The plot is watered down to predetermined humidity. Humidity controller is triggered, and the relay K2 opens its contact pair K2.1 and K2.2. Stops the supply of power to the traction relay. The recoil spring is compressed, closes the valve and leads to the original position solenoid: watering stops. The device may repeat the above operation several times within one inclusion. Upon expiration of the time allotted to the device, the contact K1.2 opens. Food stops, the machine switches off.

The device can launch at any time. You just need to click on 2…3 button SBI, is connected in parallel to contacts hours.

The scheme of connection opening and closing valve of the mechanism shown in figure 4. Length of the traction plate depends on type of used crane, and the power of the traction relay. Approximate length: 45 mm, width 10 mm, thickness 3 mm. A solenoid switch is mounted on the metal plate-rack, the bent radius on both ends. One of them has the same diameter, which is the case of the traction relay, the other — as feed pipe. Such a design has the strut, which is geared recoil. Types of racks are shown in figure 5.

The device can be applied and improvised traction relay. The cut shown in figure 4. These windings and the dimensions of the parts given below. Device drawbar — figure 6.

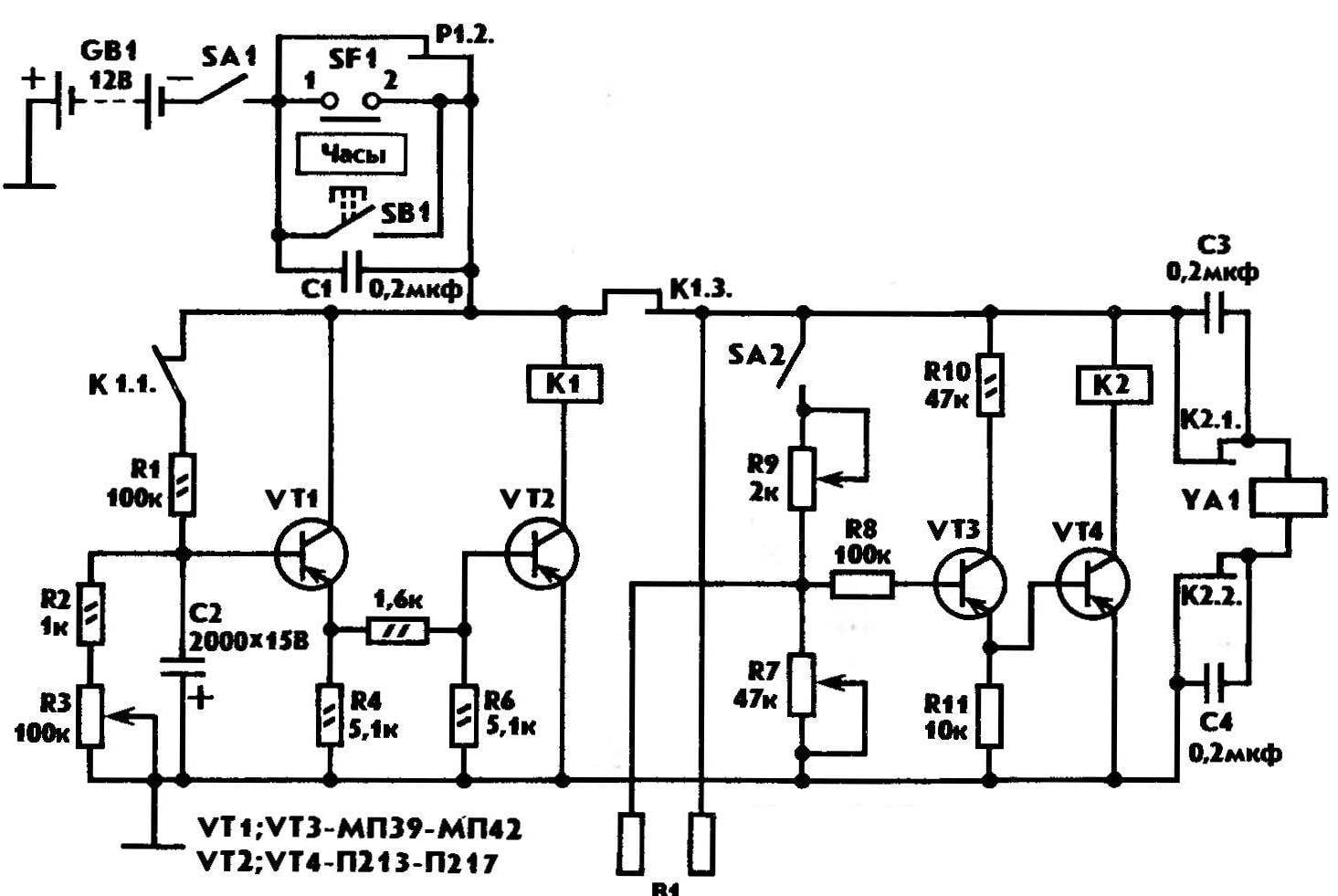

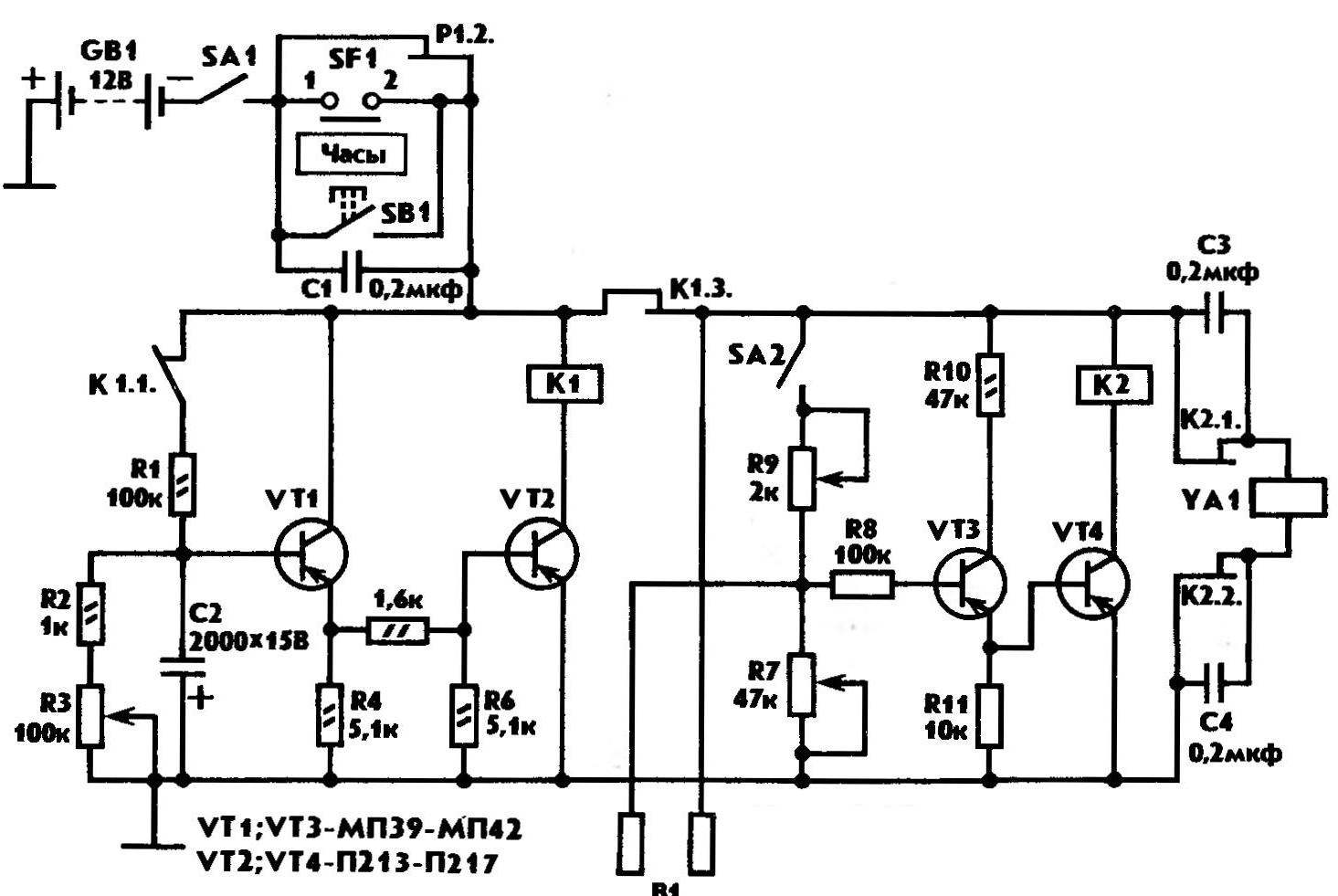

Now about the device used in detail. The data of the resistors and capacitors shown in the diagram (Fig. 1), the button — bell. Transistors: /T1, VT2 — low-power, low-frequency, p-n-p type, VT3, VT4 — any larger or medium-power, R-p-R type (for example, a series KT816).

As a K1 you can apply relay RES—22 (passport RF4. 560.163) or other similar relays (one with normally closed pair of contacts and two normally open), reliably trigger voltage of 10-12 V.

The traction relay has two windings. One is used to obtain the stationary magnet and the second to move the traction rod. They are connected in parallel. You should consider the fact that the winding must be wound in different directions. The winding can be wound in one direction, but then the first end must be connected to the beginning of the second, and the beginning to the end of the second. Each winding comprises at 5720 turns. Winding is wound with a wire PEL-1 to 0.5.

The enclosure must be made of non-magnetic material, brass or aluminum.

Move drawbar — 40 mm, diameter 30 mm, length 90 mm. To facilitate core of its nasal part worn down to 10 mm, it is propyl depth of 10 mm, a width of 3-4 mm. It is used for connecting the rod with the pulling plate.

The transformer of the power supply is wound on the core Network Ш25х71 mm. coil, designed for 220 V, contains 550 turns of wire PEL-1 0.5 (127 V — 320 turns of the same wire). The secondary winding is designed for a voltage of 12 V and contains 30 turns of PEL-1 to 0.9. Windings are isolated from each other cloth insulating tape, or varnished cloth. The assembled rectifier diode series Д242. The filter capacitor (C2) has a capacity of 1000— 2000 UF, the voltage of 12 V.

The power supply can be placed in a common housing with a gun, and in a separate case.

If the correct Assembly of the establishing device is configured for the desired percentage of moisture watered plot. May experience some difficulties when setting up the mechanism for opening and closing the valve. In this case, you need to pick up the return spring at which the solenoid will begin to operate normally. Instead of the spring can be applied to ordinary, quite elastic, the elastic, able to ensure reliable operation of the mechanism.

It is particularly convenient to use this machine in greenhouses and greenhouses. Applying the system of automatic ventilation, they can be made fully automated.

Yuri YUDIN, g. Safonovo, Smolensk region.

Many plants, like tomatoes, during its growth and fruiting require a lot of moisture, so they often have to be watered, especially in hot season. The proposed machine will help you save valuable time and eliminate the need to be constantly “tethered” to their Pets. Just turn on the power and set the clock correct time of watering. The device is simple to manufacture, and at the same time it is reliable in operation.

Many plants, like tomatoes, during its growth and fruiting require a lot of moisture, so they often have to be watered, especially in hot season. The proposed machine will help you save valuable time and eliminate the need to be constantly “tethered” to their Pets. Just turn on the power and set the clock correct time of watering. The device is simple to manufacture, and at the same time it is reliable in operation.