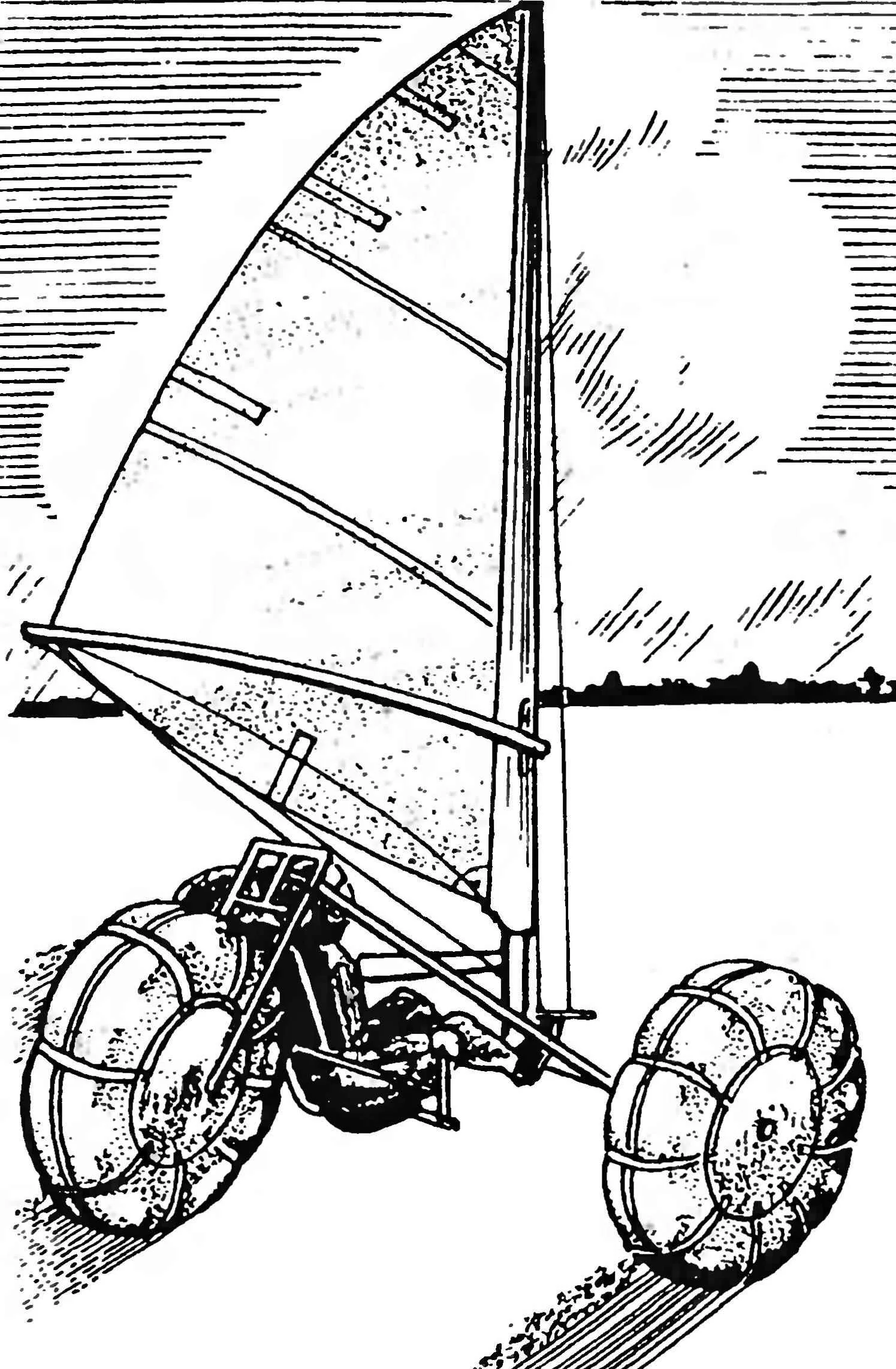

In the last decade, especially popular among Amateur designers use motor vehicles on light wheels with cameras-Pneumatics. The amazing maneuverability of these machines prompted the sailing enthusiasts to use the unique properties of the wheel-Pneumatics when you create year-round sailing.

In the last decade, especially popular among Amateur designers use motor vehicles on light wheels with cameras-Pneumatics. The amazing maneuverability of these machines prompted the sailing enthusiasts to use the unique properties of the wheel-Pneumatics when you create year-round sailing.

This publication acquaints readers with such a vehicle.

So, get to work. I advise you to start with the most difficult — with the manufacture of the trolley.

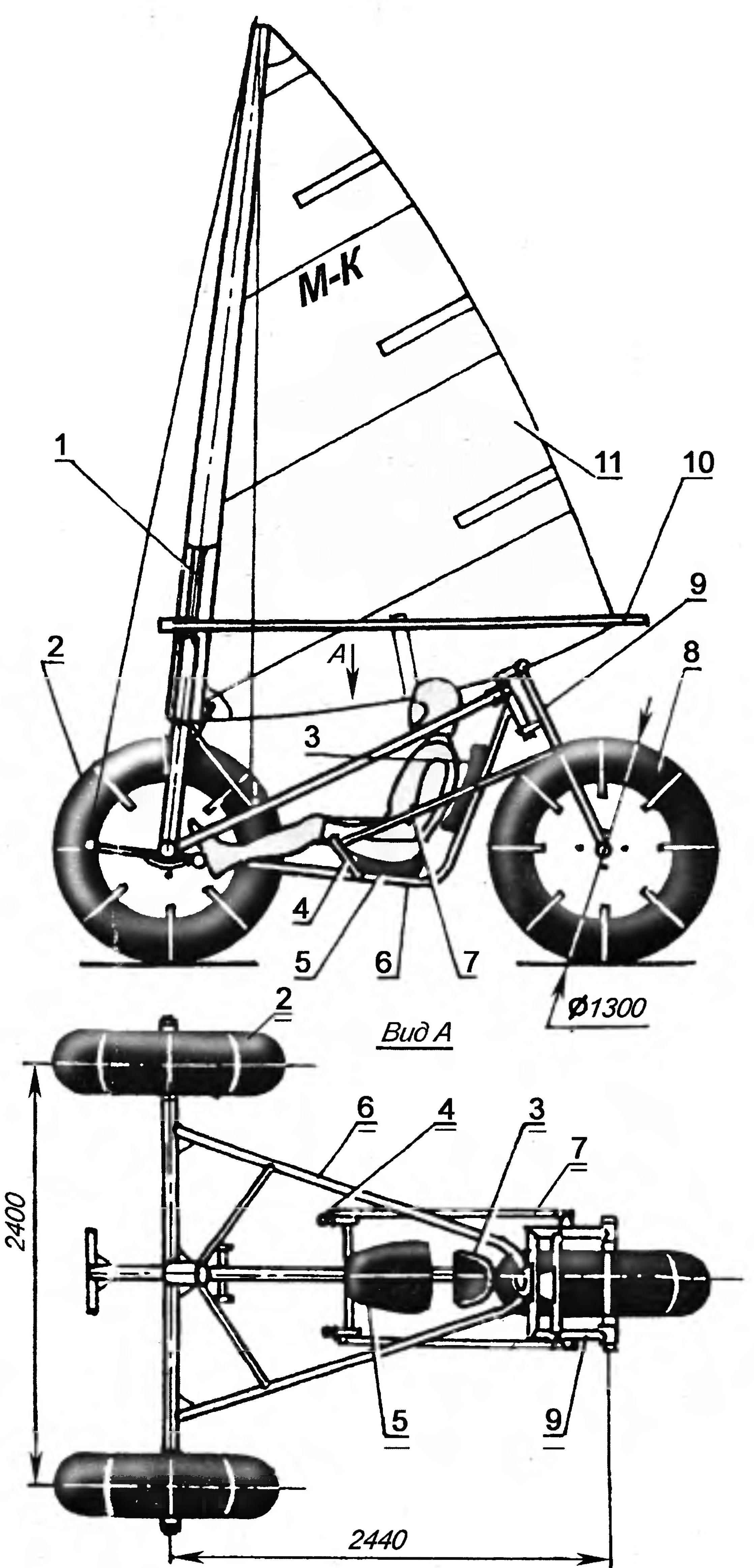

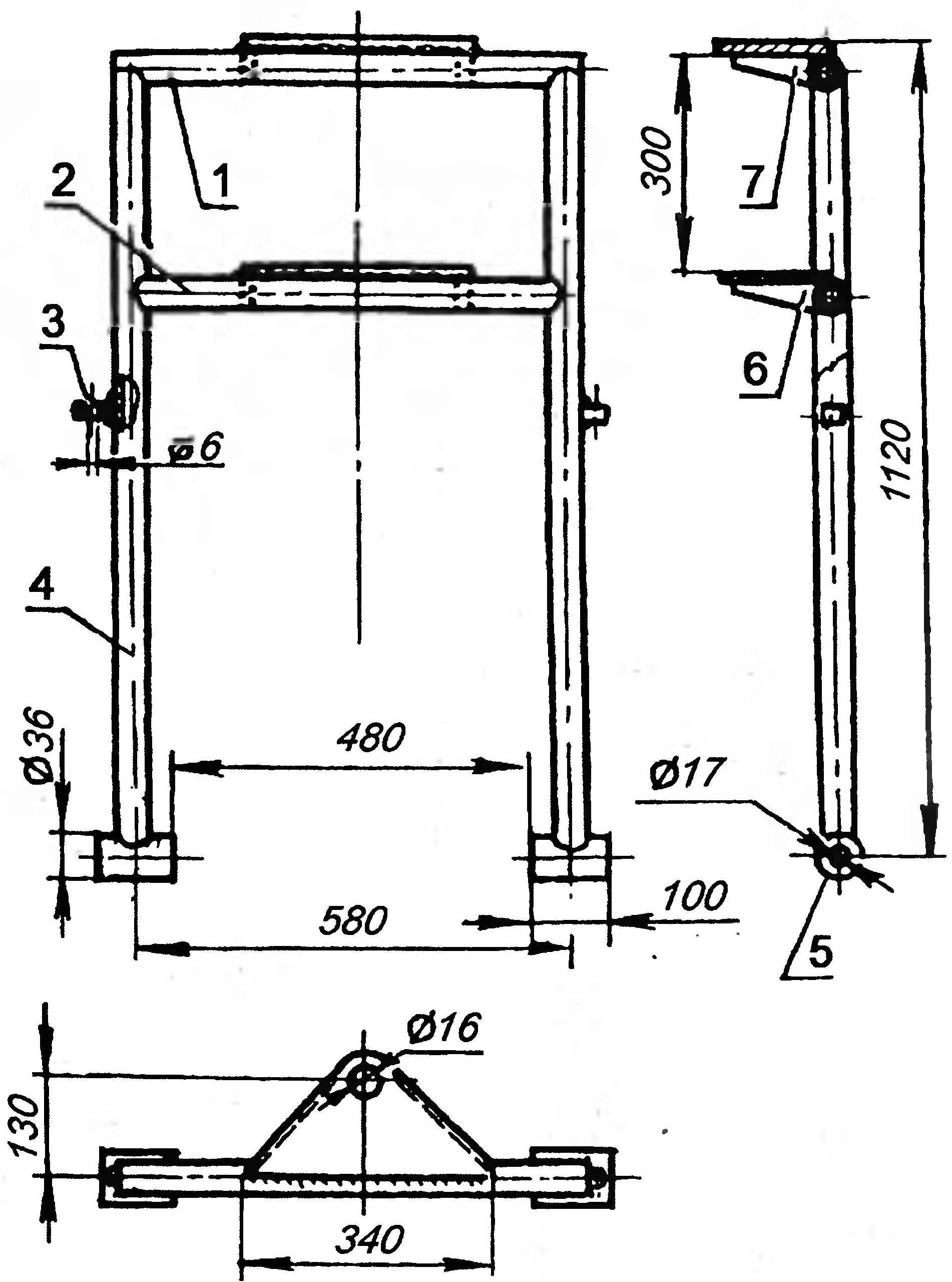

Trolley frame is welded from thin steel tubes. That frame turned out to be symmetrical and without bias, it makes sense to build it to build a kind of slipway. In the simplest case — smooth area of the floor on which are mounted, in accordance with the dimensions of the truck front axle and rear fork controlled along with the steering column.

The next phase — the manufacture and adjustment of the Central beam of the frame. This item has a curved shape, so you’ll have to use a tube Bender. It is desirable to heat the bending place of a gas burner or blowtorch, which will help to avoid dents and corrugations. Then the pipe is fitted to the front axle and the steering column and welded thereto by several welding spots.

The next phase — the manufacture and adjustment of the Central beam of the frame. This item has a curved shape, so you’ll have to use a tube Bender. It is desirable to heat the bending place of a gas burner or blowtorch, which will help to avoid dents and corrugations. Then the pipe is fitted to the front axle and the steering column and welded thereto by several welding spots.

Now we have to prepare for the Assembly is curved in the form of the letter “V” tubular part forming a side member of the frame. All seams are permanently welded only after careful validation of the docking elements of the frame.

Next on the Central tube of the frame in the dock with the front axle fixed mast glass — steel thin-walled pipe, the inner diameter of which somewhat more of the outer diameter of the mast.

Next on the Central tube of the frame in the dock with the front axle fixed mast glass — steel thin-walled pipe, the inner diameter of which somewhat more of the outer diameter of the mast.

A few words about rear steering fork. As can be seen from the drawings, it is welded from steel pipes, two feathers and two crossbars. To the latter is welded on so-called bridges — a triangular steel plate: they plug connects to the steering column.

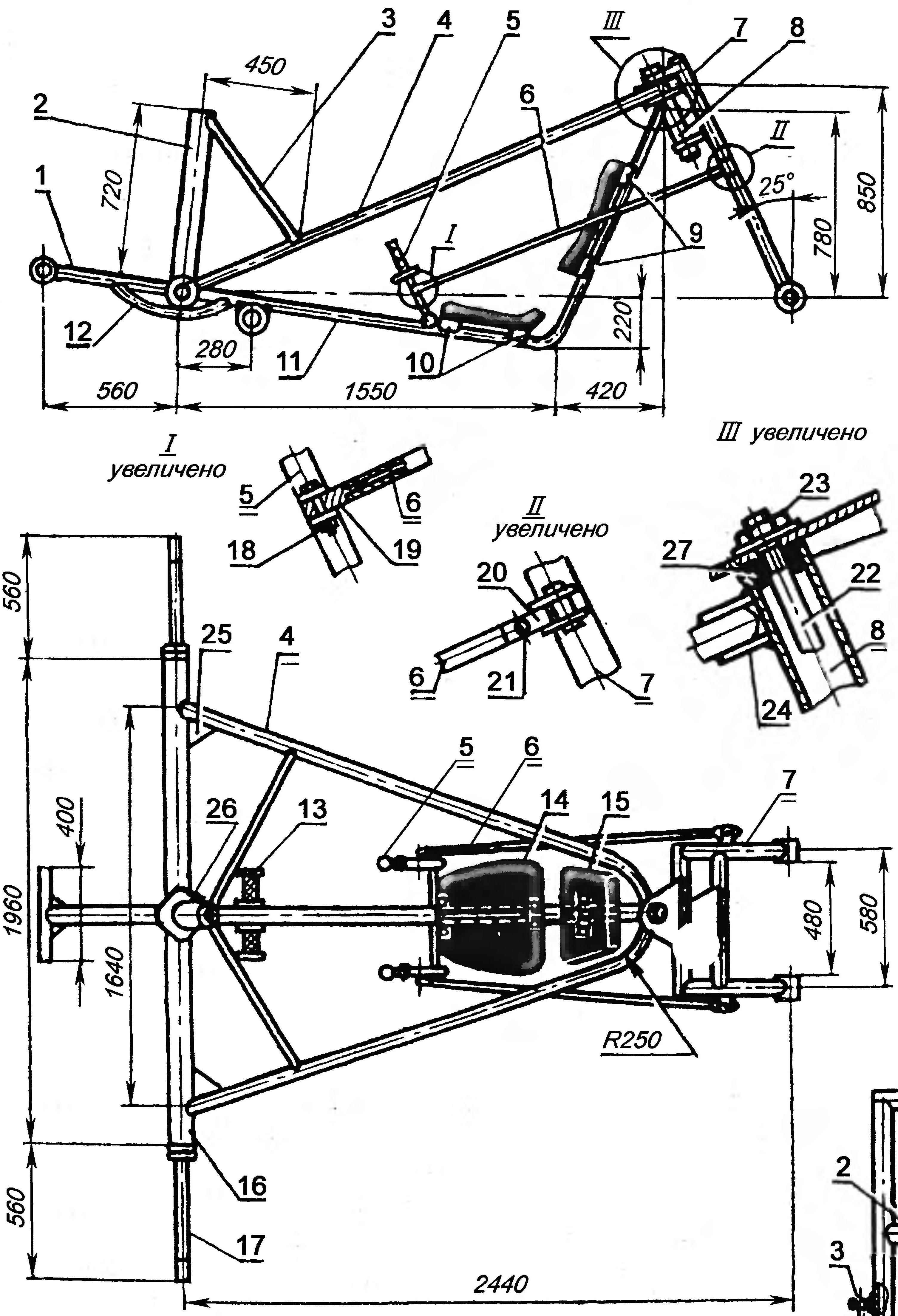

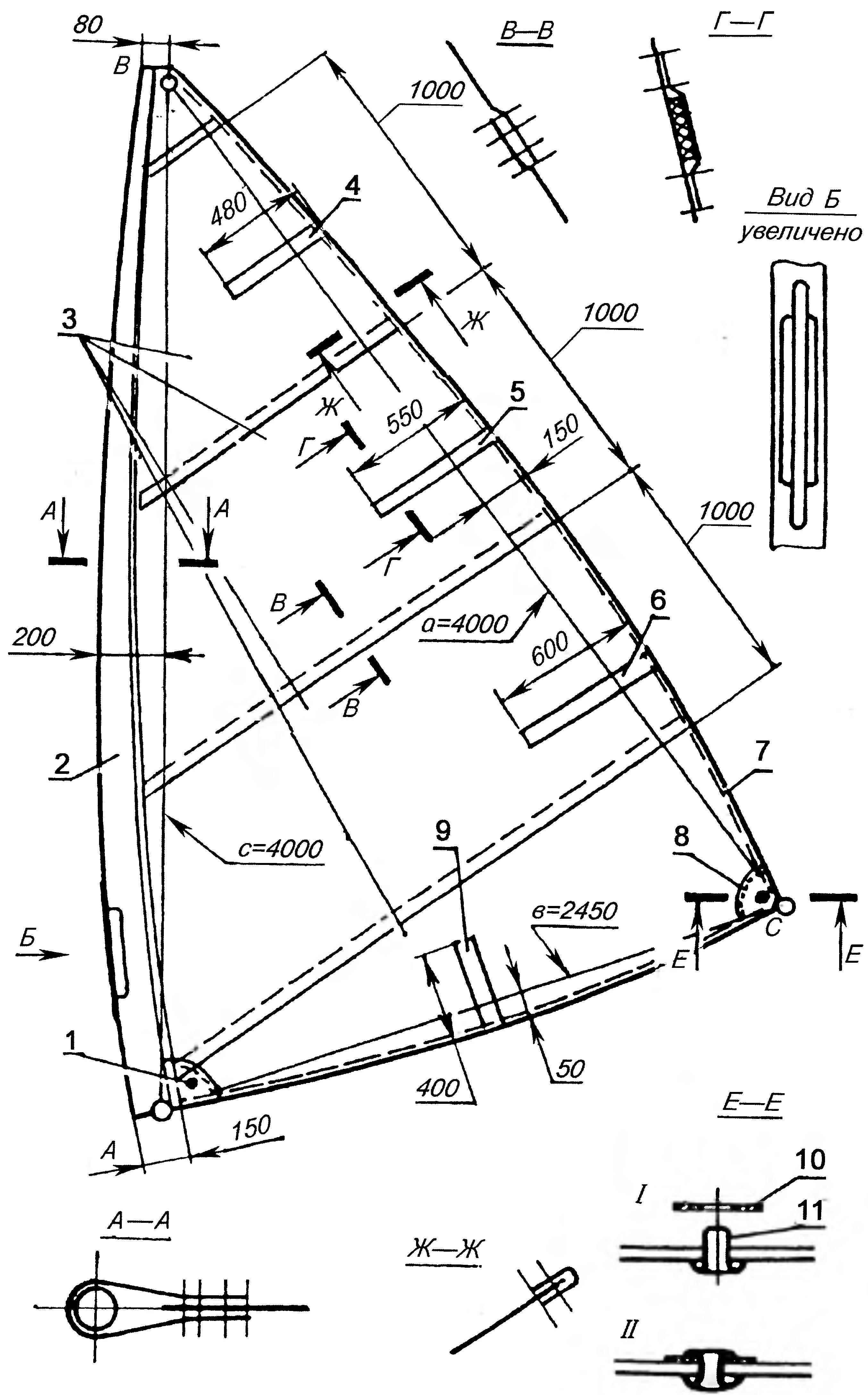

Manufacturer of sails, start with the pattern. The first step is to mark on a level floor, or several sheets of plywood, or even on the asphalt pad main triangle, and then, putting the value in the “sickle” on the back and bottom scattering sails, to hold the smooth curves similar to those shown in the figure.

Next job — the layout of the seams. The first line is the seam from the tack (front lower) corner of sail, perpendicular to the rear line of the main triangle. The layout of the rest of the joints is parallel to the first, with a step corresponding to the width of your existing fabric.

After sostragivaja panels, the sail is trimmed to the rear, front and bottom katarinam and sewn laderman designed for elastic elements of lat that supports the back and bottom of foot.

Incorporation of rear and bottom skinoren is produced using a tape — synthetic or cotton. The last is necessary only to pre-decapitate — soak, dried and ironed.

Incorporation of rear and bottom skinoren is produced using a tape — synthetic or cotton. The last is necessary only to pre-decapitate — soak, dried and ironed.

To fix the sail on the mast provided the so-called mast pocket doubled folded strip of fabric, tutu is to the luff of the sail. In Shkotovo and gulsoom corners attached to the grommet — brass bushing intended for Sterlikov — braces of the sail.

The mast of a sailboat it is possible to whittle from quality pine lumber or plywood smooth from straight grained planks with a thickness of about 10 mm. Wooden mast should be tapered in the upper part its diameter is about 30 mm to 55 mm.

And the last piece of the mast — boom-wishbone, resembling two bows put together. Make it the easiest way of duralumin tubes with a diameter of 22 mm; at the front fixed poluchaut of wood or PCB.

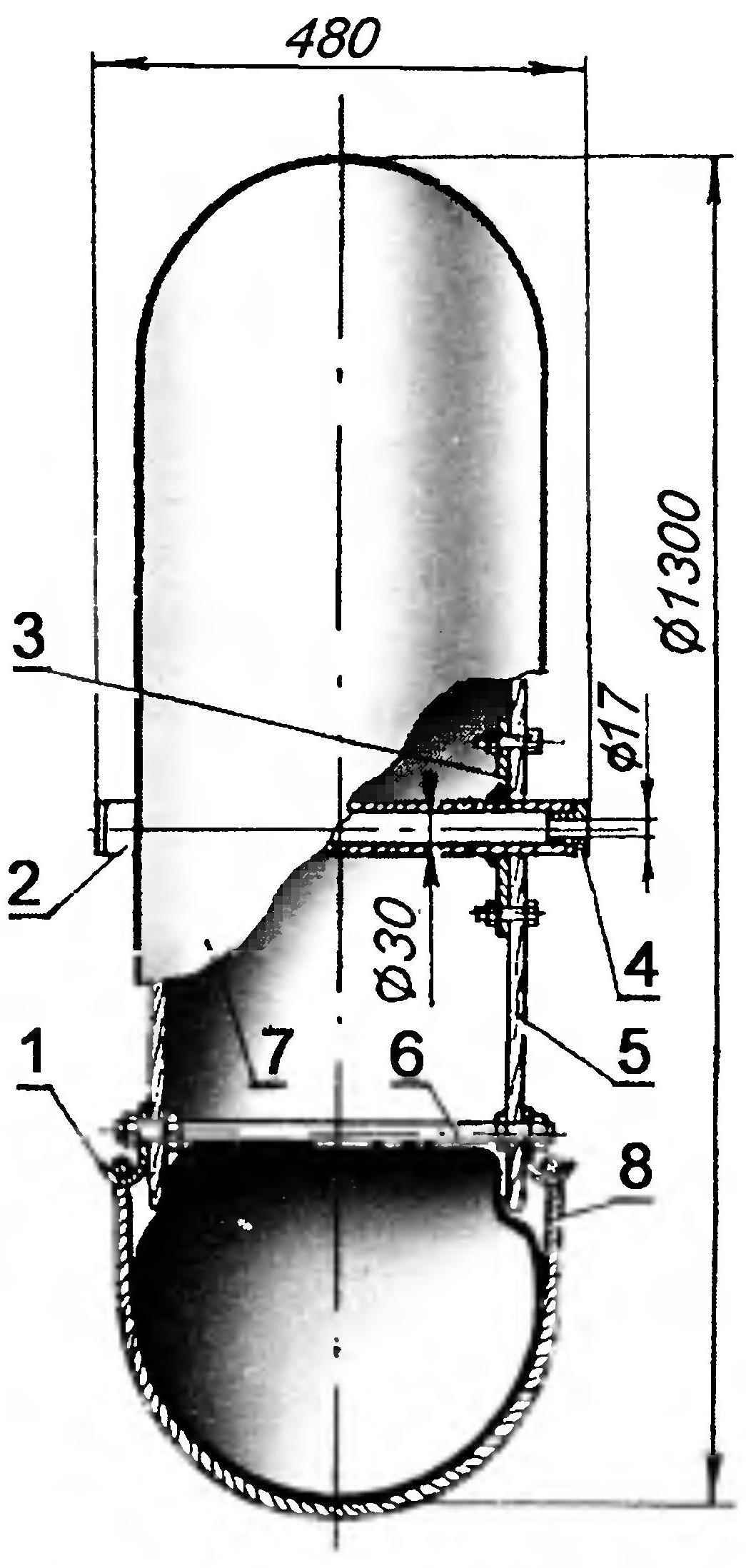

Pneumatics wheels of the cameras from the truck. Depending on their geometrical parameters are selected and the sizes of wheel hubs. The basis of each amount of the sleeve — cuts steel pipes with welded thereto flanges and pressed into inserts of bronze or PTFE.

Wheels are cut from plywood with a thickness of about 12 mm on the hub, they are fixed with M6 bolts and nuts, and with each other are connected to long steel studs, nuts and washers.

The front wheels rotate on the axle shafts — steel threaded studs mounted on the front beam of the frame.

I. SERGEEV

Onoznaczenia:

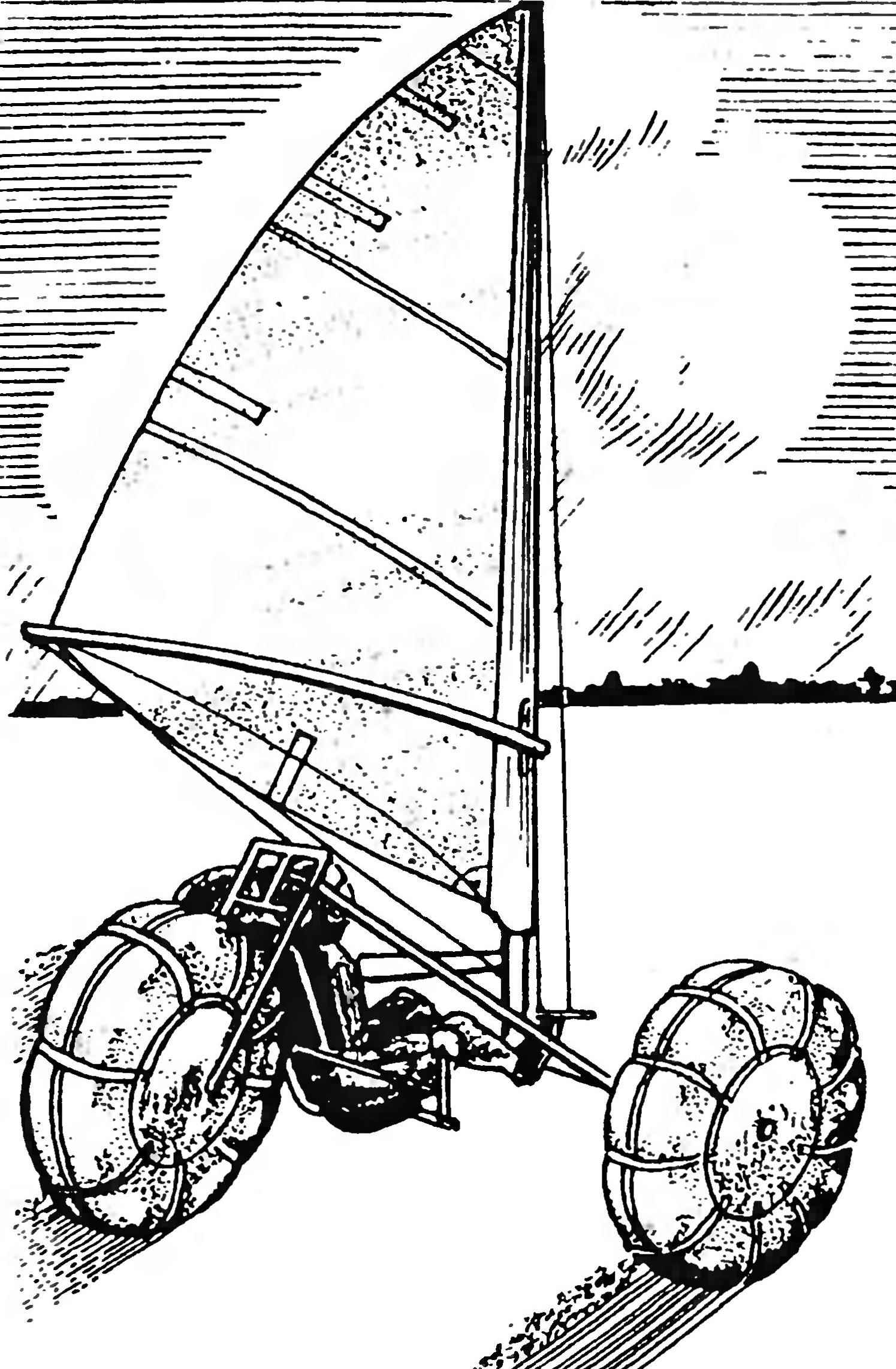

Sailing Buer on low-pressure tires:

1 —the mast;

2—front wheels;

3—back;

4—steering levers;

5—seat;

6—frame;

7—tie-rod;

8 is rear wheel driven;

9—plug the rear wheels;

10—geek wishbone;

11—sail.

The track frame of a sailboat:

1—bowsprit (tube 30×2);

2—masted glass (tube 60×2.5);

3—brace (pipe 20×2,5);

4—zone of the top frame (tube 30×2);

5—steering levers (tube 22×2,5);

6—rods (pipe 16×2);

7 — plug the rear wheels;

8—steering column (tube 36×2,5);

9 the mounting brackets of the backrest (band 4×40);

10—mounting bracket of the seat (band 4×40);

11, the Central beam (tube 30×2,5);

12—jumper (tube 22×2,5);

13—kickstand (tube 22×2,5);

14—seat (plywood, foam and PU leather);

15 – the back (plywood, foam and PU leather);

16—front beam (pipe 36×2,5);

17—the driveshaft;

18—bolt of M6 with nut and washer;

19 — tie rod;

20—double hinged fork (sheet s3);

21—axle fork, horizontal (screw M6 with nut and washer);

22—pin M12 hinge the steering column;

23—nut M12 with washer;

24—reinforcing the gusset plate (the sheet s2,5);

25—angular gusset plate (sheet s3);

26—Central gusset plate (sheet s3);

27—bushing (bronze, textolite or PTFE).

Managed fork rear wheel:

1 —upper cross member tube 30×2,5);

2—the bottom cross member (tube 30×2,5);

3 —Sukhar (square 16);

4—pen (tube 30×2,5);

5—Bush;

6, the lower bridge (the sheet s2,5);

7 — high bridge (the sheet s2,5).

Sail:

1,8—eyelets;

2 — mast pocket;

3—the sail (the drawing shows a variant with a panel width of 1100 mm);

4,5,6,9—laderman;

7—rear part;

10—washer of the grommet;

11—the piston of the grommet (I and II stage installation of the grommet).

Wheel:

1—locking nylon rope;

2, the Central sleeve (tube 36×3);

3—flange (sheet s2,5);

4—bushing (bronze, textolite or PTFE);

5 —cheek (plywood s10.. .12);

6—stud with four M12 nuts and washers;

7—pneumatic(camera from truck tire);

8—the rope or belt (nylon).