At the same time, the staff servicing electrical systems often have to deal with the devices of relay protection, automation, electrical equipment of machines powered by both AC and DC voltage of 24 and 36 in. Often have to work in conditions when the faint glow of “nenok” is perceived with difficulty, besides the possible false testimony of the neon lamps, which often turns from capacitive leakage current through the insulation intact electric cars, even when sensitive gauges do not detect the presence of voltage. Conversely, SPST indicators (e.g. UNN-1, JN-90) will not light up if the voltage is present, if the person is standing on dry non conductive floor or stand is dressed in boots with thick rubber soles.

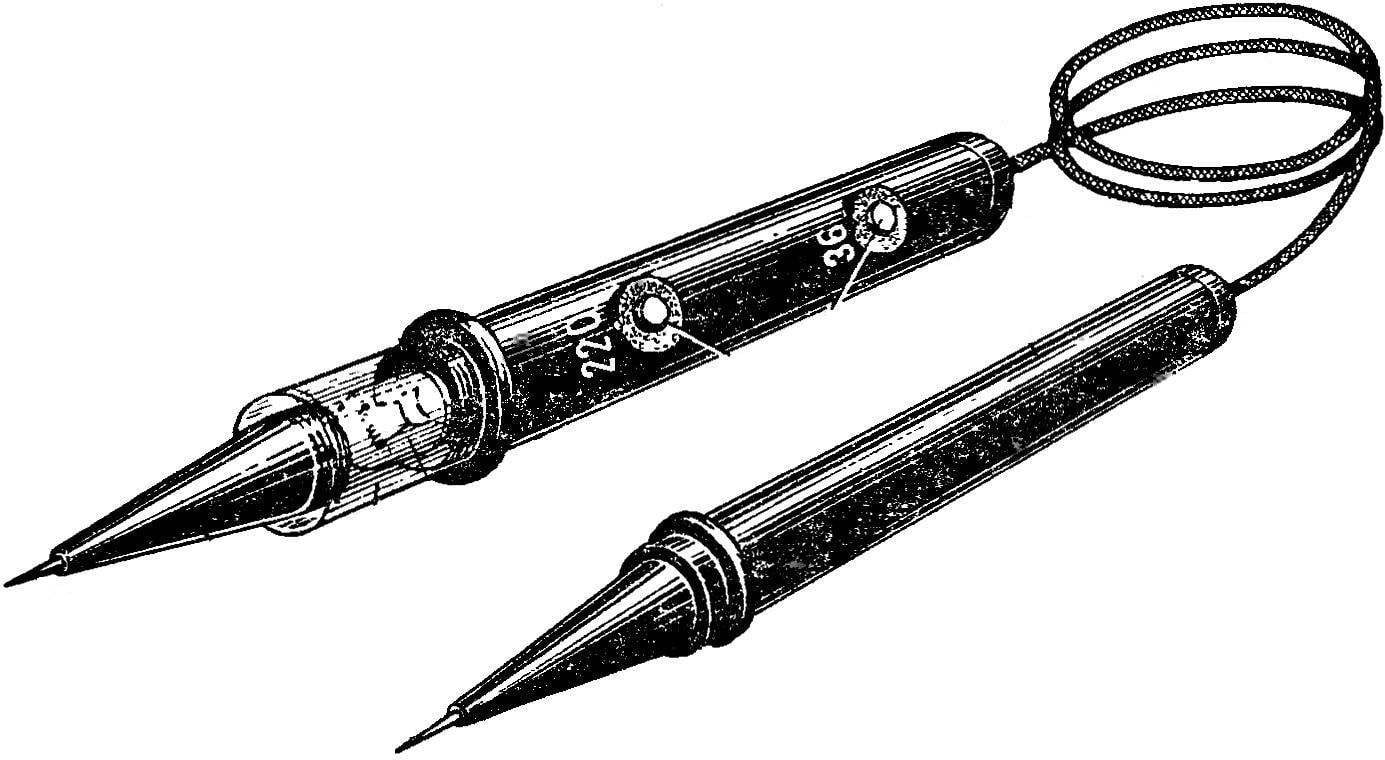

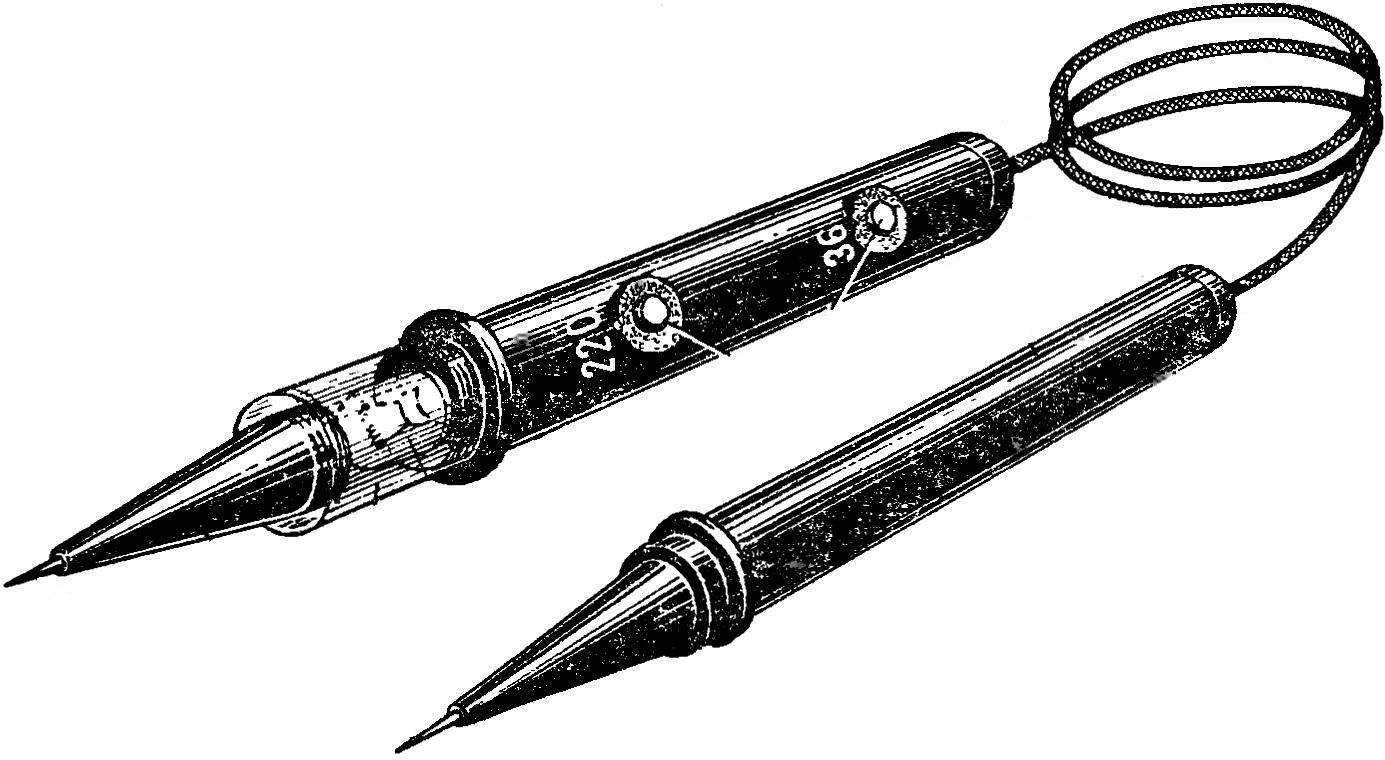

Probe readers, has no mentioned shortcomings. It consists of the indicator and the auxiliary probe (Fig. 1) connected by a wire.&the Probe is a cylindrical body with an annular safety lip, in front of which is a glass protective caps and cones with metal pins at the ends. In the indicator probe is equipped with two micro switch MP-5, closed by rubber pads. An indicator is the bulb of the MH-36 (36V, 0.12 A). Both probes are connected by two wires with reinforced insulation, is placed in a rubber tube.

Fig. 1. Multirange voltage:

1 metal pin, 2 — cone, 3 — cap 4 — bulb MH-36, 5 — micro switches MP-5, 6 — the case of the flat probe, 7 — the case of the auxiliary probe 8, 10 — end cap, 9 — connecting wire.

Connection diagram of elements of the universal probe electrician shown in figure 2. Each probe set on the five limiting resistors MLT-2. The probe detects the presence or absence of voltage in AC or DC, in the following terms: “36” (24—48V), “220” (110—250V), “380” (250—420В).

Fig. 2. Diagram of the universal probe.

When the voltage 380-420 to enable the micro switch is not necessary, and the lamp lights up when touching live parts of the installation. At a voltage of 110, 127 or 220 V push button S1 “220”: the resistors are shunted, and the lamp burns brightly. When the voltage is 24, 36 or 48 In, press the button S2 “36”, additional resistors are disabled.

If the voltage is unknown, first touch the pins, not pressing buttons, and then manipulate any of the buttons S1 and S2.

In addition, using the probe it is easy to verify the integrity of the relay coils and contactors (if series connection with the appliance) to determine the polarity of DC by connecting in series c probe diode Д7Ж or Д226Б.

In the industrial manufacture of the body of the probes are conveniently stamped out of plastic, and if small-scale or single — all parts machined from hard rubber, vinyl plastic or organic glass (Fig. 3).

Fig. 3. Body parts (positions are the same as in Fig. 1).

A pilot batch of samples was introduced at Kharkiv regional enterprise rural electric networks (HORSES) and in the transport machine-building plant im. Malyshev V. A. the results of the trial operation of the universal probe electrician recommended for mass production, and at ENEA USSR awarded a bronze medal.

V. GUREVICH

Recommend to read FLOATING WITH A CAR It's good to live on the bank of a wide, full-flowing river! True, this convenient transport artery often becomes an annoying obstacle to communication between settlements. A motorist... CABIN BOAT “RUSLAN” — Look, look — the Martians! surprised and enthusiastically shouted we met the boys when Ruslan, bristling with television and radio antennas, approached the pier. We looked at each...  electrical Work on a modern industrial enterprise impossible without measuring instruments, many of them are very complex.

electrical Work on a modern industrial enterprise impossible without measuring instruments, many of them are very complex.