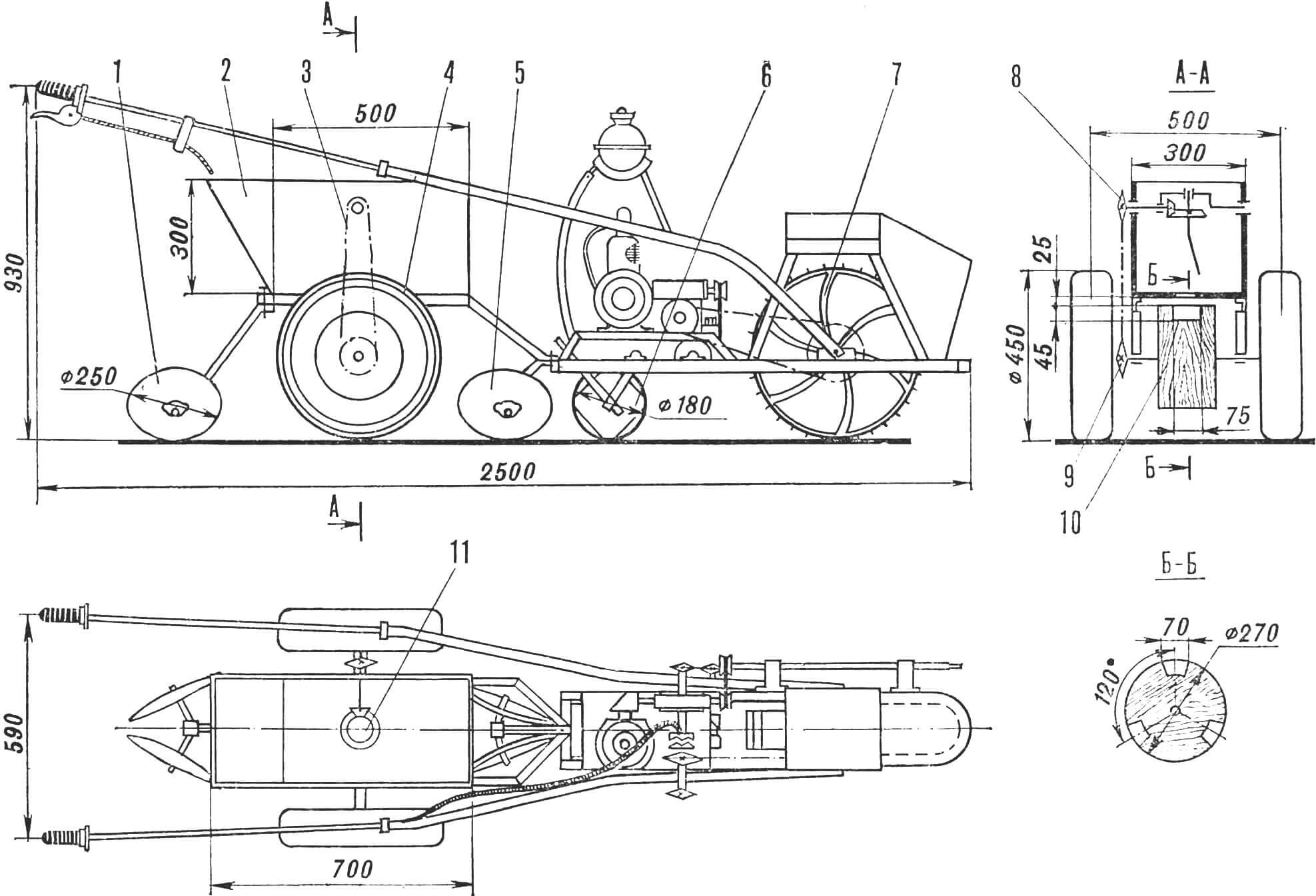

1 — engine, 2 — gear with gears, 3 — worm gear, 4 — sprocket, 5 — rear axle, 6 — wheel, 7 — bushing-roller chain, 8 — V-belt drive, 9 — power take-off shaft, 10 — steering linkage, 11 — lever, 12 — front wheel fork, 13 — steering gear, 14 — drum cam, 15 — sprocket wheel drive with cam clutch, 16, 17 — sprockets, 18 — cable drive of the dog clutch

We would be wrong to claim that the USMM-2 “CINDERELLA” is a design-perfect machine, fully meeting all technical requirements. That’s why our work will now be aimed at its modernization: increasing the frame size, redesigning units, replacing the engine with a more powerful one, equipping “CINDERELLA” with hydraulic devices, improving the power transmission, and control mechanisms.

Thus, “CINDERELLA” will help cultivate a new generation of technology enthusiasts, creatively relentless and design-thinking youngsters who will become excellent agriculture specialists in the near future.

Fig. 5. Arrangement of main units on the universal agricultural machine USMM-2 assembled with a vibrational cultivator (dotted lines show the components of ‘CINDERELLA’ in the one-wheeled version).

Fig. 5. Arrangement of main units on the universal agricultural machine USMM-2 assembled with a vibrational cultivator (dotted lines show the components of ‘CINDERELLA’ in the one-wheeled version).

It is used for non-bulldozer plowing, loosening, cultivating, sowing cereals and vegetables, thinning, planting and hilling potatoes, mowing weeds, digging pits up to 50 cm deep, transporting goods, and other tasks.

***

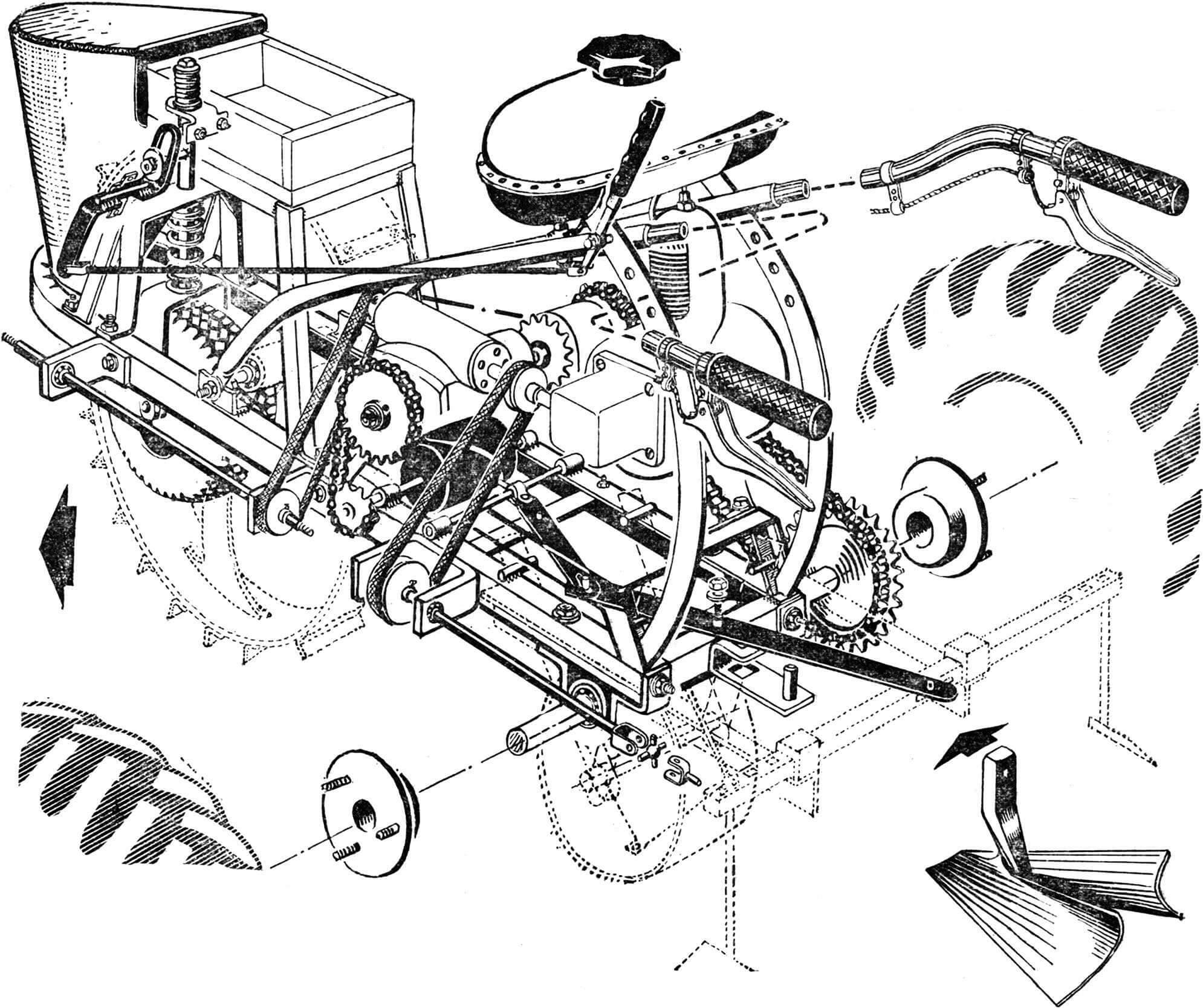

The machine is made in the form of a unique unified chassis with a set of various hitch and trailer working mechanisms. Depending on the nature of the work performed, the chassis of “CINDERELLA” relies on one, two, or three wheels. For example, a one-wheeled version is used for thinning beets or hilling potatoes, a two-wheeled version for mowing, and a three-wheeled version for transporting goods, digging pits, and other tasks.

The machine is equipped with a “Friendship” type engine, driving a worm gear (gear ratio 40:1). The output shaft of the latter gear is connected to the mower mechanism. The worm wheel shaft has two exits; it is equipped with a ratchet clutch for different versions of the chassis. Below the gear is a cam drum that activates some mounted mechanisms. Above the engine is a fuel tank.

Fig. 6. ‘CINDERELLA’ (one-wheeled version) with a potato planting unit:

Fig. 6. ‘CINDERELLA’ (one-wheeled version) with a potato planting unit:

1 — covering unit, 2 — hopper, 3 — vibro-seeder chain, 4 — seeder wheel, 5 — plow, 6 — depth control wheel, 7 — driving wheel, 8 — vibro-seeder drive sprocket, 9 — driving sprocket of the vibro-seeder, 10 — planting rotor, 11 — vibro-seeder gearbox.

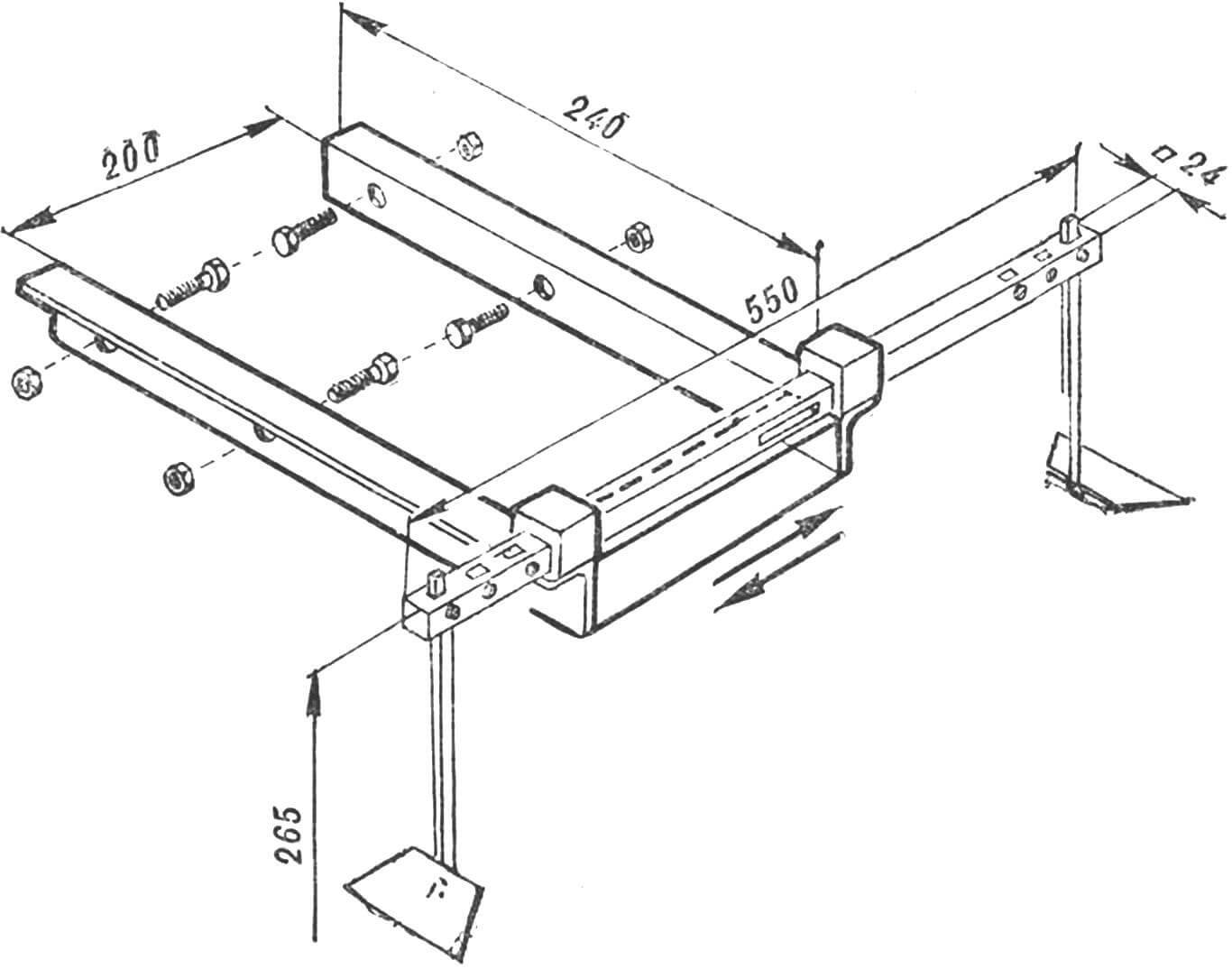

Control of “CINDERELLA” is carried out by levers mounted on handles. The handles are made extendable, consisting of 3/4 and 1/2-inch water pipes. The height of the handles is adjusted by special brackets. The length and height of the handles depend on the type of working mechanism attached to the tractor. The depth of soil processing is adjusted by the depth control mechanism located at the rear of the machine. It consists of a bracket with an attached wheel and a fixing rail.

In the front part of the machine, above the wheel, there is a box for tools and ballast, which is filled to increase the wheel’s traction with the soil.

N. Obrezha