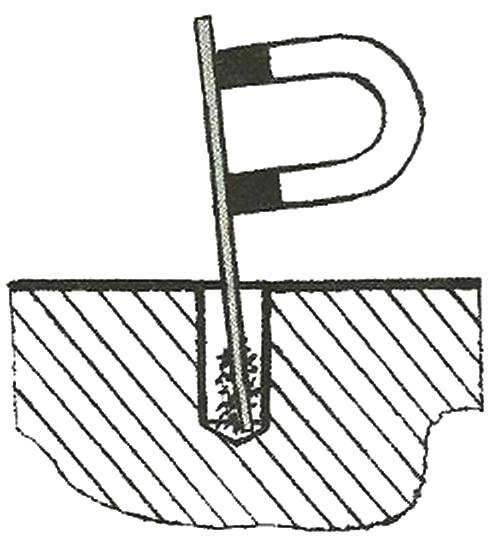

When drilling in ferrous metals, blind holes, and especially cutting them in thread, at the bottom remain shavings and sawdust, which is not so easy to remove, especially if the part is massive. “Call” to the aid of the magnet and any steel rod – you can even blunted nail or screw. The terminal will drop to the bottom of the hole, and the magnet attach to the protruding part. Move the lower end of the rod on the bottom, without releasing it from the magnet, and remove from the hole. Sawdust will be at the end of the rod. To be sure, repeat the operation. Similarly, you can get accidentally fallen in tight spaces steel detail.

Recommend to read

TRUCK WITH MANIPULATOR

TRUCK WITH MANIPULATOR

This universal machine with a capacity of 2.5 t built Ustinovich V. S. Stern Rostov region the engine of the machine from the tractor T-40: diesel, 4-cylinder, air-cooled output of 50 HP... IF WIT…

IF WIT…

A quick key. Participants NTTM Novokuibyshevsk a freight motor transport enterprise Governance transport control embedded high-speed universal wrench for screwing of pins. Thanks to the...

When drilling in ferrous metals, blind holes, and especially cutting them in thread, at the bottom remain shavings and sawdust, which is not so easy to remove, especially if the part is massive. “Call” to the aid of the magnet and any steel rod – you can even blunted nail or screw. The terminal will drop to the bottom of the hole, and the magnet attach to the protruding part. Move the lower end of the rod on the bottom, without releasing it from the magnet, and remove from the hole. Sawdust will be at the end of the rod. To be sure, repeat the operation. Similarly, you can get accidentally fallen in tight spaces steel detail.

When drilling in ferrous metals, blind holes, and especially cutting them in thread, at the bottom remain shavings and sawdust, which is not so easy to remove, especially if the part is massive. “Call” to the aid of the magnet and any steel rod – you can even blunted nail or screw. The terminal will drop to the bottom of the hole, and the magnet attach to the protruding part. Move the lower end of the rod on the bottom, without releasing it from the magnet, and remove from the hole. Sawdust will be at the end of the rod. To be sure, repeat the operation. Similarly, you can get accidentally fallen in tight spaces steel detail.

When drilling in ferrous metals, blind holes, and especially cutting them in thread, at the bottom remain shavings and sawdust, which is not so easy to remove, especially if the part is massive. “Call” to the aid of the magnet and any steel rod – you can even blunted nail or screw. The terminal will drop to the bottom of the hole, and the magnet attach to the protruding part. Move the lower end of the rod on the bottom, without releasing it from the magnet, and remove from the hole. Sawdust will be at the end of the rod. To be sure, repeat the operation. Similarly, you can get accidentally fallen in tight spaces steel detail.

When drilling in ferrous metals, blind holes, and especially cutting them in thread, at the bottom remain shavings and sawdust, which is not so easy to remove, especially if the part is massive. “Call” to the aid of the magnet and any steel rod – you can even blunted nail or screw. The terminal will drop to the bottom of the hole, and the magnet attach to the protruding part. Move the lower end of the rod on the bottom, without releasing it from the magnet, and remove from the hole. Sawdust will be at the end of the rod. To be sure, repeat the operation. Similarly, you can get accidentally fallen in tight spaces steel detail.