There are many enthusiasts for whom a velomobile has become not just a hobby but a passionate obsession. And then there are people for whom a velomobile is literally life itself. More accurately, it’s about the ability to move around, which, in essence, is interconnected.

For such a means of transportation, speed and load capacity are not important; rather, different technical characteristics matter: light weight, maneuverability, ease of handling. And most importantly, the velomobile should be comfortable and easy to use, occupy little space when stored, and ideally serve as a good exercise machine. Who among optimists, whose mobility and social circle are limited for some reason, doesn’t dream of restoring their mobility!

Today, abroad, many companies produce velomobiles for people with disabilities. These vehicles have foot-operated, hand-operated pedal drives, or a combination of both. Often, additional electric drives powered by a battery are installed on such velomobiles. For people with limited mobility, super-lightweight high-speed sports velomobiles and even track-driven velomobiles have been created, on which particularly daring disabled optimists can climb high into the mountains.

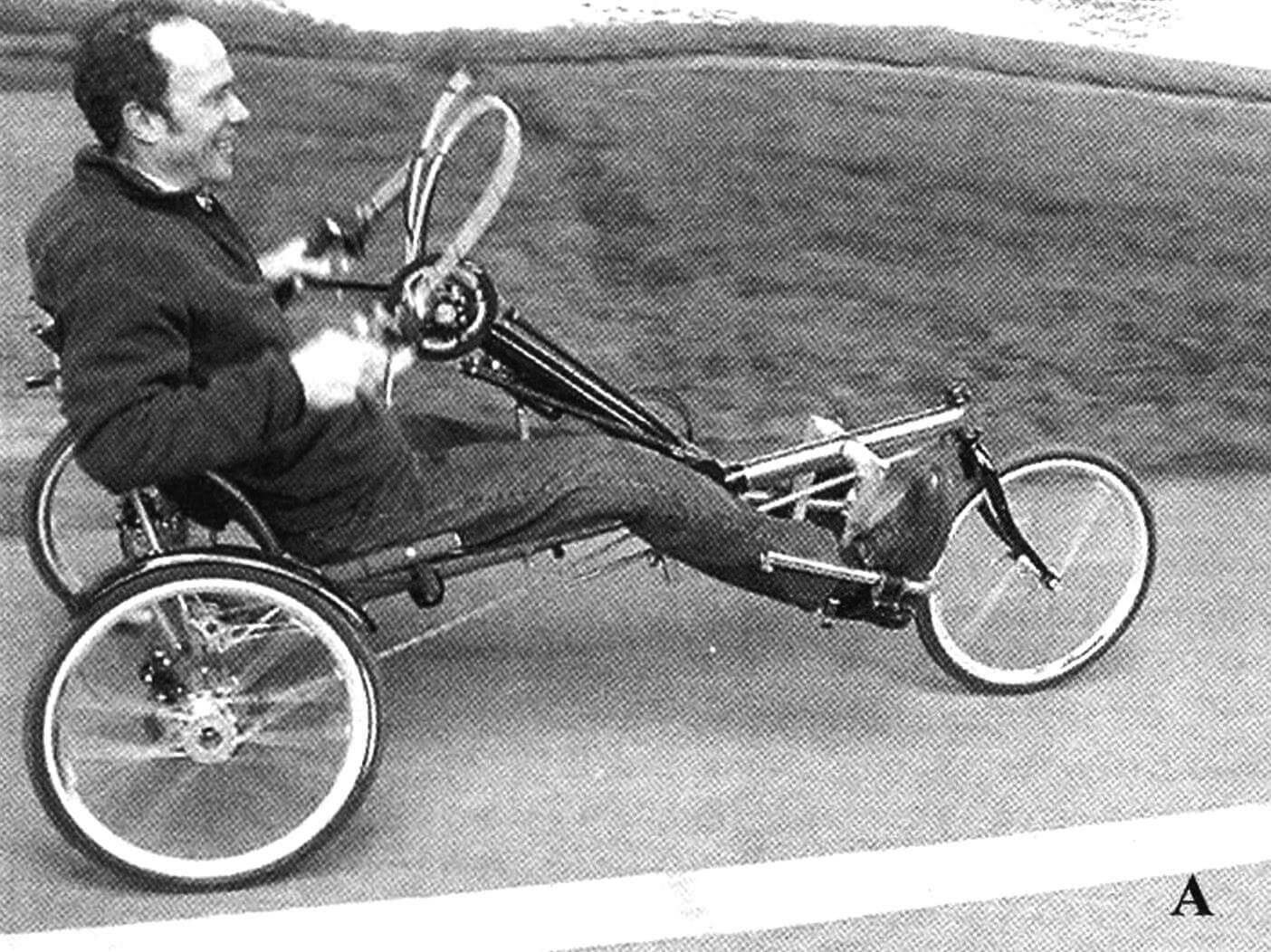

A — high-speed with combined (manual and foot) drive and manual control; B — track-driven snowmobile with manual velo-drive and control

But all this is not available to us. And imported velomobiles do not always fully meet the desires of the future owner. After all, you want the design to take into account your specific features, your capabilities, your wishes. In short, you need a custom project! But will anyone take it on?

This is probably how the energetic disabled girl from Nizhny Novgorod reasoned when, for several years, she unsuccessfully tried to find a company to manufacture a personal velomobile for herself. In the end, a manufacturer was found.

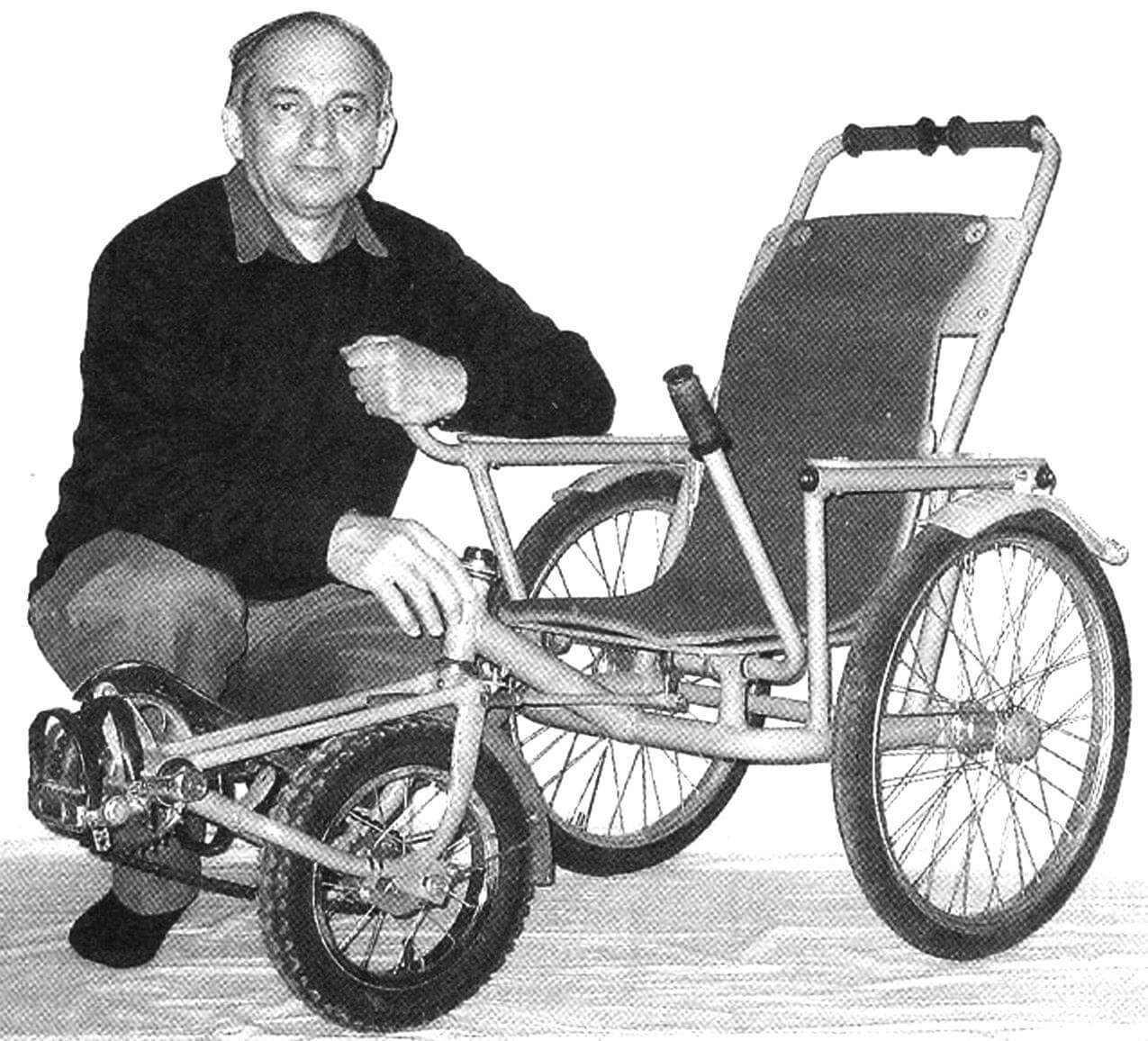

And on a sunny May day, a miniature velomobile (or rather, it would be called a “velohod”) made by the Moscow company “ETRA” entered the girl’s room. Olya Zotova was delighted not only with the bright green color of the construction but also with the name composed of the letters of her last name and first name — “Zolga.” This is definitely her velomobile!

The first test, the first “shakedown” of the new design. It should be noted that Olya already had experience riding a homemade analog wheelchair. But it brought neither satisfaction nor joy. And now: two hours of taming initially disobedient pedals and control lever — and “Zolga” slowly rolled out to explore the surroundings, charting new routes to parks, shops, theaters. Who knows where her owner will decide to go now!

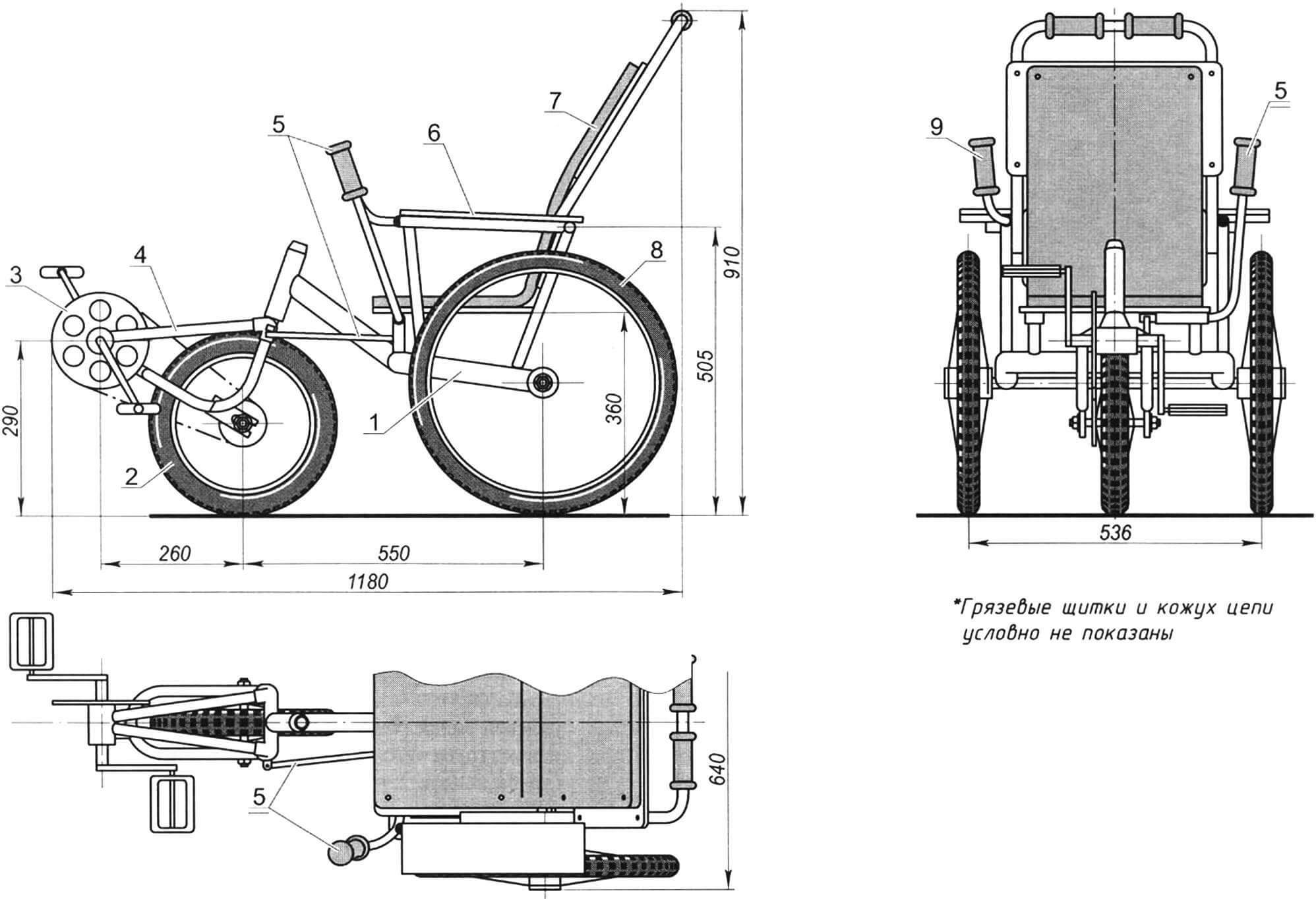

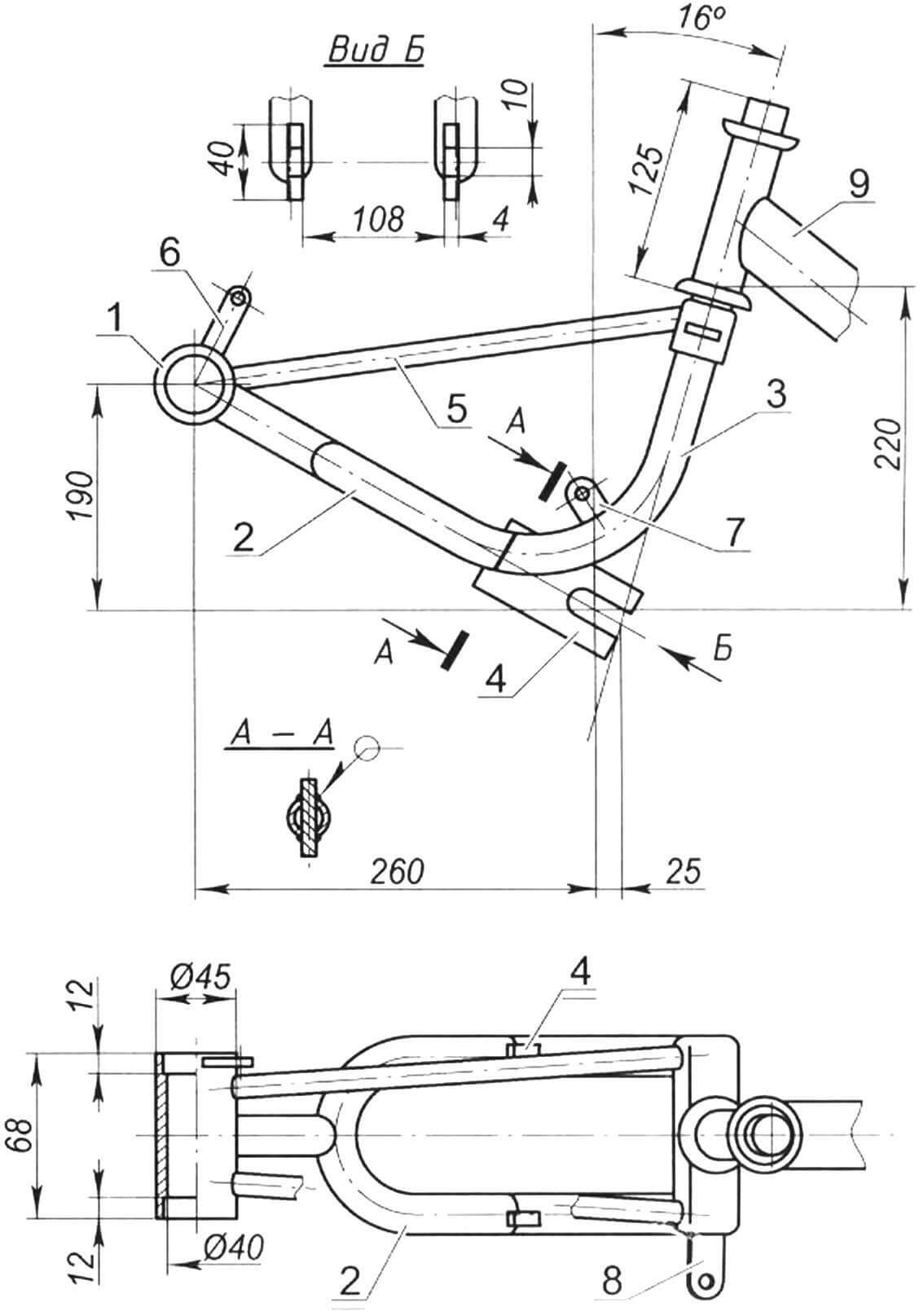

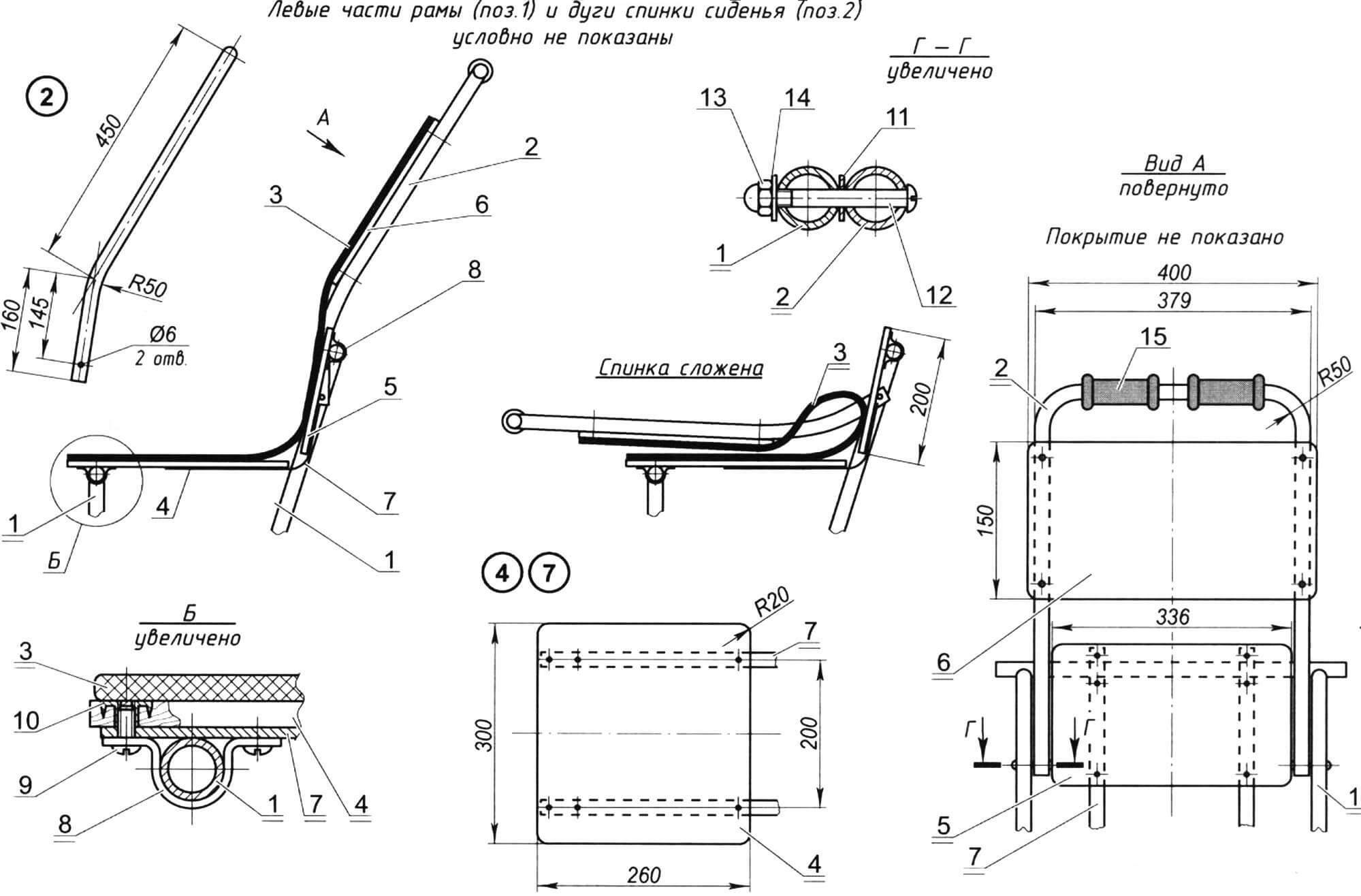

1 — frame; 2 — front steerable and driving wheel (from a children’s bicycle); 3 — pedal drive (from a teenage bicycle, sprocket z = 40); 4 — stem; 5 — steering control; 6 — armrest (plywood s8, 2 pcs.); 7 — seat; 8 — rear support wheel (2 pcs.); 9 — handle with fixed grip

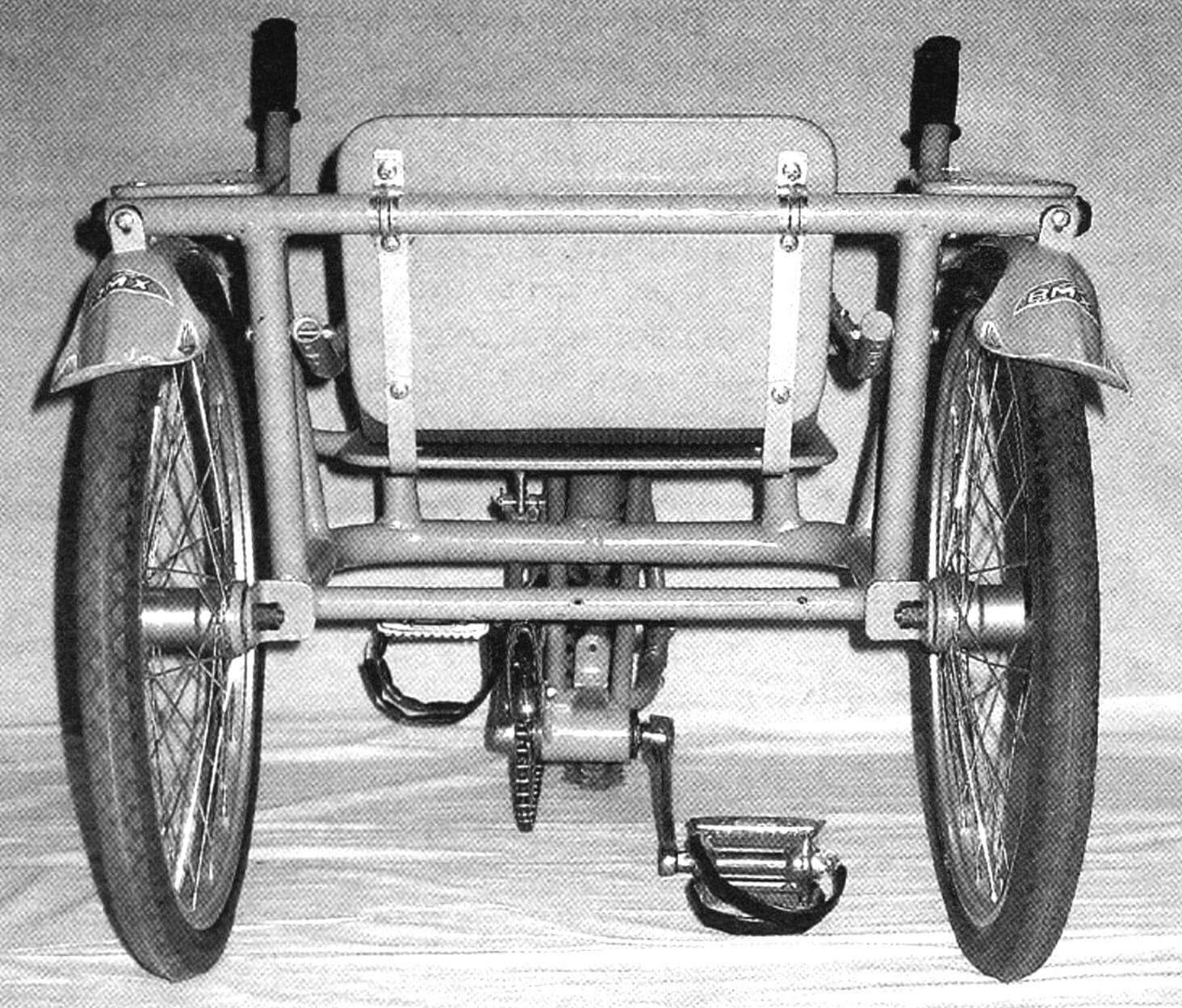

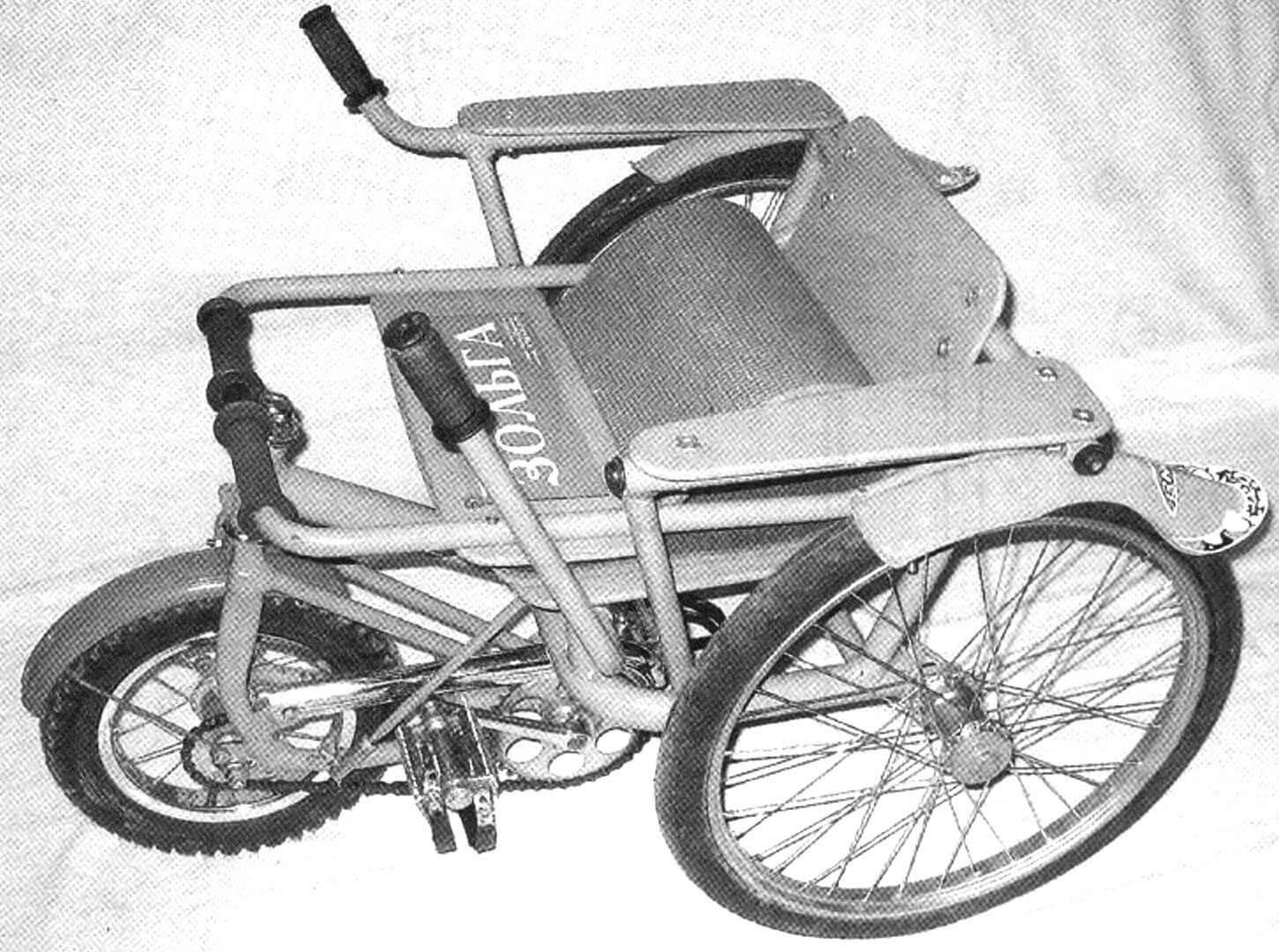

The velomobile, or more precisely, the cycle stroller, is designed for the height of the owner, which is 155 cm. Its overall dimensions (width, height, length) are 640x910x1180 mm, respectively, and in the folded state, it measures 640x650x920 mm.

The “Zolga” is simple in construction, compact, and partially folds for storage. However, its main feature is its amazing maneuverability. This characteristic allows riding it not only outdoors but also indoors, in a room. The width of the cycle stroller is only 640 mm, making it easy to navigate through narrow doorways and elevator openings. The weight is 19.5 kg. The “Zolga” can be used as a cart for goods in a self-service store: the P-shaped support of the seatback plays the role of a handle, allowing the stroller to be pushed in front. Holding onto this handle, the cycle stroller can be lowered or raised on stairs or assist the owner in overcoming curbs.

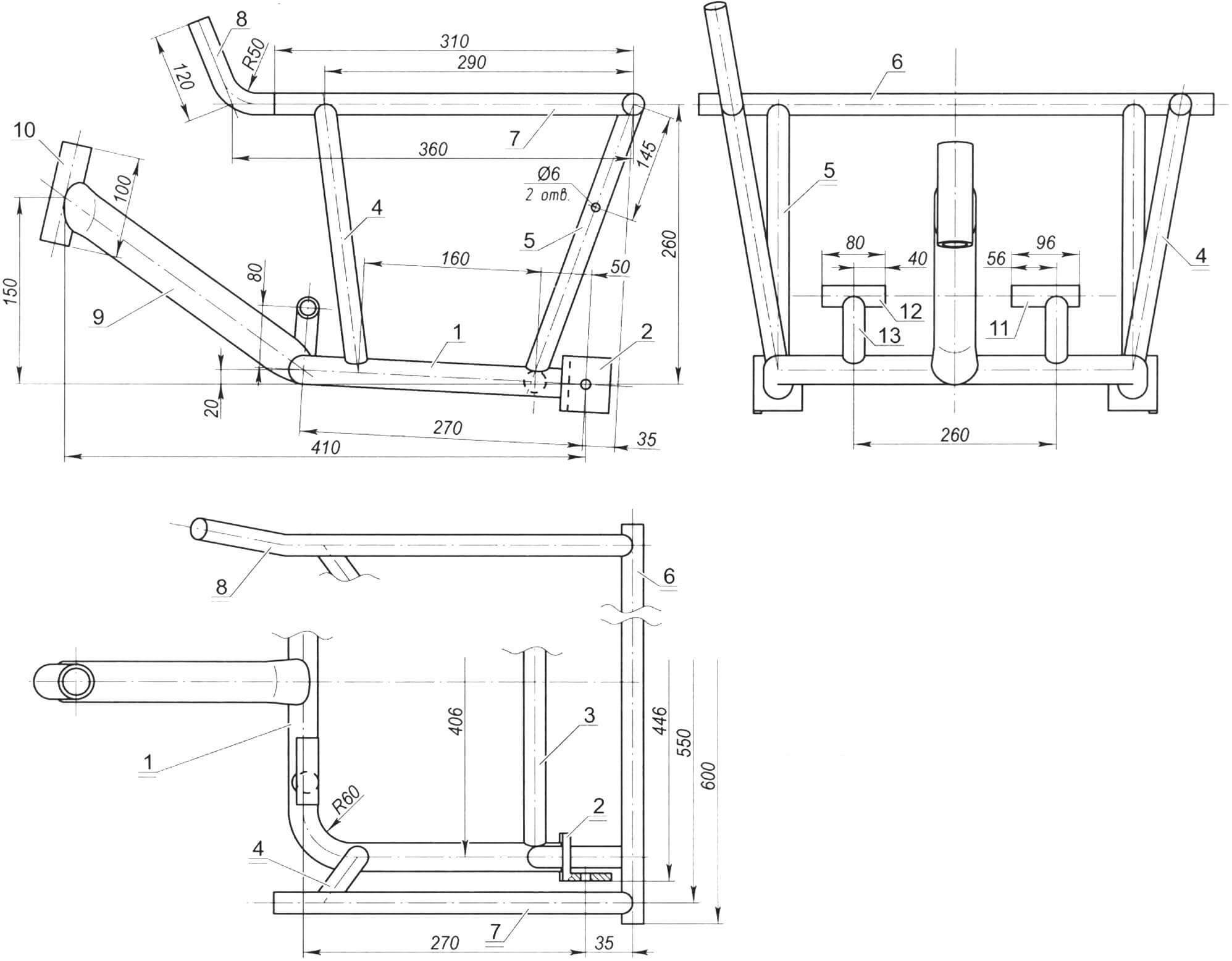

1 — base (tube Ø32×1.5); 2 — rear wheel axis mounting bracket (angle 40×40, 2 pcs.); 3 — clamp (tube Ø25); 4,5 — front and rear uprights (tube Ø25, 2 pcs. each); 6 — support for the seat back arch (tube Ø25); 7 — armrest supports (tube Ø25, 2 pcs.); 8 — fixed handle (tube Ø25); 9 — drawbar (tube Ø40); 10 — stem bushing (tube Ø32); 11 — left (as per direction) seat support (tube Ø20×2, L = 96)); 12 — right seat support (tube Ø20×2, L = 80); 13 — seat support uprights (tube Ø20, 2 pcs.)

The basic structure is a welded spatial frame made of thin-walled (1.5–2 mm) steel tubes. In shape, the frame resembles the frame of a chair seat, which, in fact, it is. Therefore, like any chair, it has armrests and a backrest (although not as luxurious). The support arch of the backrest is bent from a 20 mm diameter tube with a fairly thick wall of 2.5 mm, as it also serves as a handle for moving the stroller.

Top and bottom backrest supports and the seat base are made of moisture-resistant 8 mm bakelite plywood, and so are the armrests. A solid polyurethane foam (PU) cushion, 12 mm thick, made from a camping foam pad, is attached to the backrest supports and the seat base with M6 screws with large-diameter washers.

To fix the M6 screws, 8 mm diameter holes are drilled into the supports, in which furniture nuts with “prongs” are hammered with a hammer. It should be noted that armrests are attached in a similar way, only with M5 screws (three each). The lumbar support of the backrest and the seat base are connected by 20 mm wide and 2 mm thick aluminum strips, which are attached to the supports of the seat base and the support of the backrest with steel clamps using M6 screws.

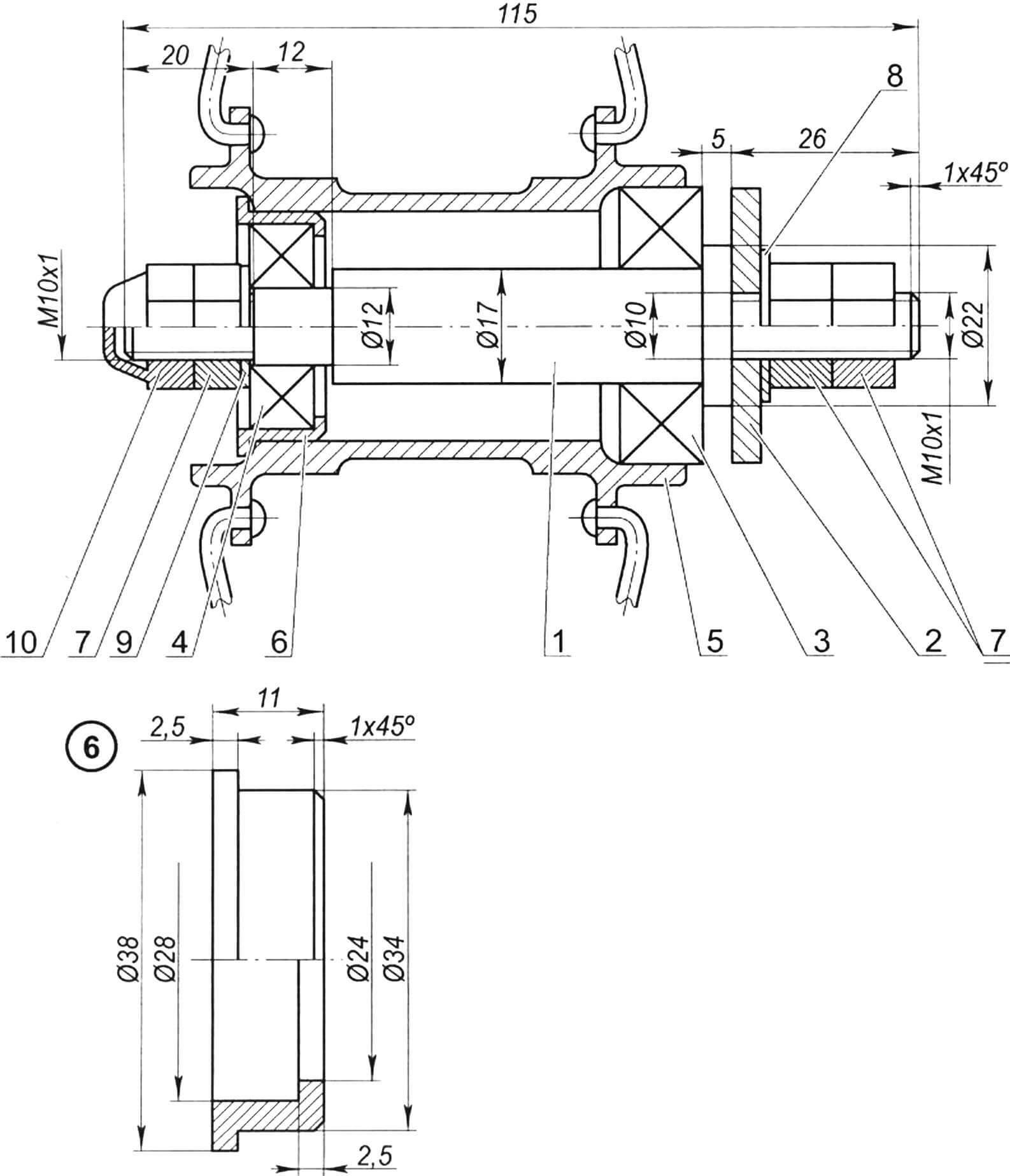

The rear 20-inch support wheels are from a road bicycle. A bearing 60203 is pressed into the “torpedo” hub from the inner end, and a bearing 60101 in a cup and an axle with a collar from the outer end. The hub of the wheel on the axle is fixed with M10x1 nuts, one of them is locking. Each axle is also fixed in the frame bracket with these nuts.

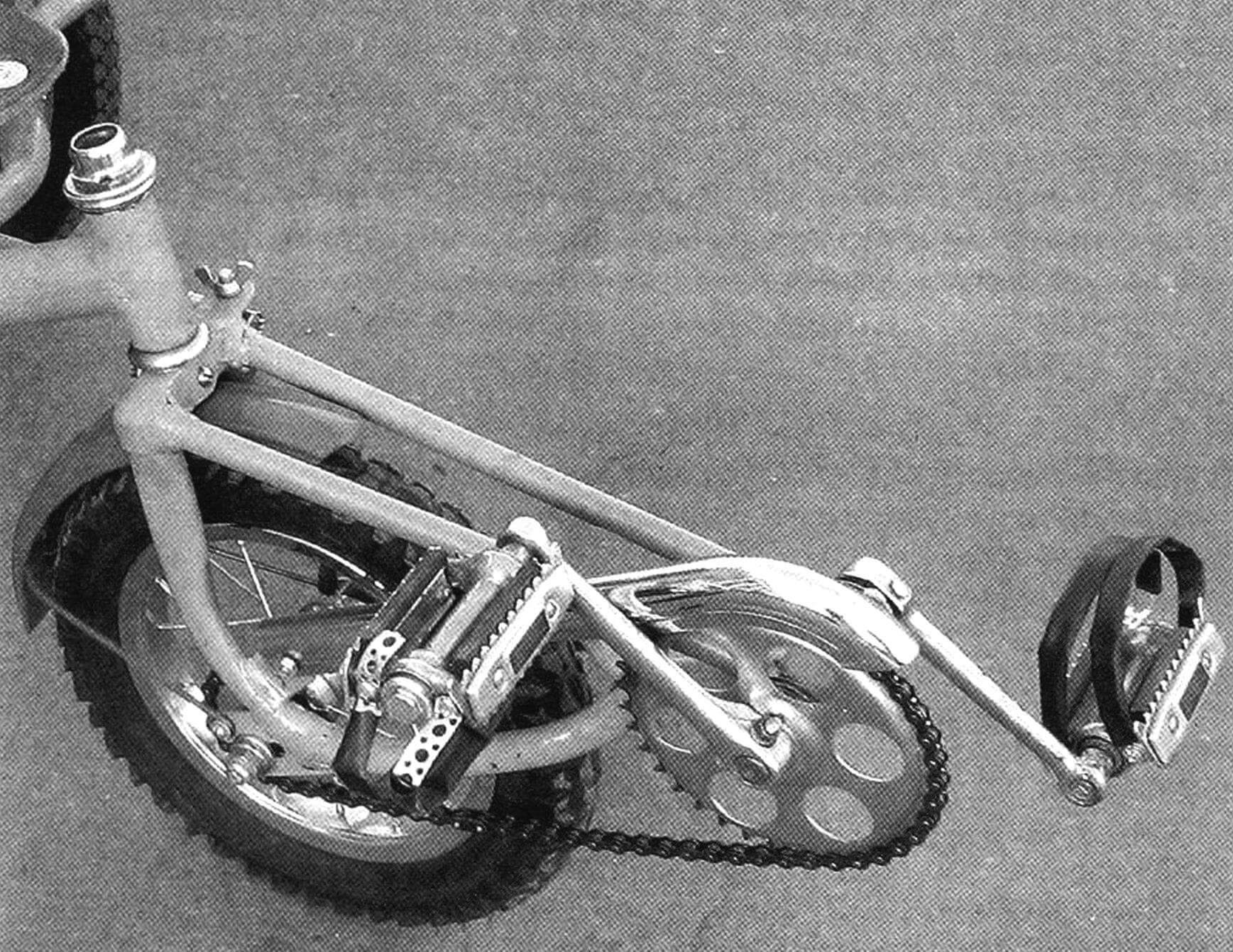

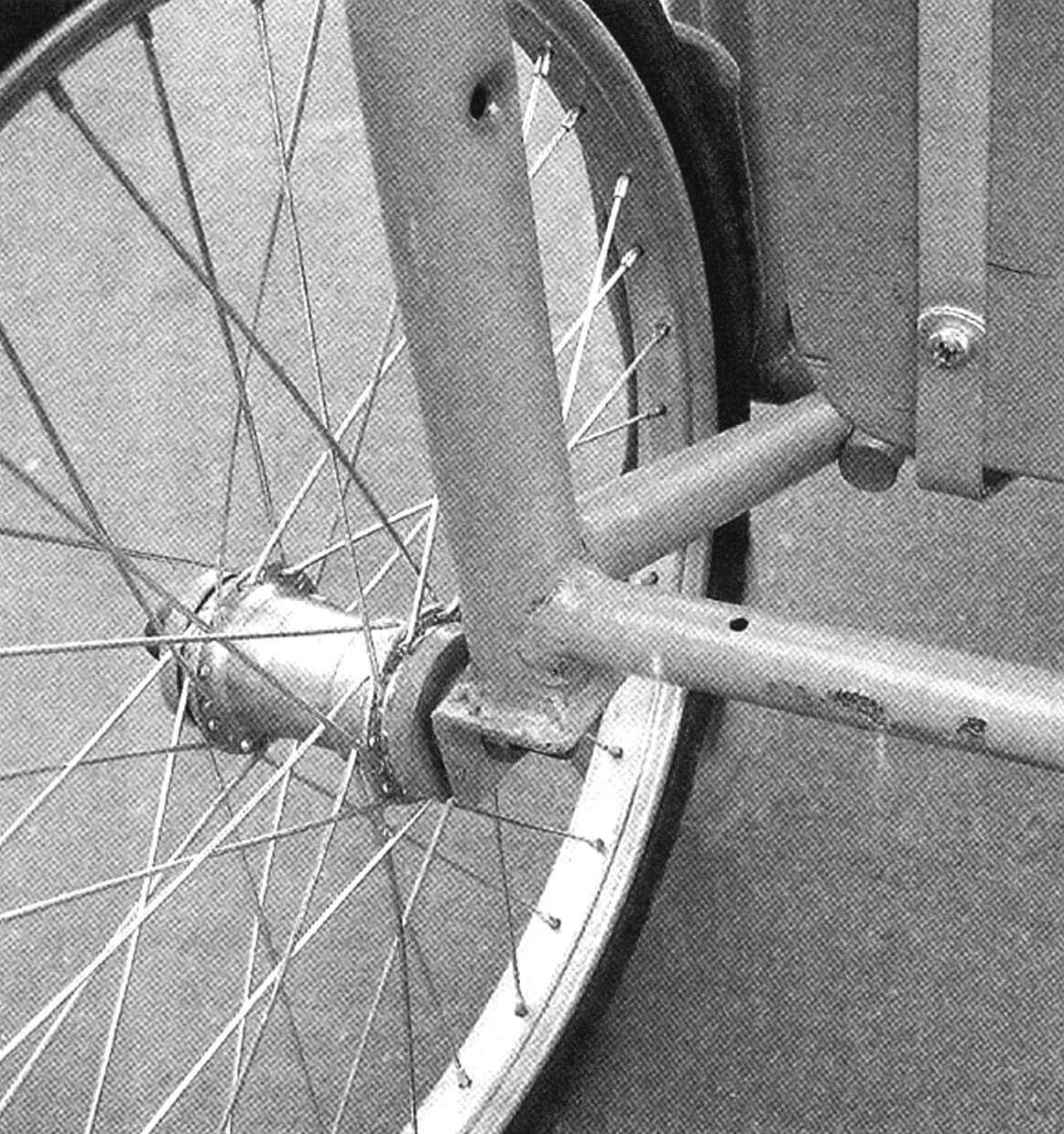

The velomobile uses a scheme with a front driven (also steerable) wheel (the “mazurchak” scheme). The front wheel with a diameter of 12.5 inches is assembled on a standard “torpedo” hub. The drive extension is combined with the front wheel fork and welded from two shortened bicycle forks. When manufacturing such a small and quite responsible unit, it was necessary to strictly maintain the parallelism of the wheel axis and the bottom bracket axle. Therefore, the welding of this unit was done in a jig.

The content of the bottom bracket unit is borrowed from a child’s bicycle. The length of each crank is 140 mm, which is quite acceptable for confident and not tiring pedaling.

**Translation:**

1 — bottom bracket shell (tube Ø45×2.5); 2 — brace fork (from the “Friend” bicycle); 3 — steering fork (from the “Butterfly” bicycle); 4 — front wheel axle attachment bracket (strip 40×4, 2 pcs.); 5 — clamp (tube Ø14×1.5, 2 pcs.); 6,7 — chain guard mounting brackets (strip 20×2.5); 8 — swivel lever-piglet (strip 20×4); 9 — frame drawbar

The rear wheels are rigidly attached to the frame through angled brackets (more precisely, their axles are attached, and the wheels are then put onto the axles). The wheel hubs have been modified for standard bearings (previously, there were two cones, and balls were placed between them without separators).

1 — axle (steel 45); 2 — frame bracket; 3 — bearing 60203 (40x17x12); 4 — bearing 60101 (28x12x8); 5 — wheel hub; 6 — bearing 60101RS cup; 7 — M10 nuts and lock nut; 8,9 — washers; 10 — cap lock nut

The wheels are equipped with mudguards. Moreover, over the rear wheels, they are attached with thickened rubber washers so that during the trip, if necessary, their position can be manually adjusted. Wooden plugs are glued into the open ends of the frame tubes, to which rubber cushions – stops – are attached with screws.

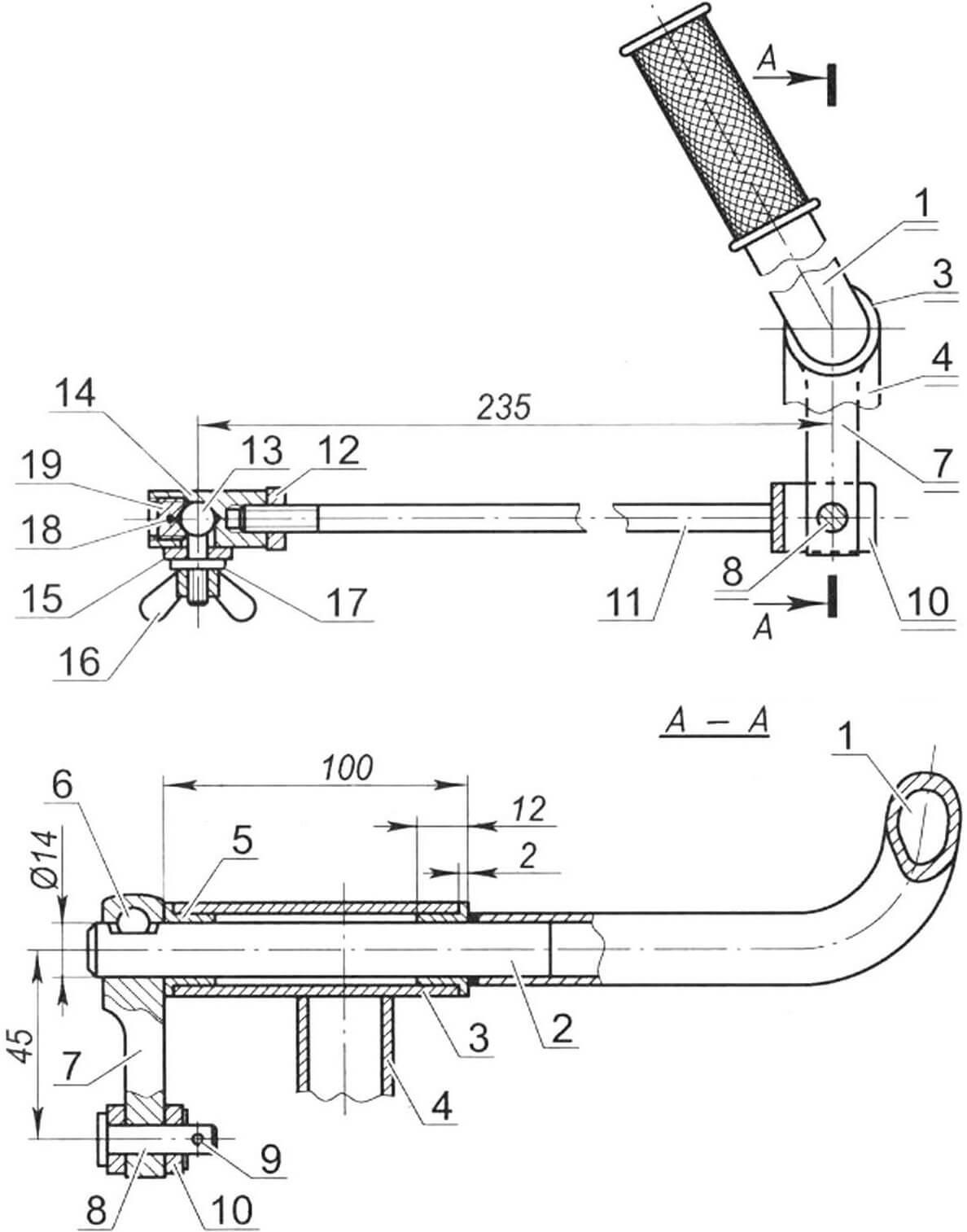

The velomobile is steered with one hand using a G-shaped lever that moves forward and backward (correspondingly, turning left and right). A handle is attached to the end of the long (vertical) arm. The short (horizontal) arm of the lever on sliding bearings (polypropylene) is mounted in a guiding tube – the left (as per direction) extended seat support, and on its end, a wedge is fixed, made from a shortened left pedal crank. A rod (8 mm diameter) through a ball joint connects the lever-piglet (welded to the drive fork) with the wedge of the steering lever shaft. In the photo, the joint connects to the piglet from the bottom. However, this is not essential. The steering lever’s range of motion is limited on one side by a cushion-stop.

1 — steering control lever (tube Ø22×4); 2 — lever shaft (circle 14); 3 — shaft bushing—left (as per direction) seat support; 4 — seat support upright; 5 — sliding bearing (brass, circle Ø20, 2 pcs.); 6 — wedge; 7 — piglet (shortened bicycle crank); 8 — pin Ø6; 9 — cotter pin; 10 — fork tie rod; 11 — rod (circle Ø8); 12 — lock nut; 13 — ball joint; 14 — ball joint housing; 15 — swivel lever-piglet; 16 — sheep nut; 17 — spring washer; 18 — plug; 19 — plug cotter pin

The steering device is adjustable: control can be performed not only with the left hand (as in the example shown) but also with the right hand (with a symmetric installation of the G-shaped lever and other elements) or even with both hands (with the installation of two G-shaped levers with a set of elements).

To secure the feet on the pedals, strips of perforated mounting tape are fastened with standard M5 screws, onto which a plastic cover is put.

The frame and other metal components are coated with primer (“for rust”) and two layers of alkyd enamel. Wooden parts are treated with protective compounds before painting.

For partial folding of the cycle stroller for storage, the tie rod end needs to be disconnected (by unscrewing the sheep nut) and the drive turned 180 degrees (pedals under the seat), while the seat back should be tilted forward onto the base.

1 — frame; 2 — seat back arch (tube Ø20×2.5); 3 — covering (foam pad); 4 — seat base (plywood s8); 5 — lumbar support base (plywood s8); 6 — seat back (plywood s8); 7 — connection (duralumin strip 20×2.2 pcs.); 8 — clamp (steel strip 20×2.4 pcs.); 9 — clamp attachment (screw M6, 4 pcs.); 10 — anchor nut M6 (with sharp “teeth,” embedded in plywood, 4 pcs.); 11 — washer (s1, 2 pcs.); 12 — bolt M6 (2 pcs.); 13 — cap nut M6 (2 pcs.); 14 — washer; 15 — handle of the seat back arch (rubber, 2 pcs.)

With such a small wheelbase, the cycle stroller could overturn during maneuvering. However, the “Zolga” is equipped with a “smart” steering system: the driver tilts the lever, and at the same time, they must lean to the side of the turn, thereby preventing the velomobile from tipping over. Braking is performed like on a bicycle – by pedaling backward.

Of course, the maximum speed of the “Zolga” is not high: 15 – 20 km/h, but the stroller is not designed for racing. The turning radius around the outer rear wheel when turning left is 1500 mm, when turning right – 1650 mm, which means that a platform with a diameter of just over three meters is sufficient for turns.

The weight of the stroller is about 19.5 kg.

After several training sessions, it is possible to learn to operate the velomobile using only legs (without the help of hands). To do this, loosen the sheep nut and disconnect the steering linkage: in this case, the “Zolga” can almost “turn on the spot”.

“After a few months of using the velomobile, O. Zotova wrote: ‘Yesterday, I rode the “Zolga” for two hours. Well, what can I say… Super! Pedaling is much easier than on the old stroller. For the first ten to fifteen minutes, I couldn’t handle the steering: I wanted to turn right – it turned left, I wanted to turn left – it turned right, but then everything went smoothly. … Everything suits me in the “Zolga,” and I’m not going to change anything. I won’t give up the “Zolga” for any amount of money now. You know, I once had my wheelchair stolen, so now I’m afraid the same thing might happen to the “Zolga.” I won’t survive that.'”

V. Ulyanovsky