Height of rig from the deck, mm: 950

The height of the head sail a triangle from the deck, mm: 750

Sail area, m2 : 0,2

The amount of lat at the grotto: 4

on the jib 3

The length of the lat at the grotto, mm:

average — 80

extreme — 60

Lat length on staysail, mm: 30

The width of the base plates palovich angles, mm:

the grotto — 15

on the staysail — 12

For the construction of this microage’ll need to cut from plywood 4 mm thick (suitable construction, although preferably aviation) the jig-template. It consists of two elements: the “plane” and “template deck”. After finishing of workpieces to the exact dimensions of both plates are glued together perpendicular to each other with a combination of marking lines of “frames”. Then prepare seven plywood templates of the cross sections of the body.

In cemented angular pattern on PVA are installed on both sides of the case are foam cleats 85X95X750 mm. They can be combined of several parts. Pre-bars are mounted “on point” in the bow and stern. After gluing (nitrocream cannot be used — it dissolves the foam) parts are cut on vibrolance pattern. The final profiling is performed using a thin sharp knife, made of canvas luchkovoj saws, and emery paper. Having an exact match of cross-sections of workpieces of the case “samotnym” patterns, they are carefully separated from the conductor and fixed with PVA on the finished keel plate.

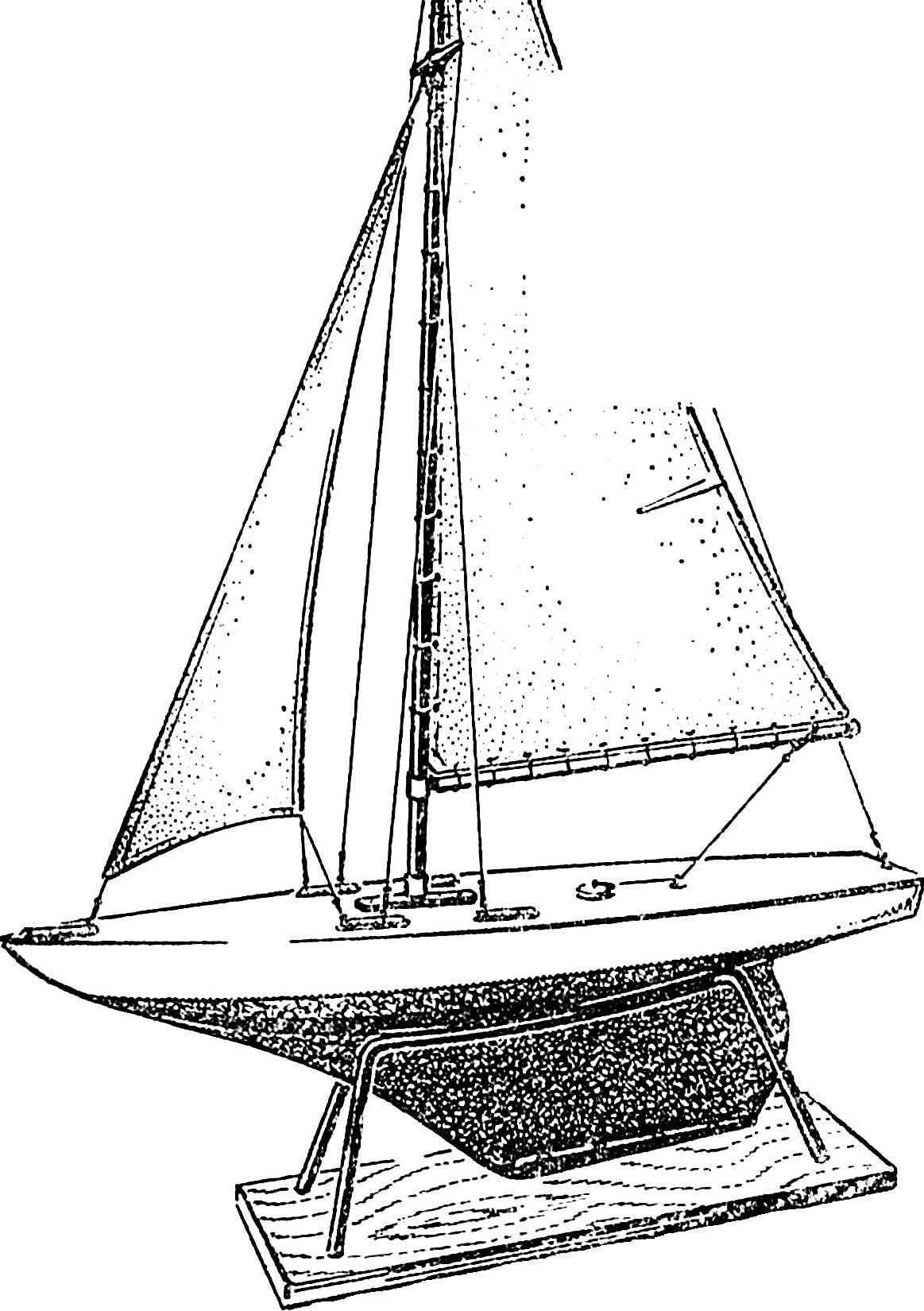

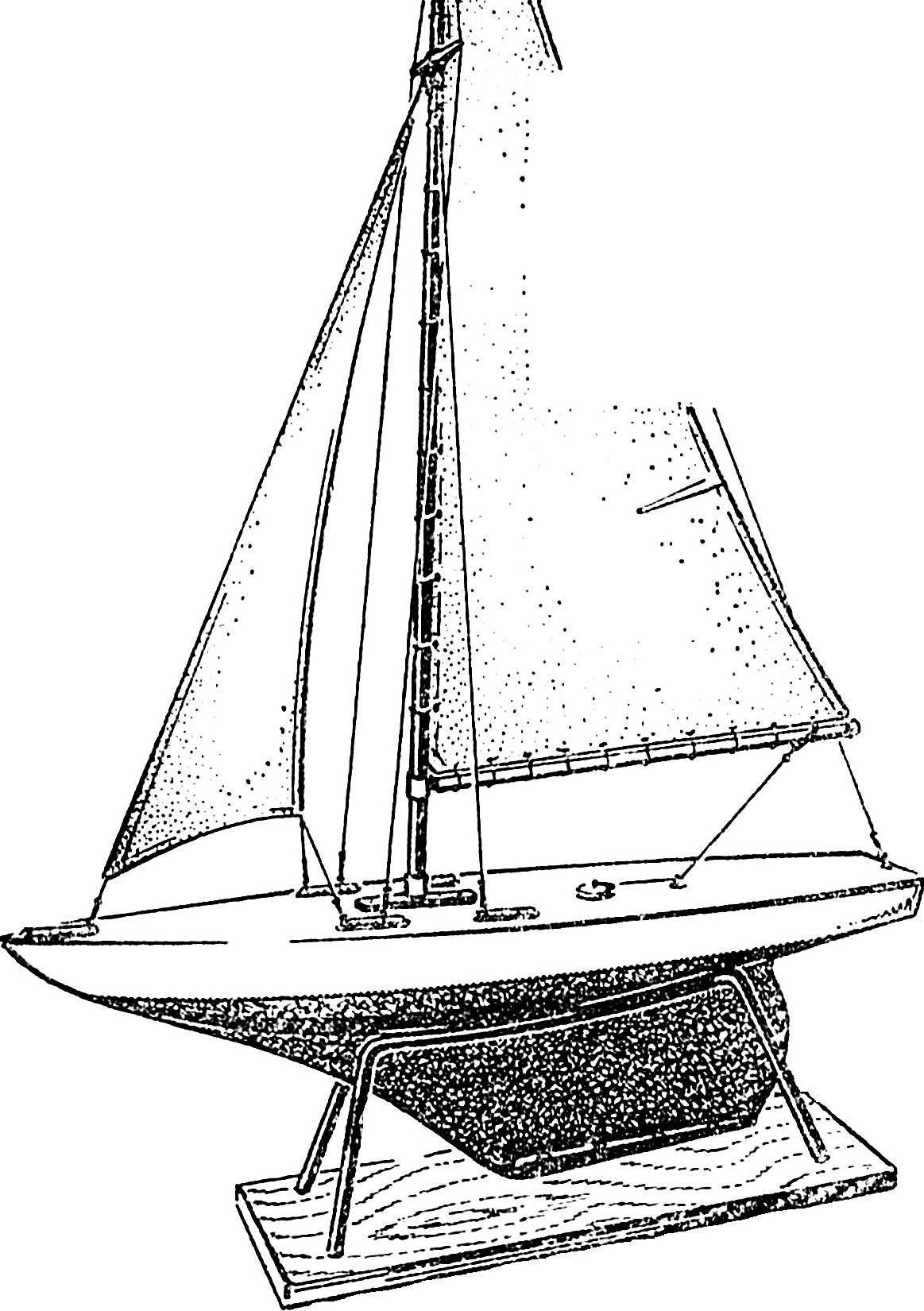

Fig. 1. Model yachts with bezrabotnym case:

1 — body, 2 — shtag-potens, 3 — forestay, 4 — jib, 5 — guys-potens, 6 — mast, 7 — the gaff rig, 8 — romanti, 9 — Grot, 10 — guy, 11 — aftersteg, 12 — mainsail, 13 — boom-sheet, 14 — imitation of the winch, 15 — keel plate, 16 — plate.

On a diametrical plane in foam cuts Midel’veys of pine slats 3X20X750 mm, and on the sides of the attachment points of vant-putenkov rail 3X20X200 mm.

To reduce the consumption of epoxy glue and to reduce the mass of the model, it is useful to wrap a case with a newspaper on liquid PVA glue. After it dries prosceniums body, covered in epoxy resin and cut fiberglass sheets. When the epoxy cured, the workpiece pressurewhat on the deck to a plane using a large sheet of sandpaper mounted on your desktop. The deck is closed with a sheet of plywood or a layer of fiberglass.

Finished case again carefully vyshkurivaetsya and then painted. On the deck on the DP installed metal steps-plank with holes for the pin on the spur of the mast, cut and glue to the forestay – and vant-potency mounted “sheet winches” and the rings for the transaction of the boom and the jib of the Scots.

Fig. 2. The conductor pattern of the case with installed foam block on one side.

Fig. 3. Templates and body parts.

Round the mast vystrugivajut from a light grained wood. Length — within the rules — 910 — 945 mm, the cross section of the NOC of the mast is 6 mm, middle part — 12 — 16 mm, spur — 10 mm.

Spurs is enhanced by a metal ring with a height of about 10 mm, bottom axis is screwed a brass screw. After trimming head needs to be holes stepsaway strap. End of the boom is hung on the hook, soldered to mounted on the mast second metal ring.

For a geek, try to find solid wood. After mounting the ferrules serverlists holes to bind the boom-sheet.

The gaff rig can be beech, plastic or aluminum. In the center of the billet is drilled a hole for the mast, and then the gaff rig is maximally facilitated.

Mounted on mast standing rigging is made using mortise chick — plates of solid wood mm. размером3Х7Х10 Waiting for the complete curing of the adhesive, they attach to the required form. In conclusion, the metal parts of the mast to Polish and wood varnish.

Standing rigging (shrouds, forestay, the forestay and aftersteg) — of nylon fishing line or steel wire.

The fabric for the sails in front of the crack needs to be washed and ironed. She applied templates (across the cloth!), encircle them with a pencil and on the obtained contour are doing two or three lines a thin thread. On top of them are seam zigzag and then trim the excess material. To sail sew lat pockets and plates palovich angles. Pattern smooth iron and according to the preliminary layout pressurewhat to the mast.

Developed but still not fully tested, another method of manufacture of sails, when the lacing pattern is replaced by the impregnation of the edge of the cloth with white glue. Technology works with sails from Mylar film to stay is not necessary — it is well known modelers.

In conclusion, the finished model is very lightweight, its body weighs just 450 g 750-800 g vs obtained by classical methods of construction with a stacked frame and plywood sheathing.

With case mixed design

The draft of this microage was based on the real “star” class, with a stacked body and angular lines of the type “Sharpie”. To reduce the weight of the keel plate in comparison with the first option changed its shape.

Fig. 4. Boat model with housing mixed designs (designation of elements in Fig. 1.). Stand can be used as a bench during Assembly of the housing.

Fig. 5. The details of the case.

Fig. 6. The Assembly of the frame body.

Fig. 7. The case with partially foam-filled sections set.

In the manufacture of such model patterns of cross-sections is not required. Instead, they applied conventional plywood formers, which are mounted directly on the keel plate. After mutual adjustment of these parts and Midel’veys set set on the table the keel up, the frame is aligned and the joints spilled epoxy. Now it is time for installation of elements of the longitudinal set of the housing. It Reiki at the time of bonding tied to the ends of the soft wire.

Waiting for the curing of the adhesive, frame Malchut large cloth, pasted on the plate of hatred. Between all the frames and stringers glued plate foam 10 mm thick. wooden Internal body parts, like joints, should be further impregnated with epoxy resin.

On the external side, the extra foam is cut with a sharp knife and body vyshkurivaetsya. The last operation requires special attention — at the slightest excess pressure on the instrument panel will turn concave relative to the frame. The surface of the hull is covered with fiberglass on epoxy glue. Further operations are completely similar to the first version of the model. In this case, body weight is in the range of 450-600 g.

D. VYSHESLAVSKY, Chisinau

Recommend to read AND THE SWARM — IN A BAG Everyone who decides to engage in beekeeping must prepare themselves for many things. Including the fact that they will have to "remove" swarms alone. This task, I know from experience, is... EXECUTIVE CAR GAZ-14 “CHAIKA” The once super popular in the narrow circles of the party-state nomenclature Executive car GAZ-13 "Chaika" in the 1960-ies began to lose its appeal. Pretentious machine with the design...  Today we introduce modelers-students with two versions of microart class P. the Elegance of the external lines, simplicity of design and manufacture — this is an incomplete list of advantages of these models, designed and built by young athletes Moldovan CSUT under the guidance of an experienced teacher, a veteran of labour and fleet D. Vysheslavsky. Using new technology, children have made significant weight reduction of the housings and the models themselves. Steel yachts virtually unsinkable, increased their rapidity. As soon as the young modelers have gained experience of commissioning models and the ability to feel the weather, the performances microparasite this type of steel to bring them consistent success on the scoring starts.

Today we introduce modelers-students with two versions of microart class P. the Elegance of the external lines, simplicity of design and manufacture — this is an incomplete list of advantages of these models, designed and built by young athletes Moldovan CSUT under the guidance of an experienced teacher, a veteran of labour and fleet D. Vysheslavsky. Using new technology, children have made significant weight reduction of the housings and the models themselves. Steel yachts virtually unsinkable, increased their rapidity. As soon as the young modelers have gained experience of commissioning models and the ability to feel the weather, the performances microparasite this type of steel to bring them consistent success on the scoring starts.