Worldwide specialists in armored vehicles by the famous Soviet main battle tank T-72 “Ural” and his heir — the Russian main battle tank T-90. But few know that the basic design and technical solutions used in these combat vehicles were tested on prototypes of tanks “Object 166Ж” and “Object 167”.

Worldwide specialists in armored vehicles by the famous Soviet main battle tank T-72 “Ural” and his heir — the Russian main battle tank T-90. But few know that the basic design and technical solutions used in these combat vehicles were tested on prototypes of tanks “Object 166Ж” and “Object 167”.

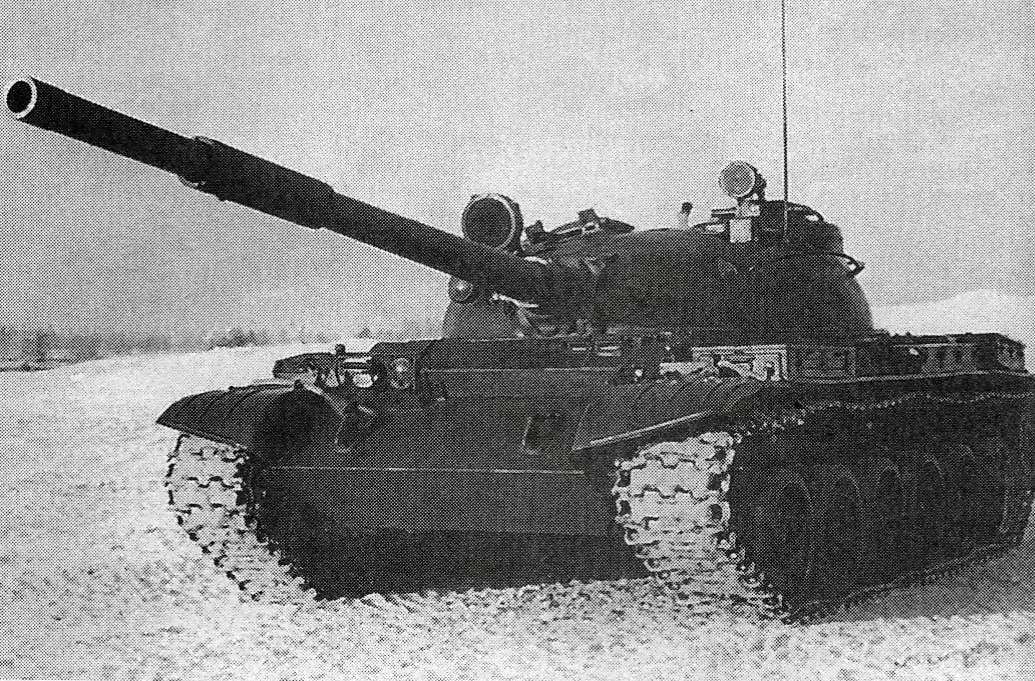

Of the above two machines, the prototype of a medium tank “Object 166Ж” was a production medium tank T-62, which was installed automatic loader designed for the theme of experimental design work (OKR) “Acorn” On the tank T-62 in the domestic and foreign literature is well known enough. But on the experimental middle tank “Object 167” is not often mentioned. Even in the books of the FSUE “Production Association “Uralvagonzavod” devoted to the history of the T-72, this machine, in our view, paid little attention. This is despite the fact that in 1970-ies of the last century, prototypes of a medium tank “Object 167” and various projects its modifications have examined the use of guided weapons, mechanized loading cannons, multi-fuel diesel engine with supercharging, system hydrocarbonate the movement of the tank and chassis with the supporting rollers. Subsequently, the circuit layouts of these machines with automatic loader used when creating a main tank T-72. Therefore, an experienced medium tank “Object 167” can rightly be considered the transition from the T-62 to T-72 tanks, that is to say, the “grandfather” of the “Ural”.

Experienced tank “Object 167” had been developed in 1961 to take the initiative in honor of the XXII Congress of the CPSU design Bureau of the plant number 183 in Nizhny Tagil under the leadership of chief designer L. N. Kartseva. Originally the idea was to improve the T-62 tank by installing a more powerful engine with a supercharger and new suspension. “Binding” of the engine is engaged the motor office under the leadership of L. A. Vaysburd, and on a new selectcol suspension worked S. P. Petrakov. Lead engineer on the car were V. N. Venediktov.

New technical solutions in comparison with the tank T-62 under the project were: the installation of more powerful weapons, semi-automatic gun loading, the use of radiation materials beschastnova air cleaner, air use of diesel In to 26, system hydrocarbonate of the transmission and supporting rollers and the supporting rollers of smaller diameter in the undercarriage of the First prototype tank “Object 167” Zavod No. 183 was made in September 1961 Only 1961, he released two experimental tank “Object 167”.

The tank was planned to install a 125-mm smoothbore tank gun D-81, stabilized in two planes, the initial velocity armor-piercing projectile of 1800 m/s and a unitary shot. The first samples due to the lack of a smoothbore gun D-81 were installed 115-mm smoothbore tank gun U-5TS, too, stabilized in two planes with semi-automatic loading and initial velocity armor-piercing projectile 1550 — 1600 m/s With a gun was the coaxial machine gun SGMT 7.62 mm direct fire cannon from the gunner had daylight articulated telescopic sight ТШ2Б-41 and night sight TPN-1-41-11. The latter was connected parallelogram drive with a gun cradle that ensures the synchronicity of his work with a gun. The turret twin installation ranged from -6 to +16°. Speed vectoring twin installation from the control panel of the stabilizer “meteor” in the vertical plane ranged from 0.05 to 4.5 ° /s, horizontal: 0.05 to 18 deg/sec. When firing indirect fire was used side level and azimuth pointer

Tank “Object 167” had surpassed the mass-produced T-62 firepower, maximum, and average velocities, power density, smoothness, protection against ionizing radiation In the ammunition of the tank consisted of 40 unitary shots, which were placed in the tower — 2 PCs., front tanks-racks — 16 PCs., in laying the engine bulkhead — 19 items, on the left side — 1 piece, and on the starboard side — 2 piece Ammunition gun SGMT consisted of 2500 rounds 10 tapes, which were placed in the tower (on the right side) — 4 tape in the rack and 1 tape in the store on the machine gun mount; in the fighting compartment — 3 tape in the shops in the batteries; 2 tapes in the shops on the left side from the engine bulkhead. In addition, fighting compartment in the installation housed the AK-47 7.62 mm and grenades f-1 in the amount of 12 pieces that fit in recesses of the hull.

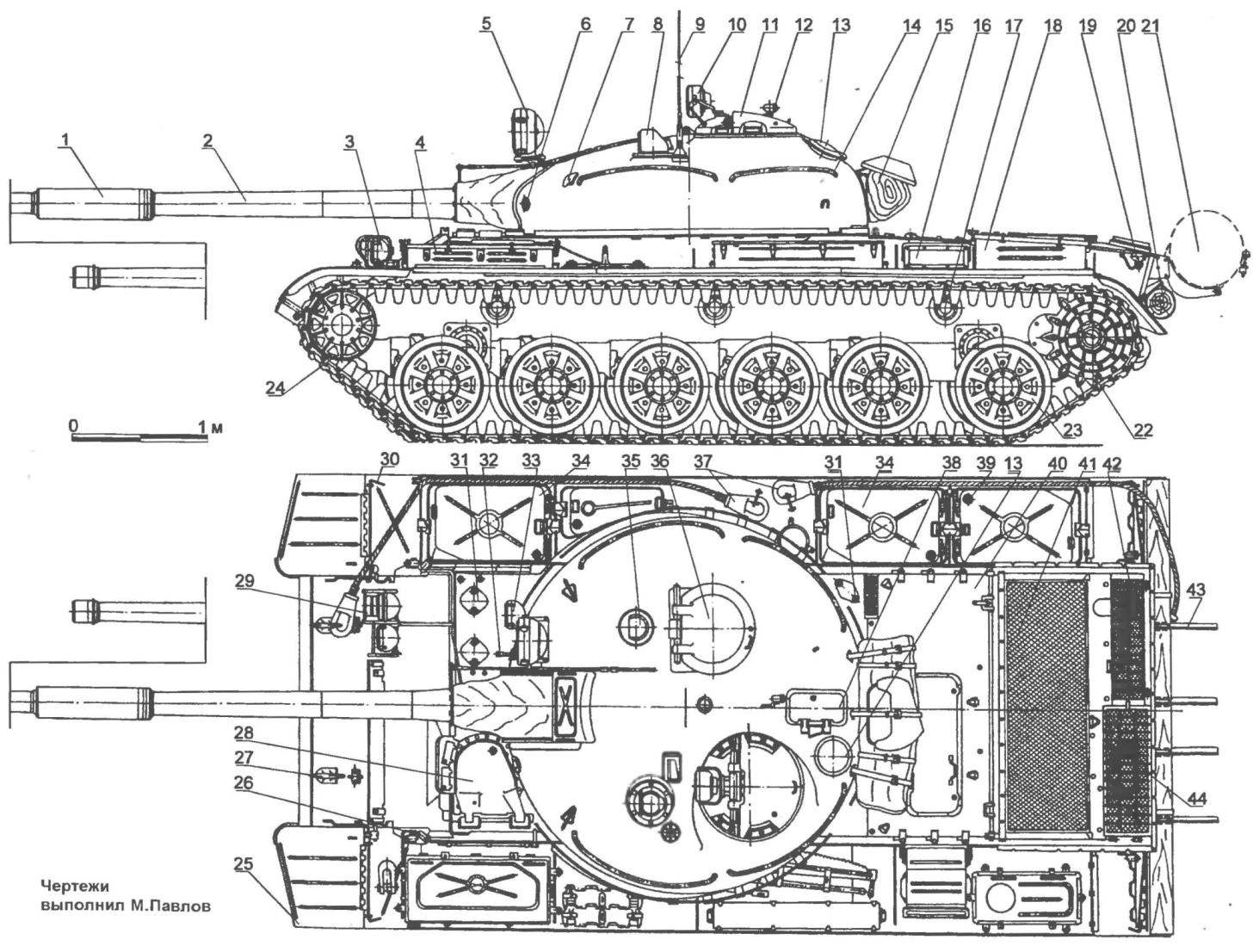

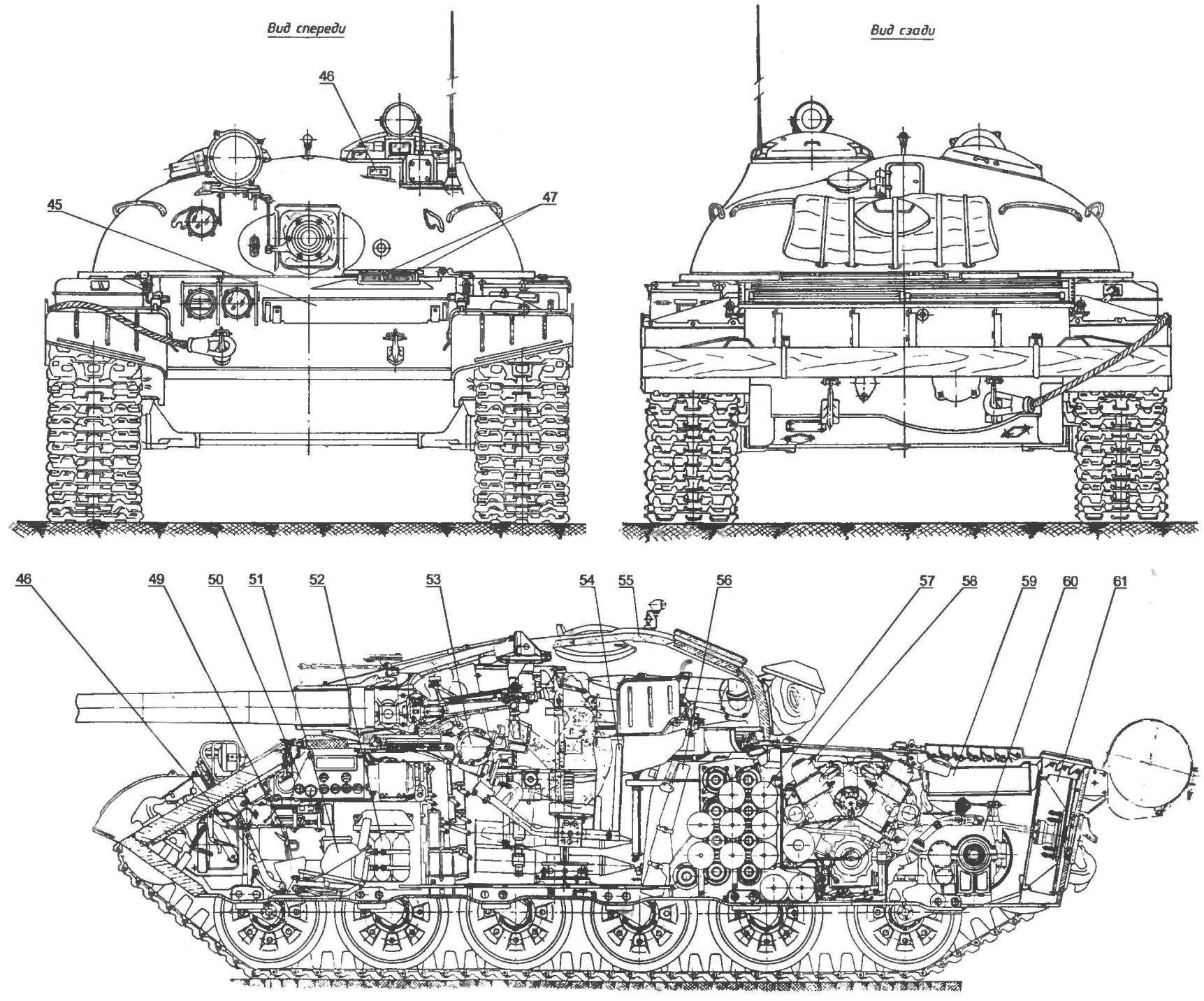

“Object 167”:

1 — ejector; 2 — barrel cannon U-5TC; 3,33 illuminators of the device night vision of the driver; 4,18 — boxes spare parts; 5 illuminator night sight; 6 — the recess of the sight ТШ2Б-41; 7 — hook 8 — lens night sight TTTN-1-41-11; 9 – antenna radios; 10 — illuminator of the night vision device commander; 11 — cover of the hatch of the commander’s cupola; 12 — upper marker light; 13 — armor of the fungus; 14 — handrail; 15 — covers, tarpaulin; 16 — output collector; 17 — roller; 19 — tail light; 20 — the log for recovery; 21 — additional barrel of diesel fuel; 22 — driving wheel; 23 — support roller; 24 — guide wheel; 25 — front flap mud flap; 26 — front position lamp; 27 — towbar; 28 — cover of the driver’s hatch; 29 — headlight with svetamaksimova nozzle; 30 — torsion bar front mud flap; of 31.39 — filler caps of fuel tanks; 32 — 7.62-mm coaxial machine gun SHTM; 34 – external fuel tanks; 35 — surveillance device charging; 36 — cover loader; 37 — towing ropes; 38 — cover flap for removal of spent cartridges; 40 — top deck, 41 — protective mesh water cooler diesel V-26; 42 — protective mesh of air output from the fan MTO; 43 — bracket barrels of diesel fuel; 44 — protective mesh oil cooler diesel V-26; 45 — grasevina Board, 46 — surveillance device gunner, 47 — observation devices of the driver; 48 — PMP control lever; 49 — selector lever transmission; 50 — junction box offices; the 51 — seat driver; 52, the cylinders of the TCO; 53 — the elevating mechanism of the gun; 54 — seat gunner; 55 — liners; 56 — laying the personal weapons of the crew; 57 — shots in the rack; 58 — diesel V-26; 59 — water radiator In diesel-26; 60 transmission; 61 — fan

In 1963 — 1964 years in the secondary weapon on one of the prototypes of the tank “Object 167” on the stern of the tower mounted launcher with three guides for 9М14 ATGM “baby”. Additional weapons could hit armored targets of the enemy at ranges of 2 — 3 km, where cannons were less effective. Generally, the firing range of the “little ones” at moving and stationary targets ranged from 500 to 3000 m, with a hit with 1 — 2 shots. As a sighting device when firing ATGM used regular tank sight the Time of transfer of the complex from traveling to combat position ranged from 11 to 24 s.

The armor protection of the tank — protiven-row. Inside and outside the crew compartment was installed the plate of radiation of materials (lining and nadbai). For mass conservation within the existing limits with the installation of the lining and nadboy somewhat reduced thickness of lower frontal (80 mm), coarse (30 mm) and side hull plates (70 mm) compared to tank T-62. Also, changed the design of the driver’s hatch. It is shifted to the right by 50 mm forward and 20 mm and the manhole cover plate torsion bar suspension, opened on hinges to the left. To accommodate the new increased cooling rear sheet was tilted by 13°50’ ago. Above the fan in the rear is a flip cover installed blinds, adjustable seat of the driver. The roof over the engine was made hinged on the same hinge with the torsion bar, and a roof over your radiator. This construction of the roof over the engine-transmission compartment (MTO) is allowed to cancel the hatch above the air cleaner. The fan partition and fencing of torsion bars made of aluminum sheets. In the partition MTO made vazduhoplov for cooling of the generator. For ease of placement of the driver’s compartment under his seat in the bottom completed the punch to a depth of 25 mm.

Tower machines borrowed from the T-62, but with the introduction of the lining it made the following improvements: increased the size and number of bonok for the attachment of interior equipment and a few have changed their position: the thickness of the hatch cover charging reduced from 25 mm to 20 mm; the commander’s hatch cover has eliminated the signal flap; reinforced torsion hatch loader.

In addition, in comparison with the serial tank T-62, in an experimental machine changed the design of check valves and the placement of some nodes of the system of fire-fighting equipment (PPO): its cylinders mounted at the driver.

The composition of anti-nuclear protection, in addition to installing anti-radiation lining was part of a special air-separators that supply cleared of radioactive dust air into the crew compartment and create overpressure, and to ensure that the hull and turret are equipped with special seals. Anti-radiation lining was made from two types of materials developed by the branch of VNII-100 and of NIIPM POV 20 and POV-20/50C. The thickness and types of shielding material was chosen on the basis of given thickness and configuration of armor protection of the tank. At thick armor, significantly have affected the dose of gamma radiation, applied material STAND-20 thickness 20 — 30 mm, and for small thicknesses of the armor — STAND-20/50C with thickness of 40 — 60 mm. From one side the lining was prepisovanie belting for better bonding with the armor, and on the other hand was pripressovyvaja non-combustible layer, protects it from exposure to open flame, the radiation Leaves the material was attached to the armor with a special adhesive designed of NIIPM and additionally pressed the bolts through the washers.

To improve the dynamic qualities of the tank in the power pack installed In diesel-26 with a capacity of 515 kW (700 HP) at engine speed 2100 rpm, with the result that power density has increased to 14 kW/ton (19,1 HP/t). Diesel-26 with the drive centrifugal blower, based on the production V-55, had the same seats that serial, and installed on the same sub base. Start engine (core) is carried out using compressed air from two five-liter cylinders, auxiliary — starter ST-16M. To ensure a reliable engine start in cold days the tank was fitted with a nozzle heater with forced fuel feed and boiler cylindrical jacketed type. The capacity of the fuel tanks (reserved) as compared with fuel tanks the T-62 was increased to 40 l by increasing the capacitances of the nose tank and the right tank rack and was 715 l only shelves placed additional fuel tanks with total capacity of 285 liters Reserve tank “Object 167” on the highway reached 550 — 600 km.

In the engine cooling system was used somireddy radiator pipes and corrugated plates with an increase of 25% cooling surface To improve the conditions for the entry of cooling air into the fan last installed inclined, which in turn allowed us to increase the length of the radiator. In the lubrication system used an oil cooler with a larger 47% of the cooling surface

In the cleaning system applied the new beschastny air cleaner, VTI-A, consisting of 120 high-efficiency cyclones, collected in a battery. Removal of dust from the silos was made ejection method, similar to serial cleaner. Install air cleaner new design ensured a high degree of purification of air by the ratio of dust passing through at average operating mode 0,1 — 0,2%.

In connection with the installation of a more powerful diesel engine all transmission units increased maintaining the interchangeability with a serial transmission units of the T-62. In the drivetrain changed the design of the input gear, which now had a drive to the generator, and introduced gidrostroitely control the main clutch and steering. For better cooling of the gearbox its upper crankcase were cast with fins. In the lock-up clutch planetary rotation mechanism mounted friction discs 17 and turn brake had pads made of plastic (instead of cast iron). The fan drive friction disc is also made from plastic instead Ferodo. With the goal of providing high-speed change gear ratio side of the gearbox.

The chassis was used torsion bar suspension with original lever-arm hydraulic shock absorbers at the extreme nodes 1, 2, 5-m and 6-m knots at each side mounted travel stops of beams the effective length of the torsion increased, simultaneously reducing the diameter of 42 mm Is allowed for by increasing the dynamic travel of the rollers to 242 mm to obtain a smoother ride. From each Board were mounted three and six support rollers with rubber solid tires. The diameter of rollers was reduced from 810 mm to 750 mm, and their drives were now made of aluminum alloy AK-6 To eliminate the abrasion and destruction of disks in contact with their crest of a caterpillar in the collapse of each carrier roller on the inner surface of the disk was zapressovyvat steel ring flange. Followers of rollers was set at welded to the hull brackets on two needle bearings, double-row Fixation of the balance weight from the axial displacement was carried out ball lock On support odnomandatnik rubber rollers with a diameter of 250 mm was mounted protection in the form of a steel ring on the outside diameter of the tire.

The mechanism of a tension idler fulfilled with one globoid worm pair, which is provided as the tension of the caterpillar, and the fixation mechanism in a predetermined position. Hydraulic vane dampers have been increased in 2,5 times the volume of the working fluid.

Chassis tank included the use of two types of caterpillars: rubber (RMS) and an open metal hinge (OMSH). Caterpillar RMS with a width of 580 mm was collected from 86 units, with a pitch of 157 mm. It links consisted of two trucks, which were connected nozzles. In the middle of the link on two fingers mounted detachable comb, mounted with the pinch bolt. The caterpillar RMS consisted of 96 units. For caterpillars with RMSH used crowns sprocket wheel with 13 teeth for caterpillar with OMSH — with 14 teeth. Permutation of the crowns was performed on the same hub wheels. On released the prototype machines were installed caterpillar with OMSH.

Electrical equipment of “Object 167”, made in a single-scheme, different from the electrical equipment of the T-62 is mainly the installation of the generator G-10 with a capacity of 10 kW with drive from the input gearbox (instead of the generator G to 6.5); saleregular P10-up TO (instead of R-5M); filter f-10 (instead of f-5); two batteries 12СТ-70 (instead of four 6СТЭН-140), new instrument panel of the driver and changed the layout of electrical equipment in the fighting compartment of the tank through the installation of two batteries. Means of communication borrowed from the tank T-62.

To overcome water obstacles “Object 167” equipped with equipment for underwater driving (OPVT).

The tank was in full production tests, and then in landfill NIIBT Kubinka. The latest medium tank “Object 167” were recommended to the adoption of the Soviet Army, but he was not accepted due to the deployment of work on a fundamentally new design and layout solution medium tank “Object 432”.

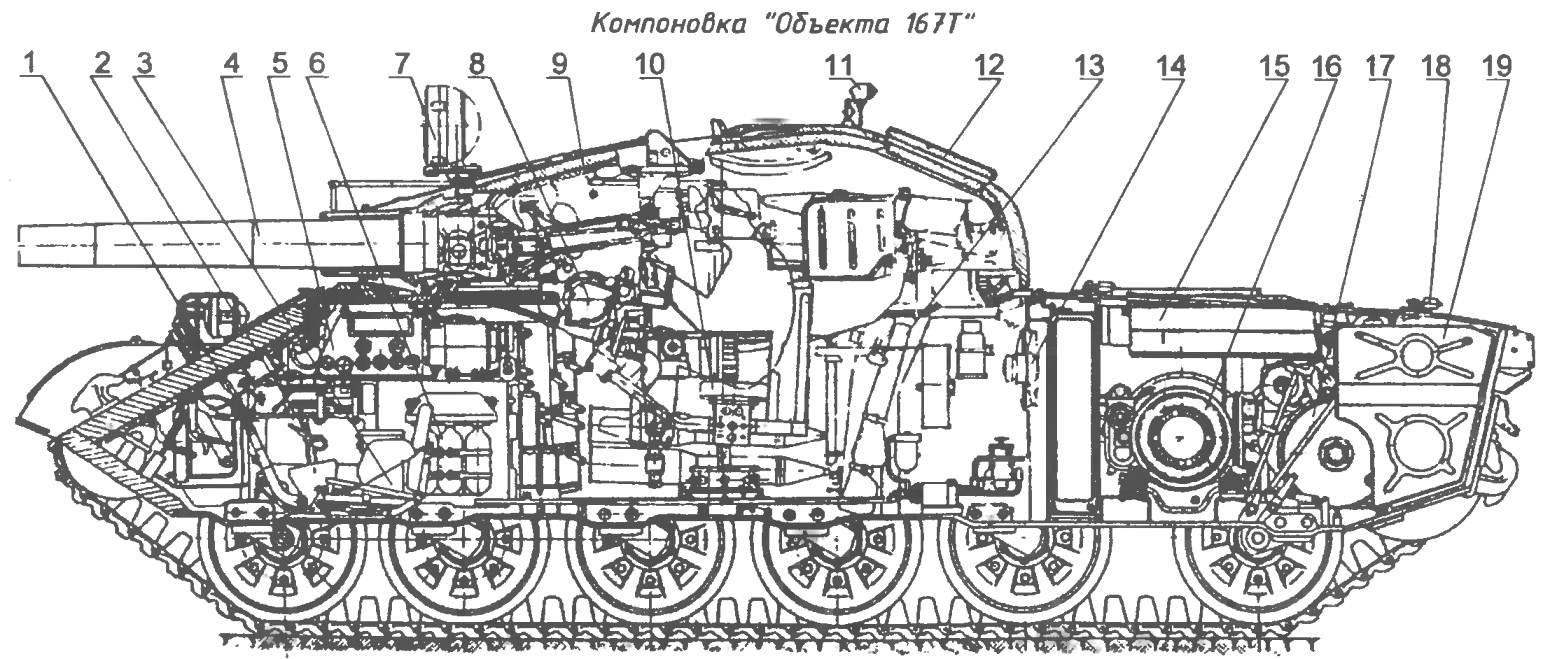

The layout of the “Object 167Т”:

1 – control lever of PMP; 2 —shift gear box; 3 – seat of the driver; 4 — 115-mm gun U-5TS; 5 — junction box offices; 6 cylinders system PPO; 7 — illuminator night sight; 8 — the lifting mechanism of the gun; 9 — liner; 10 — seat gunner; 11 —upper marker light; 12 — cover flap for removal of spent cartridges; 13 — laying the personal weapons of the crew; 14 — fan of the fighting compartment; 15 — unit of air cleaning with the inertial frame; 16 — GTD-3T; 17 – transmission; 18 —tail light; 19 — fuel tank

But the story of the experimental tank “Object 167” is not over. In early 1961, the team of design Bureau of plant No. 183 started to design a new tank with a gas turbine engine, a preliminary study which was started in KB of the factory the year before. This was the debut for the design team, headed by L. N. By cecevim and was fraught with many new and unexplored. As co-executor of the Creator of the engine for the tank attracted Omsk KB-29 of the Ministry of aviation industry of the USSR, started at the time of serial production of helicopter gas turbine engine GTD-3. It and took as the basis of future tank of the power plant. To embed in the tank had a revision of the GDT-3, which established the reduction gear and adjusted the fuel and the equipment with respect to tank conditions. These works were performed by specialists of Omsk under the leadership of chief designer V. A. glushenkova, and in KB Uralvagonzavod parallel to the designed system components and assemblies of the power plant. As the base chassis selected prototype medium tank “Object 167”. Part of the creative team of the construction Bureau of factory No. 183, worked on the creation of experimental tanks with gas turbine engines, consisted of L. S. Dolgov, M. G. Kizin, E. B. Babel, V. M. Dudakov, V. M. Mamaev, A. I. Bolshakov, S. F. Petrov, I. M. Khovanov, V. N. Coastal, Y. M. Pospelov, p. P. Nikulin, V. And Stepanov, and more. . this work was Headed by Deputy chief designer V. N. Venediktov and I. A. nabutovsky.

During 1961 — 1962, the factory No. 183 designed experimental tanks.

“Object 167Т” GTD-ZT;

“Object 167ТУ” GTD-that had short start-up time in low temperatures;

“Object 166ТМ” based on the serial of the T-62 with engine GTD-that, but with the chassis of the tank “Object 167”.

In 1963 he assembled the prototype tank “Object 167Т” with a twin-shaft gas turbine engine GTD-ZT plant.Baranov.

The prototype tank “Object 167Т” in contrast to the basic sample of the tank “Object 167” — was equipped with a gas turbine engine with the serving systems, and new transmission. Installing GTD required the creation of a special system of air purification and increase the fuel capacity due to higher specific fuel consumption compared to diesel. The development of new transmission in a short time fulfilled designer I. M. Khovanov, and its refinement and production led by the designer L. S. Debts.

The fighting compartment and the compartment of “Object 167”, as well as arms, ammunition, suspension and chassis, significant differences from the prototype had. External difference was only in the roof of the MTO.

In MTO two-shaft gas turbine engine GTD-ZT with a capacity of 515 kW (700 HP) was mounted across the hull. Vacant due to the compactness of the power plant amounts MTO has posted two additional 310-litre tank, bringing the total fuel capacity to 1580 L. the Estimated reserve tank on the highway was 211 km For cleaning and circulating air, and to cool the GTE used the original compressor design with a inertia grid and axial fan. developed by a group of specialists of construction Bureau of plant No. 183 under the leadership of I. A. Nabutovskii. Clean air after separation of dust in excess of the amount received in the MTO, it naduva that have a positive impact on the work of the TBG. Part of the air with the separated dust directed at the cooling of the oil cooler and then blowing the engine outside, on a specially organized route, mingling with the exhaust gases of the engine, emissions into the atmosphere. The coefficient of purification of air from dust in the testing conditions reached 95 — 96%, in line with the requirements of the head of the Institute VNII-100

The fan unit with the dust separator attached to the lifting roof of the MTO. The fan drive was through a cardan shaft from the rotor of the turbocharger GTD When lifting the roof of the MTO separation of the propeller fan shaft from the gearbox, located on the front crankcase of the engine, occurred at the splined connection.

The composition of single-threaded mechanical transmission consisted of a step-down entrance reducer, twin-shaft gearbox, two planetary gear sets rotate (PMP) and two combined side of the gearbox. The main clutch was absent. A three-speed manual gearbox with disc and synchronizers operating in oil friction devices, made in the same block with the PMP. provided three speeds forward and one reverse gear. In the absence of the main clutch his functions were fulfilled by two at the same time the lock-up clutch PMP, worked in oil. For reliable torque transmission in PMP two-stage used very rare in tank lock epicycle planetary gear set with the carrier. At rectilinear motion in each PMP torque from the drive shaft to the driven is transmitted through the lock-up clutch, bypassing the planetary gear set, which in this case, the power is not passed, since the sun gear when the lock was free link lock-up clutches had a spring on and off the hydraulic Disc brake turning in PMP, who worked in oil, had a hydraulic on and snap off. Floating belt stopping brakes dry friction had a drive as from the brake pedal and levers control the rotation. Final drives borrowed from the tank T-62. The volume occupied by the transmission of the experimental tank and the transmission of the serial tank T-62 was virtually the same. Transmission had a hydraulic servo control.

In caterpillar tracks compared to the base tank to the second nodes of the suspension optionally ricinoleate hydraulic shock absorbers.

The electrical system, unlike the tank “Object 167”, equipped with generator G-6.5-driven transmission.

In my first trial run of the prototype tank “Object 167Т” was released on 11 April 1963. For rastiannes, sodden circuit, the polygon of the factory tank with a turbine engine showed an average speed of 41.2 km/h — one and a half times greater than the serial car with a diesel engine. The maximum speed was increased to 64 km/h. However, field tests of the machine conducted in July 1964 — January 1965, showed that, despite increased fuel capacity, the cruising range was about 1.7 times less, and fuel consumption is about 2.3 times more than the tank with diesel. A significant drawback in the case of serial production of such machines was very high cost GTD

Further development of the tank “Object 167Т” has not received, since the installation of GTE caused intractable problems associated with cleaning the air and great fuel economy.

Further work on gas turbine topics in the construction Bureau of factory No. 183 was aimed at improving the efficiency and reliability of GTE, transmission, and air purification systems. For example, the value of the ratio of dust passing through the air cleaning unit brought to 2 — 3% (vs 4 — 5% on the tank “Object 167Т”), the culmination of all the work in this direction was the creation of a prototype tank “Object 166ТМ” which mounted the improved air cleaner, transmission and more efficient engine GTD-this. Work on the installation of gas turbine engine in a tank factory No. 183 continued until 1967, and then they stopped, because the design office has failed to fundamentally solve the issues of reducing fuel consumption and reducing the cost of the tank with a gas turbine engine.

The prototype tank “Object 167ТУ” made was not.

Based on the results of testing of tanks “Object 167Т” and “Object 166ТМ” design Bureau of the plant number 183 came to the conclusion on the unpromising tank with a gas turbine engine and all efforts concentrated on building tanks with diesel engines.

Tank “Object 167”

Despite the fact. that attempts to fit the helicopter engines work in the power plant of the tank is not yielded positive results, they are allowed to define the main features of the application of GTE in tanks under different conditions of operation and the concept of creation of systems of the power plant (vozdukhoplavania, air purification, provision of scuba driving, etc.) as a result of the works of local designers came to the conclusion about necessity of creation of the TBG, is specially designed for the tank. The government’s decision acknowledged the appropriateness of works on creation of the tank gas turbine engine in the aviation industry that had a high technological and production potential for the serial production of GTE.

Although preference is given to the military leadership and the government of the USSR Kharkiv experienced tank “Object 432”, developed in KB Malyshev plant Lod the leadership of A. A. Morozov, the team of Uralvagonzavod did not lose hope on the possibility of adopting experimental medium tank “Object 167” and continued to work on its improvement KB Nizhny Tagil factory and developed machine with 125-mm tank gun and automatic loader (“Object 167М”), with a high level of radiation protection (“Object 167Д”). It should be noted that according to the draft modernized tank “Object 167М” in addition to the 125 mm smoothbore gun with automatic loader had a combined protection hull and turret, and side latticed steel shields protecting the fuel tanks and equipment placed on the shelves only from cumulative shells of the enemy.

In January 1963, L. N. Kartsev wrote a letter N. With.Khrushchev, in which because of unavailability of the Kharkiv machine again requested permission to start serial production of the tank “Object 167” Uralvagonzavod instead of the T-62. In this letter 22 March 1963, chaired by F. R. Kozlov, the Deputy Chairman of USSR Council of Ministers convened a special meeting at which the chief of the tank troops of the Soviet Army Marshal of armored troops PP Poluboyarov and Chairman of the State Committee of the USSR Council of Ministers for defence technology S. A. F. Zverev assured Kozlov that the tank “Object 432” will soon be finalized and put into production on all the tank factories, including Uralvagonzavod, therefore, to release the tank “Object 167” makes no sense. In his memoirs, former chief designer of KB Uralvagonzavod L. N. Kartsev described conclusion, FR Kozlov on this subject:

“Of course, “Object 167” better than the T-62, but we will take on the production of a more perfect tank “Object 432″. Please give my gratitude to the staff of the design Bureau”.

After hearing my story, the Director of the plant (I. V.Okunev) was very saddened, but I told him: “Ivan, you calm down, there will come a time when, as it happened with the tank T-62, they will beg you to put on the production of “Object 167″, in which we install your autoloader, best of Kharkiv”. He immediately called the chief accountant of the plant I. D. Aborowa and gave the order to open a work order to create autoloader”.

In 1963, the automatic loader, developed by designers of factory No. 183 “Object 167М”, manufactured and installed in one of the prototypes of the T-62 (“Object 166Ж”). Work on his finishing completed in 1965. In the end Tagil autoloader was more perfect than Kharkiv, designed for tank “Object 432”. It was simpler in design, reliable in operation, ensures the transition of the driver from the Department of management in combat without performing any preliminary work and increased the survivability of the tank when firing. The autoloader had the capacity 21 shot separately-tubular loader

Since 1966, the plant № 183 was ready to produce tanks T-62 with automatic loader and ammunition used on the tank “Object 432”. However, the question of serial production of such tanks by the country’s leadership was not even considered for the above reasons. As a result, in the next eight years (1966 to 1973), the plant № 183 produced T-62 with an autoloader.

However, the tank “Object 167” had not forgotten. When in may 1964 at the plant No. 183 put two experimental 125-mm tank gun D-81, KB plant returned to the project tank “Object 167М”. Using the experience on the machine immediately started working on setting the gun D-81 in the prototype of the T-62 with the autoloader, because the size of the guns caliber 115 and 125 mm was not significantly different from each other.

By November 1967 the Uralvagonzavod produced the prototype of the T-62 with 125-mm tank gun D-81 and autoloader, which was timed to the 50 anniversary of the USSR. About the further destiny of this machine L. N. Kartsev says:

“November 5, 1967 at the Uralvagonzavod for the first time there has arrived the Minister of defence industry of S. A. Zverev. Being within two years in this position, he attention was paid to creation of new tanks in Kharkov and often traveled to the plant.In..Malysheva, helping the company as engineer and administrator. In the second half of the day showed him the T-62 with 125mm gun. Autoloader he liked, and he offered to install it at the Kharkov tank.

We agreed to do only with the simultaneous installation of the Chelyabinsk engine In-46 (a modification of diesel engine In-26) from the tank “Object 167”. Zverev this proposal was approved and sent to rework six of the Kharkov tanks, which for two years has been redesigned and tested in different conditions.

All nodes and mechanisms worked satisfactorily, except Kharkiv chassis. Subsequent samples were installed, the undercarriage of the vehicle “Object 167”. This tank became known as “Object 172”.

This place memories of the famous tank designer L. N. Kartsev and to finish the story of the creation of “Object 167” and its contribution to the appearance of the T-72 “Ural”. But this story would be incomplete if not to tell about some of the other machines created in prototypes and serial on the basis of “Object 167”.

Such units were treated tank missile developed in 1962, Bureau of Uralvagonzavod under the leadership of L N.Kartseva and had the designation “Object 150” — serial tank destroyer it-1, issued subsequently, on the basis of average tank T-62 (see the “MK” No. 7 — 8, 2005).

In the VNII-100 in November 1961, has developed several projects of special machines based on the tank “Object 167”, in the layout diagrams which, in addition to the crew, provided additional passive placement of three or four Marines. This resulted in an increase in vehicle weight to 38 tonnes, and the length of its body — to 6710 mm. in addition it reduces the ammunition 115-mm gun with 40 to 28 rounds and decreased clearance of the machine from 482 to 420 mm. Other specifications of the car remained the same as in the tank “Object 167”.

In another embodiment, the location of the four Marines tank crew reduced to two. As the main weapon in the turret of a tank installed a 115-mm gun reduced ballistics, but as additional weapons — ATGM “Rubin”. The ammunition consisted of 14 missiles and 26 high-explosive and shaped-charge artillery shots. The initial velocity of the projectiles was 700 m/s. Combat vehicle weight is reduced to 35 tons and the height of the roof of the tower was only 1950 mm.

In addition, in the VNII-100 in 1961 to 1962 on the basis of experimental medium tank “Object 167” had developed a special low profile assault car with a tank of jet fuel which was intended for target engagement at ranges up to 1200 m the flame thrower projectiles. Launcher for firing 180 mm actionreaction shots and the ammunition is housed in the body of the machine. The crew of two people.

In 1962 he produced a prototype which passed the control test on the site VNII-100 landfill LenVO in the amount of 53 shots.

M. PAUL and I.

References:

1. Brief description of a new medium tank (“Object 167”). Nizhny Tagil, 1961

2. Report on tests of the experimental sample 167Т medium tank gas turbine engine GTD-ZT at Uralvagonzavod. Nizhny Tagil, 1966

3. Technical project of a fighter of tanks “Dragon” elevated protective properties of weapons of mass destruction (“the Object 150”), Nizhny Tagil, 1962

4. Kartsev, L. H. My destiny Nizhny Tagil. — M.: Space, 1991, 192 p

5. Kolmakov, D. G. Time, people, tanks. — Nizhny Tagil, 2001, — 102.

6. Ustyantsev S. V.. Kolmakov DG Combat vehicles of Uralvagonzavod. T-72 Tank. — The lower Tagil OOO “Publishing house “Media Print”, 2004, — 200 p

7 Vovchanskiy E. B. As it was… Nizhny Tagil, 2001, — 88 C.

8. Babylonian E. B. As it was… Part 2. The story of the creation of the tank T72. Powerplant. — Nizhnijj Tagil, OOO “Publishing house “Media Print”, 2004, — 88 C.