Pushkin “Ah, summer red, I would love you, if not for the heat, and dust, Yes mosquitoes, Yes flies” not to recall with the advent of the hordes of winged insects that spoil our mood more than heat and humidity. And then remember the promotional video: in the fight with the flying vermin are becoming increasingly prevalent electronic protection. A few behind the effectiveness of chemical pesticides, it is more gentle to the environment, and this is now of the essence.

Pushkin “Ah, summer red, I would love you, if not for the heat, and dust, Yes mosquitoes, Yes flies” not to recall with the advent of the hordes of winged insects that spoil our mood more than heat and humidity. And then remember the promotional video: in the fight with the flying vermin are becoming increasingly prevalent electronic protection. A few behind the effectiveness of chemical pesticides, it is more gentle to the environment, and this is now of the essence.

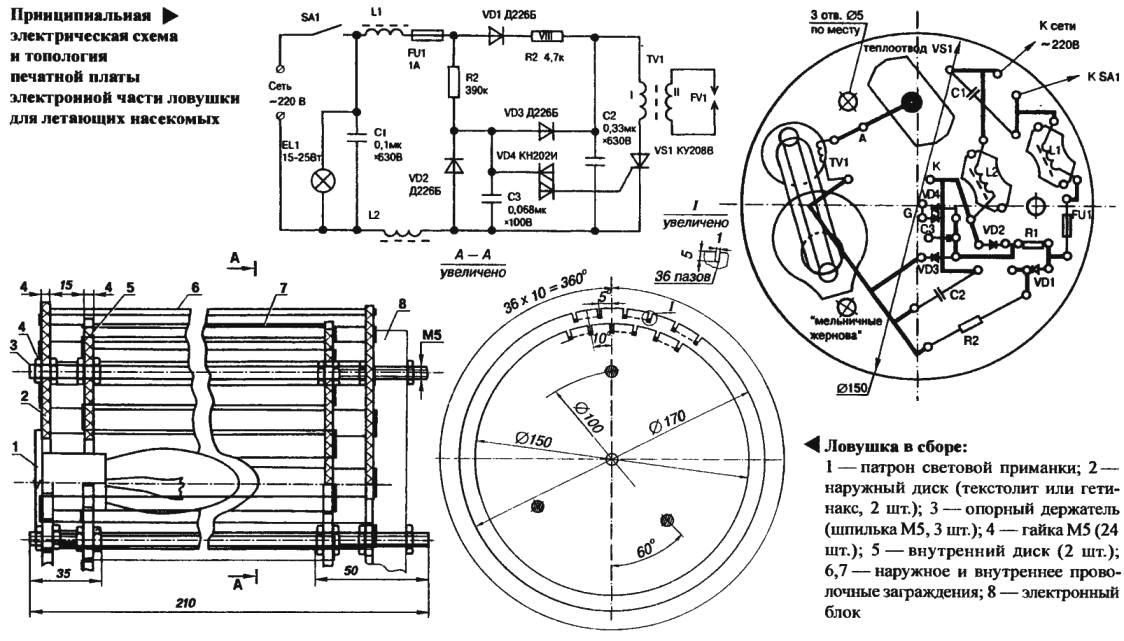

Popular Romanian edition RADIOTECHNIKA describes the original self-made trap insects, acting on the principle: to lure and “electric chair”. Day bait for insects in this trap — selenophene substance, and with the onset of dusk and the night — light trap at the base of a small incandescent lamp. A punishing weapon in any case is double row wire fence, connected to an electronic high voltage unit.

The wires are located from each other at a distance, as close as possible to elektroprovodnoi strength of air. Flying such a barrier, any insect reduces the critical gap. Should a high voltage electrical discharge, and the insect dies.

Being composed of a network of protective (noise) filter electronic regulator, high voltage transformer and double row wire fence (switching spark gap), the device works flawlessly. With its inclusion in the network starts through the filter, rectifier diode VD1 and the resistor R2 to charge capacitor C2 to the amplitude of 310 V. This voltage through the primary winding of the transformer TV1 goes to the anode of the thyristor VS1. On the other branches (R1VD2) slowly charging C1. When in the course of charging of the capacitor breakdown voltage is achieved In 25-35 dynistor VD2, the capacitor C3 begins to discharge through the control electrode of the thyristor VS1, opening it.

Now (already through the open thyristor and the primary winding of the transformer TV1) the capacitor C1 is very rapidly discharged. The resulting current pulse induces in the secondary winding II of “tnik” voltage, the value of which can exceed 10 kV. After the discharge of the capacitor C1, the thyristor VS1 is closed and the operating cycle is repeated. Recruiting will Shine the lamp EL1, trapping winged insects in the electronic trap — double row wire fence.

The values of resistors, capacitors, inductors and semiconductor devices shall be as specified in the scheme. Especially hard these requirements in relation to the high voltage unit. Transformer for him going on the basis of “tnik” of any TV. The primary winding is removed, and in accordance with its size set new — 25 turns of wire ПЭВ2 (and PEL) with a diameter of 0.8 mm. as a suitable winding II is defect-free increases (from the transformer line scan also virtually any TV black-and-white image), which was fixed for the unofficial title of “millstones”.

Work high-voltage transformer in some quiet time “grumpy”. However, these workers sounds even need, because they indicate the presence of high voltage (for example, when the electronic trap suddenly burns out the bulb). Generally, noiseless high-voltage unit can even pose a danger to careless approaching and unsuspecting person.

Bandstop filter in the input circuit is a necessary companion of any equipment, having in its composition controlled thyristor. Self-made trap-shredder is no exception, as no filter can create television and radio interference. Good protective filter high frequency inductors, wound on ferrite cores. Here each coil contains approximately 20 turns of wire ПЭВ2 (PEL) with a diameter of 0,6—0,8 mm.

The most difficult for making host design — double row wire fence (high-voltage discharger). Base to provide two pairs of disks cut from a good insulating material (e.g., from 4 mm textolite, Micarta or acrylic). On the perimeter of the disc every 10° 36 propisyvayutsya jig saw grooves to a depth of 5 mm.

The drives are mounted on three bearing holders — pins M5, length 210 mm, one end of which thread is made on the length of 35 mm and another 50 mm.

The discs under studs drilled three holes with a diameter of 5.1 mm, located on a circle with a radius of 50 mm through 120°. To this end, the center of each disk is a technological hole M8 or M10. The discs are collected into a bundle so that cuts some was offset cuts in other by 5°.

After marking and drilling holes with a diameter of 5.1 mm discs are mounted on the ends of the studs in pairs (big outside, small inside) and fixed with nuts at a distance of approximately 15 mm from each other. The bottom frame will be all of those things that are fixed on the ends of the rods with the longer, and cover with a shorter thread.

In the center of the lid with a jigsaw propisyvayutsya hole chambered for light lures. The mounting must be such that you can replace the bulb without dismantling the barbed wire (for example, securing the lamp holder on the outside). All dimensions depend mainly on incandescent lamps. Better if light lure will be a Mignon lamp.

For boom desirable bare copper wire with a diameter of 0.45—0.5 mm. It is stretched in the first grooves on the inner (small) disks, and then on the outer (large).

When using wires of the type ПЭЛ2 (or sew) a few work added: after all, the wire will have to remove the enamel insulation.

The finished structure is fixed on a plastic box, which serves to accommodate electronic parts of the trap. Of course, that the shape and size of this box must match the device’s circuit Board.

With the first inclusion in the network self-made protection from flying insects illuminate indicator light, signaling that everything is okay. About the same evidence and quiet “grumbling” of the device, warning about the presence of high voltage.

Through the double barbed wire should not slip sparks. If this occurs, the voltage of the high voltage unit is required to reduce the control electronic circuit for fixed geometrical dimensions of the wire spark gap.

The test ends with a test of electronic traps on sparking. Tools — a conventional screwdriver. When prosovyvaniya her metal rod between the two rows of wire need to have both sides throwing out sparks. Large internal resistance of the transformer itself protects against dangerous (for the person) amount of current during the formation of the discharge. But still must comply with the rules and restrictions when carrying out any work on the technique, which may be under high tension in the manufacturing process and during its operation.

N. KOCHETOV