In the design of devices and equipment before the radio often question about their design: sometimes they place boards and panels of their devices in boxes that slides, fishing gear and other containers. Ham D. Plewinski offers as buildings to use more modern products — cases videokasset: they have a low cost; plastic from which they are made, can be easily processed.

In the design of devices and equipment before the radio often question about their design: sometimes they place boards and panels of their devices in boxes that slides, fishing gear and other containers. Ham D. Plewinski offers as buildings to use more modern products — cases videokasset: they have a low cost; plastic from which they are made, can be easily processed.

However, for these purposes can be usefully applied and what is now just thrown in the garbage, namely: rigid food packaging, plastic bottles, drinks cans of coffee, etc., especially because many of these containers have a unique shape and a beautiful texture.

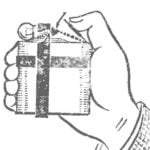

In a conventional tin can, for example, can accommodate a generator, a probe or “lotion” for the guitar (Fig.1). If the old cover was broken and it cannot be used, should be cut and the new solid material, in the same form. For securing the cover to the wall there are three small aluminum angle with threaded holes M2… M3 in both shelves. The connection of the parts is appropriate screws through the holes in the wall and the lid. This case will serve as a screen against electromagnetic fields.

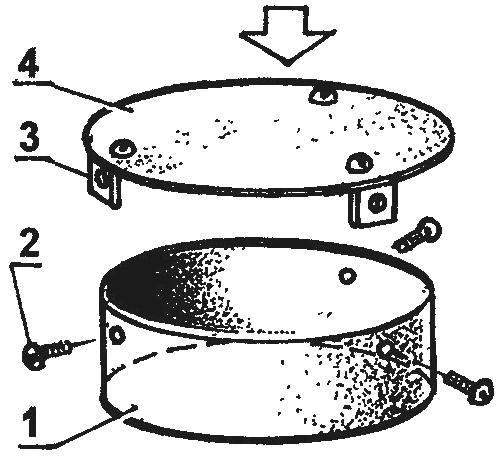

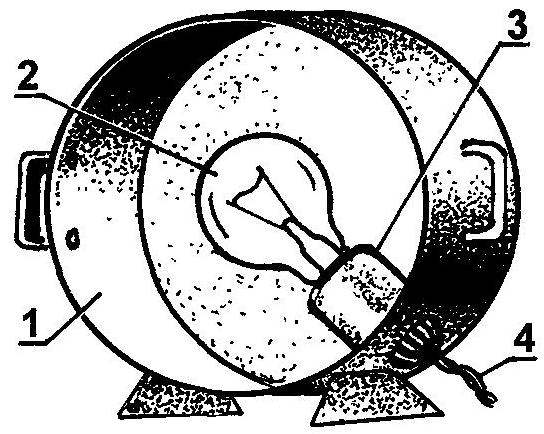

Simple but well built flashlight for UDU is made of a suitable low metal cans of coffee (Fig.2). For this we need only in the side wall of the banks to cut a hole for a light socket with a base “minion” and soldered to the wall of the two legs. The legs arch out of steel wire with a diameter of 1 mm.

Fig. 1. The housing for the generator-probe:

1 — body (low tin tin); 2 — screw M2—M3 (6 PCs); 3—aluminum bracket with the screw holes (3 PCs) 4 — cap banks

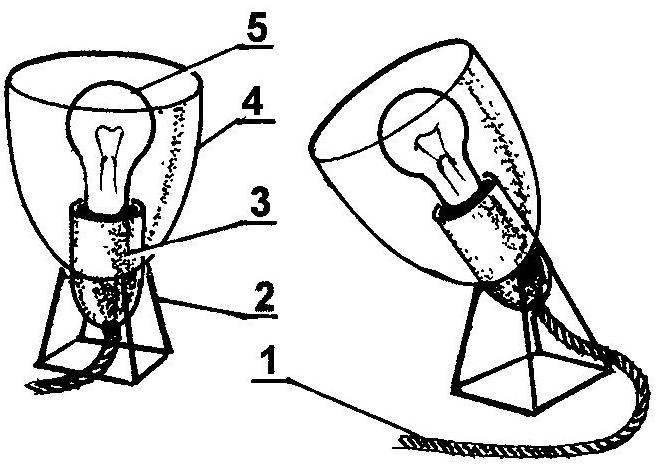

Fig. 2. Flashlight for sdes:

1 — reflector (low tin coffee can); 2—bulb (N<60 watts); 3—cartridge-Mignon; 4 — leg (wire Ø1, 2); 5 — connecting wire

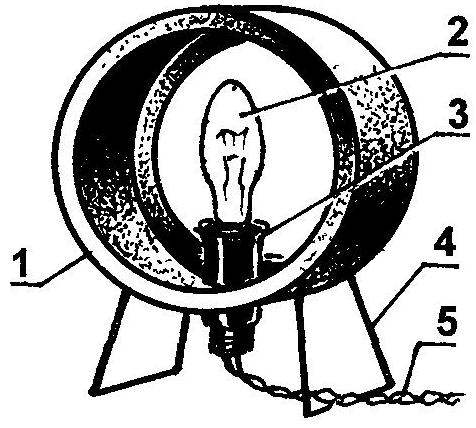

Fig. 3. The location of the electronic device in the case of a horizontally placed coffee cans:

1 — body (spray dried coffee); 2 — panel LEDs; 3 — control unit; 4 — connection wires; 5 — feet (acrylic, 2 PCs.)

Inside a tall metal coffee cans also possible to mount necessary electronic or radio devices. Position the Bank better horizontally (Fig.3). Supports are made of plexiglass to attach to the walls on glue.

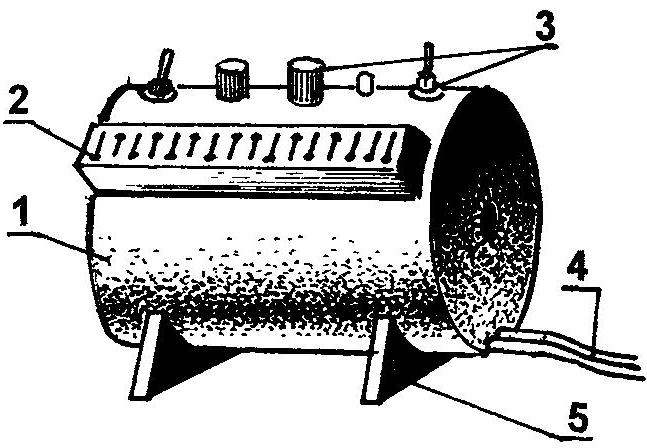

When there is a need to place the components of the device in separate buildings or when the device is in a jar just doesn’t fit are the “tandem” of two cans or even three groups (Fig.4). Banks are among themselves connected by bolts M2…M3 via vertical strips of metal or plastic. In the latter case, under heads of bolts and nuts put washer increased outer diameter.

Handheld radios usually assemble in bodies in the form of a rectangular parallelepiped. A classic example is the location details diagram in a conventional soap dish. However, the radio can be laid out differently, using as case the plastic cups (Fig.5). The PCB (like a magnetic antenna) it is better to place along the hull (horizontally or vertically), and mount it aligning capacitor and volume control. The battery, as the most massive component is placed in the lower part. A speaker mesh is at the same time a removable cover for replacing the power supply. The receiver was solid on the sides of the hull in the lower part to attach small stops from wire or plastic.

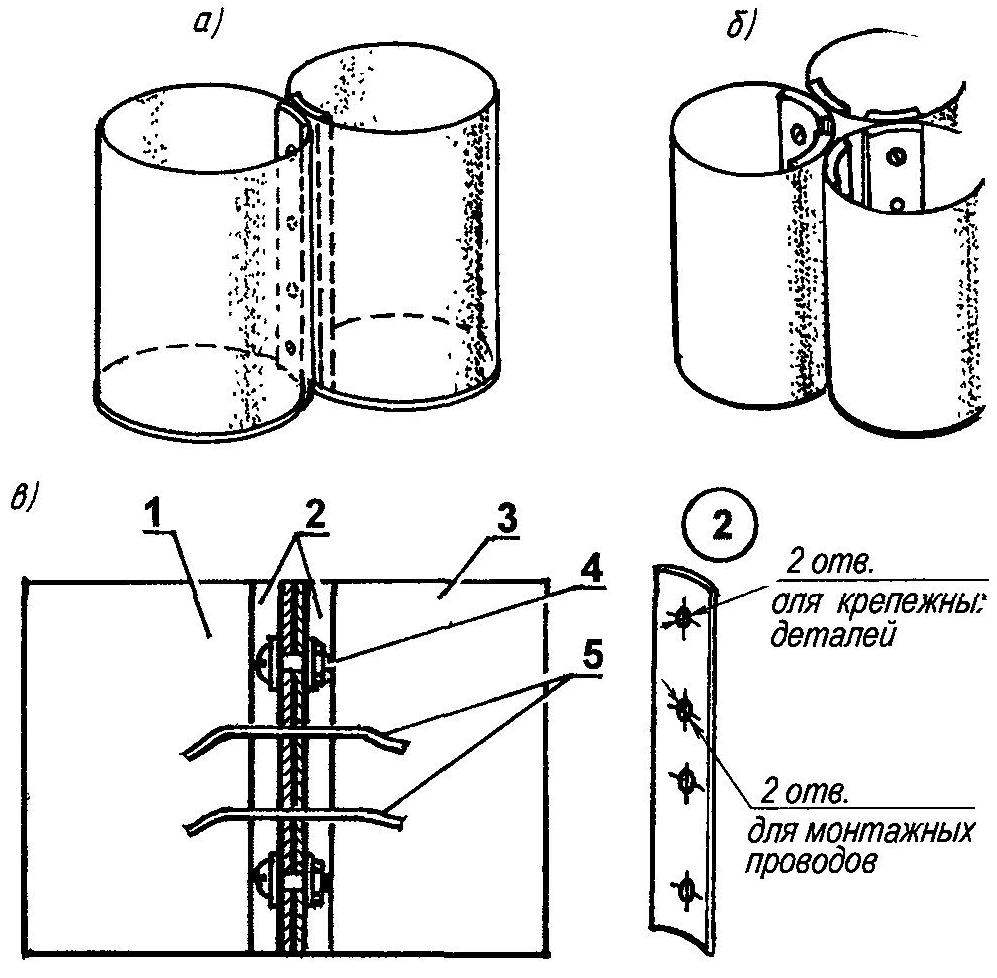

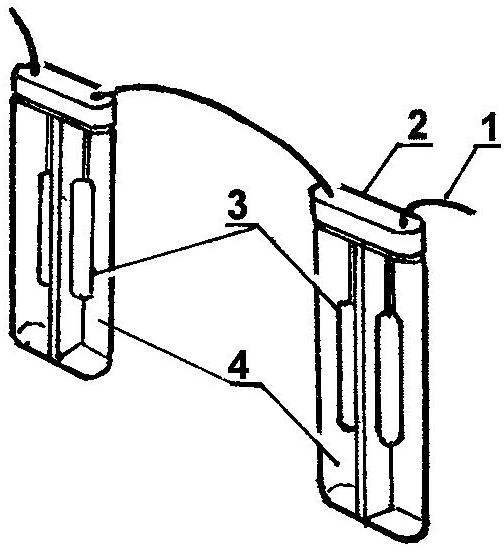

Fig. 4. Composite case (and of two cans;—three jars; in the context of joint):

1—first Bank; 2—plates (Plexiglas, aluminium, 2 pieces); 3 — the second Bank; 4 — fasteners (bolt M2 — M3 2— 4 units); 5 — mounting (connecting) wire

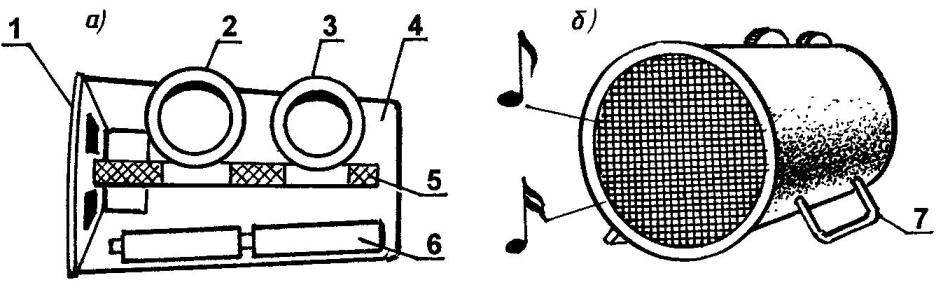

Fig. 5. The radio in the hull of a plastic Cup (a—layout, b—General view):

1—loudspeaker; 2—setting knob; 3—volume knob; 4—body; 5—charge; 6—battery; 7—an emphasis (wire, 2 PCs.)

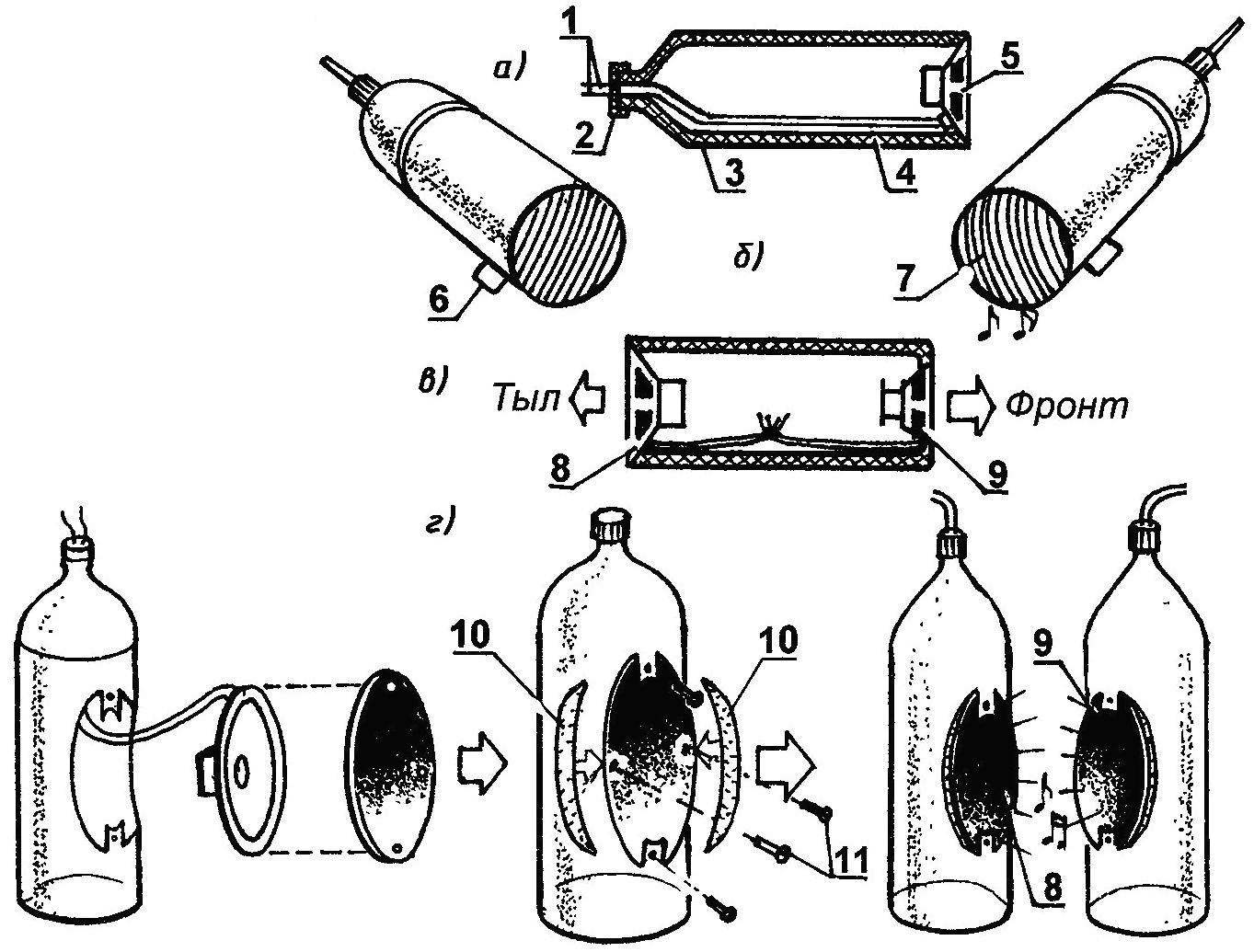

Fig. 6. Speaker system with speakers in housings made of plastic bottles (and the arrangement of acoustic element; b—the location of the speakers, the high and low frequencies; placing the speakers high and low frequencies in a single housing; g—technology manufacturing speakers with side-firing loudspeaker):

1—hook up wire; 2—cover; 3—housing (plastic bottle); 4—sound insulation (foam); 5—single loudspeaker; 6—lateral stop (2 PCs. per column); 7—decorative mesh; 8—loudspeaker low-frequency (LF); 9—loudspeaker high-frequency (HF); 10—plastic inserts; 11 screws M3 (4 pieces)

Buildings improvised acoustic systems (as) can serve plastic bottles (Fig.6). The variability of amplitude-frequency characteristics of the internal part of the bottle paste over the foam. If the speaker is placed in the bottom of the bottle (Fig. 6A, 5), for it is here cut through the hole. Leads are taken out through a hole in the lid. You can place the speakers in the corpus such as “column” 6АС-2: front—high, rear — low frequency (Fig. 6b). Figure 6g shows a sequence of manufacturing “speaker” side speaker. At the side of the bottle cut a hole previously prepared dynamic head (in this case, head with an elliptical cone, for example, 1ГД-18 or 1ГД-40). The ears are left holes, which are heated by the burnt nail holes for fastening them with two screws M3 speakers (Fig.6). The front of the speaker is covered with a metal grid. Side clearances between the speakers and enclosures are Packed with strips of plastic cut speaker holes.

The sound quality of homemade speakers, likely to be worse than the industrial, but it’s still better than the “naked” speakers, and the cost is minimal.

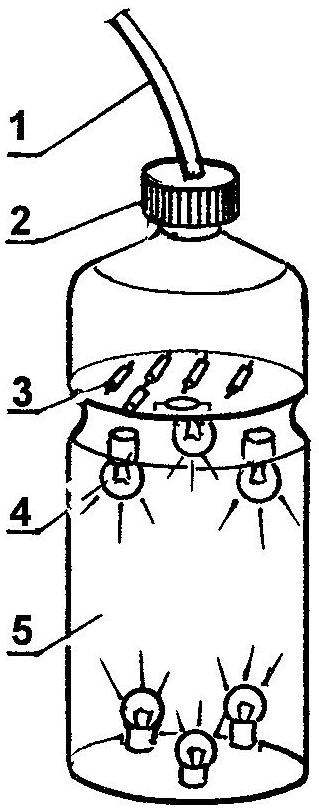

Transparent plastic bottle can be used as a housing mini-TSMU—color musical installation (Fig.7). Before you place the panels with colored light bulbs in a bottle, the latter should be cut down. Electronic circuitry can be placed outside the “screen” and inside it in the upper or lower part.

From the necks of plastic bottles you can make a mini-floodlight for TSMU—like parabolic reflectors (Fig.8). The side walls are pasted over on the inside with aluminum foil, bulb (automotive type) should try to set so that the luminous flux was parallel. Legs are made from wire with a diameter of 1 mm (or take a bottle of champagne) so you can change the angle of miniprojectors. These mini-projectors are designed to work of TSMU or CDS only in a pulsed mode, as plastic can melt from the heat.

From used clear plastic lighters you can make filters for lights, and inserting into each 1-2 lamp-type switch and closing the top with insulation (Fig.9).

Fig. 7. Mini-TSMU (color-music) in a plastic bottle:

1 — power; 2—cover; 3 — parts of electric circuits; 4 colored bulbs (as required); 5—case-screen (plastic bottle)

Fig. 8. Mini-lights color-music settings:

1 — power; 2—leg (wire Ø1); 3 — cartridges (automotive); 4—reflectors (the necks of plastic bottles, covered the inside with aluminum foil); 5—light bulbs (car 12V)

Fig. 9. Filters of transparent lighters:

1—power; 2—cover; 3—lamp; 4 — casing

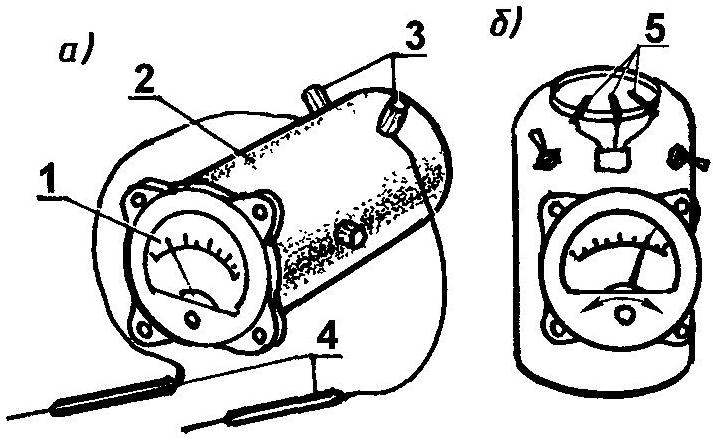

Plastic banks (e. g., glue) can be used as housings of measuring instruments (Fig.10). In the first case, the galvanometer is the end of a cylinder, and the front clip on the sidewall of the housing (Fig. 10A). If the diameter of the measuring device smaller than the internal diameter of the housing, the device housing is installed through the adapter cut from a tractable material, such as foam. In the second case, a measuring instrument mounted on the sidewall of the enclosure and input jacks (or clamps) placed on the panel, reinforced top (Fig. 10B). While the details of the scheme inside the case should be placed so that the device is not dumped to the side.

The housings radiokonstruktor presented this requirement as strength. In principle, for cases of improvised devices can be used even thin, but any plastic containers, but they need to glue the inside with fabric, for example, cotton, impregnated with an epoxy adhesive (in one or several layers) — previously cut from the fabric of the workpiece corresponding to the shape of the bottom and sidewalls of the housing.

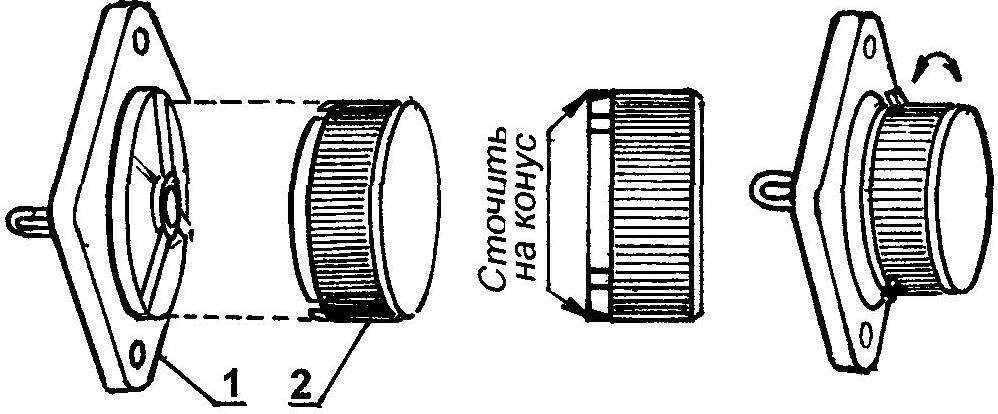

If no factory handles for loosely variables such resistors can be made of the caps from tubes of creams, toothpastes, etc. (Fig. 11). The cap is heated on the fire with a screwdriver make a hole for the potentiometer so that the potentiometer knob and the cap coincides to the axis of rotation.

Fig. 10. Measuring instruments in cases made of plastic cans (and horizontal location of the body; b—vertical design):

1 — measuring device; 2 housing (plastic Bank); 3—input clamps, 4—probe; 5 — input jacks

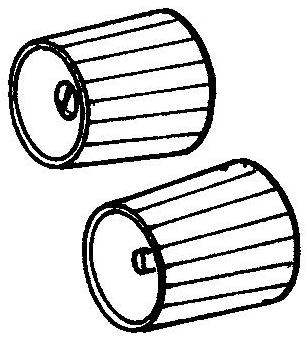

Fig. 11. Handle variable resistors (potentiometers) from the caps of the tubes

Fig. 12. Pen trimmer capacitor from the lids of plastic bottles:

1—fixed condenser; 2—handle (the lid of a plastic bottle)

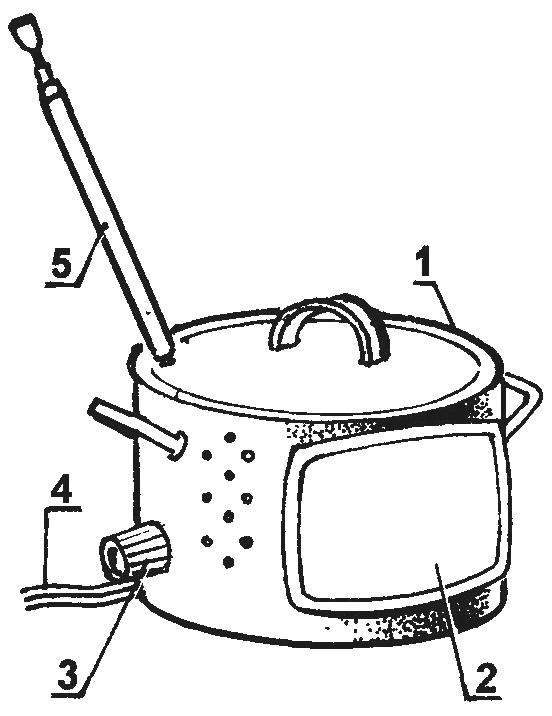

Fig. 13. Spotlight from the pan with stainless steel housing:

1 —housing (stainless steel pot); 2—light; 3—insert; 4 — power

Fig. 14. Pot with blue screen:

1—housing of the TV (pan); 2—shadow revisionday receiver; 3 — volume knob (from a tube); 4—power supply cable; 5 — antenna receiver

Plastic caps from plastic bottles almost perfect pen trimmer capacitor CCP-2 and CCP-3, which young Amateurs are often used in homemade radios (Fig. 12). Lid pliers or heated on the fire with a screwdriver doing three slots at angles of 120° to each other so that they came in three spring-elastic element located on the rotor of the capacitor. The lid should also be a little to wet under the cone is the part that will enter the rotor of the capacitor. So podstreshny is fixed on the outer shell of the receiver with a single (CPC-2) or two (CPC-3) screws with nuts.

The dustbin is thrown a lot of kitchen utensils, such as pots. However, they can also be used as housings or radiokonstruktor lighting products need only to comply with the rules of electrical safety. For example, can be made quite powerful spotlight from the stainless steel saucepan (or paste over the inner surface of the enameled pots shiny foil), securing the sidewall ceramic cartridge with bulb (Fig.13).

Inside the pan is even possible to fit a small television receiver (Fig. 14). It is only necessary in the side wall to neverlet holes for ventilation. Maybe someone thinks that this design is rather from the field of humor, but the TV will perfectly fit into the interior of the kitchen.

A. BRANITSKY, Minsk, Belarus