quickly and Easily you can make gears on a lathe with modular knurling. But the trouble is that this tool is so scarce that not even all the modelers and heard something about it. However, modular knurling successfully replace… ordinary gear! It is important only that it was made of high quality steel and well hardened, and the teeth should have enough sharp peaks.

quickly and Easily you can make gears on a lathe with modular knurling. But the trouble is that this tool is so scarce that not even all the modelers and heard something about it. However, modular knurling successfully replace… ordinary gear! It is important only that it was made of high quality steel and well hardened, and the teeth should have enough sharp peaks.

For highway car suitable gear with a module of 0.4—0.5. Before you start rolling teeth calculate the diameter of the workpiece according to the formula:

D=m(z+ 2), where D is the diameter of the workpiece, mm; m — module; Z — number of teeth of the gear.

Treatment using improvised modular knurling easy to brass and bronze, if you need gears made of steel — good gear-knurling will cope with this task. For upscale models, the engine revs up to 40000-50000 rpm, we can recommend production of blanks of annealed high-quality steel with quenching after rolling teeth.

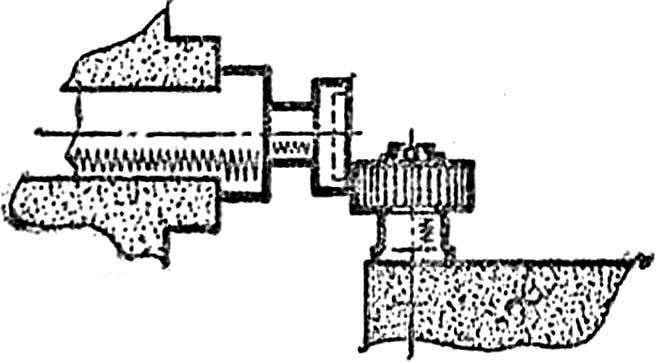

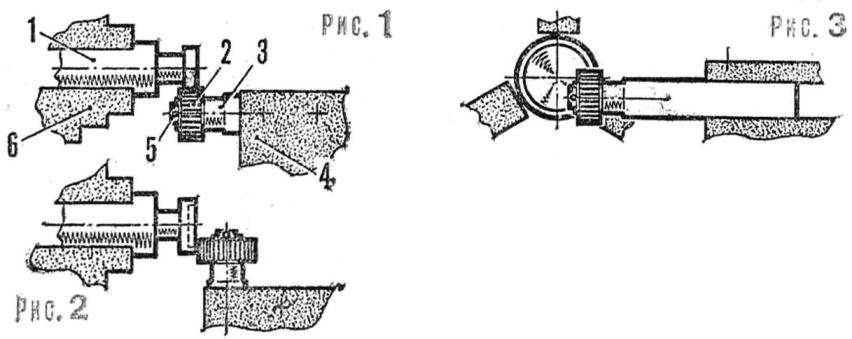

Fig. 1. Rolling of cylindrical gears:

1 — workpiece, 2 — modular knurling. 3 — holder, 4 — way tool post of the lathe, 5 — locking pin or lock washer, 6 — cartridge machine.

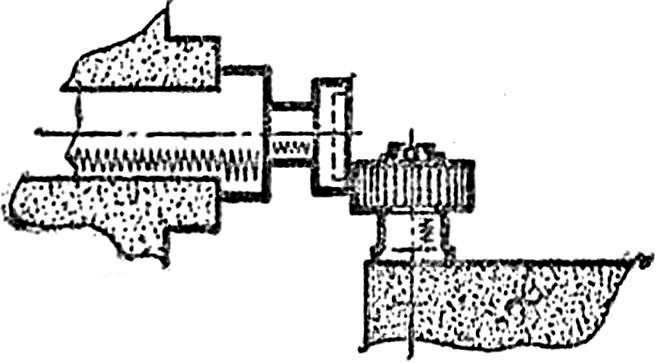

Fig. 2. Rolling disc of gears.

Fig. 3. Rolling disc hypoid gears.

On a lathe able to perform not only the conventional cylindrical “zubchatki”, but disc gear, both conventional and hypoid.

Try our method in the case, you will not regret the manufacture of all gears will give you pleasure!

A. BELOV, head of the society autocrossover modeling