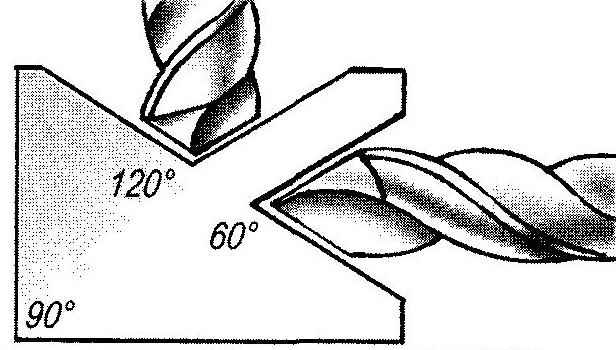

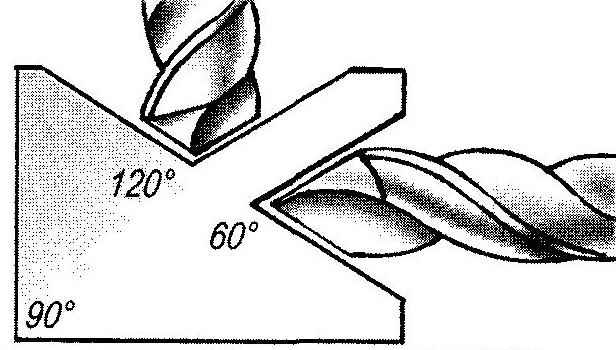

Depending on the processed material from each drill must be properly sharpened. To verify the correct angle will help a specially prepared square plate of copper or aluminium with a thickness of 1 mm.

Depending on the processed material from each drill must be properly sharpened. To verify the correct angle will help a specially prepared square plate of copper or aluminium with a thickness of 1 mm.

To become operational protractor enough to cut it cut, as shown in the picture: a large cutout at an angle of 120 degrees, the other half is 60 degrees and the surviving corner of a square is 90.

Recommend to read

LOOSEN CLIP

LOOSEN CLIP

Today there is no problem with the acquisition of standard garden tools, whether a shovel, rake, hoe. However, some work to do with the special tool still more effective: the performance... Tricopter with a video camera

Tricopter with a video camera

I spent all summer with her son, a soldering iron and Arduino IDE, not in the field with a copter, so now my free translation of article Swede David Windscale (David Windestål, I hope...

Depending on the processed material from each drill must be properly sharpened. To verify the correct angle will help a specially prepared square plate of copper or aluminium with a thickness of 1 mm.

Depending on the processed material from each drill must be properly sharpened. To verify the correct angle will help a specially prepared square plate of copper or aluminium with a thickness of 1 mm.