When connecting windings in Delta-connection capacitance of the operating capacitor is determined by the formula:

MS = 4800*I/U ,

where CP is the capacitance of the capacitor, UF; I — consumption electric current, A; and the voltage, V.

If the motor power is known, they consumed current is determined by the formula:

The capacity of the starter capacitor is selected in 2-2,5 times more than the worker, and their voltage should be at least 1.5 times greater than the supply voltage. To 220 V better to use brand capacitors MBGO, MBGP, MBGC with an operating voltage of 500 V and above. As a launcher you can use electrolytic capacitors K50-3, AGC-M, KE-2 with an operating voltage of not less than 450 In (subject to short-term switching). For greater reliability, they are included according to the scheme shown in figure 2. The total capacity is then equal to s/2. Starting capacitors sexunderwate a resistor 2С0—500 ohms, through which it will “drain” the remaining electric charge.

Operation of the electric motor with capacitor start has some peculiarities. When running in idle at the fed through the condenser coil flows a current of 20-40 ka % above nominal. Therefore, if the electric motor will be used frequently in underutilized or idle mode, the capacitance CP should be reduced.

When overloaded, the motor can stop, then to start it again, connect the starting capacitor (by removing or reducing to a minimum the load on the shaft).

In practice, values of capacities of working and starting capacitors depending on the power of the electric motor is determined from the table.

To run the motor at idle or with a small load capacitance SP can be reduced. For example, to enable AO2 motor power 2.2 kW at 1420 rpm can be used as a working capacitor 230V µf, inrush — 150 µf, With elektrodvigatel confidently run at low load for a dad.

Reversal of the electric motor is carried out by switching the phase on the winding of the switch ЅА1 (Fig. 1).

Fig. 1. Electrical connection diagram three-phase motor in single-phase network.

Fig. 2. Connection diagram of electrolytic capacitors.

Fig. 3. Electrical diagram starting devices for three-phase motor power 0.5 kW.

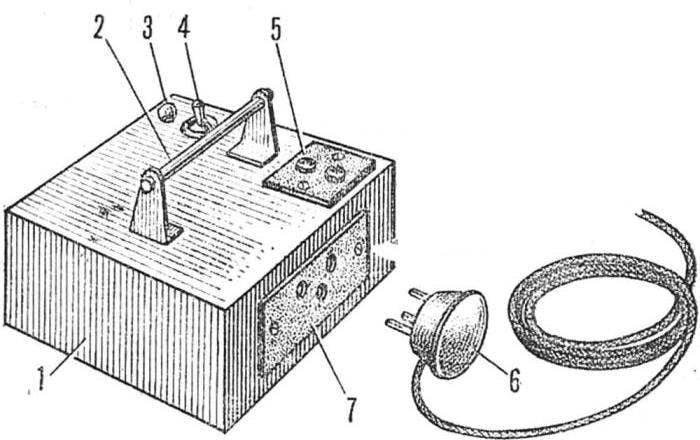

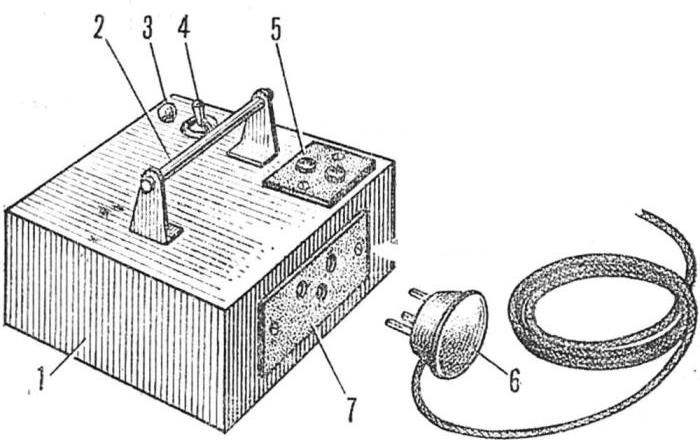

Fig. 4. The appearance of the starting device:

1 — housing 2 — handle for carrying. 3 — warning light 4 — switch off start capacitor, 5 — button “start” and “Stop” 6 — modified electronica, 7 — panel with sockets of the connector.

Fig. 5. The electrical circuit of the starting device with automatic disconnection of the capacitor p.

Figure 3 shows the electrical circuit of the portable universal unit for starting three-phase motors with a power of about 0.5 kW single-phase network without reversal.

When you click on button B1 actuates the magnetic starter KM1 (toggle switch 5А1 closed) and its contact system KM1.1, KM1.2 elektrodvigatel connects the M1 to the network of 220 V. at the same time the third contact group KM1.3 blocks SB1. After full acceleration of the motor starting capacitor C1 is cut off the switch SA1. Stop the motor by pressing the SB2.

The device used magnetic contactor type PML, designed for alternating current with voltage 220 V; SB1, SB2 — twin button ПКЕ612, SA1 toggle—switch T2-1; resistors: R1 — wire-PE-20, R2 — MLT-2, C1, C2 — capacitors MBGC voltage 400 V (C2 Deuh composed of parallel-connected capacitors 20 UF x 400); HL1 lamp KM-24 (24 V, 100 mA). M1 — motor 4А71А4 (A02-21-4) at 0.55 kW, 1420 Rev/min.

The starting device is mounted in a metal enclosure the size of 170X140X70 mm (Fig. 4). The top panel is a button “start” and “Stop” warning lamp and switch off the start capacitor. On the front side wall installed a homemade three-prong plug, is made of three parts copper pipe to round elektrowerke, which added a third pin.

To use the switch SA1 (Fig. 3) not very convenient. So it’s better if the starting capacitor will be turn off automatically with the optional relay Kt (Fig. 5) type mku-48. By clicking on the button S81 it is triggered and its contact pair K1.1 includes magnetic starter KM1, K1.2 — starting capacitor SP. In turn, the magnetic starter KM1 cambiocorsa through its contact of KM1.1, and KM1.2 and KM1.The motor 3 is connected to the network. 5V1 hold the button down until full acceleration of the motor, and then released, the relay K1 is de-energized and disconnects the starting capacitor, which is discharged through the resistor 1}2. At the same time, the magnetic starter KM1 remains on, providing power to the motor during operation. Stop the motor by pressing the button SV2 “Stop”.

In conclusion, a few words about improvements that extend the capabilities of the starter. Capacitors CP and SP can make a composite with steps 10-20 UF and connect them to multiple switches (or two or four switches) depending on parameters startup of electric motors. Bulb НL1 with damping resistors wire”, replace the neon with an additional resistor of small capacity; instead of paired buttons ПКЕ612 to use two solitary any type; fuses can be replaced automatically on the relevant cut-off current.

C. RYBAS, p. Novopetrivske, Moscow region

Recommend to read BATTERIES – ADAPTER Today, any manufactured device can be supplemented, adapted to the specific household needs of Amateur radio and give the device a seemingly non-core second life. For example, a... THE WHEELS UNDER CONTROL Camber angles and toe of the car very accurately can be adjusted, without resorting to service stations. We just need to have some plumbing skills and to have the simplest tool to their...  Many tinkerers are often trying to adapt three phase electric motors for various homemade machines: grinding, drilling, and other woodworking. But here’s the problem — not everyone knows how to feed this motor from single phase.

Many tinkerers are often trying to adapt three phase electric motors for various homemade machines: grinding, drilling, and other woodworking. But here’s the problem — not everyone knows how to feed this motor from single phase.